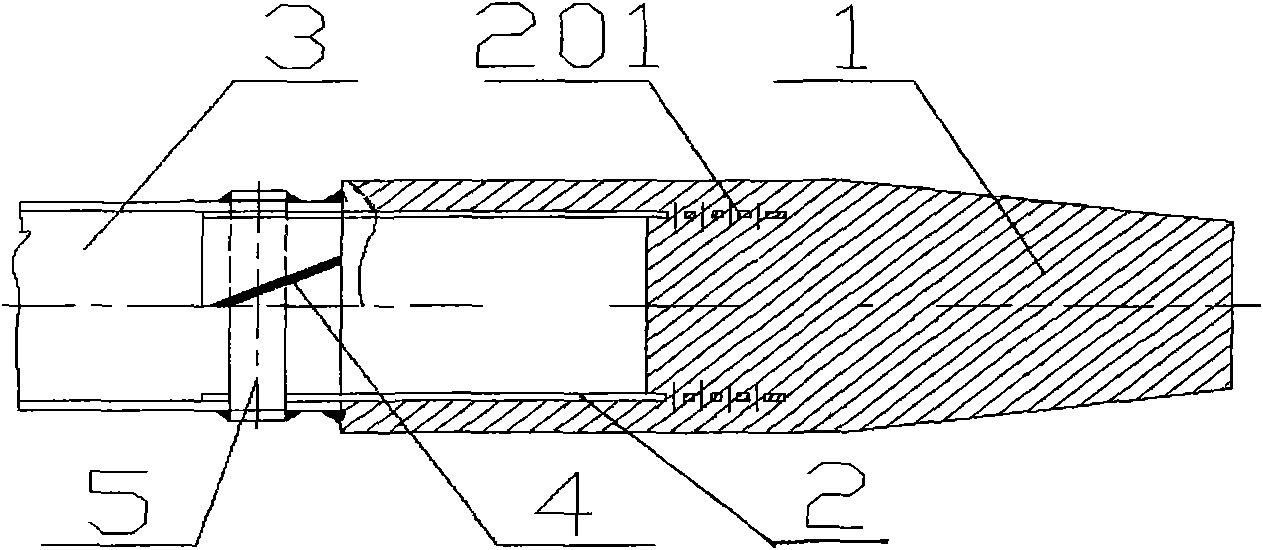

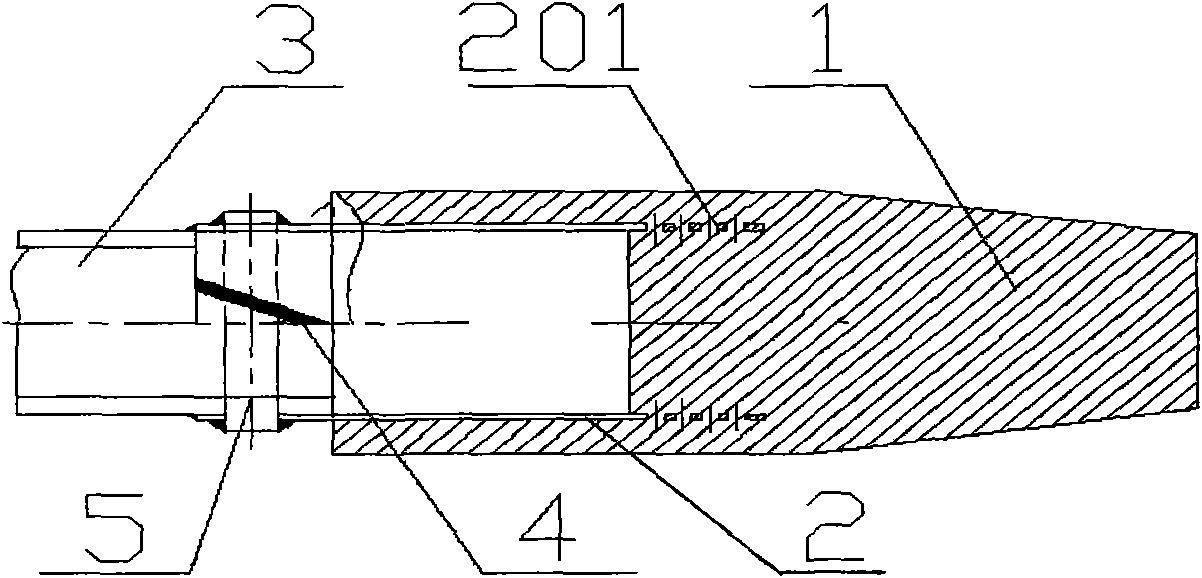

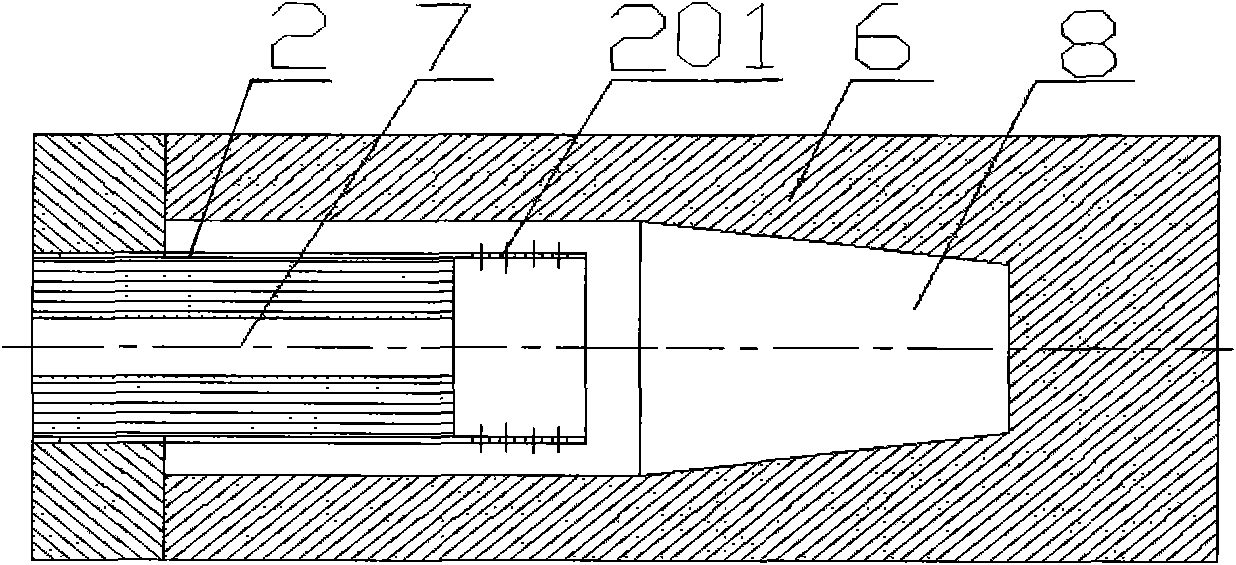

Crust-hitting hammer head for aluminum reduction cell and casting technique thereof

A technology of shelling hammer head and aluminum electrolytic cell, which is applied to kitchen utensils, rotors, cylinders, etc., can solve the problems of low hammer head cost, reduced quality of aluminum liquid, shrinkage and other problems, and can increase the welding structure of the suit and the number of inclusions. Reduced and less prone to secondary oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The composition of molten iron is 1.20% carbon, 0.5% silicon, 0.2% manganese, 0.04% sulfur, 0.034% phosphorus, and 33.1% chromium. The melting temperature is 1480°C, and it is deoxidized with 0.01-0.015% aluminum. 1.0% rare earth ferrosilicon alloy FeSiRE23 in the bag, treated by flushing method, fully stirred and removed slag, poured after covering expanded perlite on the surface of molten iron, rare earth content 0.075%, particle size of rare earth ferrosilicon alloy is controlled at 8 ~ 20mm, rare earth high chromium cast iron hammer After the head is poured and cleaned, it is kept at 880-910°C for 3 hours and cooled with the furnace for stress relief annealing. After the hammer head is installed at No. 2 and No. 3 shelling positions, it can be used for 320 days.

Embodiment 2

[0024] The composition of molten iron is 1.40% carbon, 1.5% silicon, 1.5% manganese, 0.035% sulfur, 0.036% phosphorus, and 32.5% chromium. The melting temperature is 1500°C and the furnace temperature is 1460°C. After adding 0.9% rare earth ferrosilicon alloy FeSiRE26, the rare earth content is 0.08%. , the processing method is the same as in Example 1, after the hammer head is installed on No. 2 and No. 3 shelling positions, the service time is 311 days.

Embodiment 3

[0026] The composition of molten iron is 1.65% carbon, 0.65% silicon, 0.45% manganese, 0.038% sulfur, 0.037% phosphorus, 30.6% chromium, the melting temperature is 1490°C, and the furnace temperature is 1450°C. After adding 0.80% rare earth ferrosilicon alloy FeSiRE29, the rare earth content is 0.10%. , treatment method is the same as embodiment 1, after the tup is installed in No. 2 and 3 shelling positions, the service time is 323 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com