Three-valve separated expander

A separate, tire-expanding technology, which is applied in the direction of expanding the mandrel, can solve the problems of forming tool damage, workpiece scrapping, metal fatigue, etc., and achieve the effects of increased service life, cost saving, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

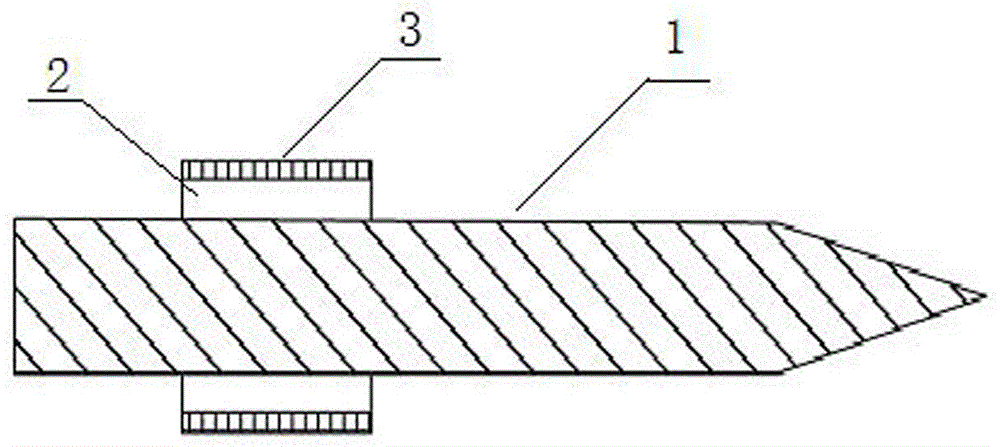

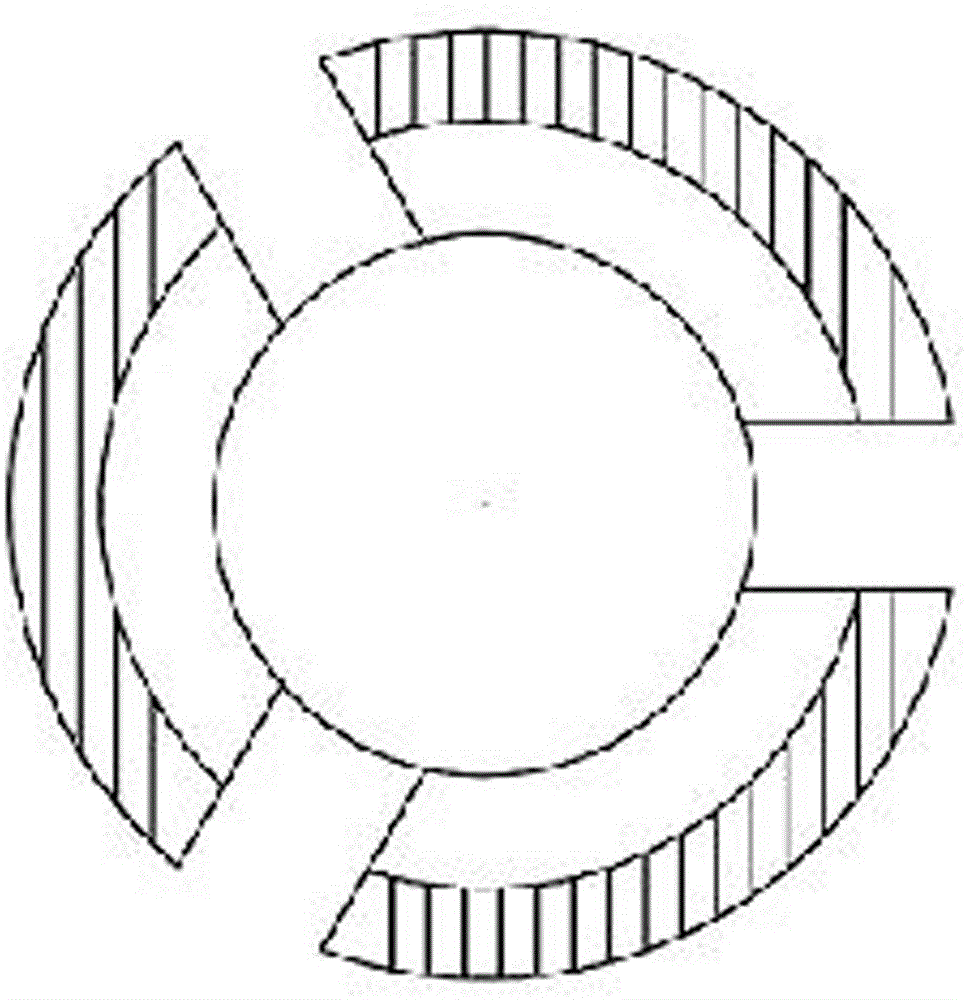

[0014] refer to Figure 1-2 , it includes a shaft (1), characterized in that: one end of the shaft (1) is a three-lobed separated structure, each petal is covered with an expanding core (2), and the expanding core (2) is covered with an expanding sleeve ( 3), the other end of the shaft (1) is a tapered thimble. The three-lobed split structure is symmetrical about the axis (1), and each petal has the same size.

[0015] The invention has low manufacturing cost, very convenient installation and removal of workpieces, and the machine tool can fully implement automatic clamping and loosening work, thereby greatly reducing manual labor intensity. One end is positioned and tightened, and the other end is tightened by the tapered thimble of the tailstock, and both ends of the workpiece are clamped simultaneously. And the three petals are completely separated and there is no problem of breakage. Thereby completely solving all existing problems of the traditional tire-increasing cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com