Apple processing device

A processing device and apple technology, which is applied in fruit pitting devices, vegetable or fruit peeling, food science, etc., can solve the problems of not being able to peel apples and shorten the cycle time of apple peeling, so as to avoid omissions and shorten the cycle time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

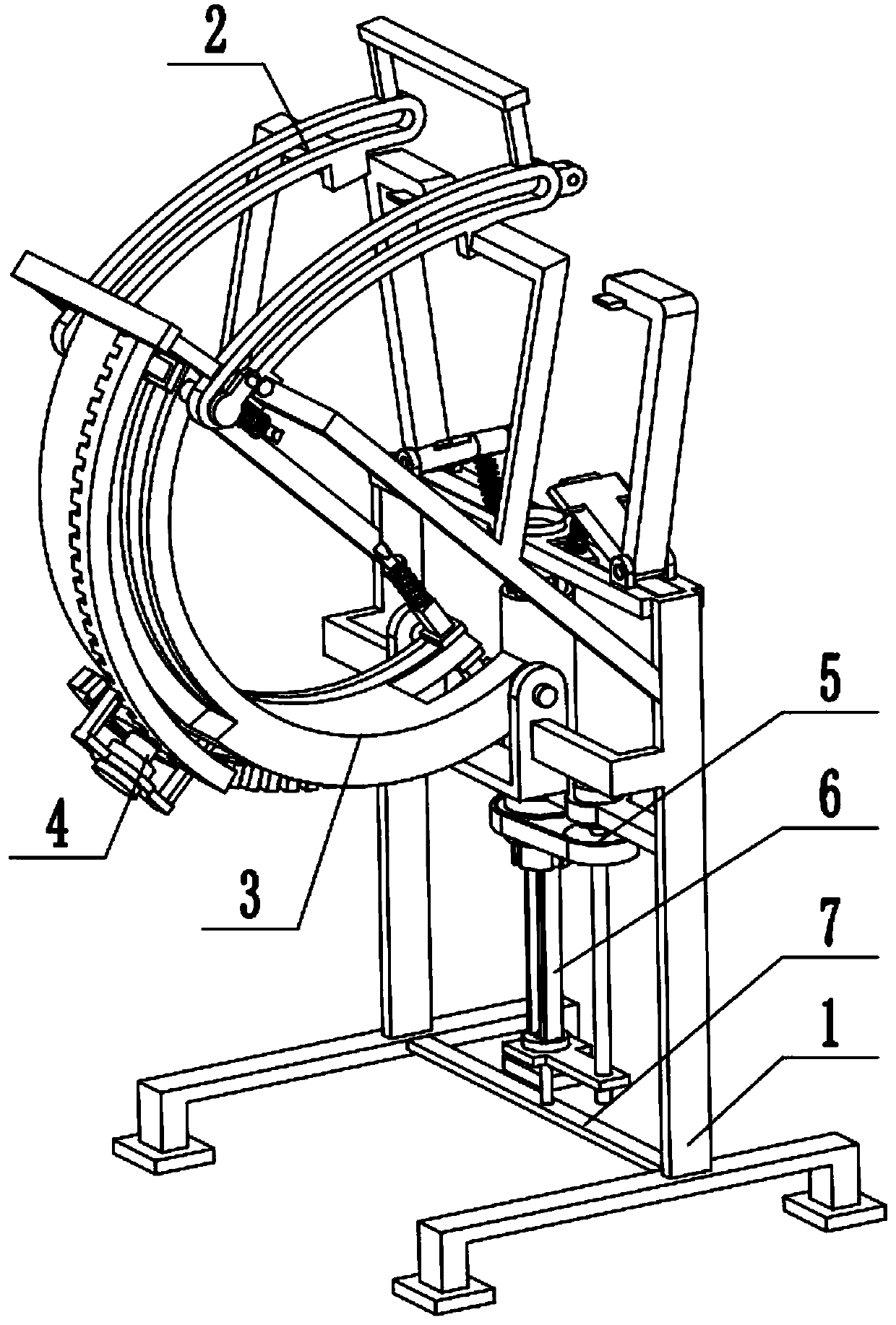

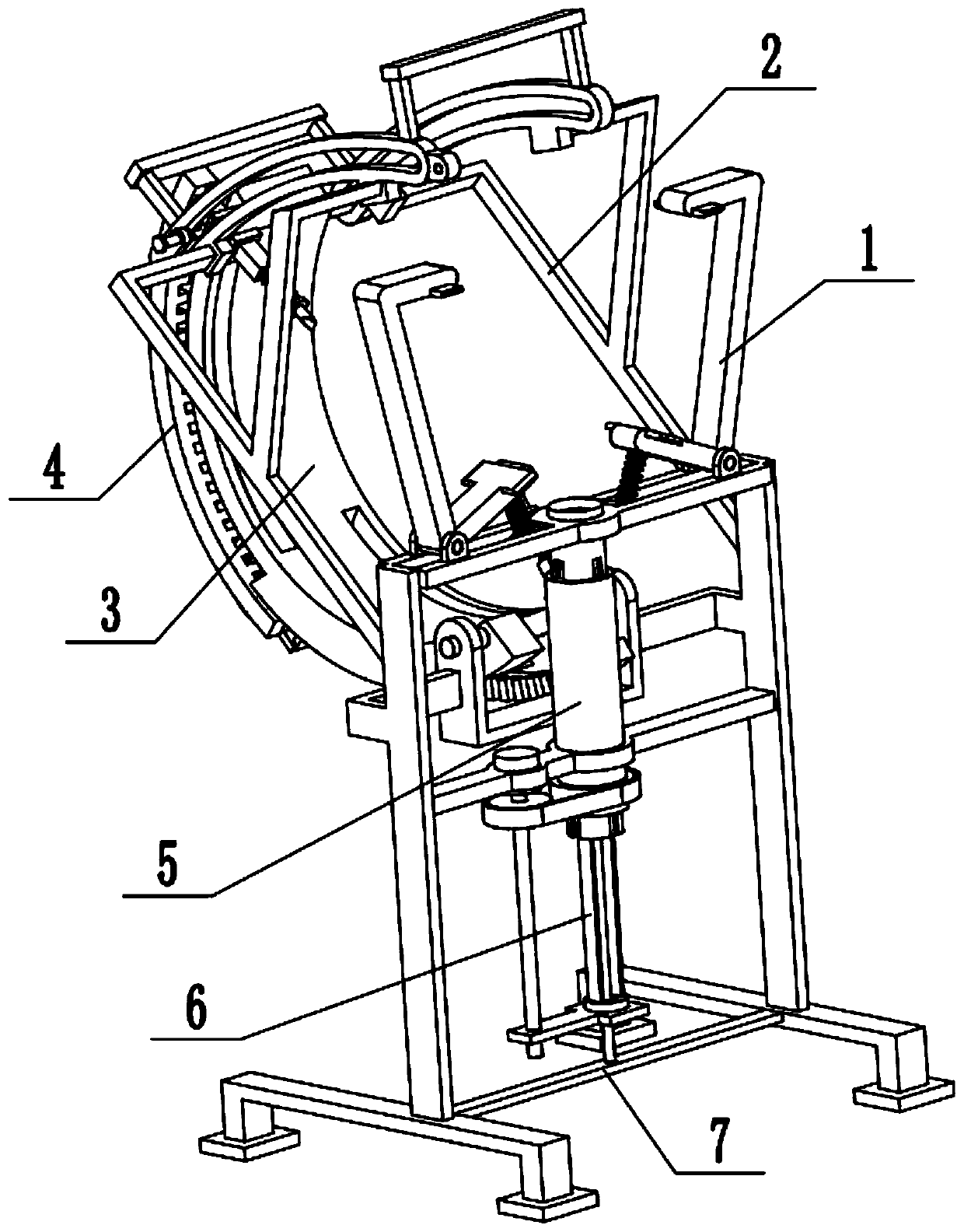

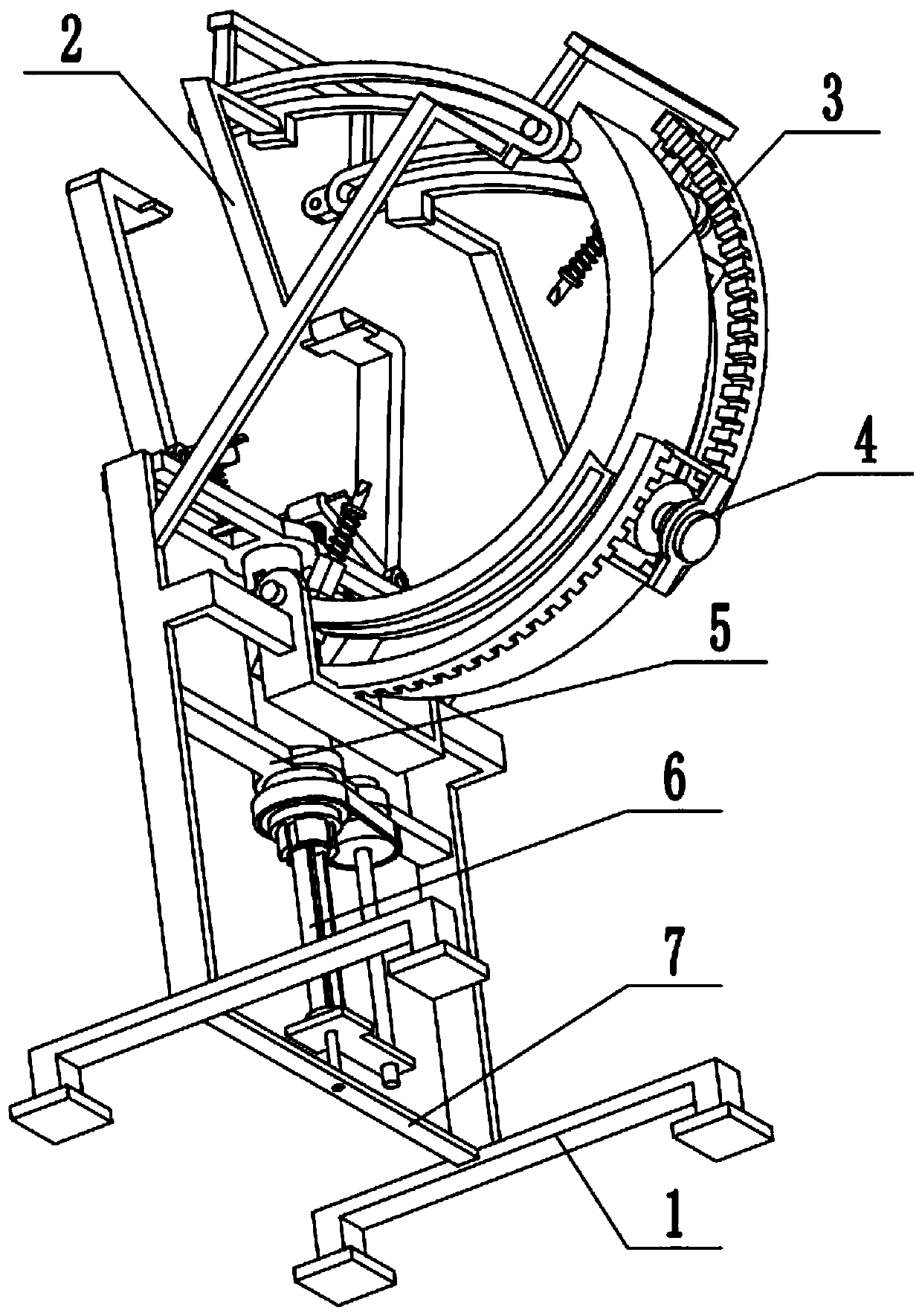

[0035] Combine below Figure 1-12 Describe this embodiment, an apple processing device, including an apple clamping mechanism 1, an adjustment seat slide frame 2, an adjustment seat 3, a cutting mechanism 4, a driving mechanism 5, a coring mechanism 6, and an ejection mechanism 7. The slide frame 2 is set on the apple clamping mechanism 1, one end of the adjusting seat 3 is connected with the apple clamping mechanism 1, the other end of the adjusting seat 3 is movably connected to the adjusting seat slide frame 2, and the cutting mechanism 4 is connected to the adjusting seat 3, the drive mechanism 5 is located on the apple clamping mechanism 1, the coring mechanism 6 is connected with the drive mechanism 5, the drive mechanism 5 drives the core removal mechanism 6 to rotate and move up and down, the core is separated from the apple, and the ejection mechanism 7 Located on the apple clamping mechanism 1, the ejector mechanism 7 is movably connected with the coring mechanism 6,...

specific Embodiment approach 2

[0037] Combine below Figure 1-12 To illustrate this embodiment, the apple clamping mechanism 1 includes a side frame 1-1, a foot 1-2, an L-shaped plate 1-3, a top frame 1-4, a rectangular through slot 1-5, and an L-shaped clamping rod 1-6, pressing plate 1-7, spring seat 1-8 and first compression spring 1-9; the two ends of top frame 1-4 are respectively fixedly connected with one side frame 1-1, and the lower ends of two side frames 1-1 One foot 1-2 is fixedly connected respectively, two L-shaped plates 1-3 are fixedly connected to two side frames 1-1 respectively, the adjustment seat 3 is connected with the two L-shaped plates 1-3, and the sliding frame 2 of the adjustment seat and the driving mechanism 5 are all located on the two side frames 1-1; two L-shaped clamping rods 1-6 are connected to the two ends of the top frame 1-4 through the symmetrical rotation of the hinge axis respectively, and the two L-shaped clamping rods 1-6 The upper end of 6 is respectively fixedly...

specific Embodiment approach 3

[0039] Combine below Figure 1-12 To illustrate this embodiment, the adjustable seat slide frame 2 includes a fixed frame 2-1, an arc-shaped chute frame 2-2, a connecting plate 2-3 and a jack seat 2-4; the two fixed frames 2-1 are respectively Fixedly connected to the two side frames 1-1, the upper ends of the two fixed frames 2-1 are respectively fixedly connected to an arc-shaped chute frame 2-2, and the two connecting plates 2-3 are fixedly connected to the two arc-shaped slides. On the groove frame 2-2, the right end of the arc-shaped chute frame 2-2 at the front end is fixedly connected to the jack seat 2-4; the adjustment seat 3 is movably connected with the two arc-shaped chute frames 2-2. Two arc-shaped chute frames 2-2 play a guiding role to the adjusting seat 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com