Cladding power stripper for removing high-order mode laser and manufacturing method of cladding power stripper

A high-order mode and stripper technology, which is applied to lasers, laser parts, laser parts, etc., can solve the problems of weakening device performance, incomplete pump light stripping, and insufficient high-order mode laser effusion. Improve the ability to be stripped, ensure safe and normal operation, and improve the effect of beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

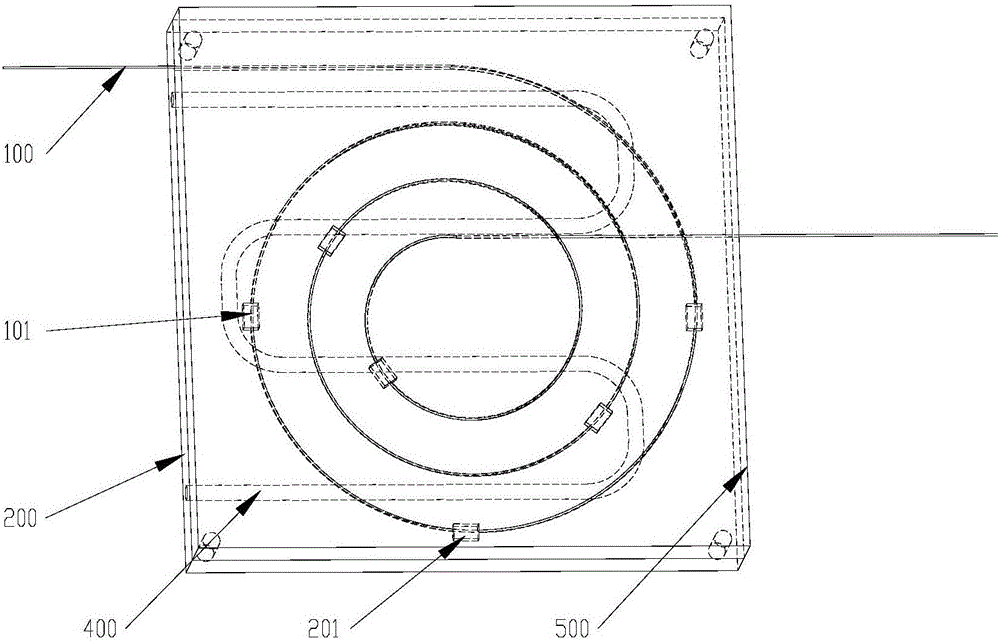

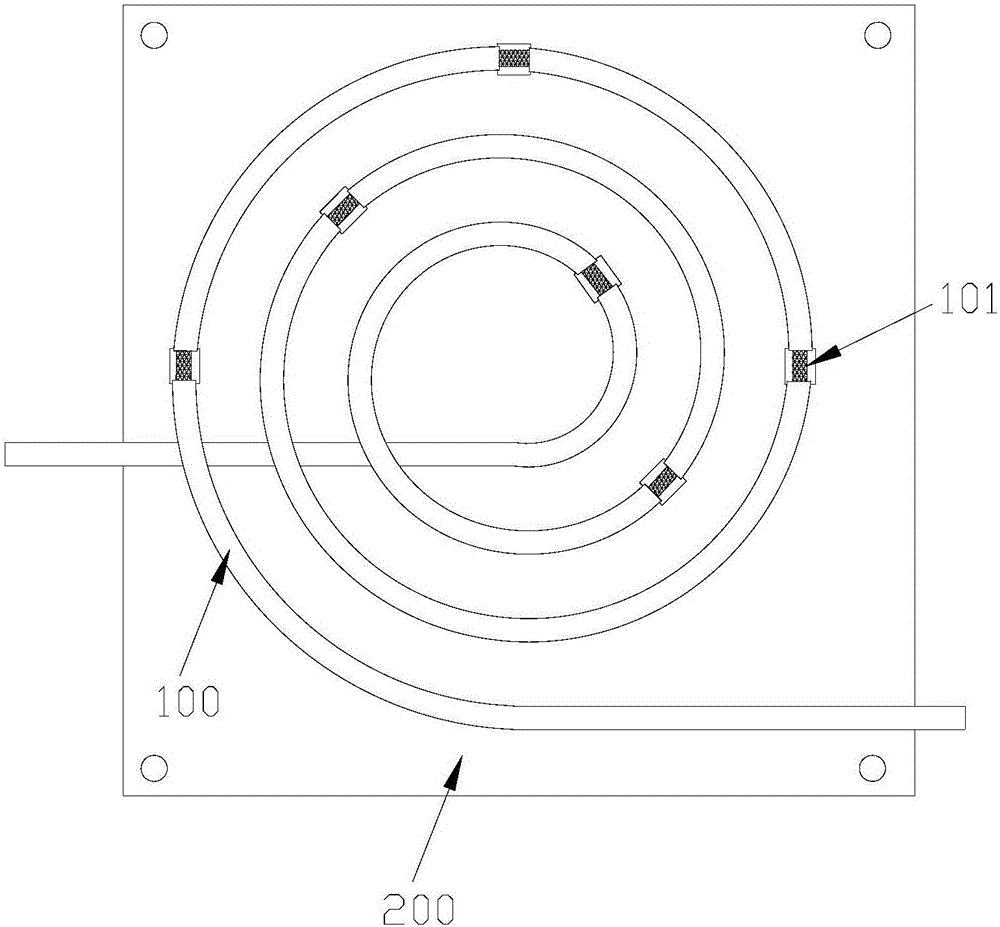

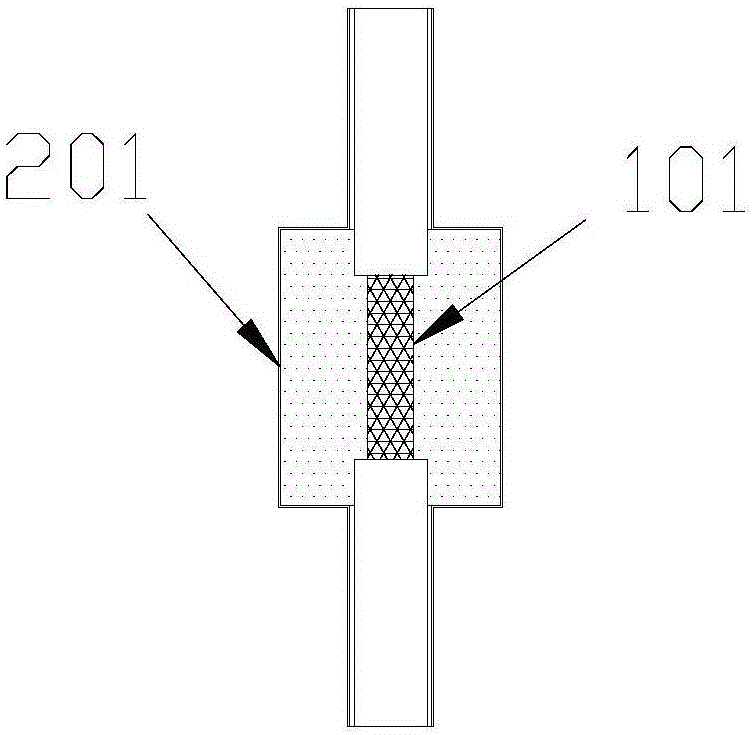

[0029] The annular water-cooling channel 400 is coiled in the annular groove of the heat sink 200, and a section of optical fiber of a specified length is cut off, coiled in the annular groove of the heat sink 200, and the optical fiber section suspended on the heat sink groove 201 is marked, and used The wire stripper strips off the coating layer of the optical fiber at the marked place, and the stripped length of the coating layer is slightly smaller than the length of the heat sink groove 201; the bare fiber with the coating layer stripped off is mechanically processed to form an optical fiber etching section 101, so that the surface Irregular V-groove morphology is formed; then the processed optical fiber is cleaned in an ultrasonic cleaning machine equipped with clean ethanol, and the surface solvent is dried with an air compression gun. The cleaned optical fiber is coiled on the heat sink 200 again, and the optical fiber etching section 101 is suspended in the center of t...

Embodiment 2

[0031] The structure of this embodiment is the same as that of Embodiment 1, except that the heat conduction medium 300 in the heat sink groove 201 is silicon carbide, and the housing cover plate 500 is made of nickel-plated brass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com