Fabric stripping device for textile processing and stripping method of fabric stripping device

A fabric and color stripping technology, which is applied in textile processing machine accessories, textile material processing equipment configuration, textile material processing, etc., can solve the problems of affecting the stripping effect, fabric color cannot be separated, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

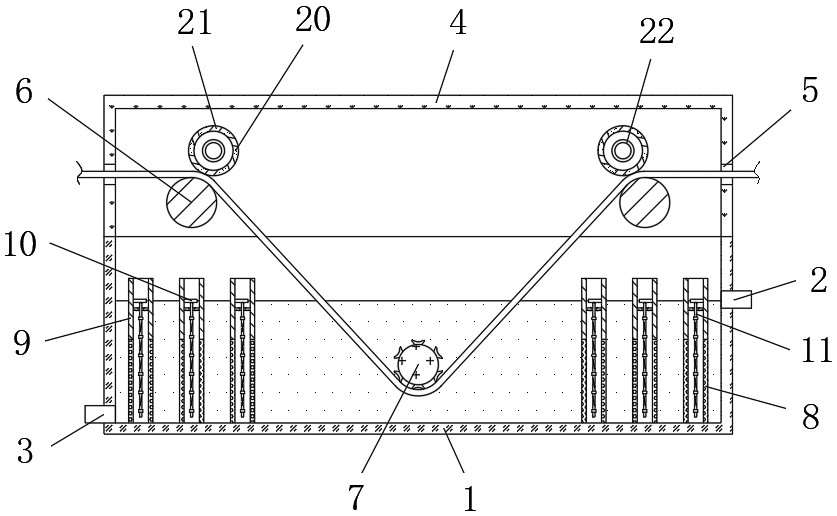

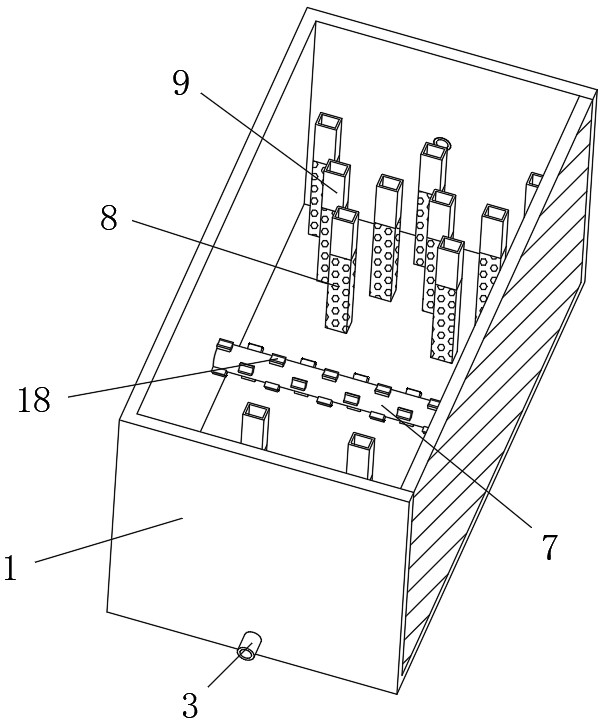

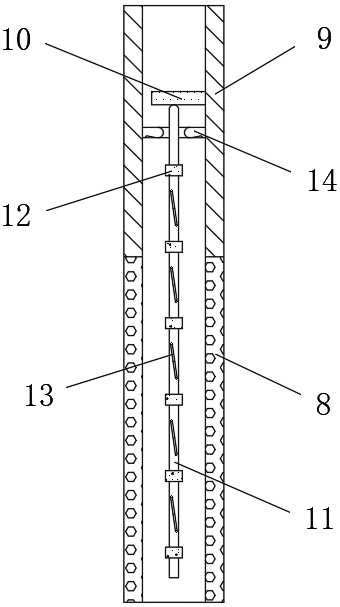

[0032] refer to Figure 1-5 , a fabric stripping device for textile processing, comprising a treatment box 1, the two sides of the treatment box 1 are respectively fixed with a liquid inlet pipe 2 and a liquid outlet pipe 3, and the liquid inlet pipe 2 is located above the liquid outlet pipe 3, and the treatment box The top of 1 is fixed with a cover box 4, and both sides of the cover box 4 are provided with through grooves 5, and both sides between the inner walls of the two ends of the cover box 4 are rotatably connected with support rollers 6, and the inner walls of the two ends of the treatment box 1 The middle position of the bottom of the space is rotatably connected with a pressure roller 7, and the top of the outer wall of the support roller 6 and the bottom of the outer wall of the pressure roller 7 are rotatably connected with a fabric, and the fabric moves toward the side close to the liquid inlet pipe 2, and the two sides of the inner wall of the bottom of the treat...

Embodiment 2

[0040] refer to Figure 1-6 , a fabric stripping device for textile processing, the circumferential outer wall of the pressing roller 7 is fixed with abutting blocks 18 equidistantly distributed, and the abutting blocks 18 are arranged at intervals, and the abutting blocks 18 are arranged on the outer wall of one side away from the pressing roller 7 It forms an arc-shaped structure that arches outwards. The outer wall of the block 18 away from the pressure roller 7 is provided with a filling groove 19 that penetrates at both ends. The inner wall of the filling groove 19 is arranged in an arc-shaped structure. In the process of relative rotation, the fabric is squeezed into the low-end filling groove 19 due to the stretching force, and the liquid in the filling groove 19 is squeezed out to increase the local liquid flow and improve the liquid and fabric and the block 18. Peeling effect at the contact position of the outer wall;

[0041] The position corresponding to the suppor...

Embodiment 3

[0044] refer to Figure 1-6 , a stripping method of a fabric stripping device for textile processing, comprising a treatment box 1, a liquid inlet pipe 2, a liquid outlet pipe 3, a support roller 6, a pressure roller 7, a fixed net cylinder 8, a connecting cylinder 9 and an atomizing vibration The sheet 10 also includes an auxiliary rod located in the fixed mesh cylinder 8, and a block 18 located on the outer wall of the pressure roller 7. The fabric in the middle position is immersed in the liquid medicine by the pressure roller 7 for soaking and stripping, while the two sides are connected. The liquid medicine in the cylinder 9 is relatively static so that the liquid medicine is atomized by the atomizing vibrating plate 10, and the atomized liquid medicine rises and contacts the fabric to improve the color stripping effect, and avoid the partial temperature difference wrinkling of the fabric caused by heating up. The color stripping is not complete, and the chemical solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com