Patents

Literature

69 results about "Silicone rubber insulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of silastic surface hydrophobic coating

The invention discloses a preparation method of hydrophobic coating on the surface of silicon rubber. The method comprises the following steps: tetraethyl orthosilicate is taken as a precursor, anhydrous alcohol is taken as a solvent so as to prepare silicon dioxide sol under the condition of alkaline catalysis, and the obtained silicon dioxide sol is added with a silane coupling agent for modification process; after the surface is cleaned, a silicone rubber insulator is dipped in the modified silicon dioxide sol to carry out film coating with a pulling method so as to form a one-time coating and obtain a micro-nanometer rough structure which is similar to the leaf of taro; and after dried, the nanometer rough structure is again dripped in self-made fluorosilane sol for a secondary film coating with the pulling method, and then placed in an oven for thermal processing under 100 DEG C to 120 DEG C. The one-time coated micro-nanometer rough structure can obtain the transparent hydrophobic coating with acid and alkali resistance, after being modified by the secondary coating with low-surface fluorosilane sol.

Owner:西安智源电缆料有限公司

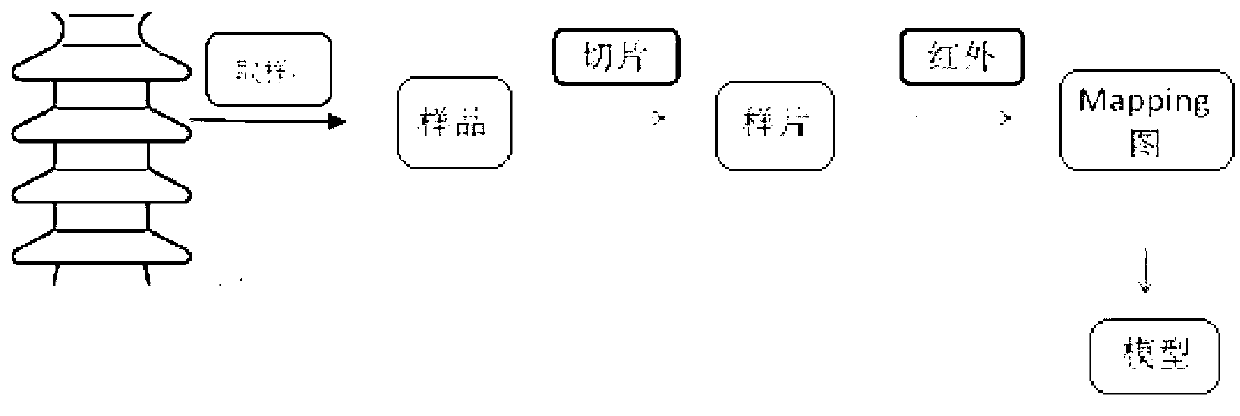

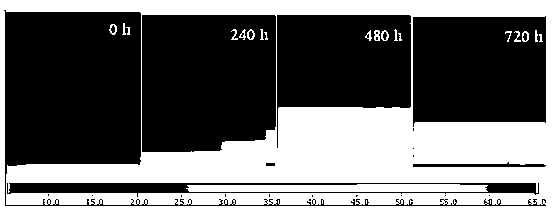

Method for identifying aging degree of silicon rubber composite insulator

ActiveCN103344605ACan quantitatively analyze the degree of agingQuantitative analysis of aging degreeColor/spectral properties measurementsTest sampleSilicon rubber

The invention discloses a method for identifying the aging degree of a silicon rubber composite insulator. The method comprises the following steps: determining the states of umbrella skirt test samples of the silicon rubber composite insulator by taking the operating age limit as reference, and selecting a sample area of each state to obtain an average-value test sample of each state; sampling and cutting into slices; performing microscopic infrared scanning on the slices by taking silicon methyl 1296 cm<-1> as a calibrated peak to obtain microscopic infrared micro-area scanning images of the slices with different age limits; calculating the ageing depth H value from the microscopic infrared micro-area scanning images, fitting the relationship between the H value of the samples with different age limits and time to obtain an ageing model; quantitatively identifying the ageing degree of an unknown sample according to the ageing model. According to the method, the ageing degree of the silicon rubber composite insulator can be quantitatively analyzed by a microscopic infrared Mapping scanning technology; the change of the silicon rubber composite insulator from the surface to the center along with ageing can be observed; the visualization degree is high.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

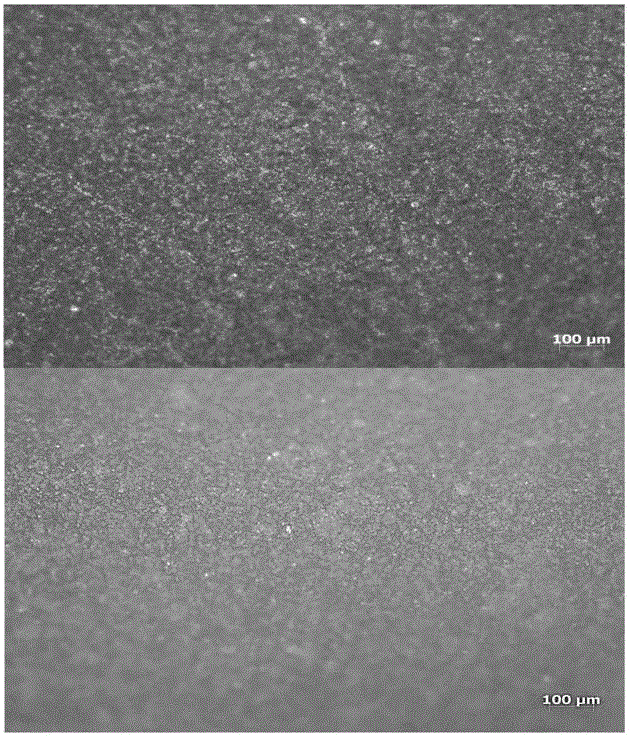

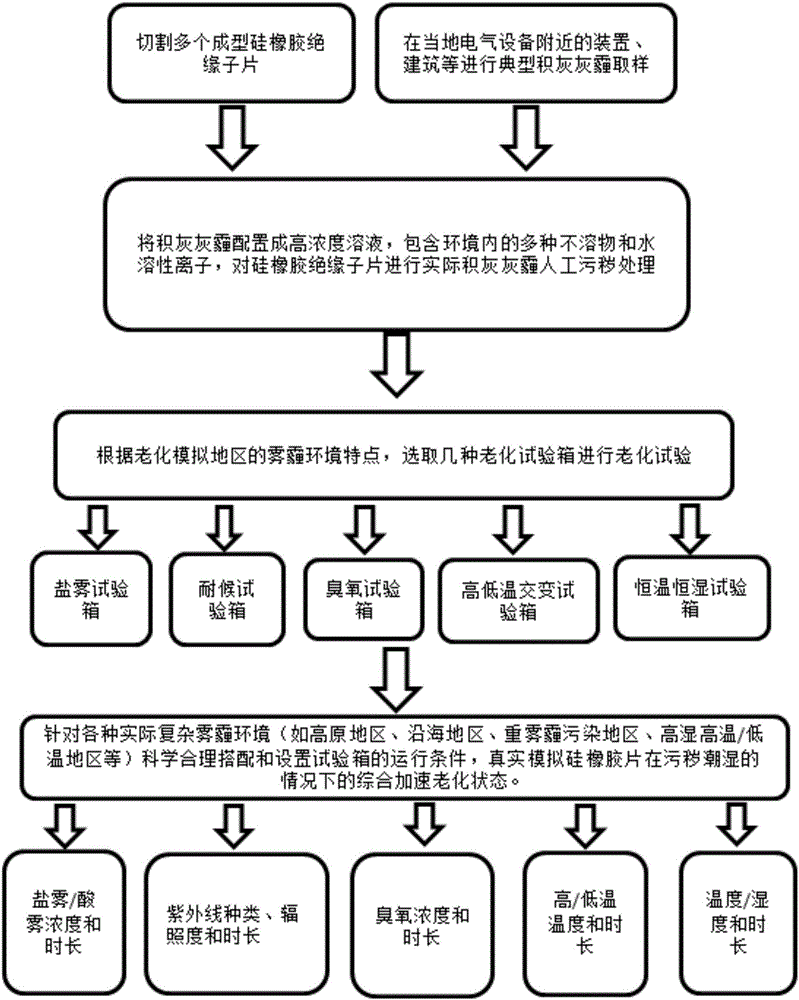

Contamination ageing test method for silicon rubber insulator

ActiveCN106769819ASmall footprintIncrease the number ofWeather/light/corrosion resistancePolymer scienceSilicone rubber insulators

The invention provides a contamination ageing test method for a silicon rubber insulator. The contamination ageing test method comprises the following steps: firstly, cutting a silicone rubber insulator string to obtain silicone rubber insulator sheets; sampling deposited ash of a to-be-detected region to obtain a dust haze sample; then mixing the dust haze sample obtained in the previous step with water to obtain a dust haze contamination solution, and carrying out manual contamination treatment on the silicone rubber insulator sheets by adopting the dust haze contamination solution to obtain to-be-detected silicone rubber insulator sheets; finally, carrying out aging test on the silicone rubber insulator sheets obtained in the previous step, and calculating to obtain a simulated aging state of the silicon rubber insulator. According to the contamination ageing test method provided by the invention, an aging effect of various complex haze environments on silicon rubber materials can be highly fitted, the experiment difficulty is simplified, the experiment cost is reduced, and the experiment time is shortened; the contamination ageing test method has an important guidance significance and economic values.

Owner:HARBIN UNIV OF SCI & TECH +3

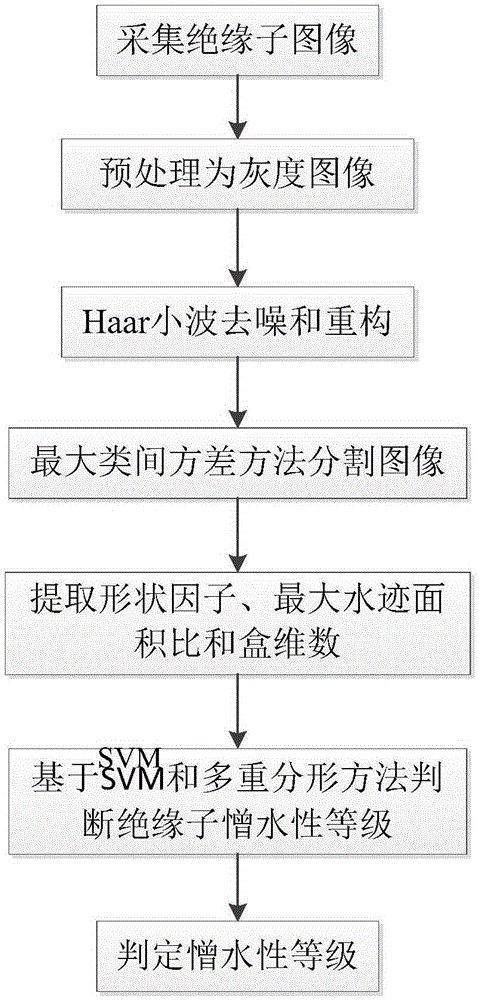

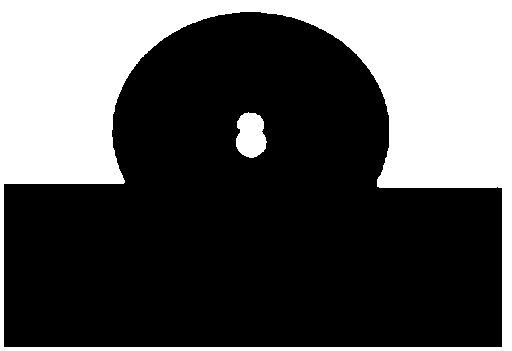

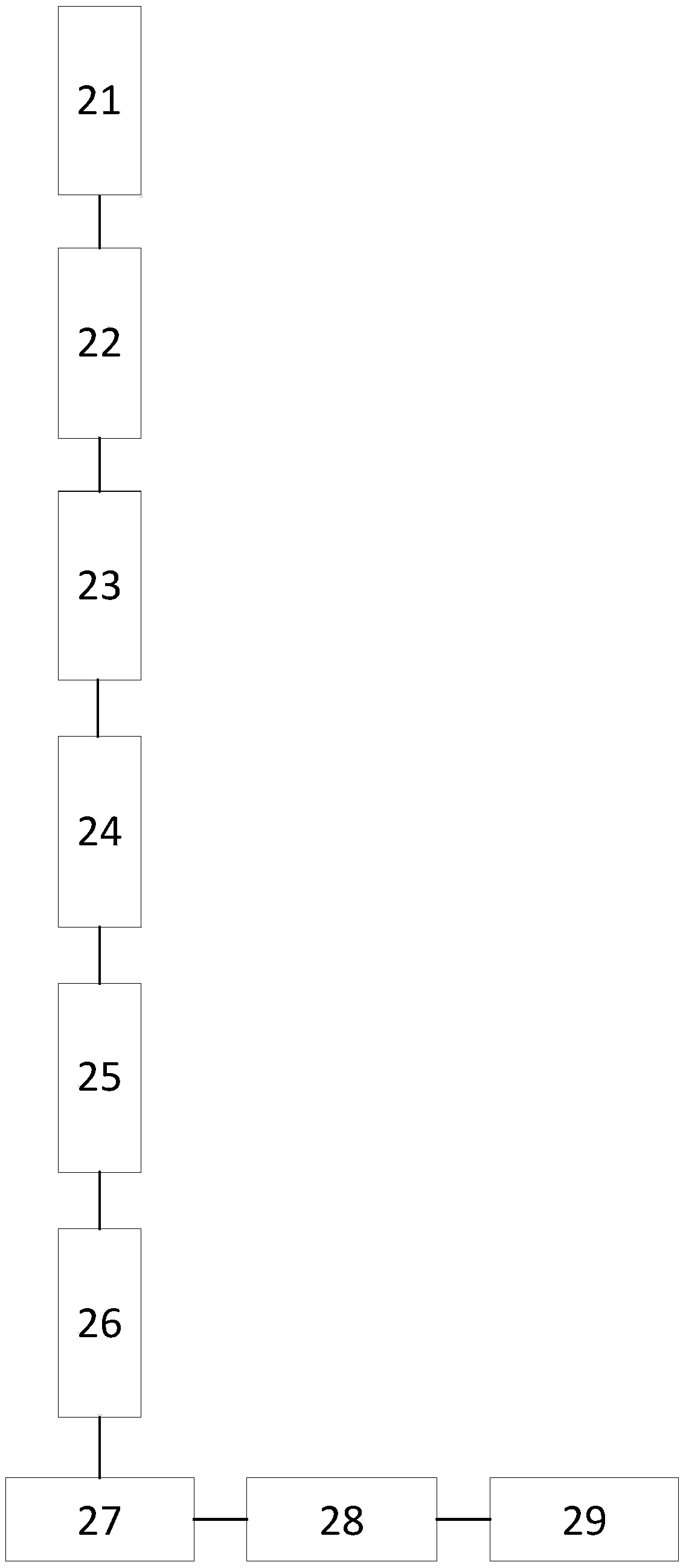

Hydrophobicity grade judging method of silicone rubber insulator

ActiveCN105300844AClassification of hydrophobicity grade speedMonitor contaminationSurface/boundary effectSupport vector machineComputer vision

The invention relates to a hydrophobicity grade judging method of a silicone rubber insulator. The hydrophobicity grade judging method comprises the following steps: acquiring an insulator image with water drops; carrying out noise filtering on the acquired image; dividing the image by applying a maximum between-cluster variance method to form a binaryzation image needed by a subsequent hydrophobicity judging research; extracting parameters including shape factors, fractal dimensions and the like from the binaryzation image to carry out hydrophobicity grading; and finally, grading the hydrophobicity of the composite insulator into three types including HC1-HC3, HC4-HC5 and HC6-HC7 by adopting a hydrophobicity grade grading method of a support vector machine, and finely dividing the hydrophobicity grade into seven grades from three types based on a multi-fractal grading method. According to the technical method provided by the invention, the hydrophobicity grades of the insulator can be relatively accurately distinguished, and relatively good evidences are provided for the pollution grades of the insulator.

Owner:STATE GRID CORP OF CHINA +1

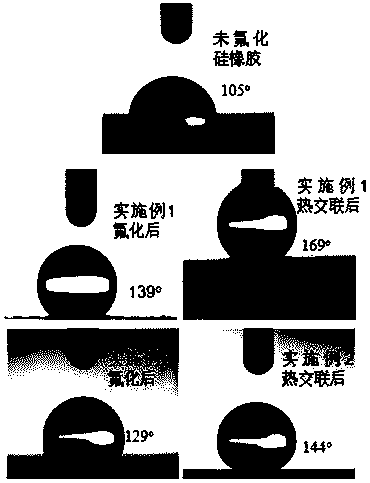

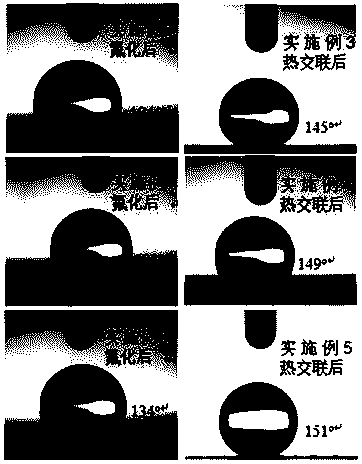

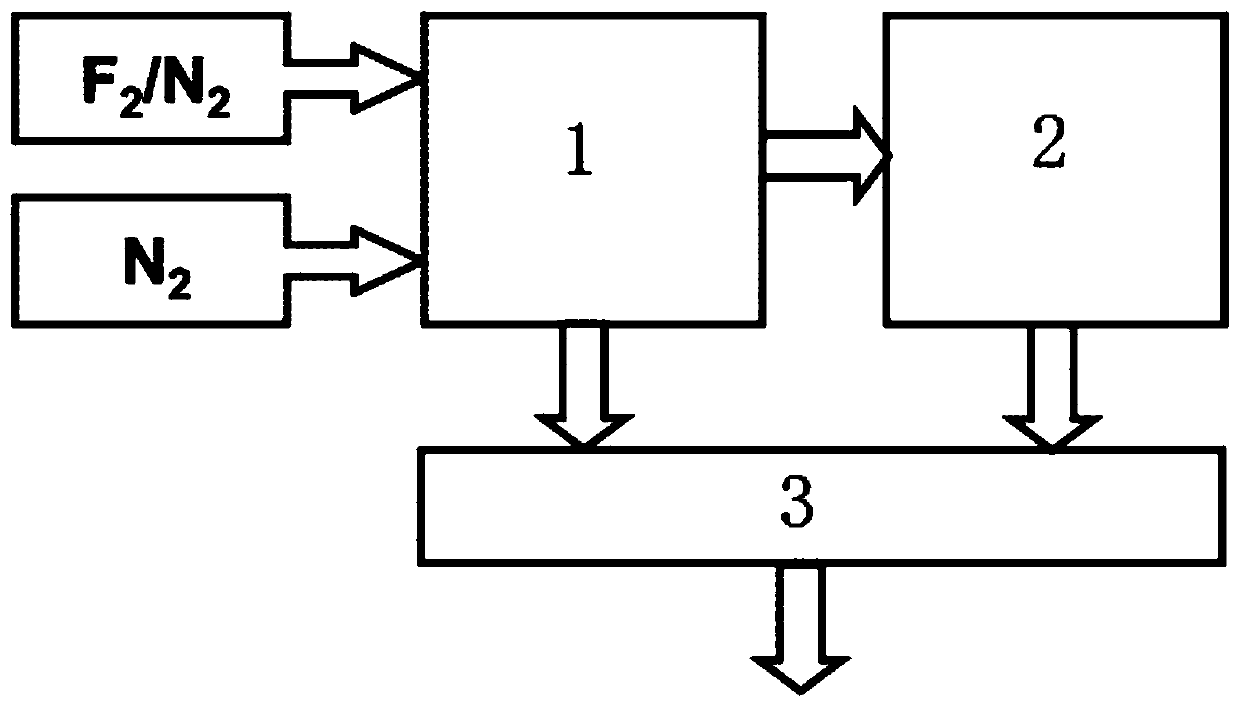

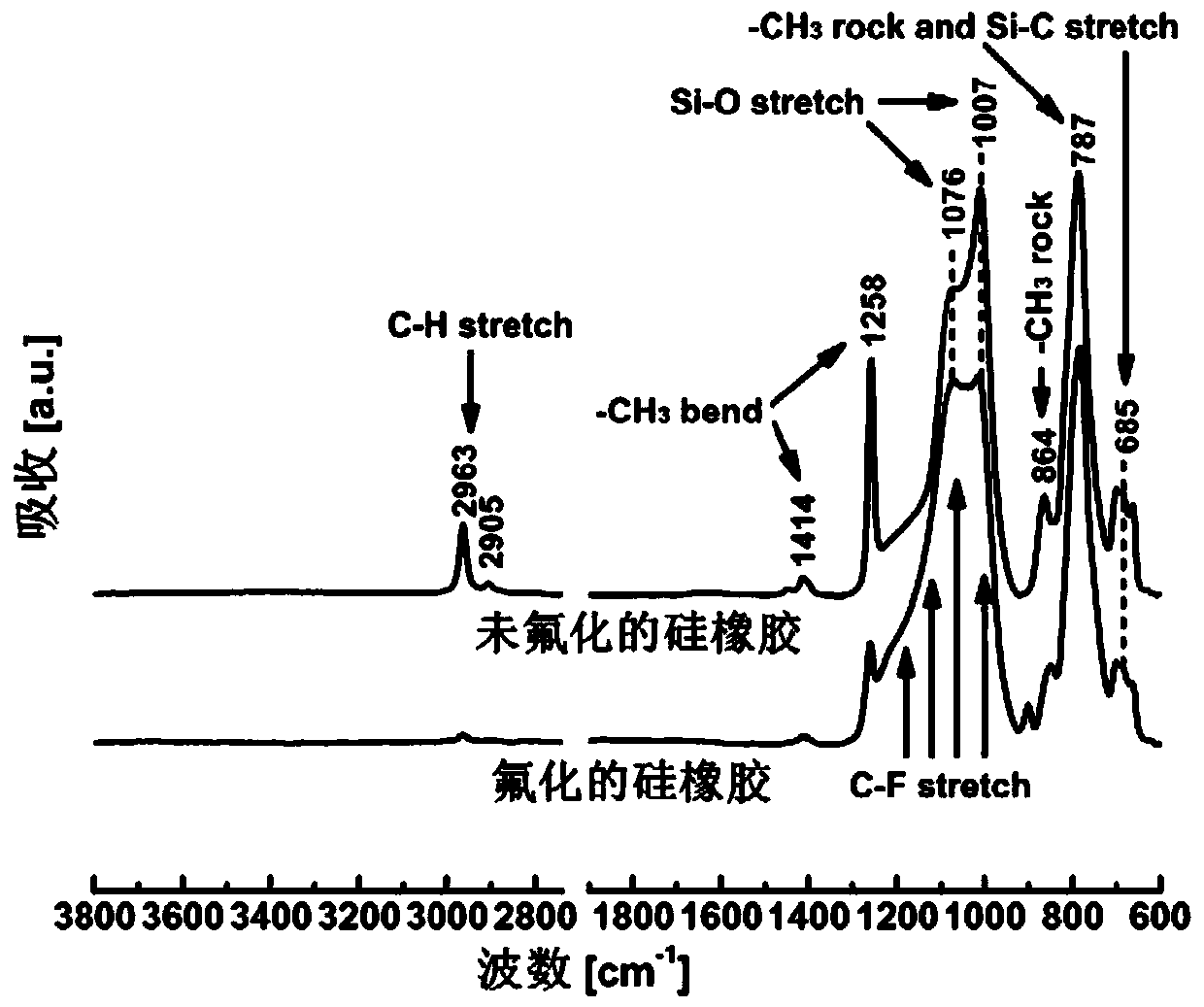

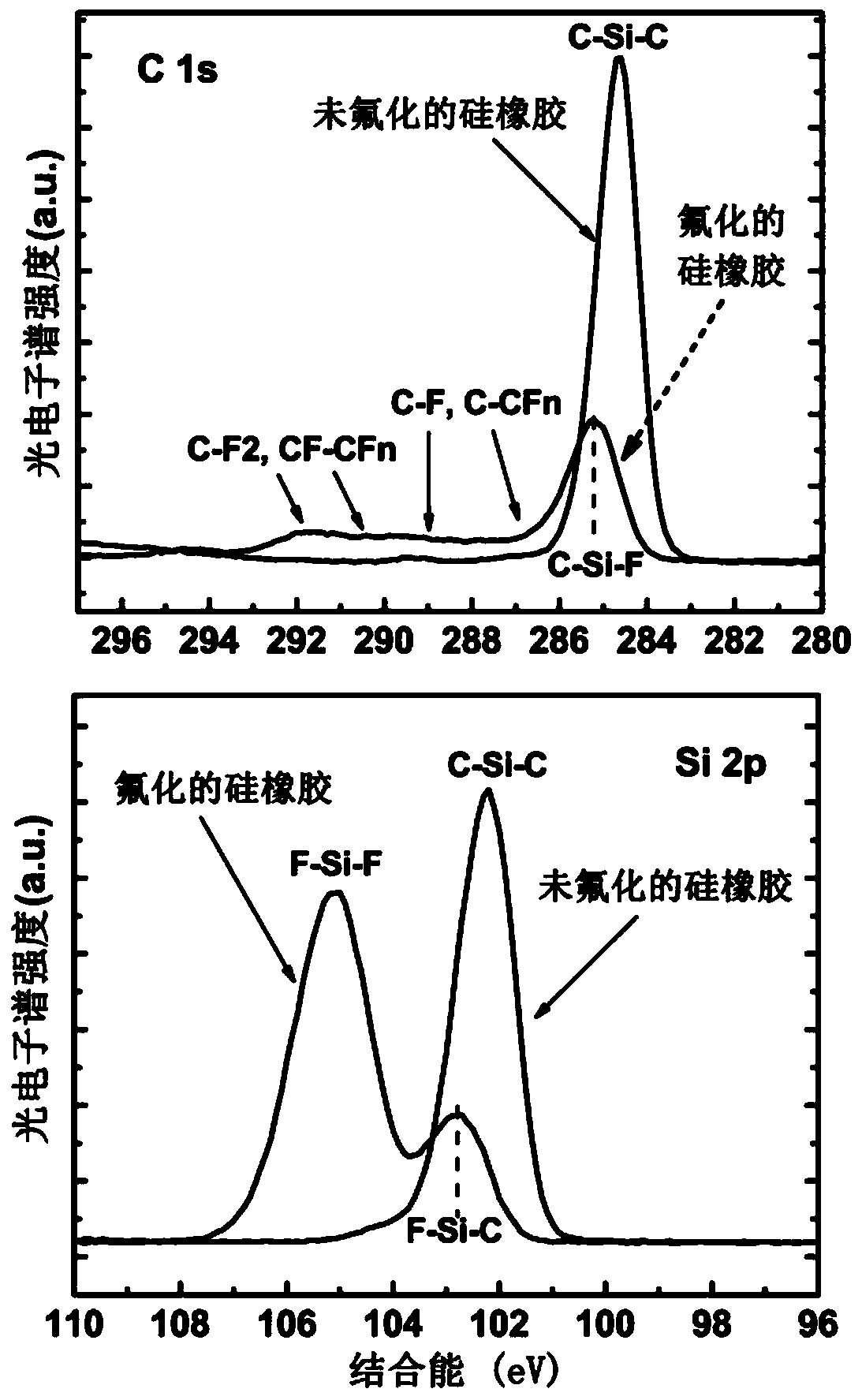

Method for remarkably improving surface hydrophobicity of silicone rubber

The invention relates to a method for remarkably improving surface hydrophobicity of silicone rubber. The method comprises the following steps: firstly, fluoridating a silicone rubber product or a product covered with a silicone rubber layer in a sealed reaction chamber; secondly, in a temperature-controlled furnace, thermally crosslinking the fluoridated silicone rubber product or the fluoridated product covered with the silicone rubber layer, wherein the fluoridating process conditions are as follows: the fluoridating temperature is room temperature or 100 DEG C, the fluoridating time is 10-120 min, a mixed gas consisting of a fluorine gas and an inert gas is used for fluorinating, the volume concentration of the fluorine gas in the mixed gas is 5-50%, and the pressure of the mixed gas in the reaction chamber is 0.2-2 bars; the thermal crosslinking process conditions are as follows: the fluoridated silicone rubber product or the fluoridated product covered with the silicone rubber layer is put in the temperature-controlled furnace at the temperature of 120-180 DEG C for 30-120min. Compared with the prior art, the method provided by the method has the advantages as follows: by adopting the method, the silicone rubber product or the silicone rubber covering layer of the product can become remarkably hydrophobic, or even superhydrophobic; the method is especially suitable to large-scale industrial production, such as surface modification of a silicone rubber insulator.

Owner:TONGJI UNIV

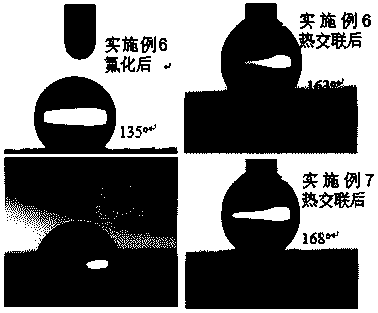

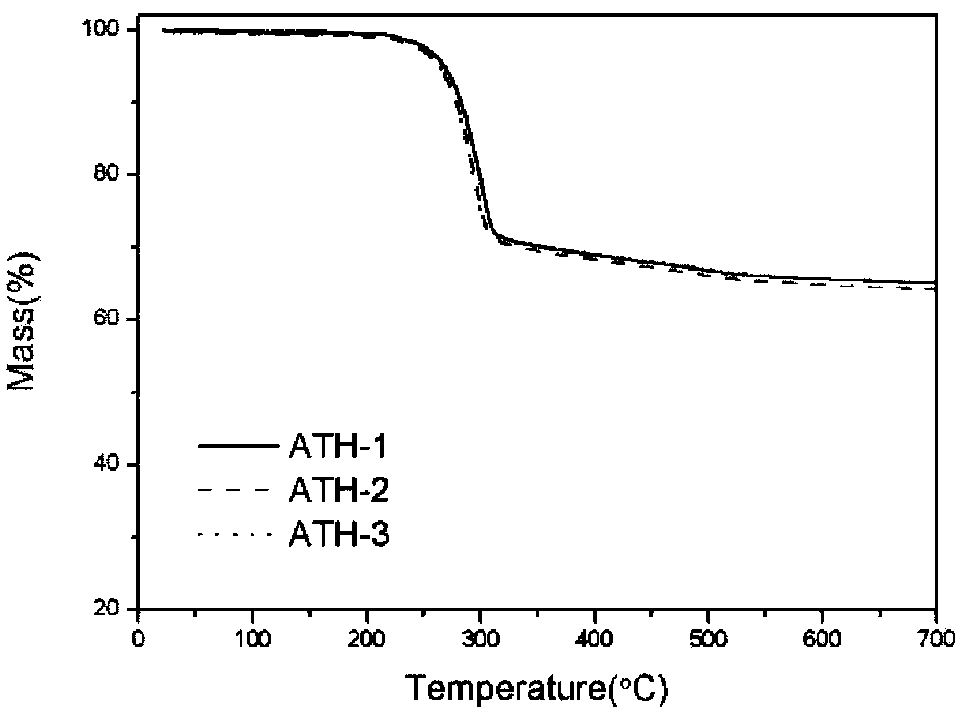

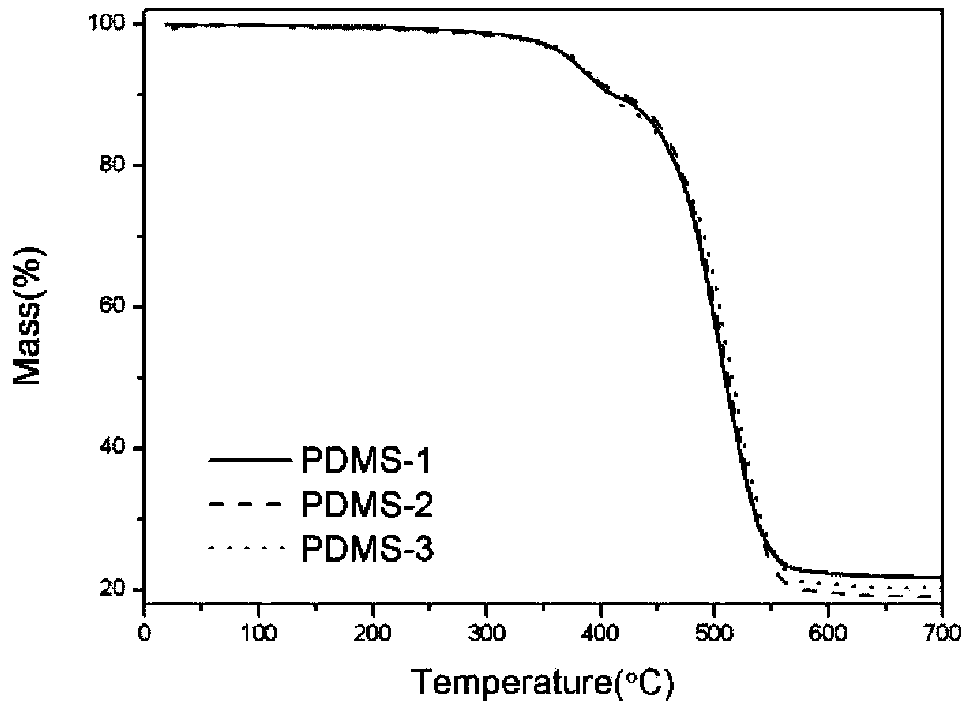

Thermal analysis method for measuring contents of polydimethylsiloxane (PDMS), SiO2 and aluminum hydroxide (ATH) in silicone rubber composite insulator

ActiveCN104237299AMaterial heat developmentSpecial data processing applicationsSilicone rubber insulatorsCalculation methods

The invention relates to a thermal analysis method for measuring the contents of polydimethylsiloxane (PDMS), SiO2 and aluminum hydroxide (ATH) in a silicone rubber composite insulator. The method comprises the steps of S1, respectively measuring the thermal gravity loss (TG) curves of the PDMS, the ATH and the SiO2 for three times by a thermal gravity loss-differential thermal analysis combination comprehensive thermal analyzer, and averaging; S2, cutting three parts from the silicone rubber insulator randomly, wherein the cut parts have the sizes of 1cm*1cm and the masses within the range of 5-50mg; pretreating, then measuring the TG curves of the silicone rubber insulator for three times, and averaging; S3, calculating the thermal weight loss rates of the PDMS, the ATH, the SiO2 and the silicone rubber insulator in the ranges of 20-360 DEG C and 360-700 DEG C according to the TG curves; S4, substituting the obtained numerical values into the formula delta M=(m(ATH)*deltam(ATH)+m(PDMS)*delta m(PDMS)+m(SiO2)*delta m(SiO2)) / (m(ATH)+m(PDMS)+m(SiO2)); and S5, working out the equation in the S4, and calculating the contents of the ATH and the SiO2 relative to the PDMS. According to the method, the contents of the three components of the silicone rubber composite insulator can be worked out by utilizing the thermal weight loss rates of the three components in the respective specific thermal decomposition temperature ranges, and a concrete calculation method is provided.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

High temperature resistant composite silicone rubber insulator formulation

The invention relates to high temperature resistant composite silicone rubber insulator formulation. The formulation comprises the following components in percentage by weight: 30-50 percent of methyl vinyl silicone rubber, 10-20 percent of fumed silica, 30-50 percent of aluminium hydroxide, 0.3-1.5 percent of hydroxyl silicone oil, micro-dosage of stearic acid , micro-dosage of platinum complex, 1-2 percent of hydrogen silicon oil, 0.02 percent of retarder, 1-3 percent of cerium siloxane, and micro-dosage of metaboric acid, wherein the content sump of the components is 100 percent. By adopting the formulation provided by the invention, only one-step vulcanization process is required, the heat resistance performance of the silicone rubber can be improved better, the components of the silicone rubber can be mixed uniformly, the processing performance of the rubber material can be improved, and the mechanical strength of the vulcanizing silicone rubber can be improved.

Owner:GUIZHOU XINKAIRONG RUBBER PLASTIC ELECTRONICS TECH

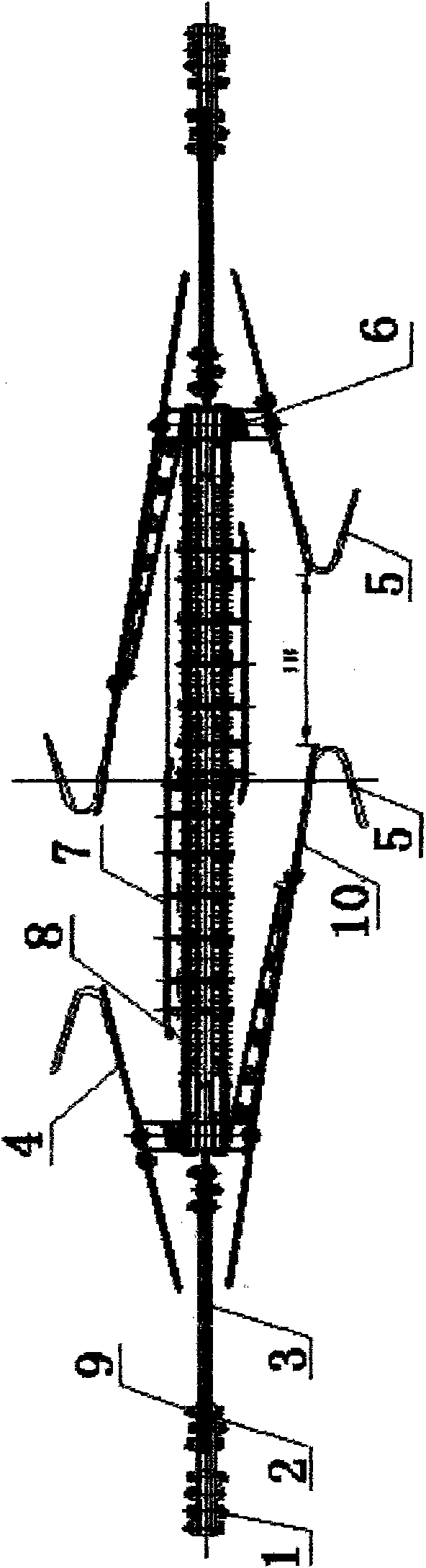

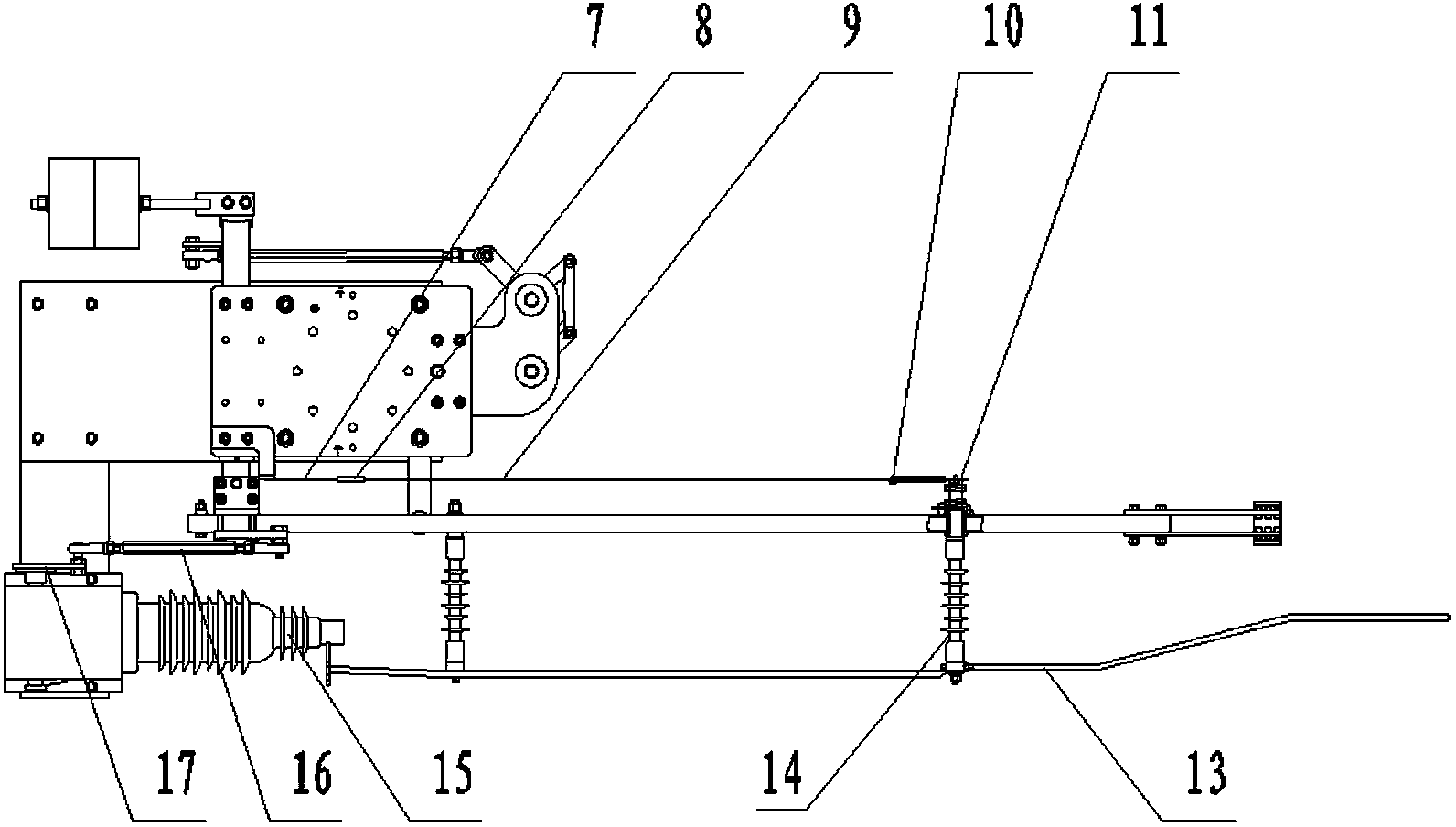

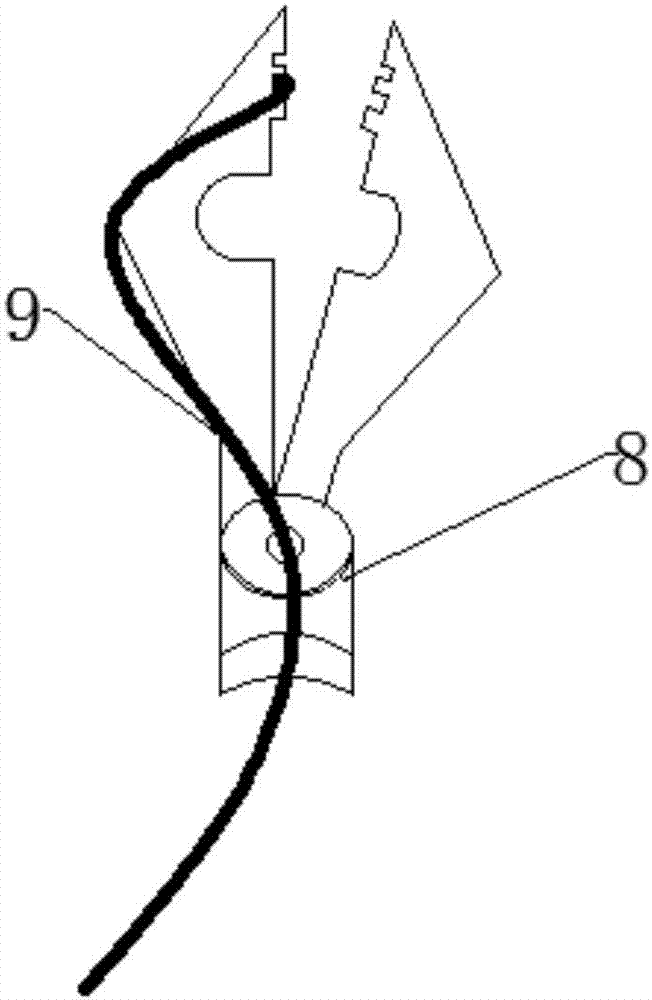

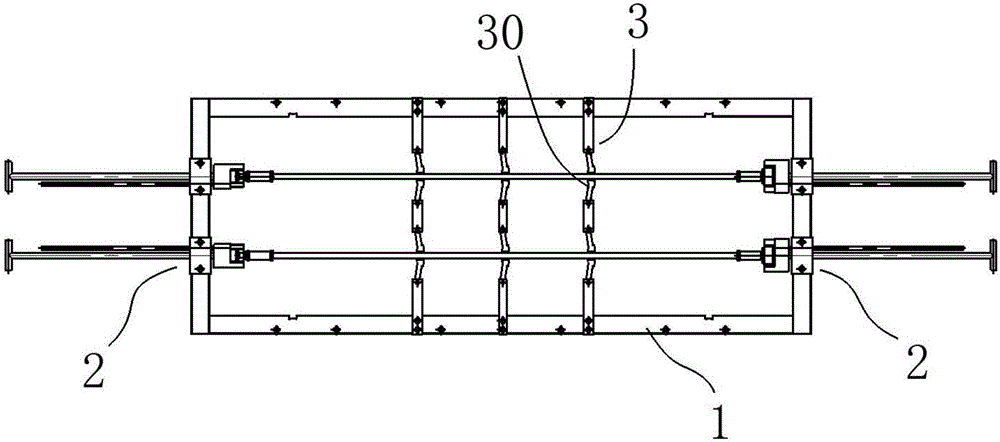

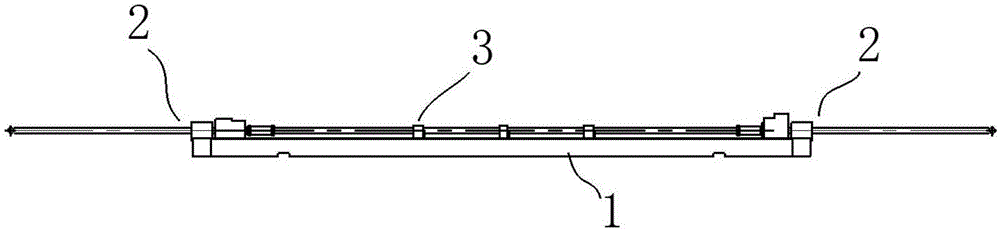

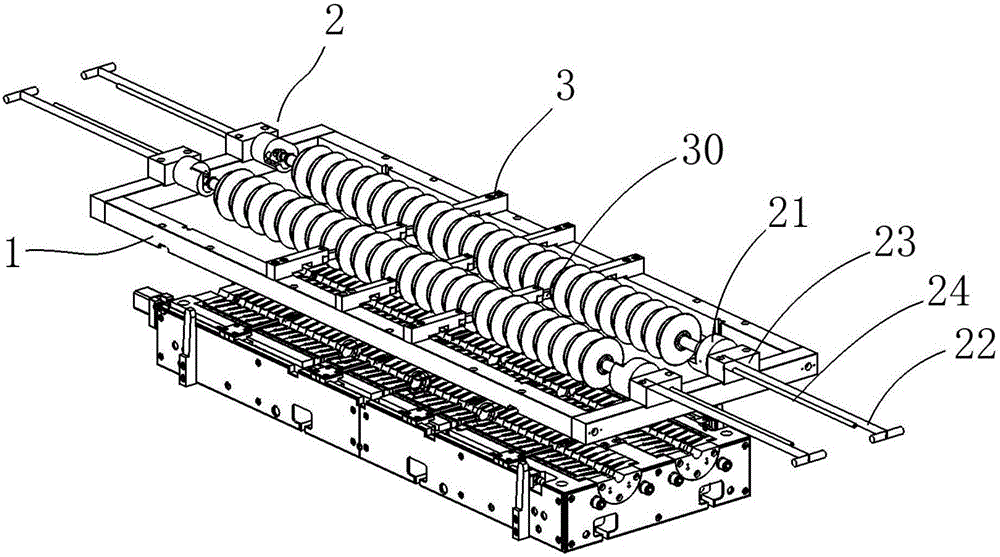

Bending moment-free anti-pollution high-speed segmenting and phase-splitting isolator

The invention belongs to equipment used in an electrified railway contact system, in particular to a bending moment-free anti-pollution high-speed segmenting and phase-splitting isolator, which is characterized by comprising a joint wire clamping plate (1), a joint wire clamp connecting plate (2), a connecting plate (3), a short sliding plate (4), a long sliding plate (10), a starting rod A (5), astarting rod B (5), a frame (6), an insulating sliding plate (7), silicon rubber isolators (8) and a fastening standard component (9), wherein the joint wire clamping plate (1) clamps a contact wire;and stressed axes of two silicon rubber isolators (8), the axes of connecting bolts at two ends of the connecting plate (3) and the groove of a contact lead are in the same axis. A pantograph of thebending moment-free anti-pollution high-speed segmenting and phase-splitting isolator can smoothly pass through at a high speed without generating bending moment, pantograph scratch and pantograph drilling. The bending moment-free anti-pollution high-speed segmenting and phase-splitting isolator cannot worn by the pantograph, has no pollution and cannot be burnt out by an electric arc.

Owner:周建科

A UHV Composite Insulator with Uniform Electric Field Distribution

ActiveCN102298996AImprove unevennessImprove safety and reliability performanceInsulatorsHigh pressureSilicon rubber

The invention relates to an extra-high voltage composite insulator with uniform electric-field distribution and belongs to the technical field of electric materials. In the extra-high voltage composite insulator, a silicon rubber insulator is connected with a nonlinear characteristic insulator; a grounding electrode end and an equalizing ring are arranged at the end of the silicon rubber insulator; a high-voltage electrode end for fixing a conductor and the equalizing ring are arranged at the end of the nonlinear characteristic insulator; the silicon rubber insulator accounts for 4 / 5 of totallength of the extra-high voltage composite insulator; and the nonlinear characteristic insulator accounts for 1 / 5 of total length of the extra-high voltage composite insulator. By the extra-high voltage composite insulator, an insulator monomer is prepared from a nonlinear composite material and is assembled by mixing the traditional silicon rubber insulator monomer, non-uniformity of whole electric-field distribution of the extra-high voltage insulator can be obviously improved, the safety and reliability in the operating process are improved, the service life of the insulator is prolonged, dimension of the equalizing ring is reduced and even canceled, and the difficulty and cost of design, production and installation of the extra-high voltage insulator are greatly reduced.

Owner:TSINGHUA UNIV +1

Detection method for ageing degree of silicone rubber composite insulator

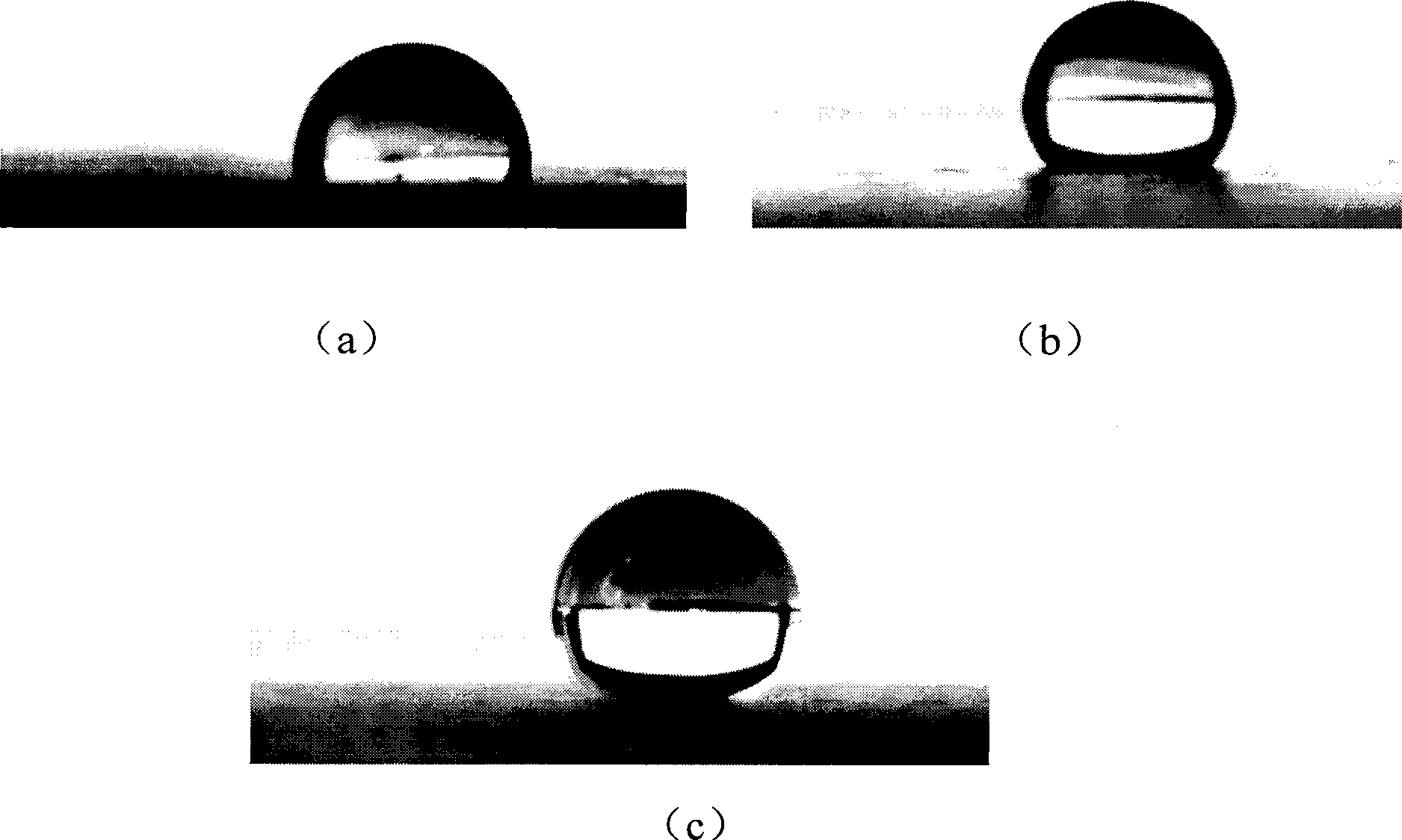

InactiveCN103344527AAccelerated agingEasy to operateSurface/boundary effectFree energiesSilicone rubber insulators

The invention discloses a detection method for the ageing degree of a silicone rubber composite insulator. According to the invention, a plurality of detection liquids are used to determine the contact angle of the silicone rubber composite insulator and calculating surface free energy and acid-alkali components thereof, and the ageing degree of the silicone rubber composite insulator is judged according to the value of the surface free energy; the ageing degree is grade I if the surface free energy is in a range of 12 mJ / m<2> to 26 mJ / m<2>, the ageing degree is grade II if the surface free energy is in a range of 26 mJ / m<2> to 28 mJ / m<2>, and the ageing degree is grade III if the surface free energy no less than 28 mJ / m<2>. The detection method is simple to operate, can reflect changing process of the surface of the silicone rubber insulator in a plurality of aspects and is applicable to assessment of ageing of the composite insulator.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

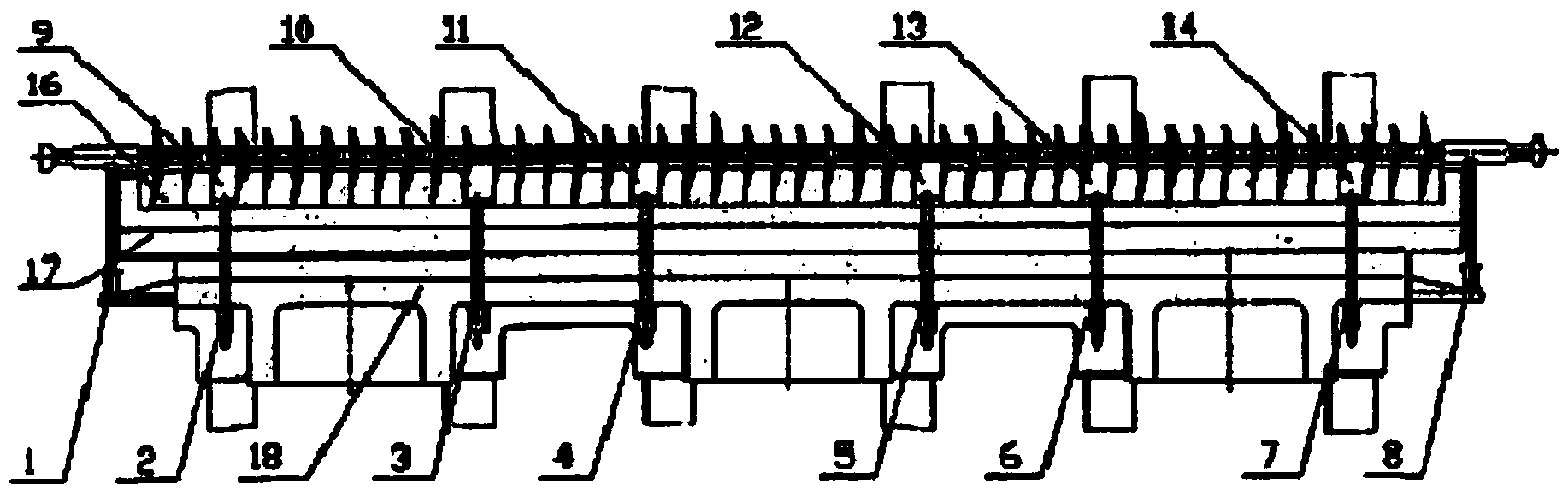

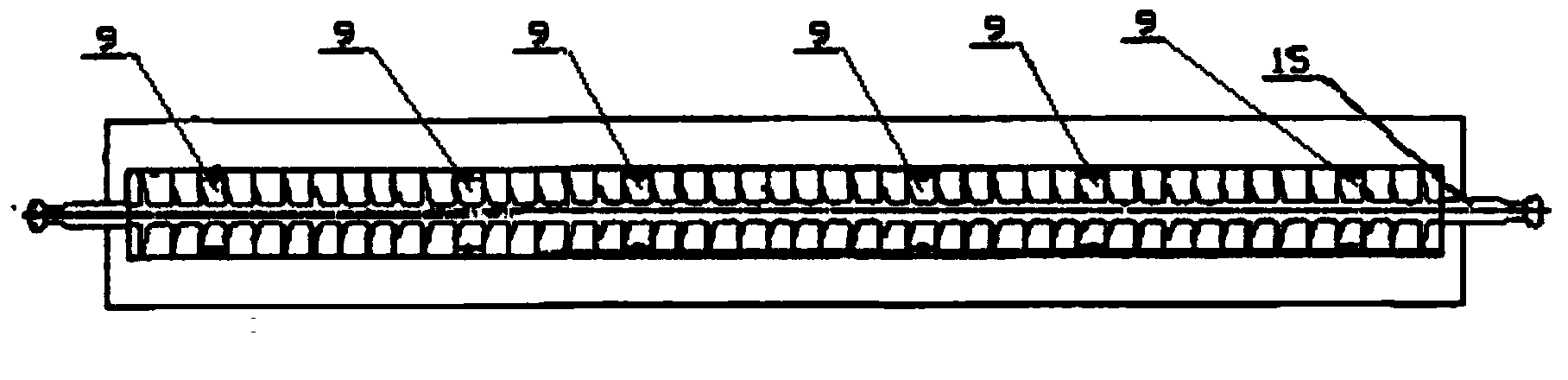

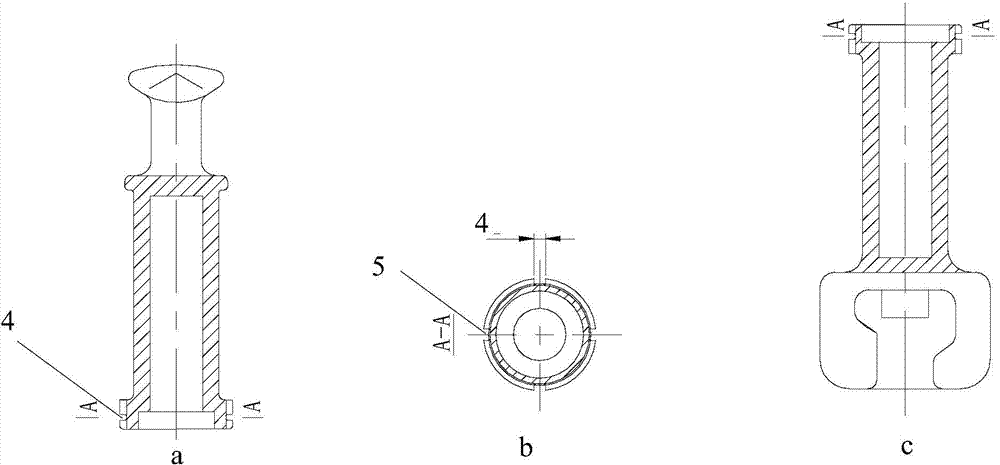

Silicon rubber insulator injection mold demolding device

InactiveCN103522504AImprove looseTo achieve the purpose of demouldingSilicon rubberSilicone rubber insulators

The invention discloses a silicon rubber insulator injection mold demolding device. The device comprises a moving template, a lower template, a lower heat plate, a mandrel, at least three movable inserts and a driving mechanism, wherein the lower template is fixedly arranged at the upper end of the moving template; the lower heat plate is fixedly arranged between the moving template and the lower template; the mandrel is placed in a cavity of the lower template; the movable inserts are arranged in the cavity of the lower template in a vertical sliding mode, the shapes of the upper ends of the movable inserts correspond to the shape of the cavity of the lower template, so that the movable inserts are combined with the cavity of the lower template to form a cavity of a product, and the at least three movable inserts are distributed along the axial direction of the cavity of the lower template; the driving mechanism is fixedly arranged on the movable template and is connected with the movable inserts to drive the movable inserts to slide up and down. According to the device, automatic demolding can be performed on the product, the production efficiency is high, and the product is not damaged easily.

Owner:南宁市博泰华五金模具厂

Silicone rubber insulator injection mold demolding device

ActiveCN107571470AIncrease productivityHorizontal dynamics are even and gentleDomestic articlesGas compressorEngineering

The invention discloses a silicone rubber insulator injection mold demolding device which comprises a base. The base is connected with a high-pressure cavity. The left side of the high-pressure cavityis connected with an air compressor. The surface of the right side of the high-pressure cavity is connected with horizontal jet nozzles. The base is provided with a rectangular groove. A stand columnis arranged in the rectangular groove. A bearing is arranged at the top end of the stand column. A rotary shaft is arranged in the bearing. The left side of the rotary shaft is connected with a motorand fixedly connected with a rotary frame. The two ends of the rotary frame are fixedly provided with negative-pressure cavities. Adsorption holes are formed in the right sides of the negative-pressure cavities. The left side of the base is connected with an L-shaped support. The tail end of the L-shaped support is provided with an air cooler. By arranging the high-pressure cavity and the jet nozzles, even and gentle air force is used for demolding, no pit is left in the surface of an insulator, by arranging the rotary frame and the negative-pressure cavities, rotation and forward pushing areconducted at the same time, and the demolding difficulty is lowered.

Owner:硅美德橡塑科技(昆山)有限公司

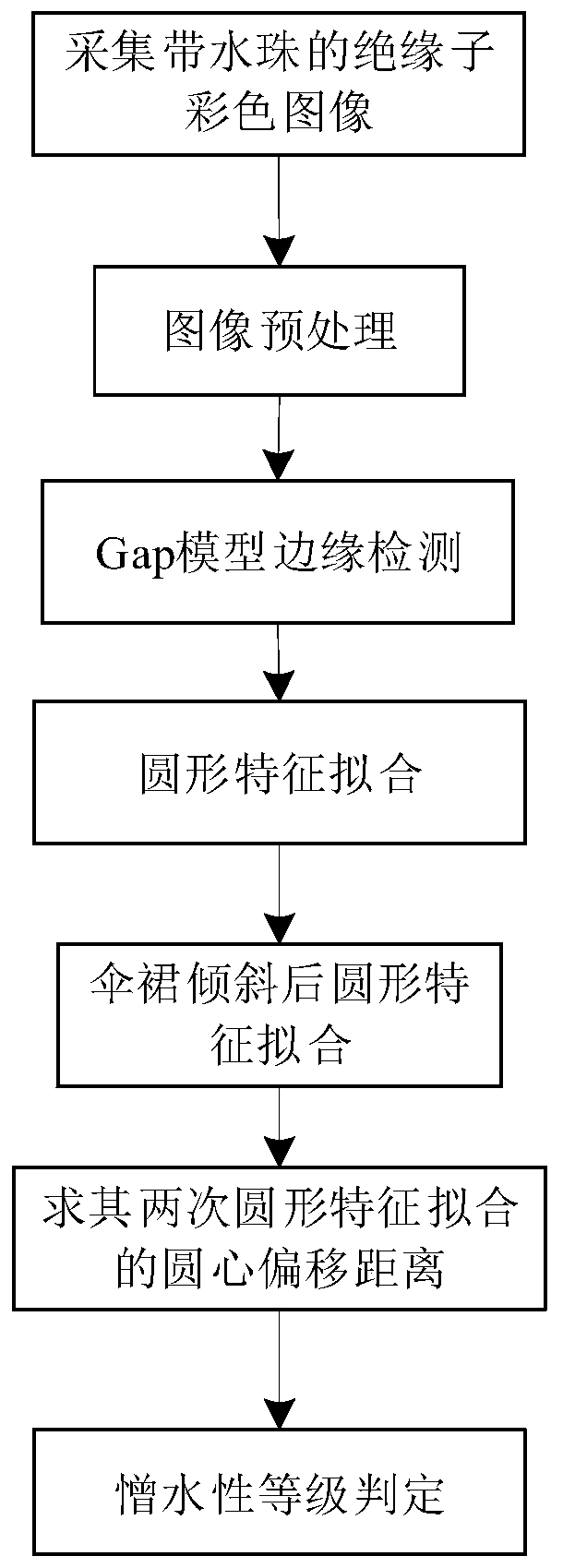

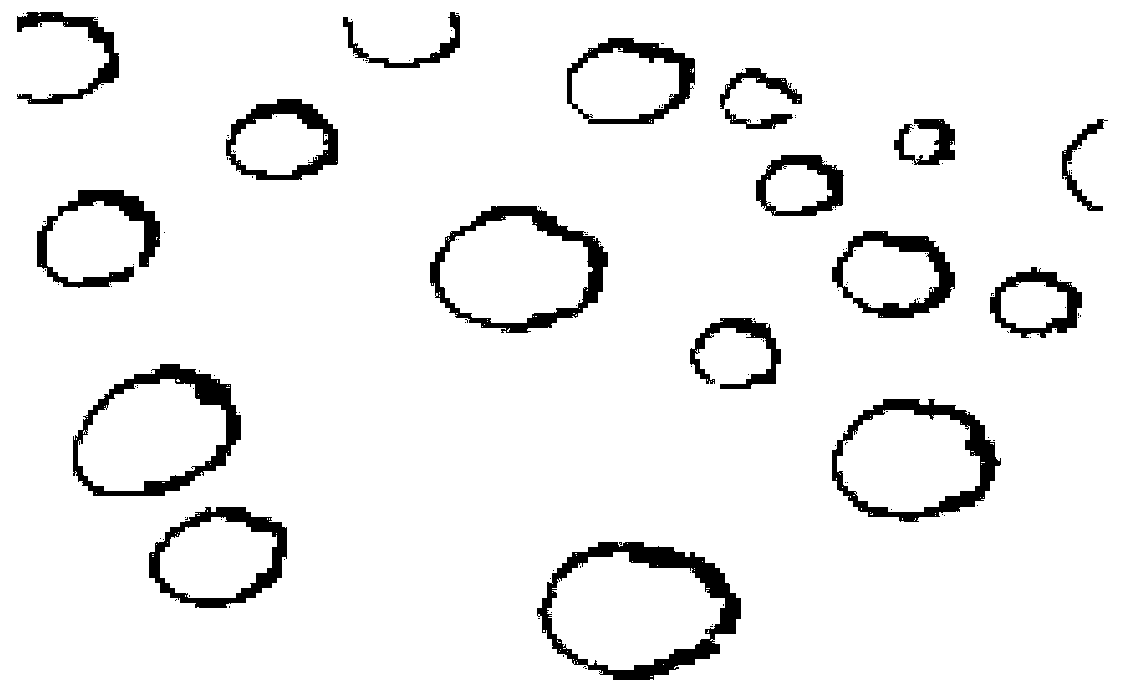

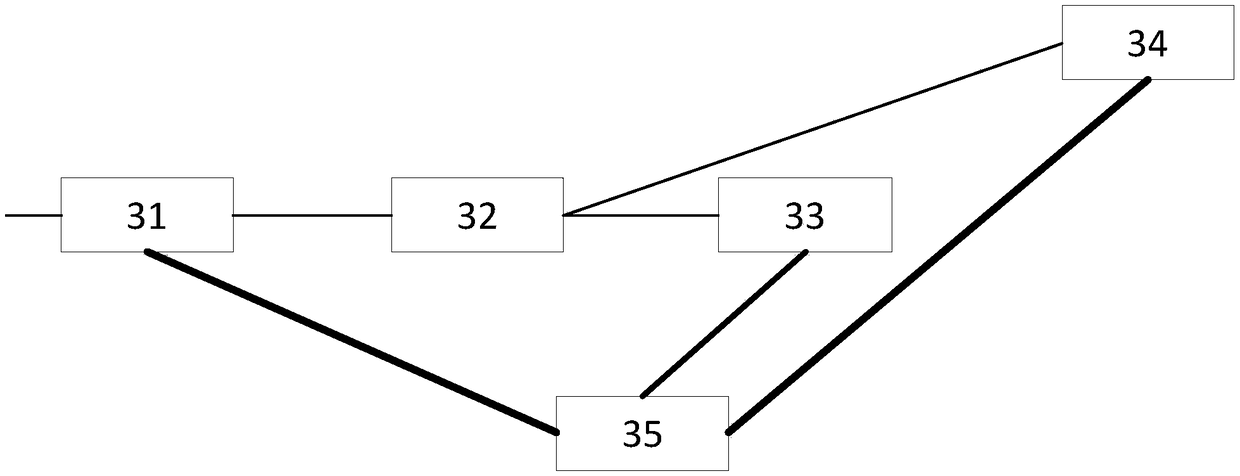

Composite insulator hydrophobicity grade determination method based on a water drop offset distance

ActiveCN109801283ASolve the problem of missing border partsImage analysisSurface/boundary effectColor imageFuzzy edge detection

The invention discloses a water drop offset distance-based hydrophobicity grade determination method for a composite insulator. The method comprises the following steps: firstly, obtaining an originalcolor image of a silicone rubber insulator with water drops; Carrying out graying processing and image filtering processing on the obtained color image to improve the contrast ratio of the image andremove the interference noise of the image; Then, an image fuzzy edge detection model based on a statistical gap membership function and correlation coefficient classification judgment is established,and the outline of the water drop or water stain is obtained; And finally, carrying out circular fitting on the obtained water drop contour area and processing the target binary image. the position information of each water drop is obtained, the moving distance of the water drops before and after the umbrella skirt is deviated is obtained, then the hydrophobicity grade of the silicone rubber composite insulator is judged, and when the deviation distance is smaller, the hydrophobicity of the silicone rubber composite insulator is better, and when the deviation distance is larger, the hydrophobicity of the silicone rubber composite insulator is poorer. According to the invention, the hydrophobic grade identification accuracy of the silicone rubber insulator is greatly improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Highly hydrophobic outdoor strain insulator

The invention discloses a highly hydrophobic outdoor strain insulator, which comprises a core rod, umbrella-shaped parts arranged outside the core rod, coatings that coat the surfaces of the umbrella-shaped parts, and end assemblies at the two ends of the core rod. The basic body of the core rod is made from epoxy resin, and the main reinforcing body of the core rod is a mixed body of directional aramid fiber material and alkali-free glass fiber that are arranged in a certain manner. The umbrella-shaped parts are made from outdoor epoxy resin high in weatherability. The highly hydrophobic outdoor strain insulator exhibits high tensile strength, high hydrophobicity and high weatherability, can be accurately controlled in molding dimension, is high in production efficiency, and is substantially improved in overall rigidness compared with silicone rubber insulators. The core rod can be better combined with the umbrella-shaped parts. In a word, the outdoor strain insulator exhibits higher tensile strength, and is high in hydrophobicity and weatherability.

Owner:赛思迈(上海)新材料科技有限公司

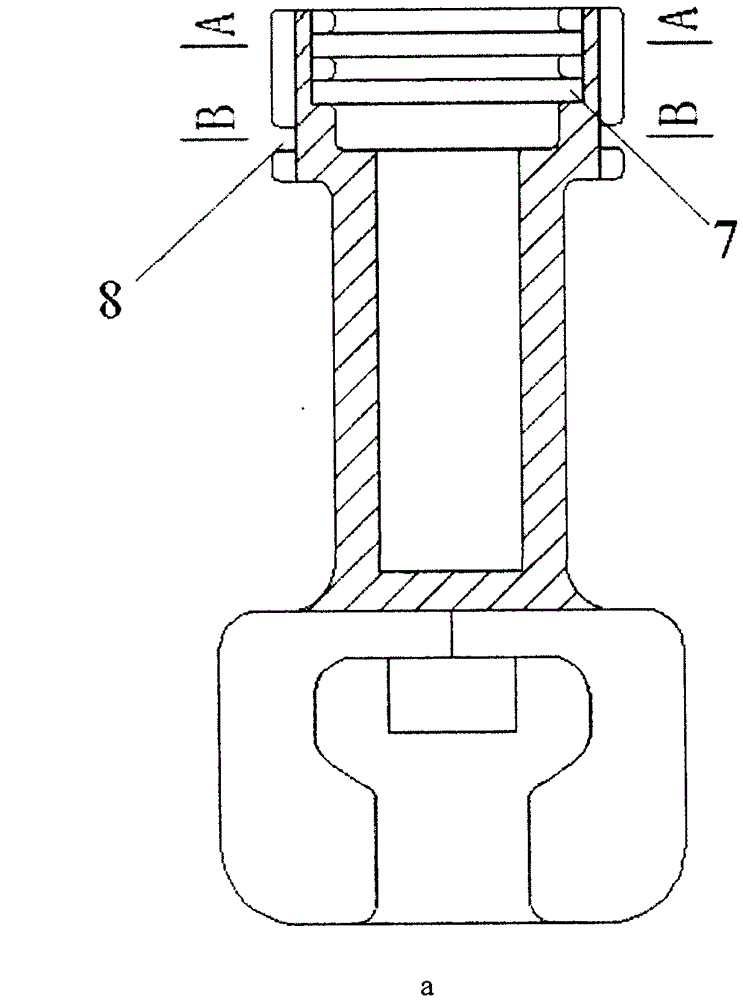

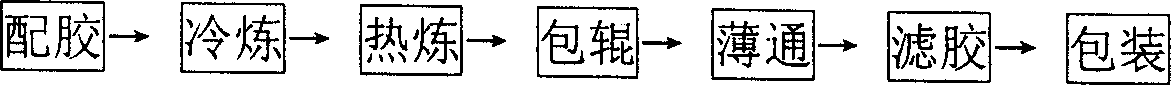

Preparation method of special material for injection moulding composite silicon rubber insulator mixing refine rubber

InactiveCN1908067AExtended shelf lifeGood physical and mechanical propertiesAcetic anhydrideTriethoxysilane

the invention discloses a preparing method of insulator melted gel, which is characterized by the following: adopting hydroxyl silicon oil through potassium hydroxide method to replace national acetic anhydride method; utilizing dynamic high-temperature method to dispose aluminium hydroxide for flame-proof material; improving mixed property and manufacturing property of gel through associating methyl phenyl hydroxyl silicon oil and silane methyl vinyl triethoxy; fitting for injecting mould.

Owner:JIANGSU HONGDA NEW MATERIAL

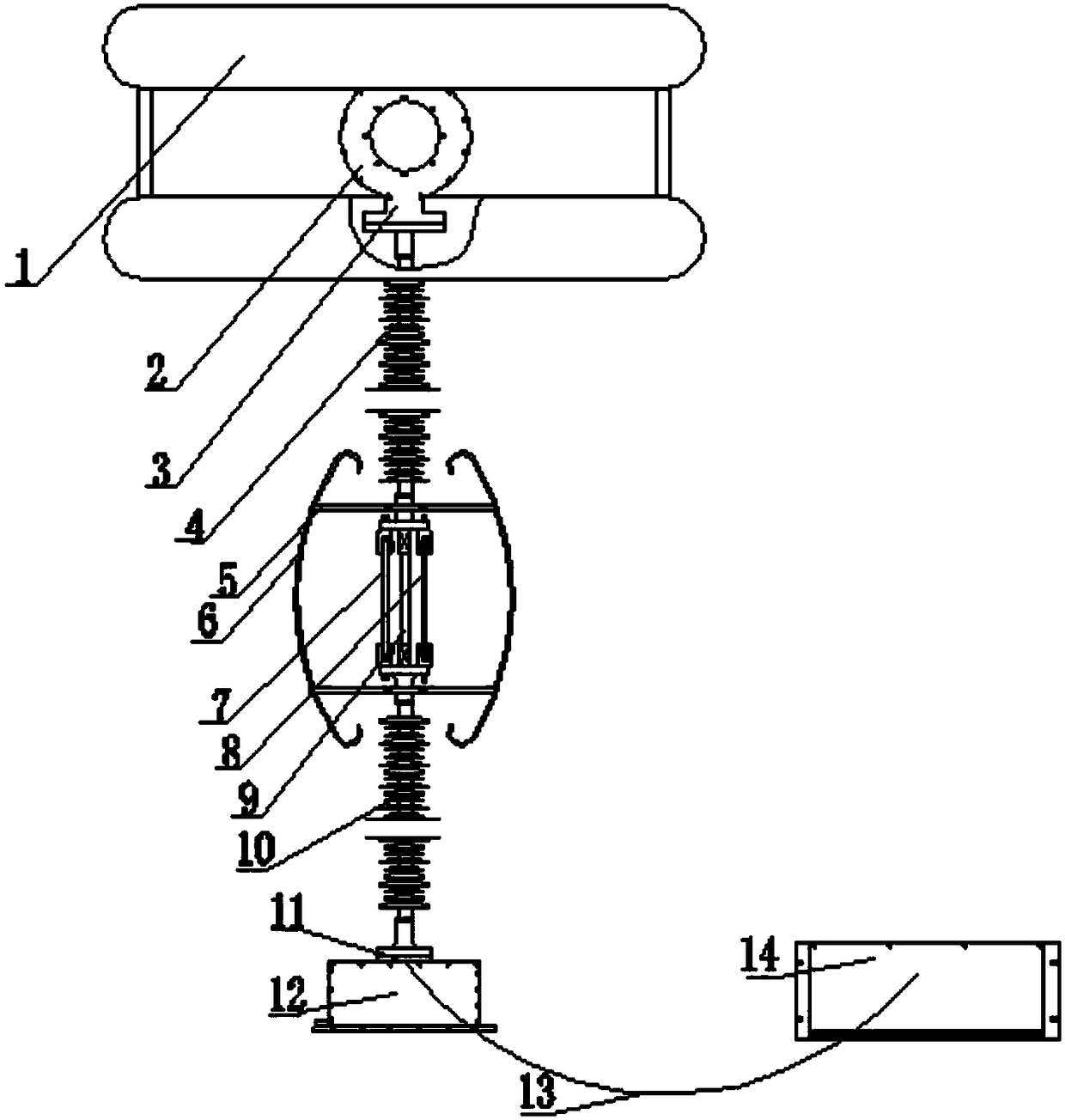

Induced current release device of 252KV outdoor high-voltage alternating-current earthing switch

ActiveCN103295829AAvoid burnsImprove securityHigh-tension/heavy-dress switchesAir-break switchesEngineeringAlternating current

The invention relates to an induced current release device of a 252KV switching extra-B-type outdoor high-voltage alternating-current earthing switch. The induced current release device comprises an auxiliary moving contact, an arc extinguish chamber, a drive device and an on-off device. The arc extinguish chamber is disposed on the outer side of the rear end of a master earthing knife. A silicone insulator is perpendicularly disposed on the outer side of the maser earthing knife. The auxiliary moving contact is hinged to the silicone insulator. The front end of the arc extinguish chamber is connected with the auxiliary moving contact through a flexible conductor. The on-off device comprises a connecting plate and a transmission link. The drive device comprises a pull plate, an adjusting sleeve, a moving contact pull rod, a turning crank, and a torsion spring spindle. The induced current release device has the advantages of simple and reasonable structure, stability in transmission and high safety.

Owner:山东泰开隔离开关有限公司

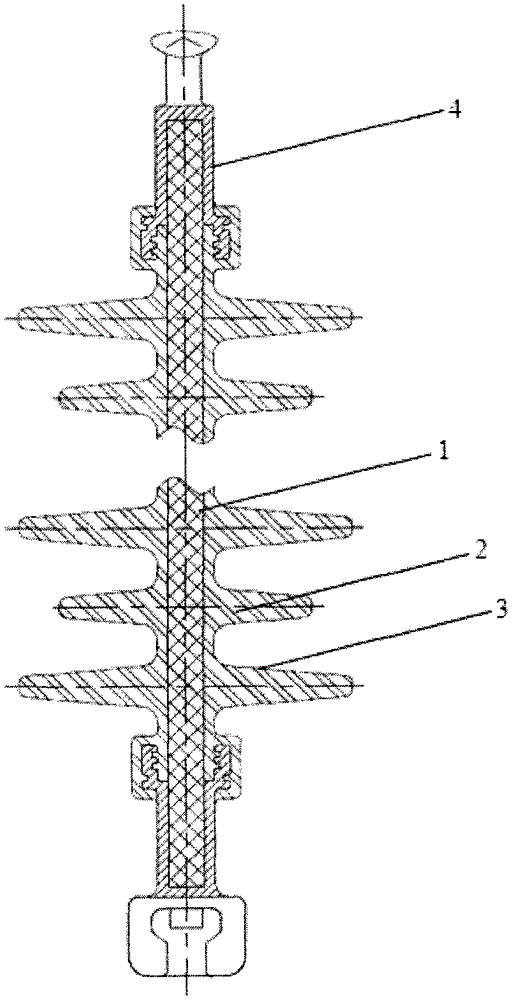

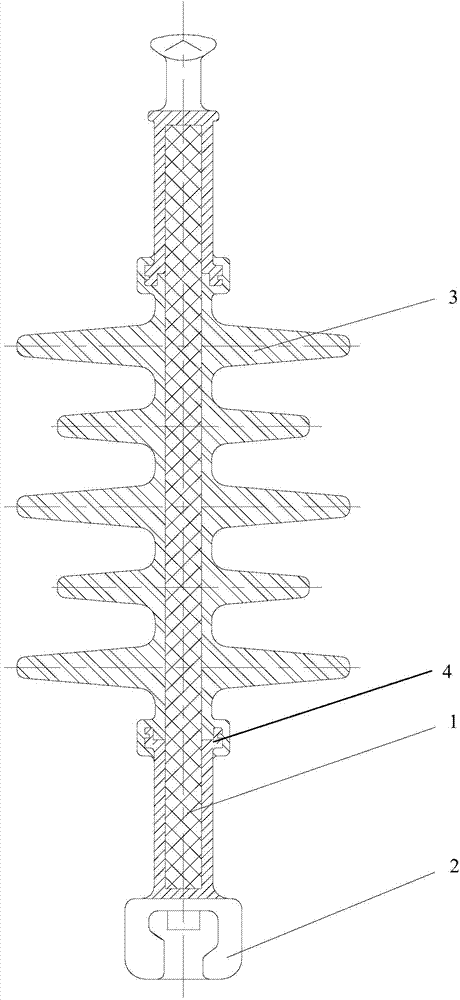

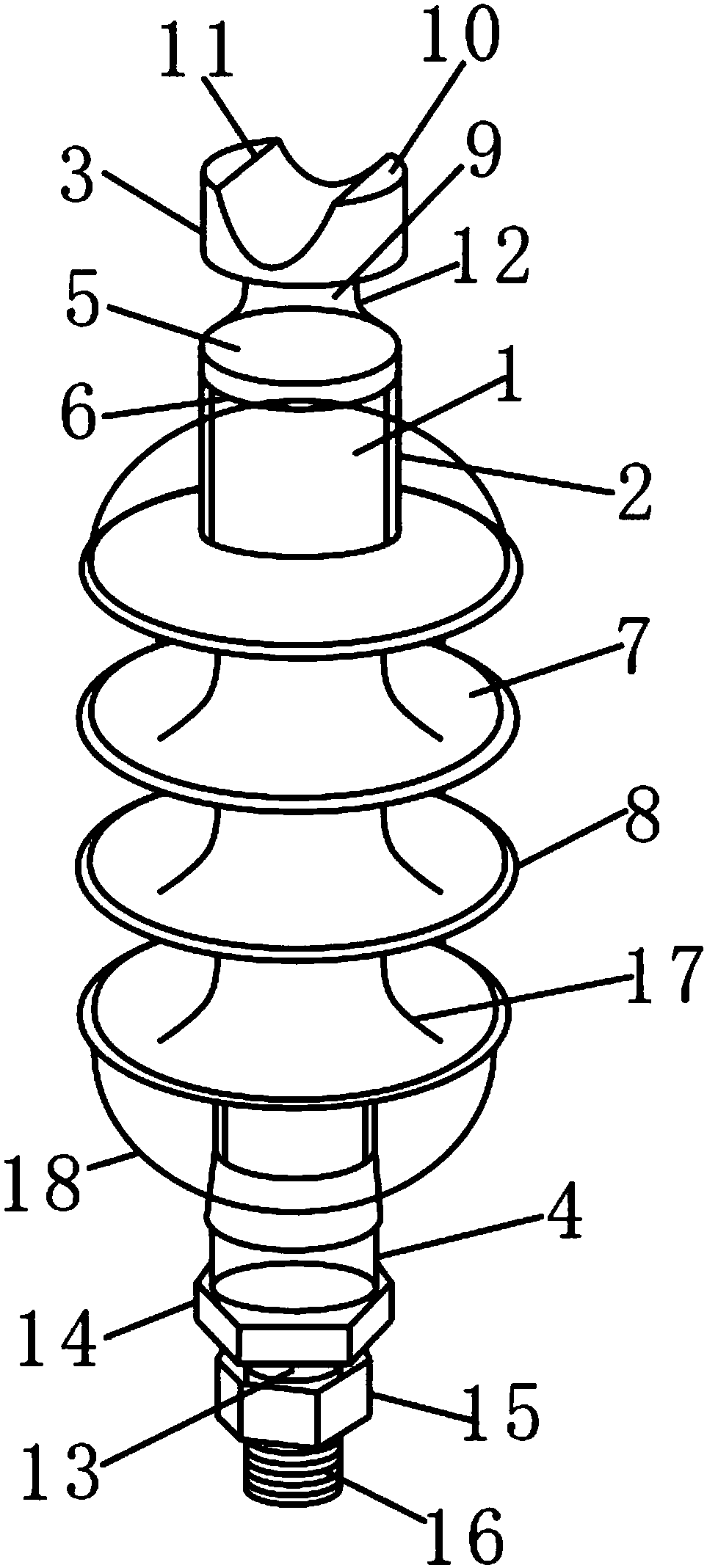

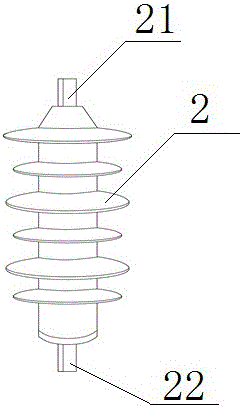

Suspension insulator

ActiveCN103617845AImprove electrical strengthIncrease stiffnessSuspension/strain insulatorsEpoxyFiber

The invention belongs to the technical field of high voltage power transmission, and in particular relates to a suspension insulator. The suspension insulator disclosed by the invention comprises a core rod 1 and a hardware fitting 2 and an umbrella skirt 3, wherein the hardware fitting 2 and the umbrella skirt 3 are arranged on the two ends of the core rod 1; the core rod is made of epoxy resin and / or an alkali-free glass fiber material, the umbrella skirt 3 is made of flexible epoxy resin, and APG (alkyl polyglucoside) equipment is utilized to form. The suspension insulator provided by the invention has the advantages that the structure is simple, the design is reasonable, the forming efficiency is high, the whole rigidity of the insulator after forming is greatly improved, the suspension insulator compared with a silicone rubber insulator has the advantages that the maintenance is simple and convenient, a bird is prevented from pecking and the like.

Owner:赛思迈(上海)新材料科技有限公司

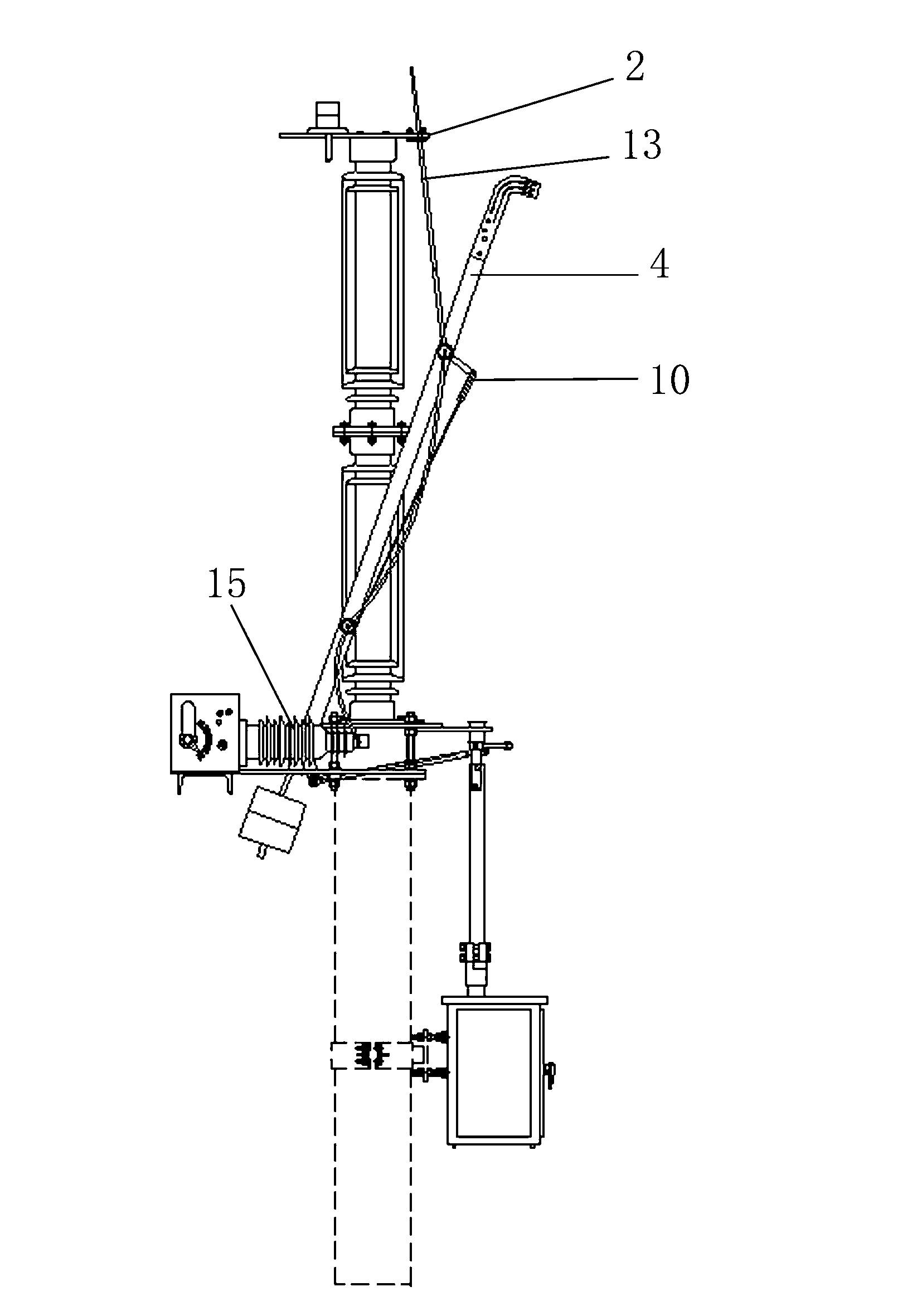

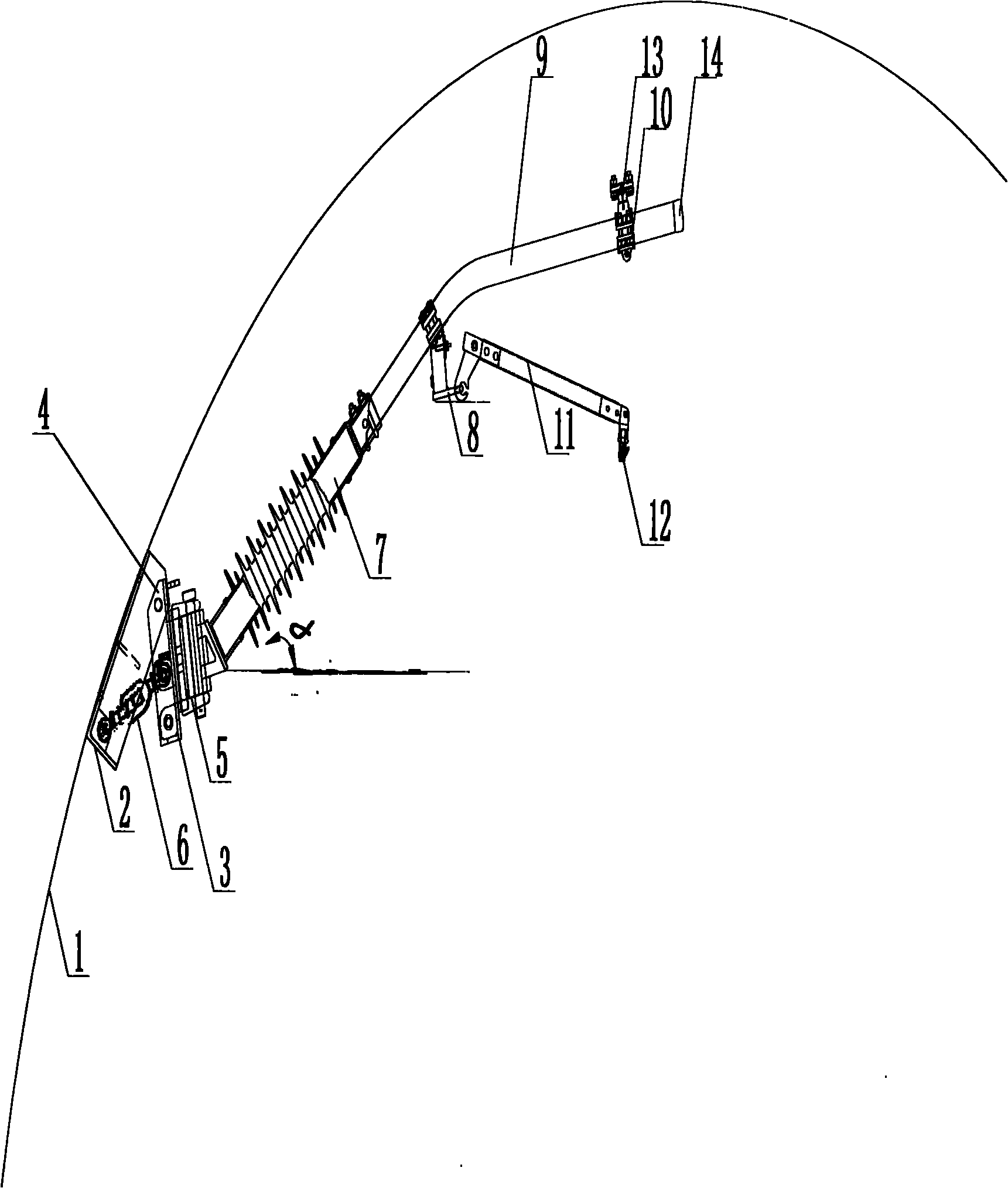

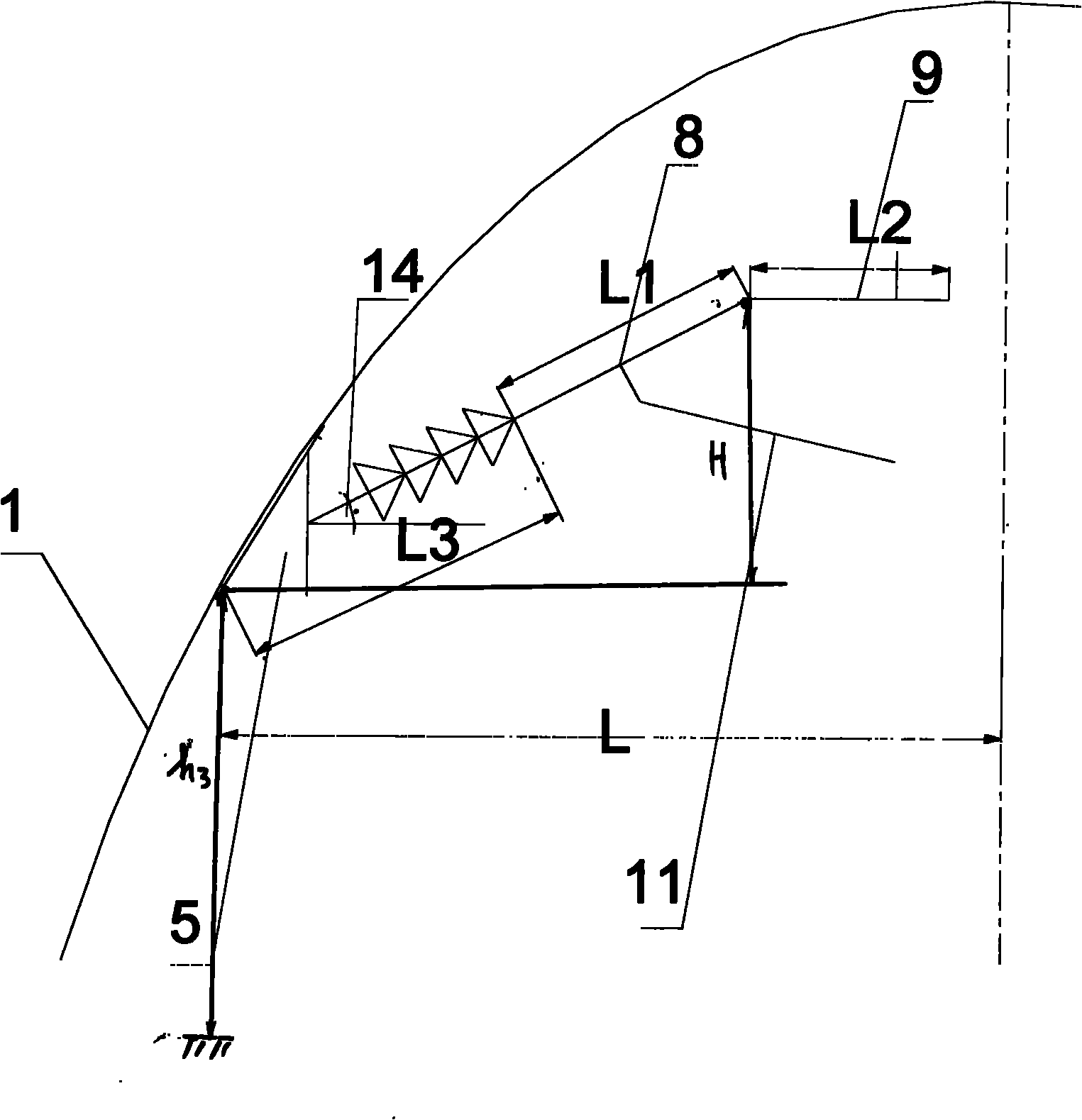

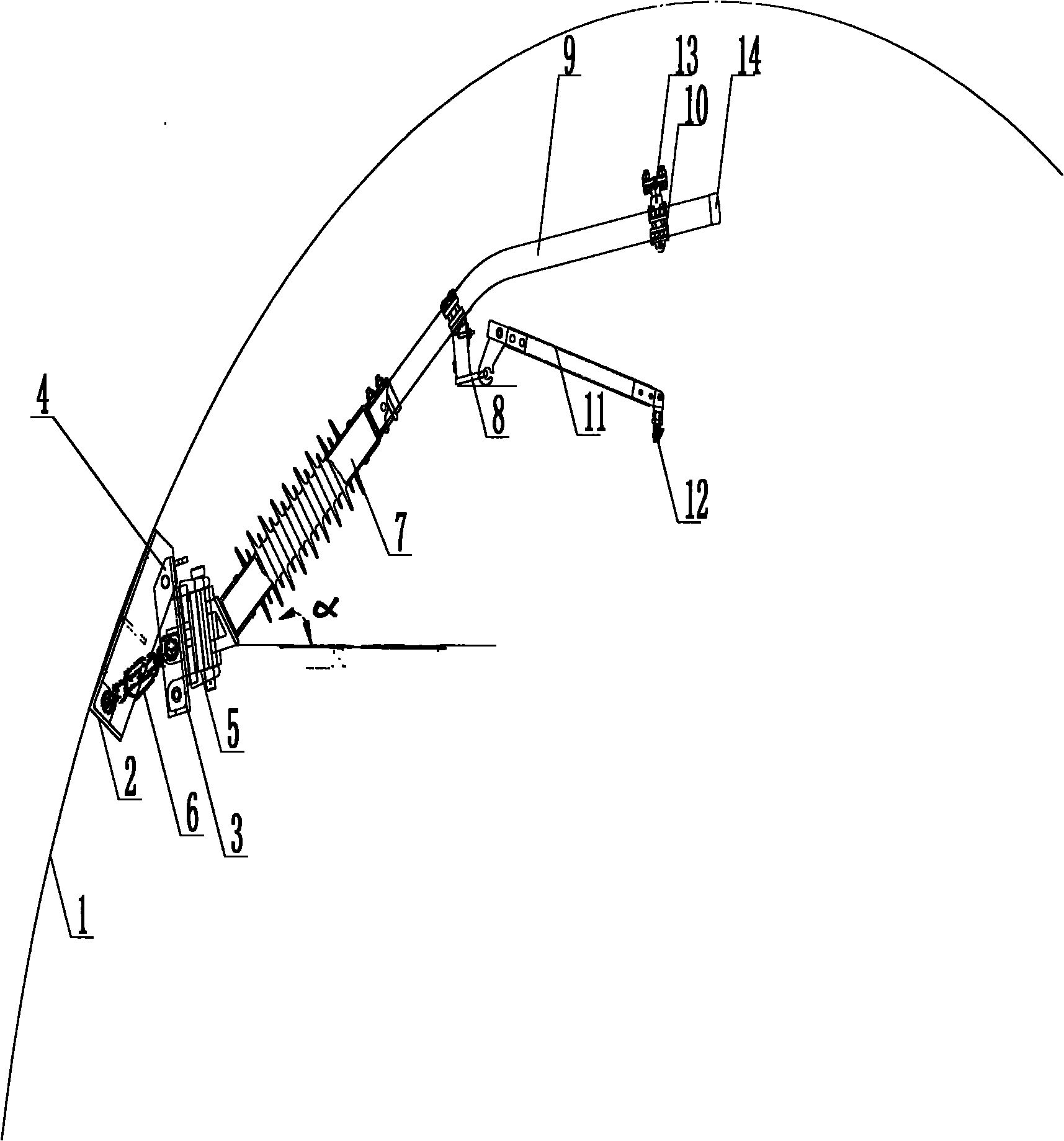

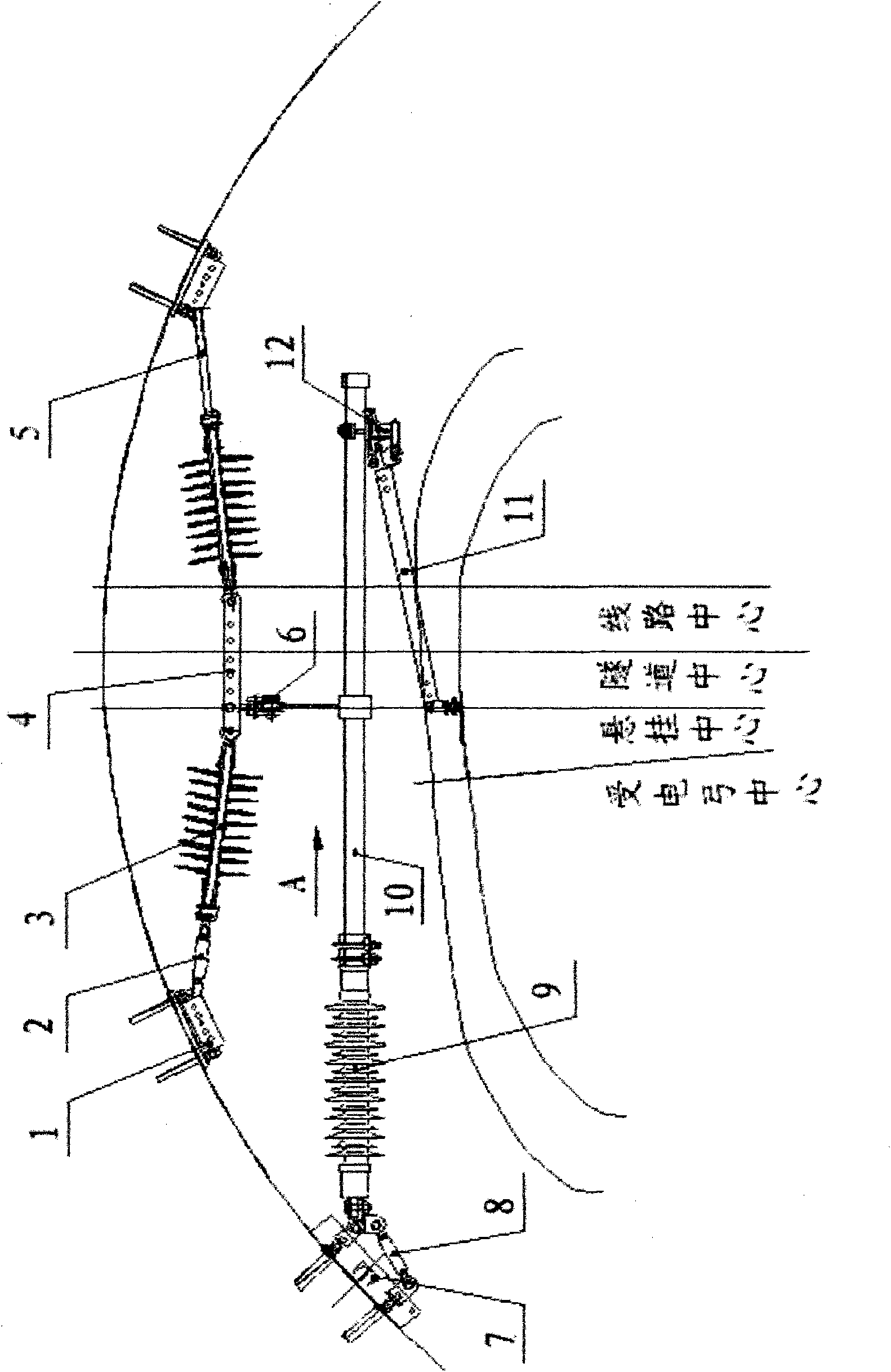

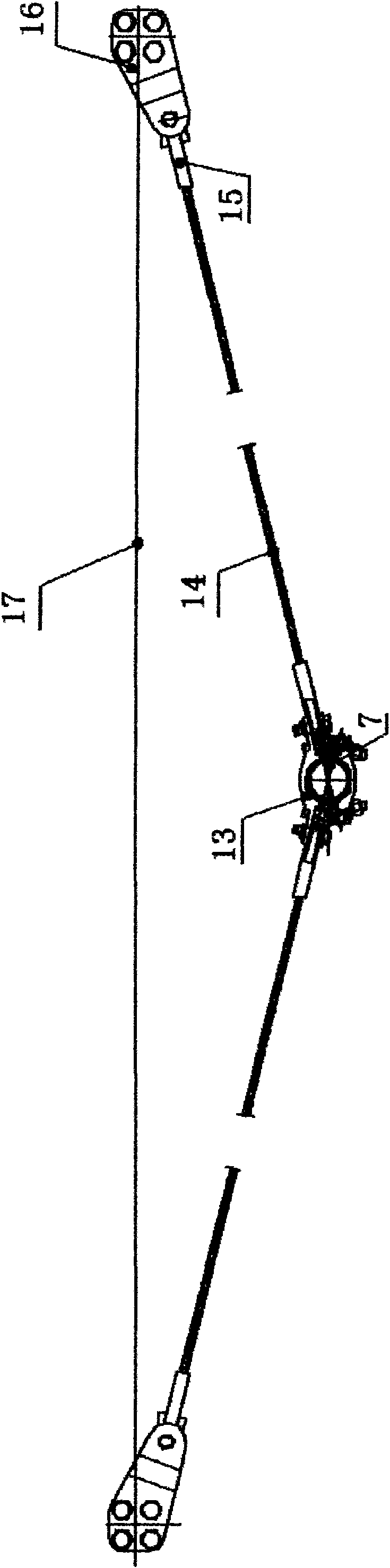

Arched wrist arm of tunnel and measuring and determining method thereof

InactiveCN102145662AOvercome unreasonable phenomenaImprove smoothnessTrolley linesMechanical measuring arrangementsEngineeringSilicon rubber

The invention discloses an arched wrist arm of a tunnel and a measuring and determining method thereof. The problem that the arched wrist arm is not installed in place in a one-lane tunnel with smaller clearance is solved. The arched wrist arm comprises a wrist arm base (5), a silicon rubber insulator (7), an oblique edge (8) of the wrist arm and a horizontal edge (9) of the wrist arm, wherein a bearing cable base (10) is arranged on the horizontal edge (9) of the wrist arm; a bearing cable (13) is connected to the bearing cable base (10); the wrist arm base (5) is fixedly arranged on a movable plate (3); one end of the movable plate (3) is hinged together with a base body (2) through a hinge (4); an adjustable screw rod (6) is arranged between the movable plate (3) and the base body (2), and the openness between the movable plate (3) and the base body (2) is adjusted through adjusting the length of the adjustable screw rod (6). Moreover, the invention provides a specific measuring method. In the invention, the phenomenon of unreasonable relationship between pantograph and catenary is overcome, and the occurrence of the reworking during the installation of the arched wrist arm of the tunnel is avoided.

Owner:CHINA RAILWAY NO 3 ENG GRP CO LTD THE ELECTRIC ENG CO LTD

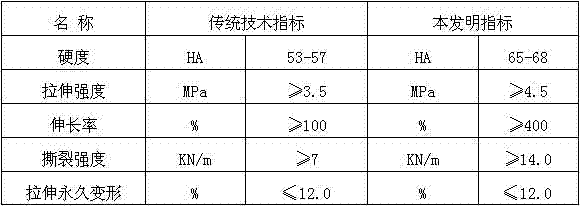

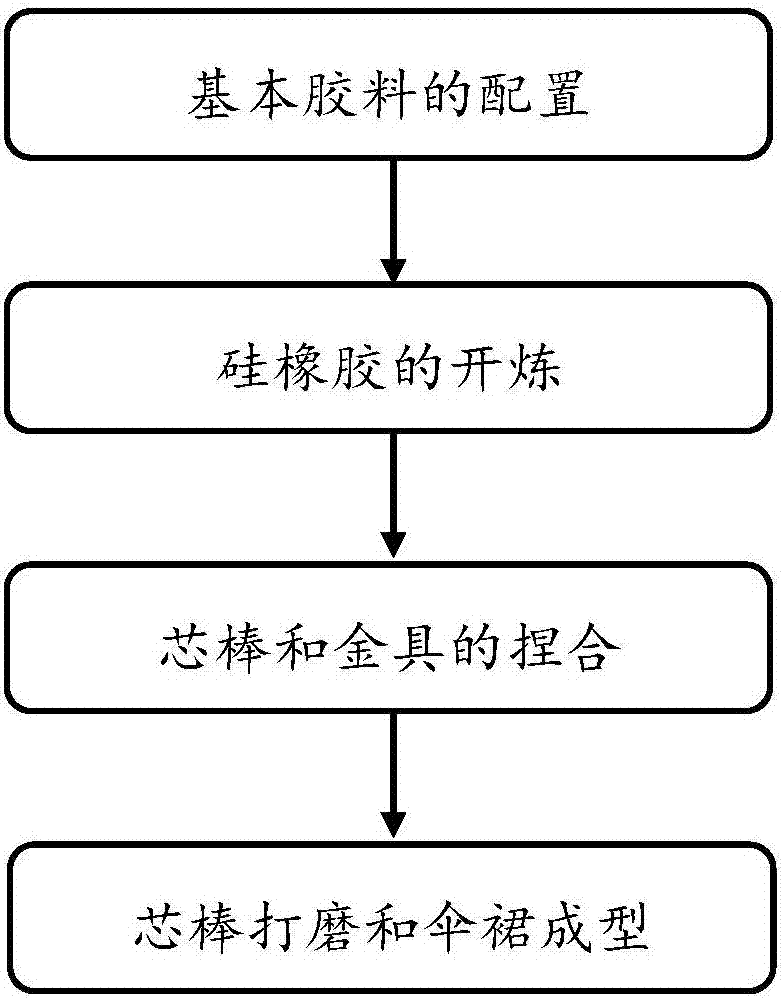

Formula and preparation technology of composite silicone rubber insulator

InactiveCN107418148AGood dispersionImprove performanceSuspension/strain insulatorsEpoxyPolymer science

The invention discloses a formula and a preparation technology of a composite silicone rubber insulator. The formula comprises raw materials in parts by weight as follows: 30-40 parts of epoxy resin, 20-30 parts of methyl vinyl silicone rubber, 10-20 parts of vinyl, 5-10 parts of precipitated white carbon black, 4-6 parts of aluminum hydroxide, 2-4 parts of hydroxyl silicone oil, 4-6 parts of 2,5-dimethyl-2,5-dihexane, 4-6 parts of silica powder, 1-3 parts of hexamethyl disilazane, 3-5 parts of median-diameter alumina powder and 5-8 parts of nano aluminum oxide. Through preparation of base rubber, open mixing and kneading of silicone rubber as well as core rod polishing and skirt forming, the insulation performance and aging resistance of the compound insulator are improved, the compound insulator has better tracking resistance, mechanical performance and hydrophobicity, and a directly formed integrated structure can further improve the comprehensive property of the overall composite silicone rubber insulator.

Owner:WUHU KAIXIN ARRESTER

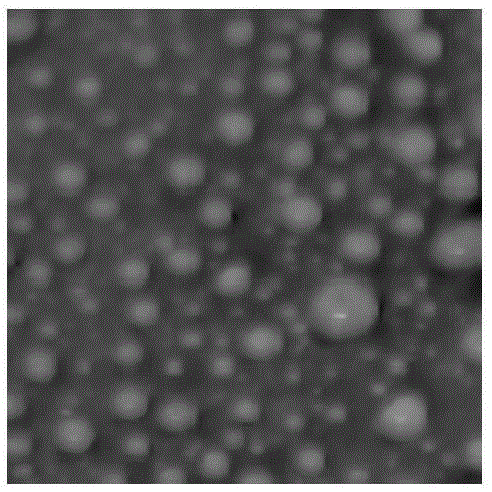

Method for preparing silicone rubber super-hydrophobic surface by virtue of n-hexane PDMS zinc oxide

InactiveCN109485891AExcellent superhydrophobic propertiesIncreased durabilityCoatingsPolymer scienceDimethyl siloxane

The invention discloses a method for preparing a silicone rubber super-hydrophobic surface by virtue of n-hexane PDMS zinc oxide. The method comprises the following steps: weighing 5g of zinc oxide, pouring zinc oxide into a beaker I containing 20ml of an n-hexane solution, and uniformly stirring, so as to obtain a solution defined as a solution 1; weighing 1g of polydimethylsiloxane, pouring polydimethylsiloxaneinto a beaker II containing 5ml of an n-hexane solution, simultaneously adding 0.1g of a PDMS curing agent, and uniformly stirring, so as to obtain a solution defined as a solution 2;uniformly stirring the solution 1 with the solution 2, so as to obtain a solution 3; and uniformly coating a silicone rubber surface with the solution 3, naturally airing, carrying out spraying testing on a silicone rubber insulator surface by virtue of a spraying grading method until relatively circular spheres are formed on the surface of the silicone rubber surface. The method has the beneficial effects that a coating layer is relatively uniform, and the silicone rubber surface can present relatively high super hydrophobicity; and the raw materials adopted in the method are easily availableand environment-friendly, the operation is simple and convenient, and the application is simple and convenient.

Owner:沈余峰

Method for improving flashover voltage of silicon rubber

Owner:TONGJI UNIV

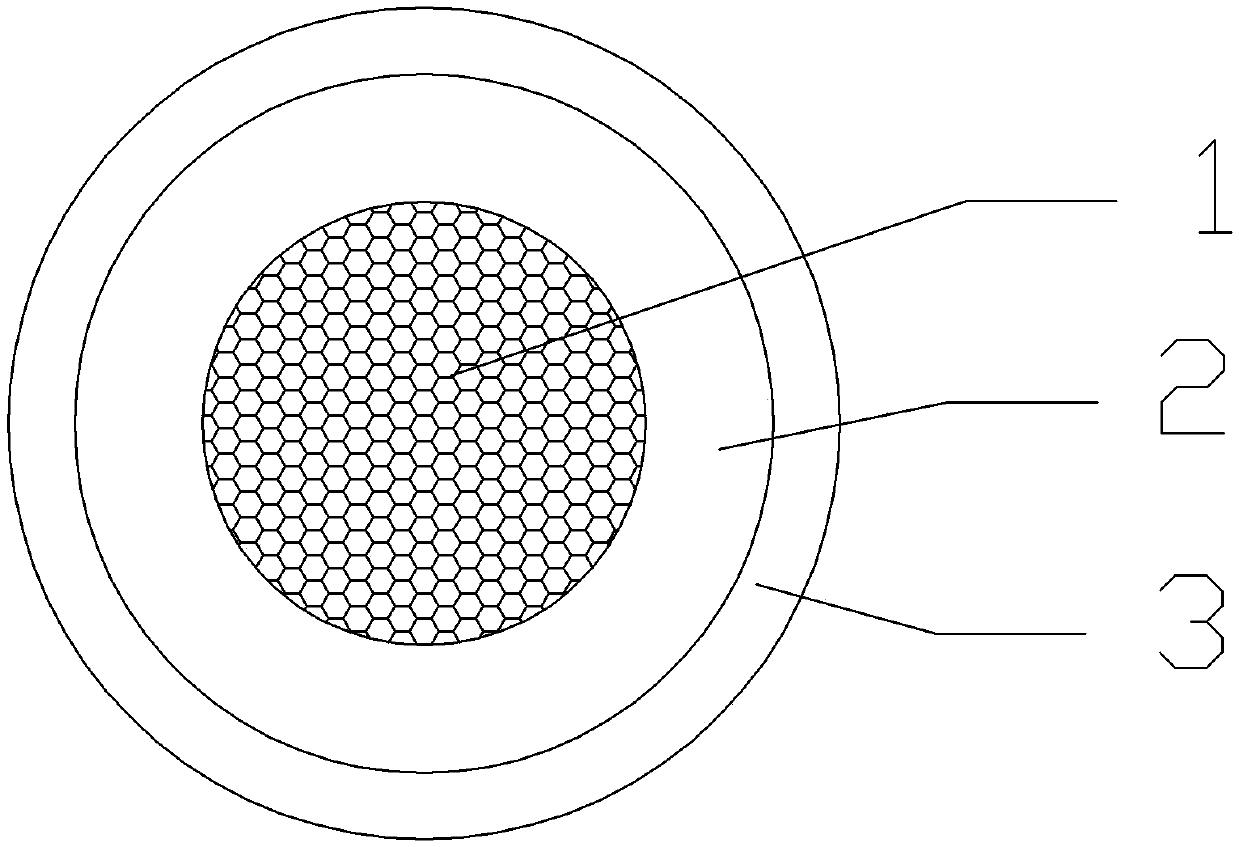

Soft ultra-wearproof cable for new-energy automobile

InactiveCN107610827AGood flexibilityIncrease current carryingFlexible cablesFlexible conductorsTinningCopper conductor

The invention provides a soft ultra-wearproof cable for a new-energy automobile. The temperature resistance, bending performance, and running safety of the cable are improved, and multiple technological requirements of product application are met. The soft ultra-wearproof cable comprises a conductor, an insulating layer and a sheath, under the cross-section state, the conductor, the insulating layer and the sheath are arranged from inside to outside in sequence in the radial direction, the conductor is an annealing bare-copper conductor or a tinning annealing copper conductor, a high-temperature silicone rubber insulator is adopted as the insulating layer, and the insulating layer closely covers the conductor in a squeezing mode.

Owner:JIANGSU HENGTONG ELECTRONICS CABLE TECH CO LTD

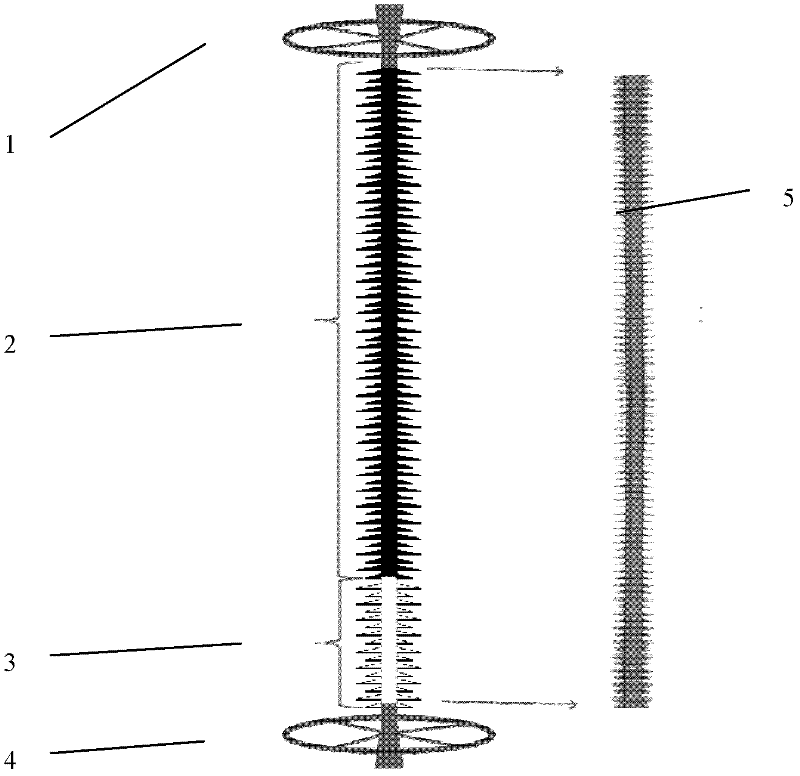

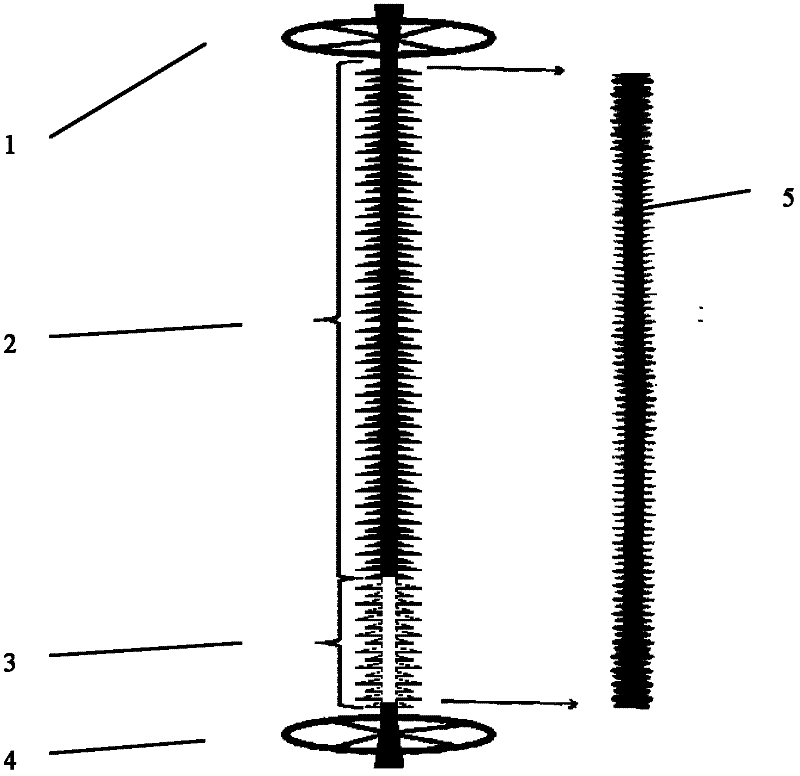

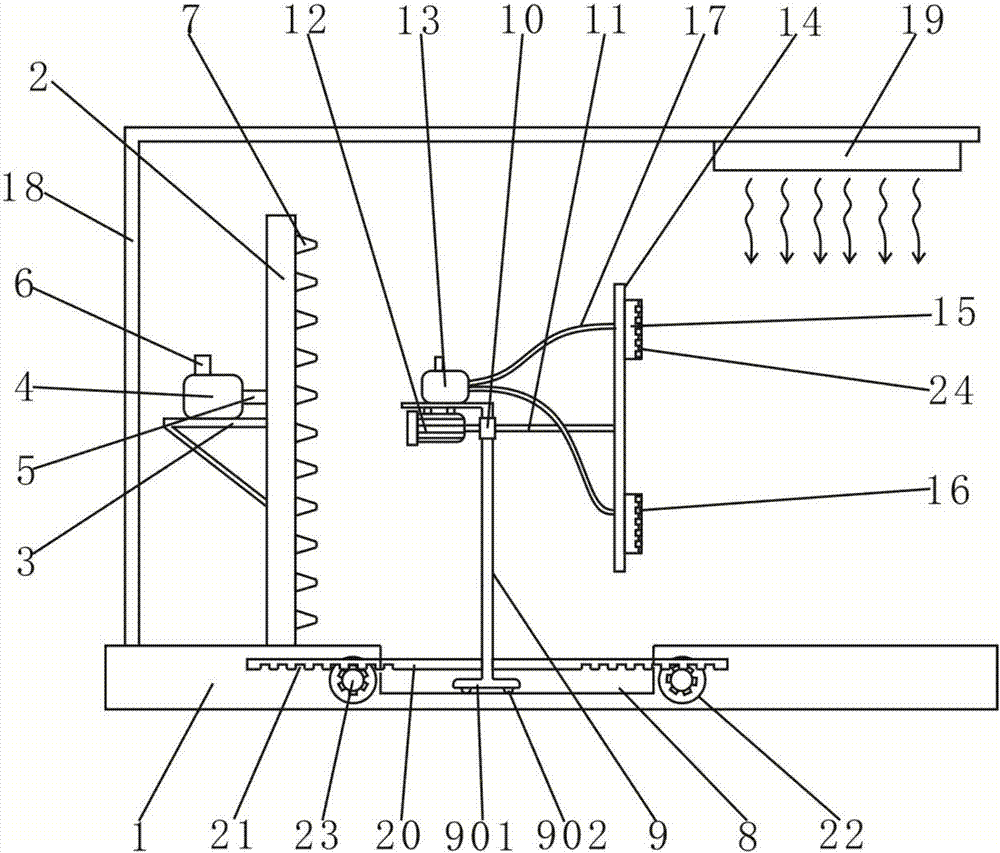

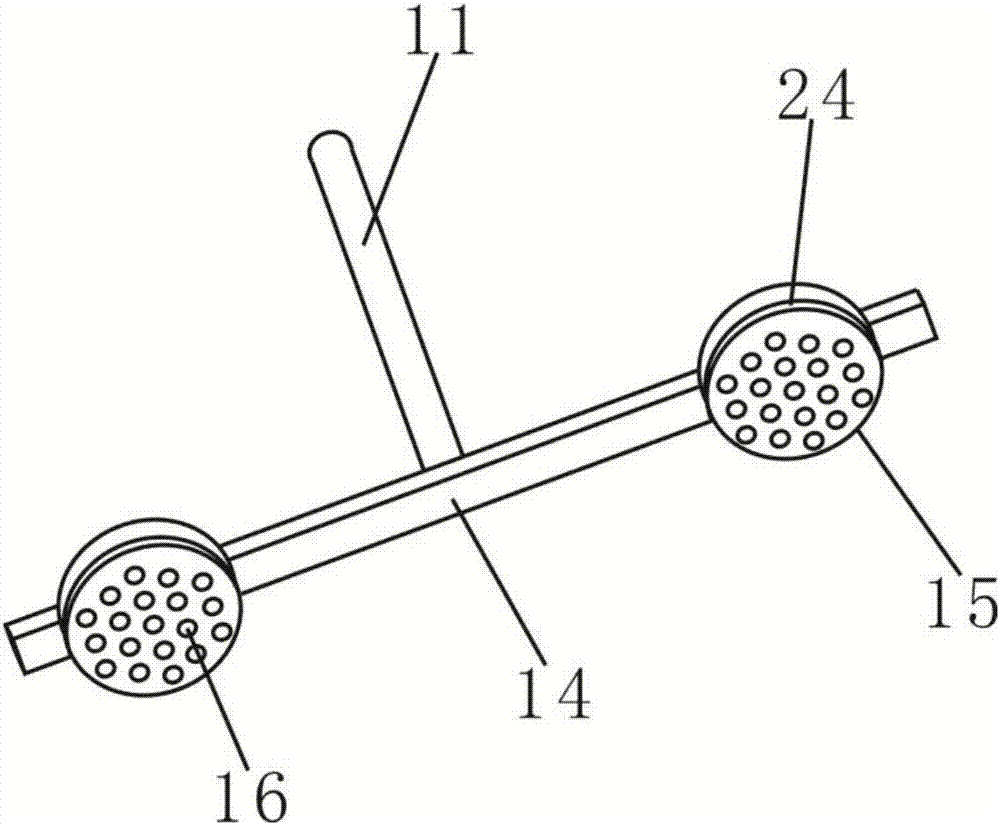

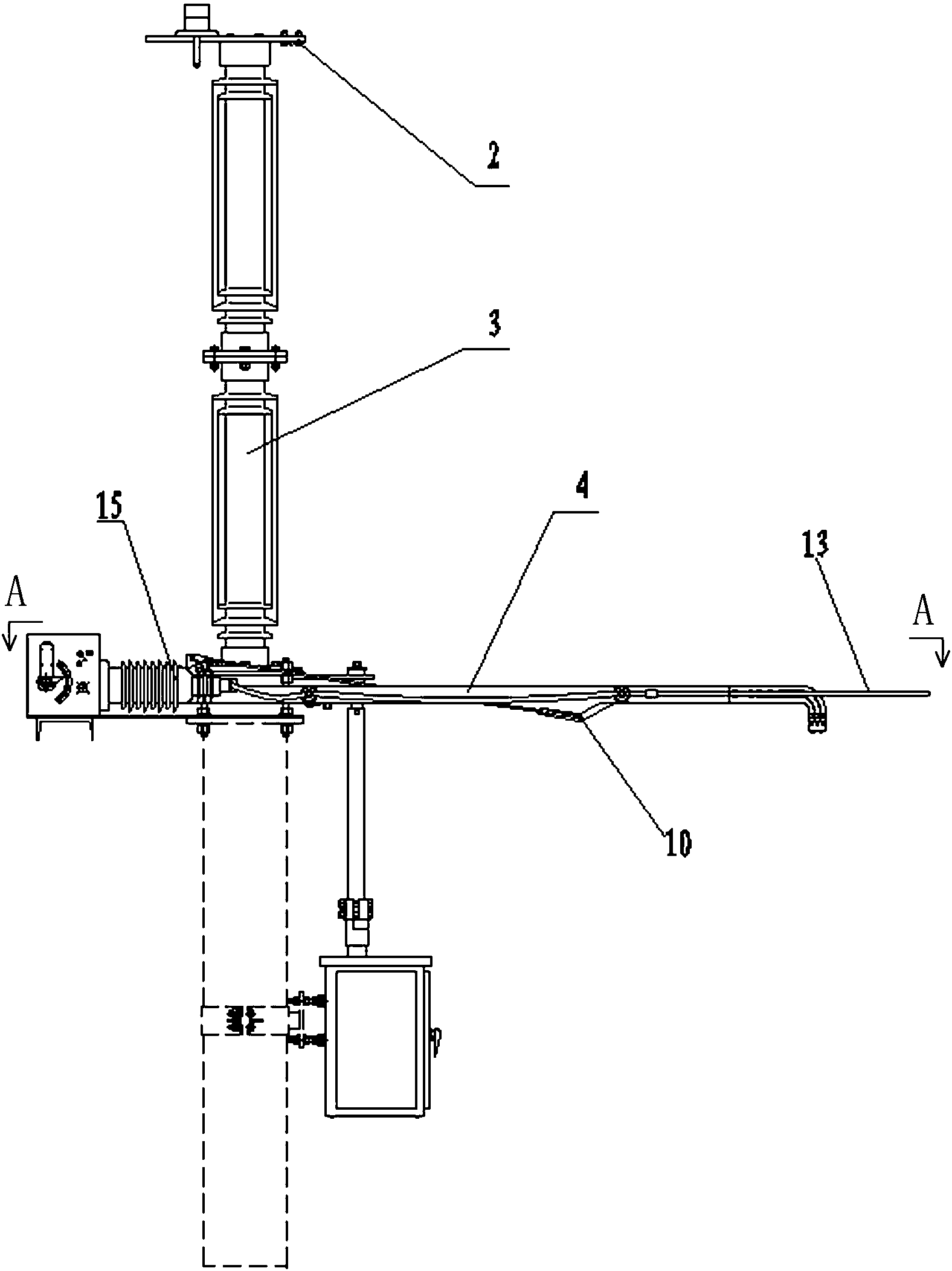

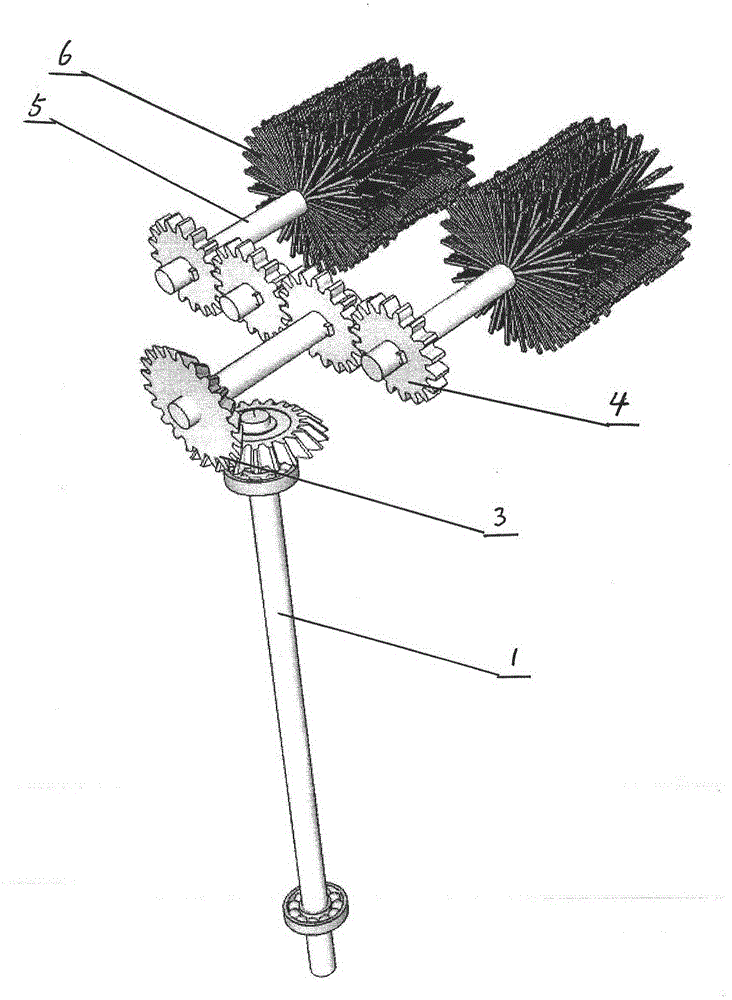

Hot-line cleaner of silicon rubber insulator

InactiveCN104588344ASolve the problem of live cleaningKeep a safe distanceCleaning using toolsDrive shaftEngineering

The invention discloses a hot-line cleaner of a silicon rubber insulator. The hot-line cleaner is formed by an electric hand drill, a transmission insulation rod, transmission shafts and cleaning brush heads, wherein the lower end of the transmission insulation rod is connected with the electric hand drill through a holding-on structure; the upper end of the transmission insulation rod is sequentially connected with the transmission shafts of the cleaning brush heads through a bevel gear transmission assembly and a horizontal gear transmission assembly to drive the transmission shafts of the cleaning brush heads, and each cleaning brush head is formed by the corresponding transmission shaft and brush hairs fixedly embedded at the periphery of the cleaning brush head. According to the hot-line cleaner disclosed by the invention, insulated transmission rods in different lengths can be assembled according to different voltage classes to adapt to the safety requirement of each voltage class, the cleaning work on the silicon rubber insulator under the situation of a hot-line electric power circuit is completed, and thus the problem of cleaning traceability of the silicon rubber insulator is solved.

Owner:乌海电业局输电管理处

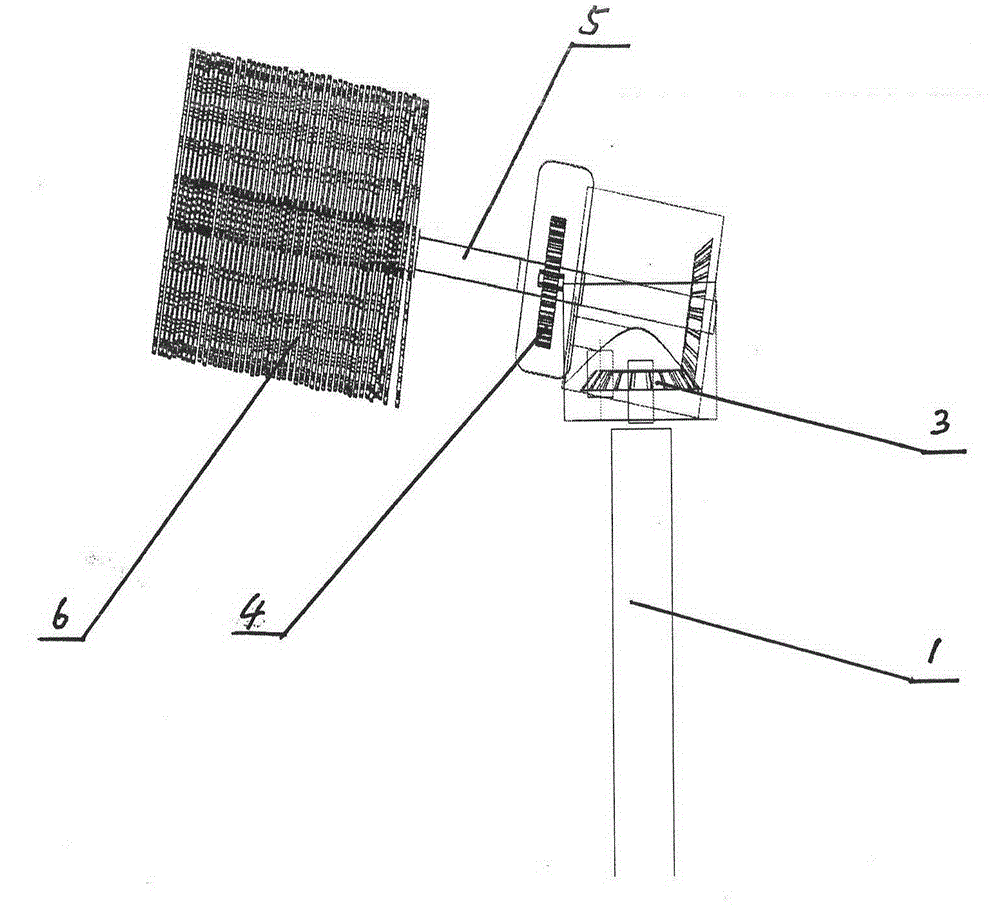

Electrified changing device for silicone rubber insulator

The invention discloses an electrified changing device for a silicone rubber insulator. The device comprises a movable base. The center of the upper surface of the movable base is provided with a sliding guiderail which extends in a radial direction. An insulated lifting mechanism is vertically inserted into the sliding guiderail. A shunting changing device is fixed on the top end of the insulated lifting mechanism. The insulated lifting mechanism comprises a lifting driving mechanism. Rotatable lifting sleeve rods sleeve the output driving shaft of the lifting driving mechanism. A width adjusting device is sleeved between the rotatable lifting sleeve rods. The width adjusting device is parallel with the movable base. The shunting changing device comprises shunting fixed bases. Each shunting fixed base sleeves top of the rotatable lifting sleeve rod. An electric fixing clamp is welded at the center of the shunting fixed base. A shunting wire penetrates through the movable clamping opening of the electric fixing clamp. The electrified changing device has advantages of accurately and conveniently realizing automatic height and width adjustment, realizing high flexibility and high convenience in use, obtaining high safety and high stability and reducing risk in live operation.

Owner:WUHU KAIXIN ARRESTER

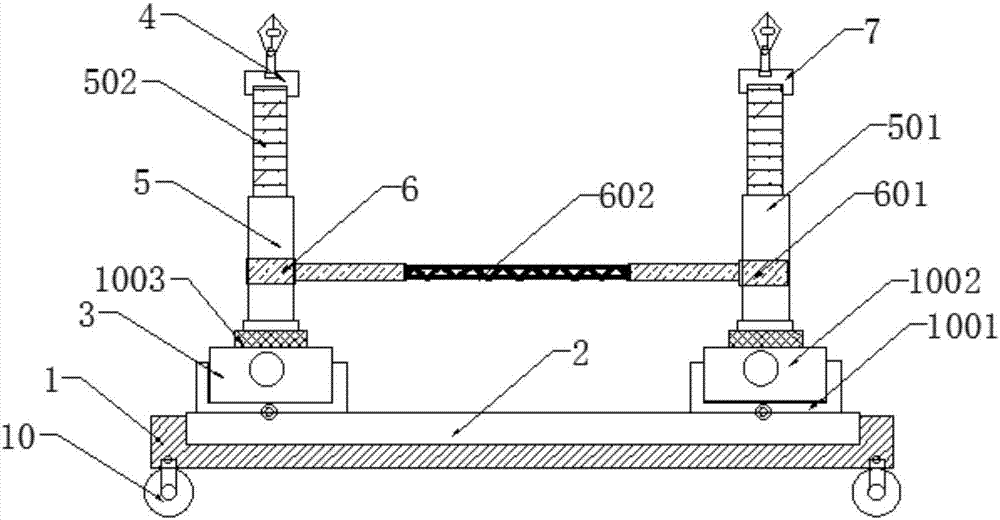

Automatic ejecting device for silicon rubber insulator finished products

The invention discloses an automatic ejecting device for silicon rubber insulator finished products. The automatic ejecting device comprises an ejecting frame, axial positioning devices and an ejecting beam, wherein the ejecting frame is arranged on a silicon rubber insulator forming lower mould in a sleeved mode, and can vertically move up and down; the axial positioning devices are mounted at the two ends of the ejecting frame for clamping and fixing two end parts of the finished product silicon rubber insulator; the ejecting frame is mounted and fixedly arranged on the frame body of the ejecting frame, is positioned on a parting surface of the silicon rubber insulator forming mould, and is perpendicular to the central shaft of the finished product silicon rubber insulator; after the silicon rubber insulator is formed, the end part of the finished product silicon rubber insulator is clamped and fixed through the axial positioning devices; when the ejecting frame moves upwards, the ejecting beam upwards ejects the finished product silicon rubber insulator; and the automatic ejecting device has the characteristics of reliable and stable ejecting motion, high ejecting efficiency, high ejecting stroke and convenient clearing of finished product flanges.

Owner:佛山华胜伟业精密模具有限公司

Silicon rubber insulator repair method

InactiveCN107196246ASolve crackingExtended service lifeApparatus for repairing insulation/armouring cablesElectrical performanceEngineering

The invention relates to the field of an insulator, and discloses a silicon rubber insulator repair method. The silicon rubber insulator repair method is characterized by comprising the following steps of: (1) cleaning dust on the surface of the silicon rubber insulator; and (2) coating a high-voltage resistance insulating sealing material, wherein the high-voltage resistance insulating sealing material is a mixture of ethylene-propylene-diene-terpolymer rubber and organic silicon rubber. According to the method disclosed by the invention, an aged silicon rubber insulator can have a high withstand voltage again, and electrical performance of the aged silicon rubber insulator sufficiently meets application requirements.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Optical direct current measuring device for direct current high-voltage transmission

The invention discloses an optical direct current measuring device for direct current high-voltage transmission. The high-voltage primary end adopts an all-fiber sensing mode, the primary end and thesecondary end adopt a polarized light transmission scheme of segmentally folded silicone rubber insulator pre-embedded polarization-maintaining fiber, and the secondary end adopts a high-speed opticalmodulation and demodulation scheme to realize the direct current measurement. A sensing optical fiber ring loop body and an upper flange structure are located at the top of an upper high voltage polarization-maintaining fiber insulator, an upper equalizing ring in located on the outer periphery of a sensing optical fiber ring body, a middle equalizing ring is located at the junction of insulatorsat both ends, a lower flange structure and a lower fiber storing box body are located at the bottom of the insulators, a high-speed demodulation unit is located on the secondary side. The optical direct current measuring device is suitable for current measurement of a high-voltage direct current, especially an extra-high voltage flexible direct current polarity bus direct current, and the performance of a control protection system is improved.

Owner:BEIJING SIFANG JIBAO AUTOMATION

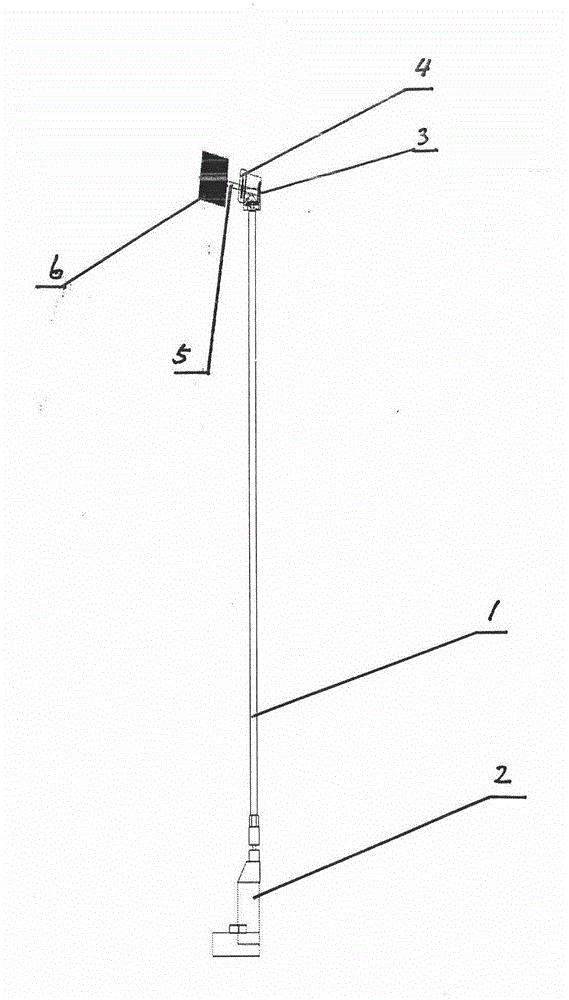

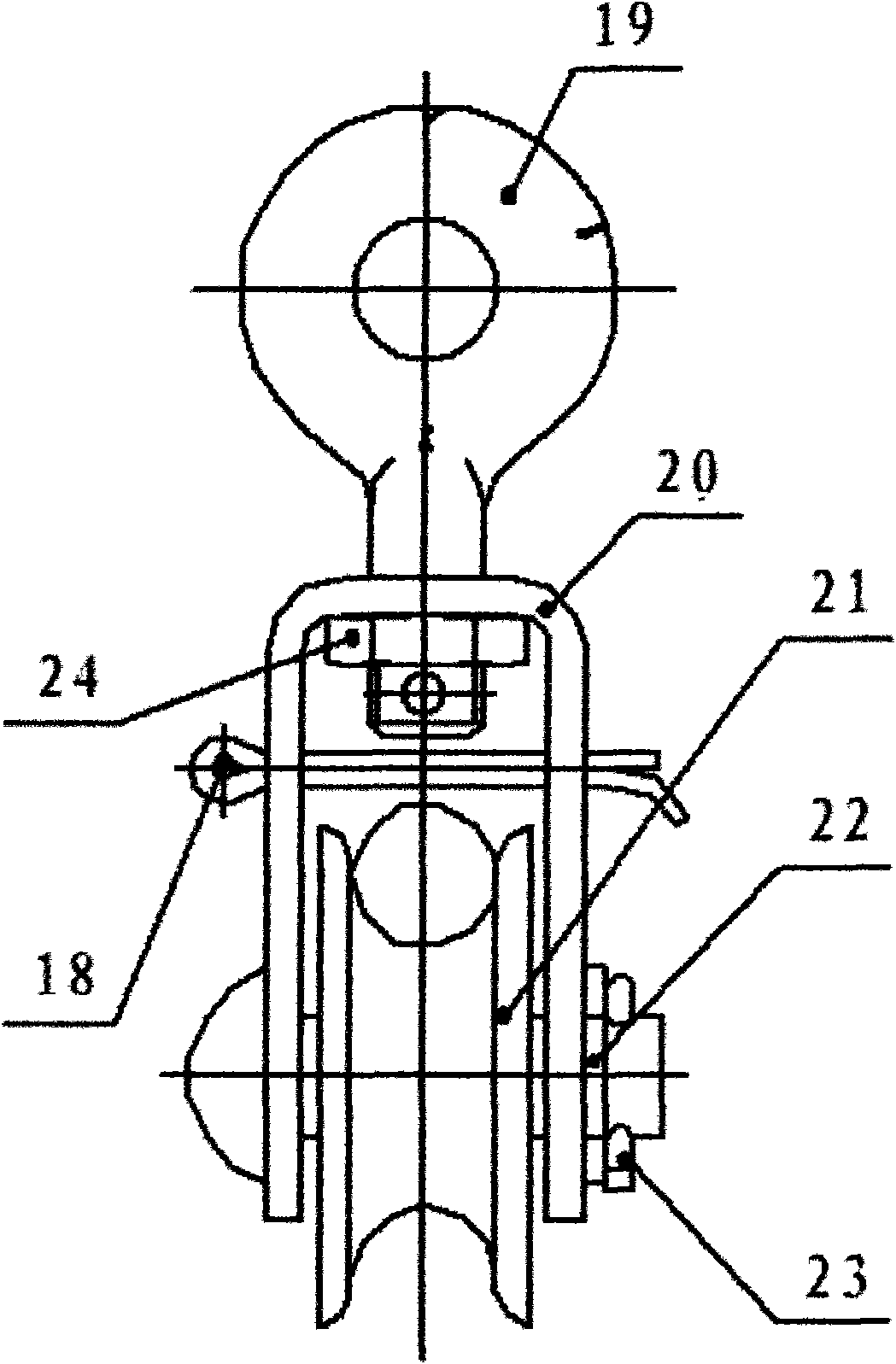

Single track tunnel overall positioning equipment

InactiveCN101665087AChange the problem of not being able to rotate in all directionsAvoid wear and tearTrolley linesEngineeringSilicon rubber

The invention relates to single track tunnel overall positioning equipment used in an electrified railway contact system, which is characterized by comprising a catenary wire hanging pedestal (1), ananti-corrosion adjusting bolt (2), a silicon rubber isolator (3), a pulley bracket (4), a ball-socket bar (5), a tunnel pulley (6) and a contact wire positioning device, wherein the pulley bracket (4)drives the tunnel pulley (6) to rotate around an ear ring (19) at 360 degrees, and a V-shaped suspension is arranged between a flat cantilever (10) and a catenary wire (17). The single track tunnel overall positioning equipment prevents abrasion, reduces hard points at a positioning point, allows a pantograph to pass through smoothly and improves the current collection effect.

Owner:周建科

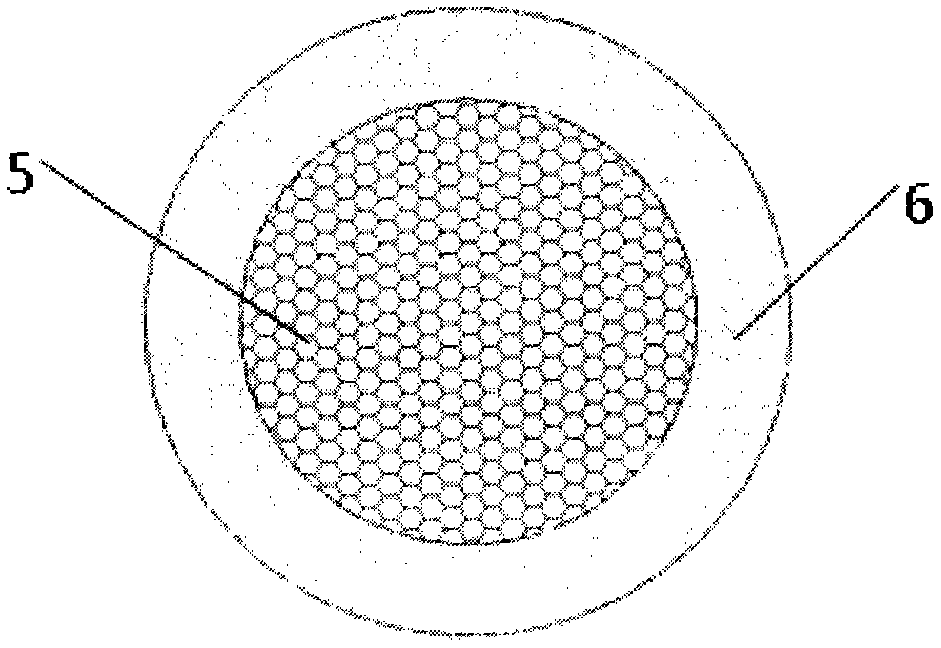

Composite suspension type silicon rubber insulator structure

ActiveCN107689273AImprove insulation performanceImprove stabilitySuspension/strain insulatorsGlass fiberEpoxy

The invention discloses a composite suspension type silicon rubber insulator structure. The composite suspension type silicon rubber insulator structure comprises a supporting core body and a composite outer sleeve, wherein a winding binding head and a mounting base frame are fixedly mounted at two ends of the supporting core body respectively; the winding binding head is made of glass fiber epoxyresin ceramic; the composite outer sleeve is made of silicon rubber; the composite outer sleeve covers the outer surface of the supporting core body; annular bulges are arranged at connecting parts of the supporting core body, the winding binding head and the mounting base frame; outer surfaces of the annular bulges are covered with silicon rubber ring sleeves; umbrella skirts are fixedly mountedon the outer surface of the supporting core body; a step type lap joint structure is arranged between each two adjacent umbrella skirts; a lap joint ring is fixedly mounted at the outer edge of eachumbrella skirt; a differentiation structure is adopted so that a creepage distance is not limited by the distance between the umbrella skirts; while the self insulating capability is improved, point discharge also can be prevented, so that the insulating capability is greatly improved; an umbrella skirt structure is improved so that the transverse mechanical property is improved.

Owner:WUHU KAIXIN ARRESTER

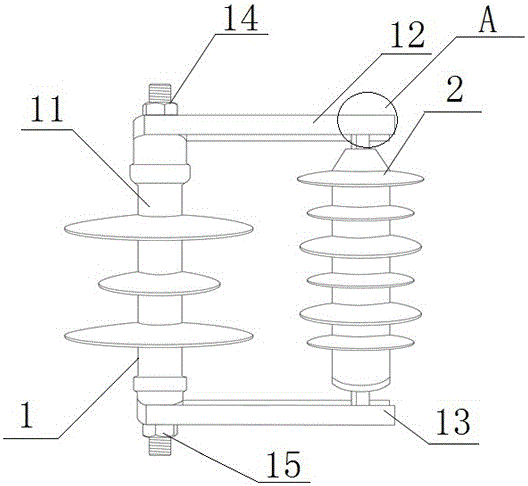

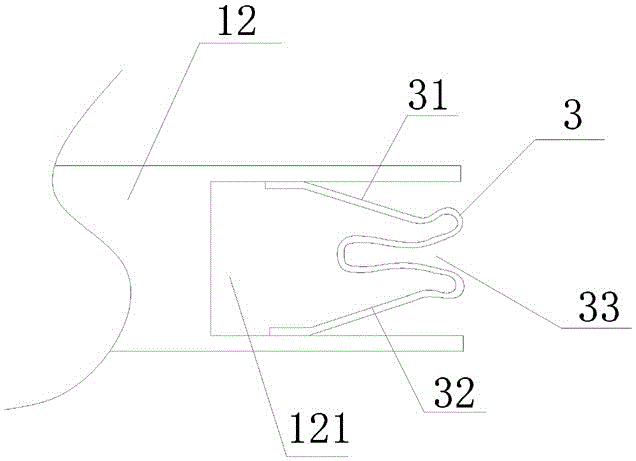

Lightning arrester capable of being dismounted on live line

ActiveCN106207934ARealization of live disassemblyRealize live installationInstallation of lighting conductorsSilicone rubber insulatorsMechanical engineering

The invention puts forward a lightning arrester capable of being dismounted on a live line. The lightning arrester comprises a silicone rubber insulator support rack which comprises a silicone rubber insulator; an upper end and a lower end of the silicone rubber insulator are respectively provided with a first support cross bar and a second support cross bar that are made of metal material and arranged perpendicular to a length direction of the silicone rubber insulator; an upper part of one end, connected with the silicone rubber insulator, of the first support cross bar is provided with a first fixing screw bolt; a lower part of one end, connected with the silicone rubber insulator, of the second support cross bar is provided with a second fixing screw bolt; the other end of the first support cross bar and the other end of the second support cross bar are provided with grooves that are respectively a first groove and a second groove; elastic cards are respectively connected in the first groove and the second groove, and the elastic cards are respectively connected with two ends of the lightning arrester in a clamped manner. The lightning arrester capable of being dismounted on the live line can be mounted and dismounted on the live line, and the lightning arrester is enabled to be convenient to test and change.

Owner:SHANDONG MEGSKY ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com