Method and device for massively producing graphene conductive slurry and prepared graphene conductive slurry

A technology of conductive paste and graphene, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problem of high viscosity of the original conductive paste, difficulty in achieving peeling effect, powder mixing Inhomogeneity and other problems to achieve the effect of improving efficiency, excellent physical and chemical properties, and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

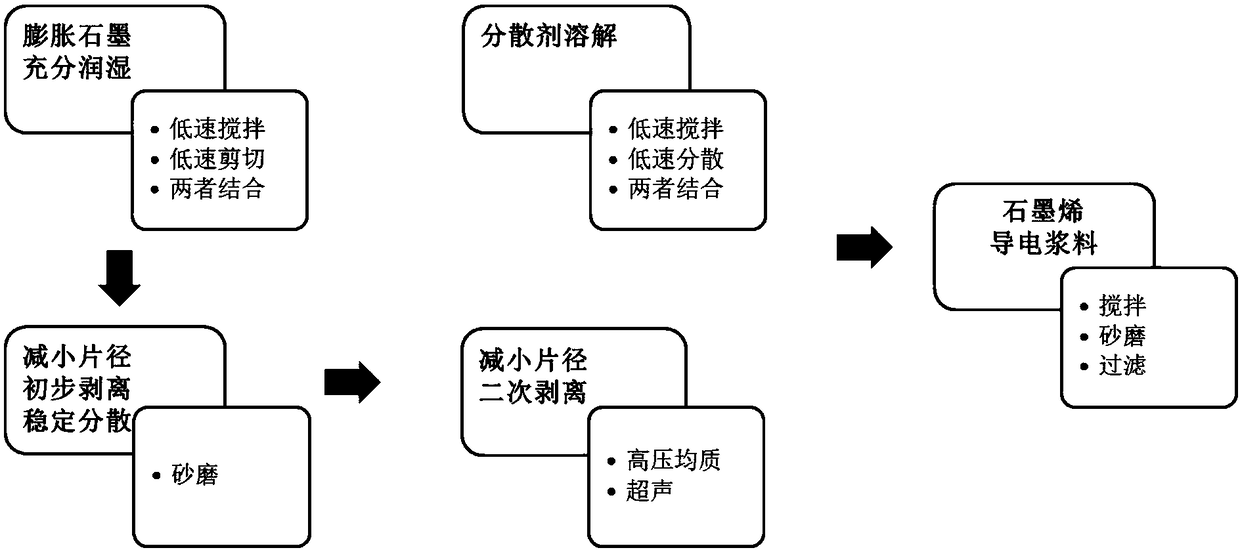

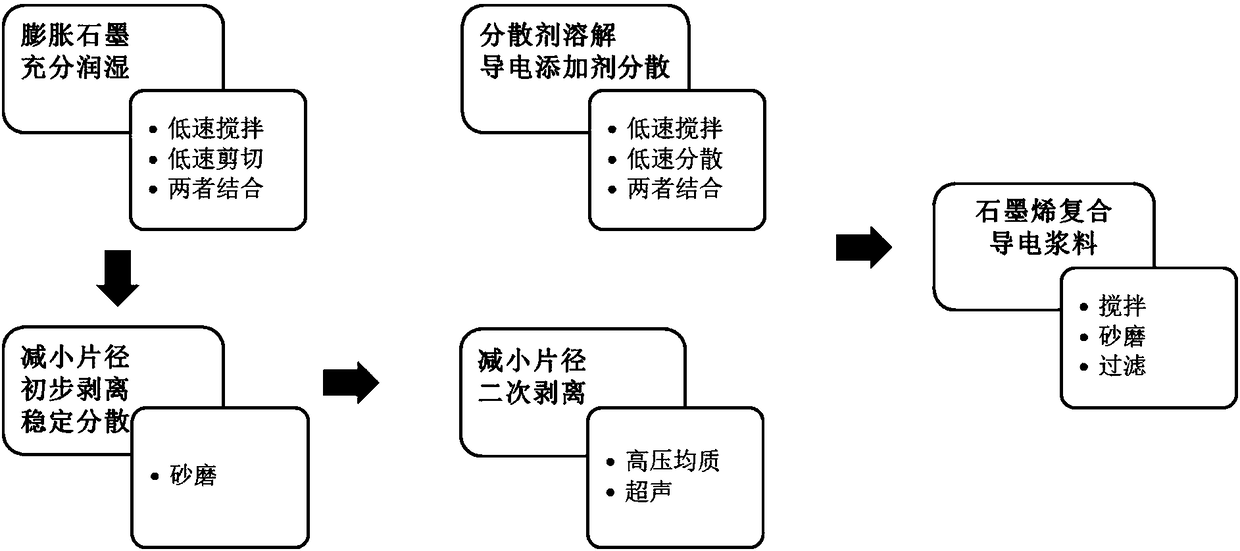

[0098] Embodiment 1 prepares graphene conductive paste

[0099] Step 1: Pre-dissolve the dispersant CMC in water in the second dispersing device to obtain a dispersant solution, and the concentration of the dispersant in the dispersant solution is 3 wt%.

[0100] Step 2: Put water and expanded graphite into the first dispersing device through the liquid feeding device and powder feeding device respectively, and through low-speed stirring, fully wet the expanded graphite in the solvent and reduce the sheet diameter. The expanded graphite is high temperature expansion Preparation method, the expansion ratio is 400, the concentration of expanded graphite in the mixture of expanded graphite and solvent is 3wt%, and the stirring time is 2h, to obtain expanded graphite dispersion.

[0101] Step 3: With the fully wetted expanded graphite dispersion in step 2, open the valve, and the expanded graphite dispersion begins to circulate between the first dispersion device, the first sand m...

Embodiment 2

[0104] Embodiment 2 prepares graphene conductive paste

[0105] Step 1: pre-dissolve the dispersant PVDF in NMP in the second dispersing device to obtain a dispersant solution, and the concentration of the dispersant in the dispersant solution is 8 wt%.

[0106] Step 2: Put NMP and expanded graphite into the first dispersing device through the liquid feeding device and powder feeding device respectively, and through low-speed stirring, fully wet the expanded graphite in the solvent and reduce the sheet diameter. Expanded graphite is high temperature expansion Preparation method, the expansion ratio is 150, the concentration of expanded graphite in the mixture of expanded graphite and solvent is 0.1wt%, and the stirring time is 0.5h to obtain expanded graphite dispersion.

[0107] Step 3: With the fully wetted expanded graphite dispersion in step 2, open the valve, and the expanded graphite dispersion begins to circulate between the first dispersion device, the first sand mill ...

Embodiment 3

[0110] Embodiment 3 prepares graphene conductive paste

[0111] Step 1: pre-dissolving the dispersant PVP in DMF in the second dispersing device to obtain a dispersant solution, the concentration of the dispersant in the dispersant solution being 8wt%;

[0112] Step 2: Put DMF and expanded graphite into the first dispersing device through the liquid feeding device and powder feeding device respectively, and through low-speed stirring, fully wet the expanded graphite in the solvent and reduce the sheet diameter. The expanded graphite is high temperature expansion Preparation method, the expansion ratio is 300, the concentration of the expanded graphite in the mixture of the expanded graphite and the solvent is 10wt%, and the stirring time is 3 hours to obtain the expanded graphite dispersion.

[0113] Step 3: With the fully wetted expanded graphite dispersion in step 2, open the valve, and the expanded graphite dispersion begins to circulate between the first dispersion device,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com