Silicone rubber insulator injection mold demolding device

A silicone rubber insulation and injection mold technology, which is used in household appliances, other household appliances, household components, etc., can solve the problems of reducing the production efficiency of rubber insulators, scrapping insulator devices, leaving pits, etc., to reduce the difficulty of demolding, Easy demoulding and scratch prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

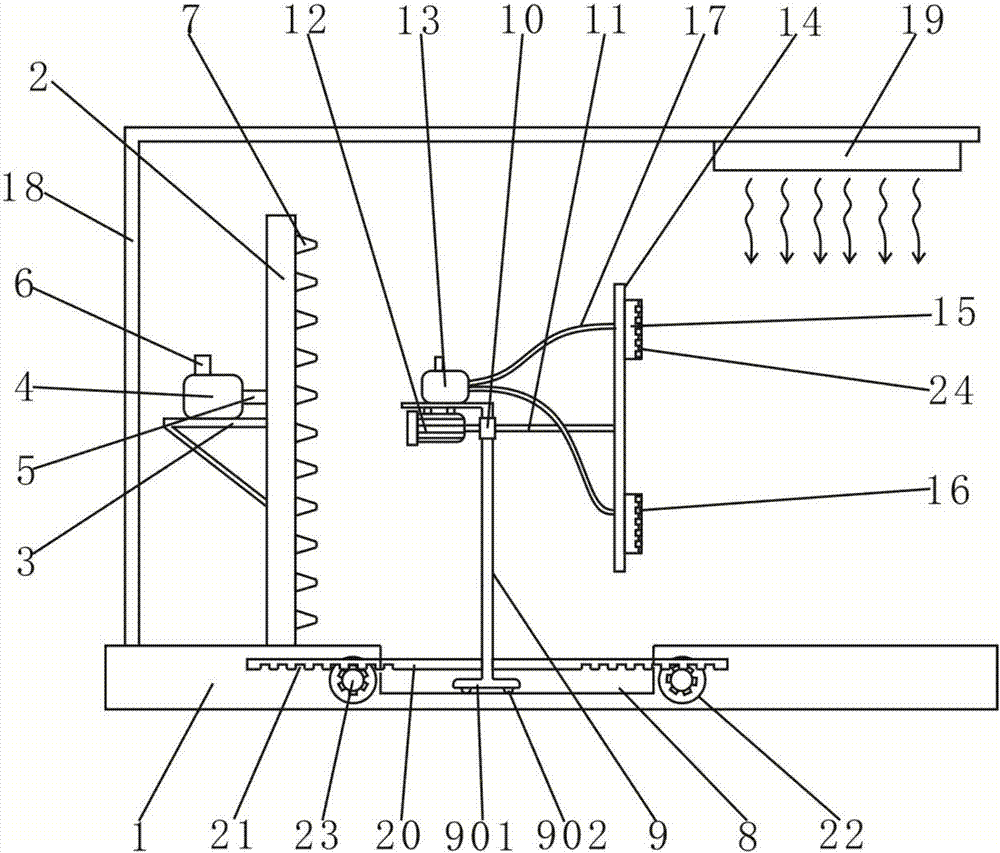

[0024] Such as figure 1 As shown, the present invention provides a silicone rubber insulator injection mold release device, including a base 1, the upper surface of the base 1 is fixedly connected with a high-pressure chamber 2, and the left side of the high-pressure chamber 2 is fixedly connected with an air chamber through a tripod 3. Compressor 4, the air compressor 4 is connected to the inside of the high-pressure chamber 2 through the air pipe 5, the top of the air compressor 4 is provided with an inlet pipe 6, and the right side surface of the high-pressure chamber 2 is fixedly connected with a horizontal injection nozzle 7, The injection nozzles 7 are distributed on the right side of the high-pressure chamber 2 at equal intervals in turn, and each injection nozzle 7 is located on the same vertical line. The injection nozzles 7 are conical, and the diameter of the end is 2mm.

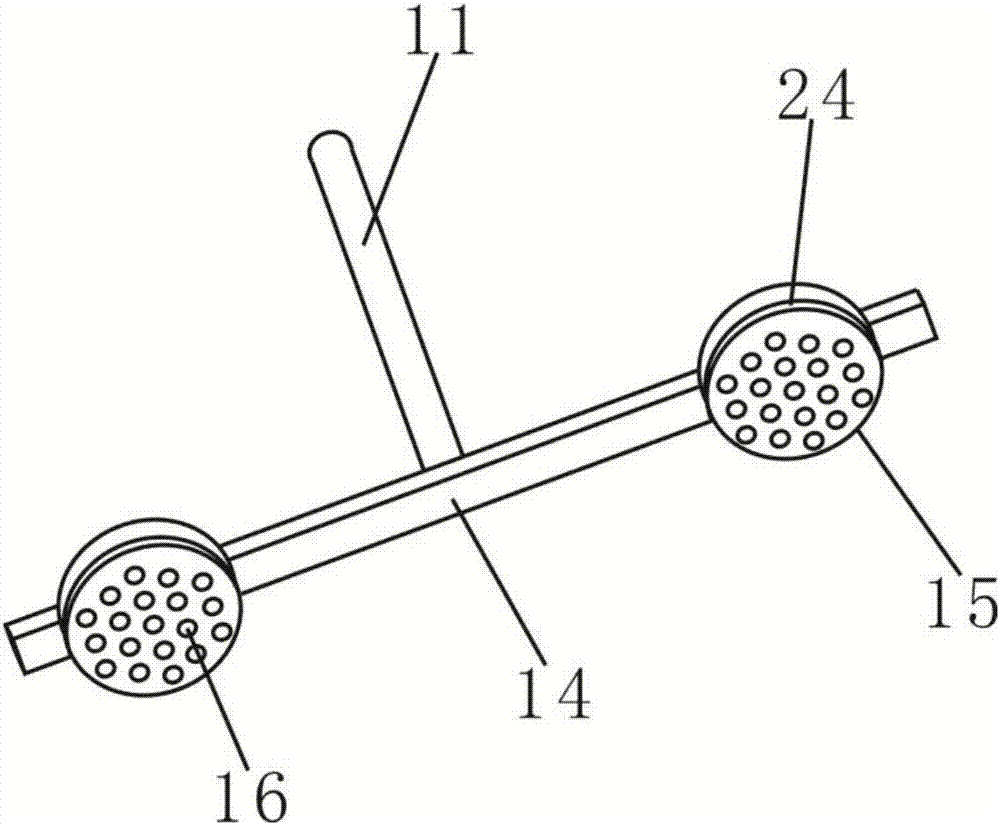

[0025] Such as figure 1 and figure 2 As shown, the center of the base 1 is provided with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com