Multi-function handle

A multi-functional, handle technology, applied in the field of multi-functional handles, can solve the problems of low disassembly and assembly efficiency, laborious operation, and no substantial improvement in work efficiency, so as to reduce the number of tool replacements, enhance reliability, and enhance work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

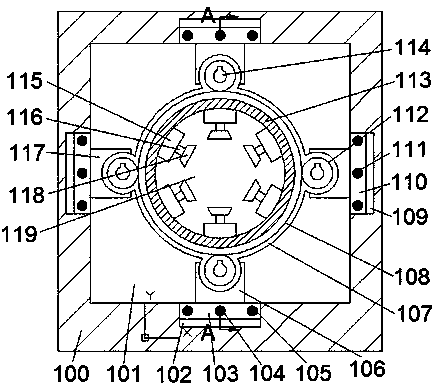

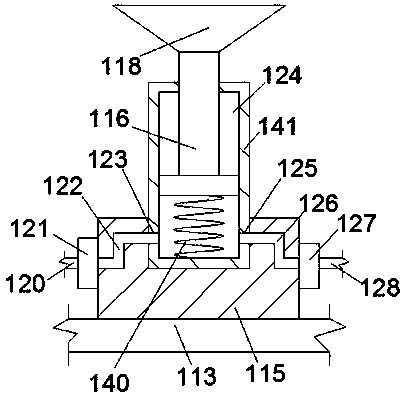

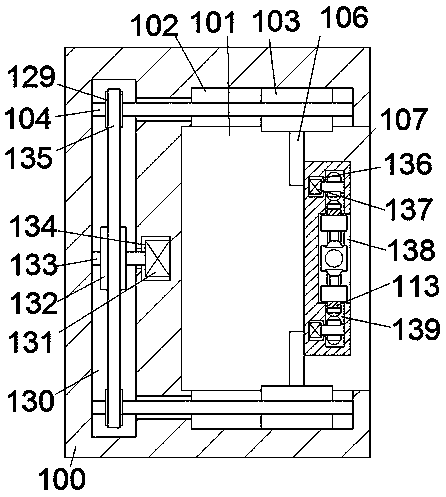

[0013] Combine below Figure 1-3 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0014] refer to Figure 1-3 , a multifunctional handle according to an embodiment of the present invention, comprising a handle body 100, a working space 101 with an opening forward is arranged inside the handle body 100, a main structure is arranged inside the working space 101, and the main body mechanism It is all the components of the multifunctional handle, mainly including: the active lead screw movable assembly, the driven polished rod movable assembly, the tooth meshing structure and the pneumatic clamping part. The upper and lower symmetrical active lead screw movable assemblies can be simultaneously Drive, wherein, the active screw movable assembly includes an intermediate tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com