Manufacturing machine for square rubber cushion block for cabinet

A rubber pad, square technology, applied in the direction of metal processing, etc., can solve the problems of affecting production progress, slow operation speed, labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

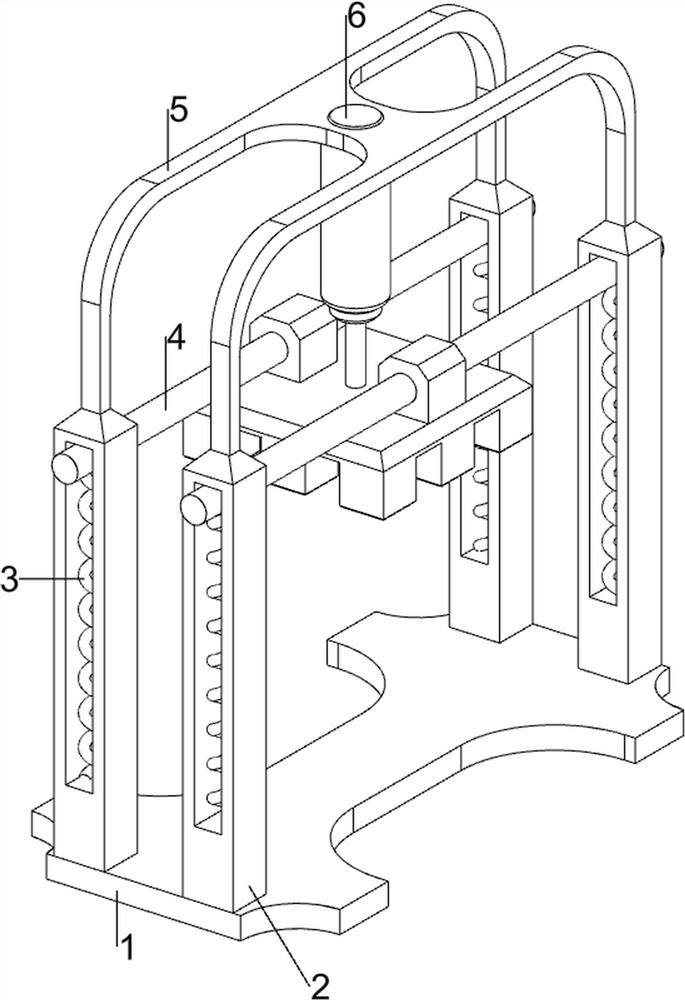

[0027] A machine for manufacturing square rubber pads for cabinets, such as Figure 1-4 As shown, it includes a bottom plate 1, a first slide rail 2, a first spring 3, a cutter 4, a placement frame 5, a cylinder 6, a placement mechanism 7 and an anti-jamming mechanism 8, and the bottom plate 1 is provided with first slide rails on four sides. 2. A placement frame 5 is connected between the tops of the first slide rails 2, a cutter 4 is slidably connected between the first slide rails 2, and the four sides of the bottom of the cutter 4 are arranged between the first slide rail 2 on the same side. There is a first spring 3, a cylinder 6 is arranged in the middle of the placement frame 5, the bottom of the cylinder 6 is connected with the cutter 4, a placement mechanism 7 is arranged on the bottom plate 1, and an anti-jamming mechanism 8 is connected between the first slide rails 2 .

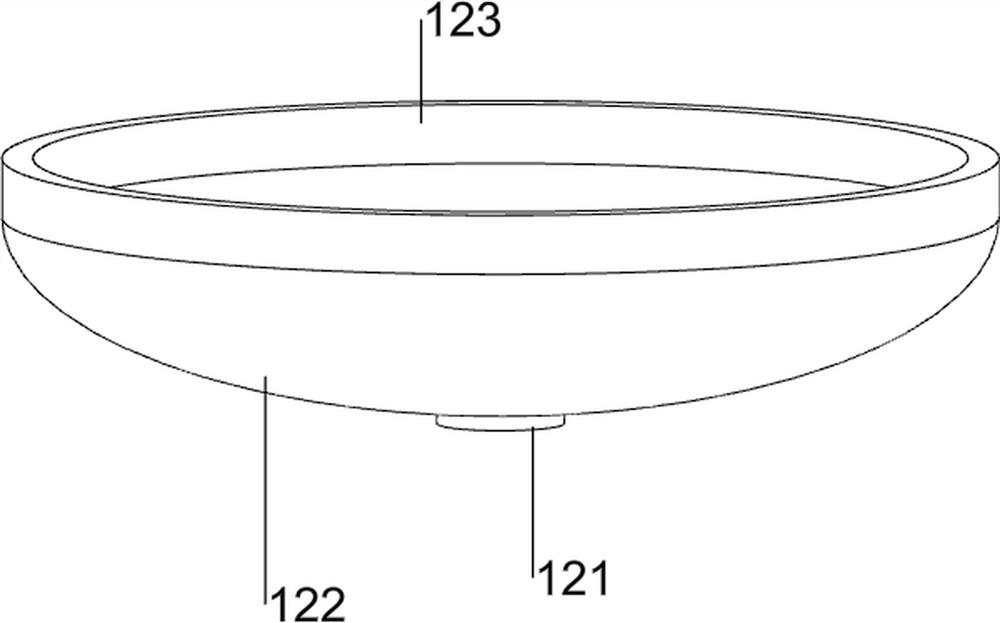

[0028] Placement mechanism 7 includes support feet 70, mounting plate 71, rotating shaft 72, sp...

Embodiment 2

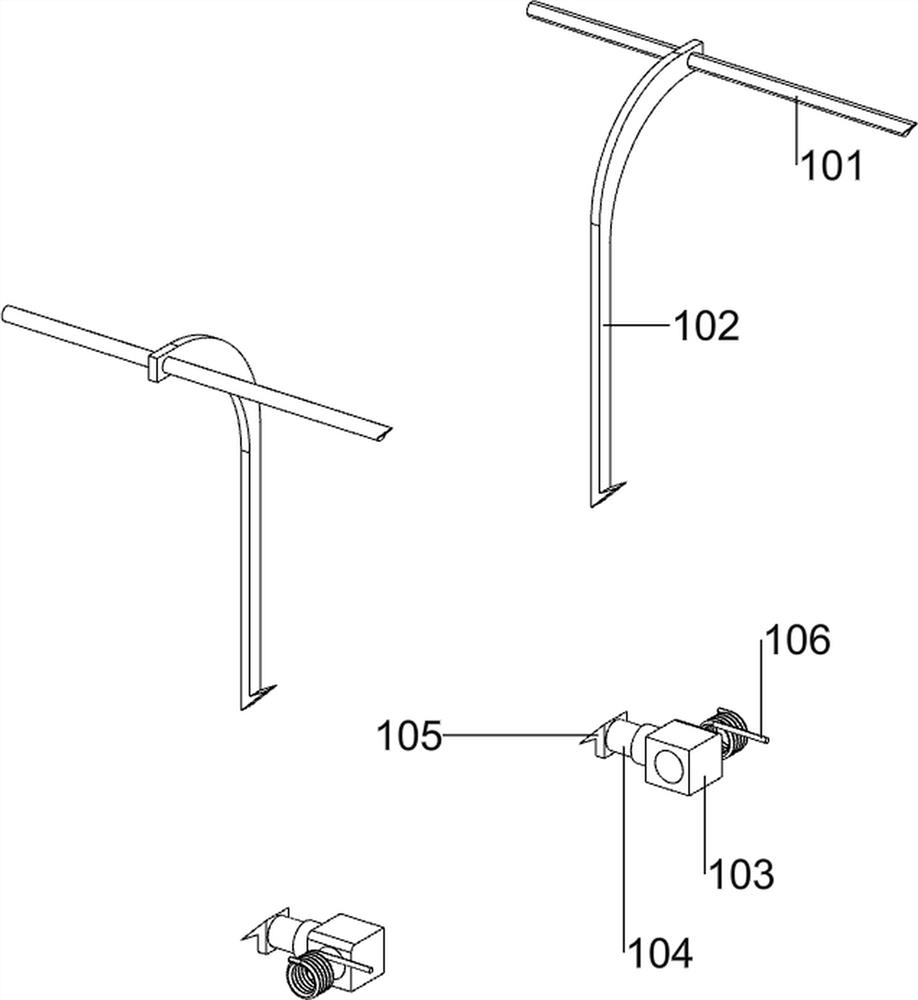

[0032] On the basis of Example 1, such as Figure 5-8 As shown, it also includes a limit mechanism 9, and the limit mechanism 9 includes a fixed frame 90, a first telescopic rod 91, a placement block 92, a moving plate 93, a fixed rod 94, a limit plate 95, a second spring 96 and a third spring. Spring 97, cutter 4 left and right sides and front side are all provided with two fixed mounts 90, are all provided with first telescopic rod 91 on the fixed mount 90, first telescopic rod 91 insides are all provided with spring, mounting plate 71 left and right sides Two placing blocks 92 are provided on the side and the front side, and the left and right sides and the front side of the mounting plate 71 are slidingly connected to the limiting plate 95, and the both sides of the limiting plate 95 and the placing block 92 on the same side are provided with a second Two springs 96, both sides of the limiting plate 95 are rotatably connected with a fixed rod 94, the fixed rod 94 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com