Patents

Literature

112results about How to "Reduce the difficulty of demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

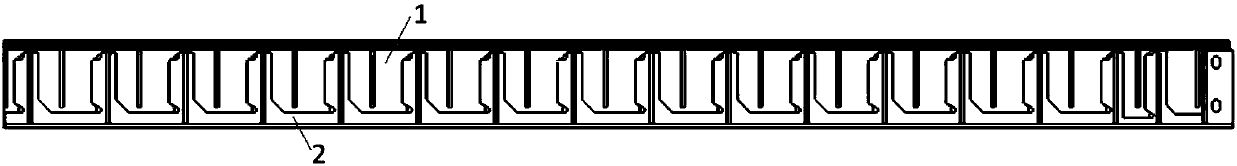

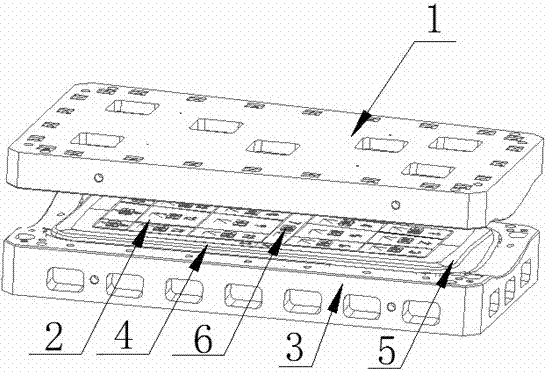

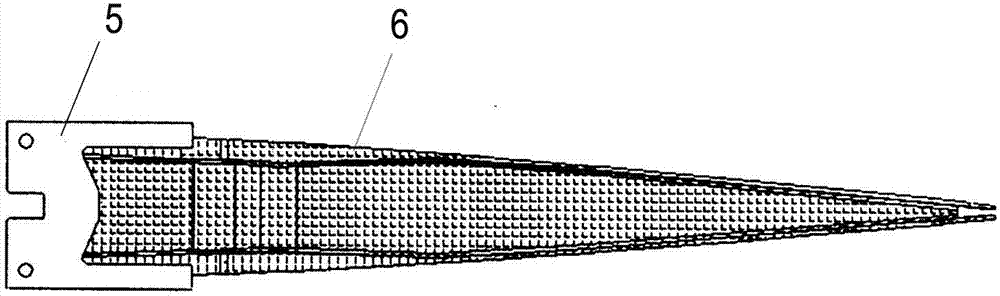

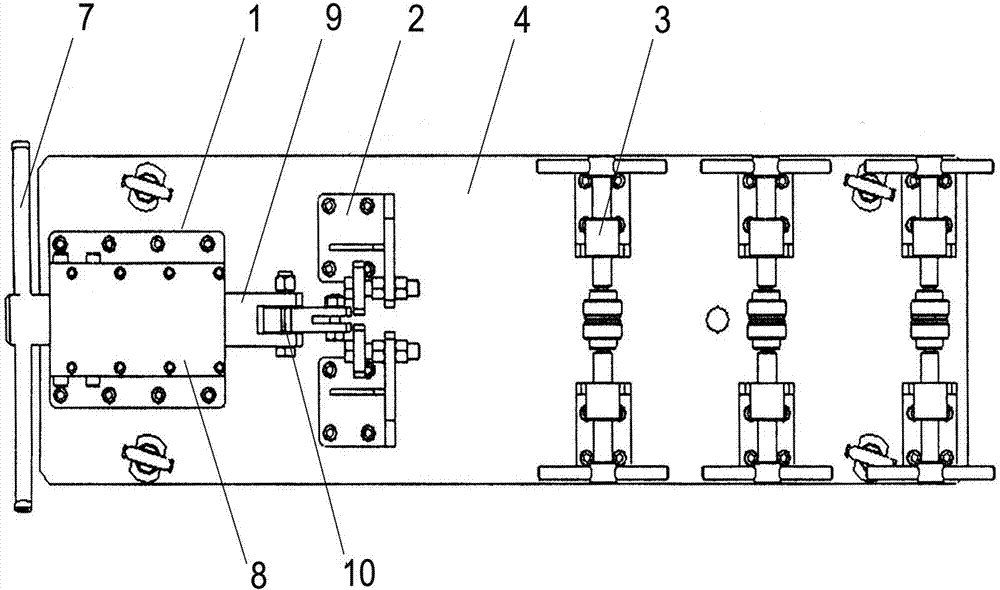

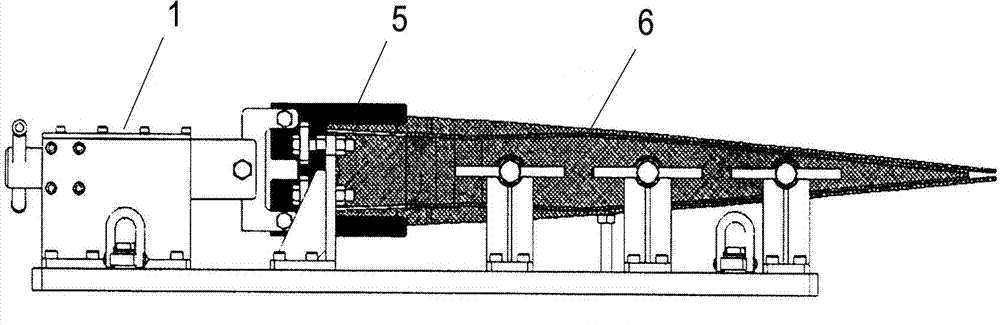

Tool and production method for producing variable cross-section type I-shaped composite part

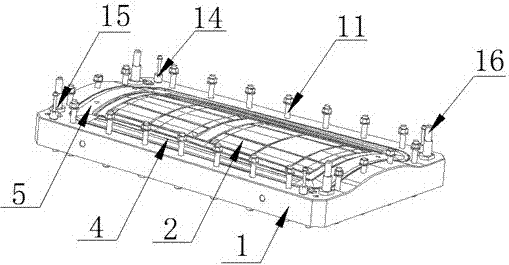

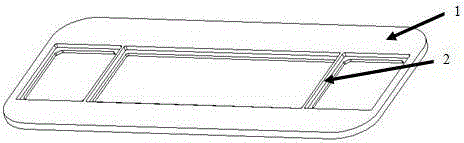

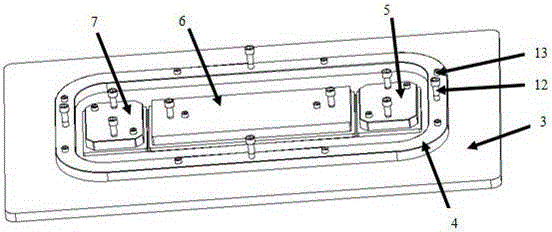

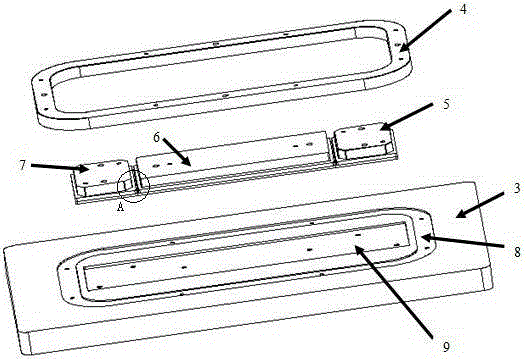

The invention relate to a tool and production method for producing a variable cross-section type I-shaped composite part. According to the technical scheme, the tool is composed of an upper male die, a lower male die, a middle spacer plate and composite even pressing plates on the two sides. The production method comprises the steps that firstly, the composite even pressing plates are made; then, carbon fiber prepregs cut into fixed sizes are laid on a forming tool; finally all parts of the carbon fiber prepregs laid well are transferred from the forming tool to an assembly solidification tool for integral assembly, and packaged in a vacuum bag; the fully sealed prepreg blank is subjected to solidification forming under the conditions of 120-180 DEG C and 0.3-0.8 mpa for 1-3 hours; and after cooling, the composite even pressing plates, the middle spacer plate, the upper male die and the lower male die are detached to obtain the variable cross-section type I-shaped composite part. According to the production process, the pressure transmission efficiency of the part in the solidification process can be improved; generation of the structure defect of the part is reduced; the shape and the internal quality of the part are ensured.

Owner:SHENYANG AIRCRAFT CORP

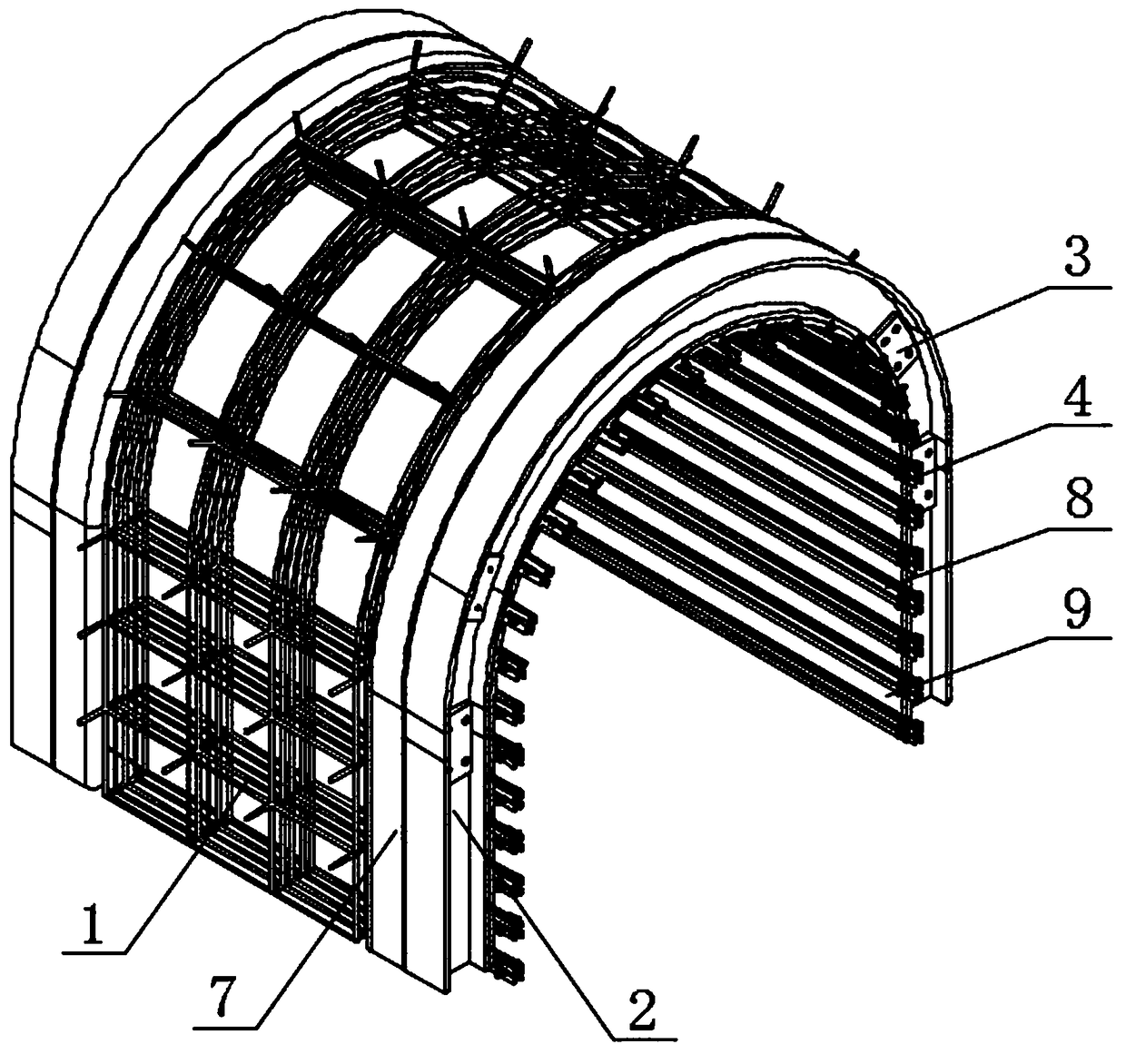

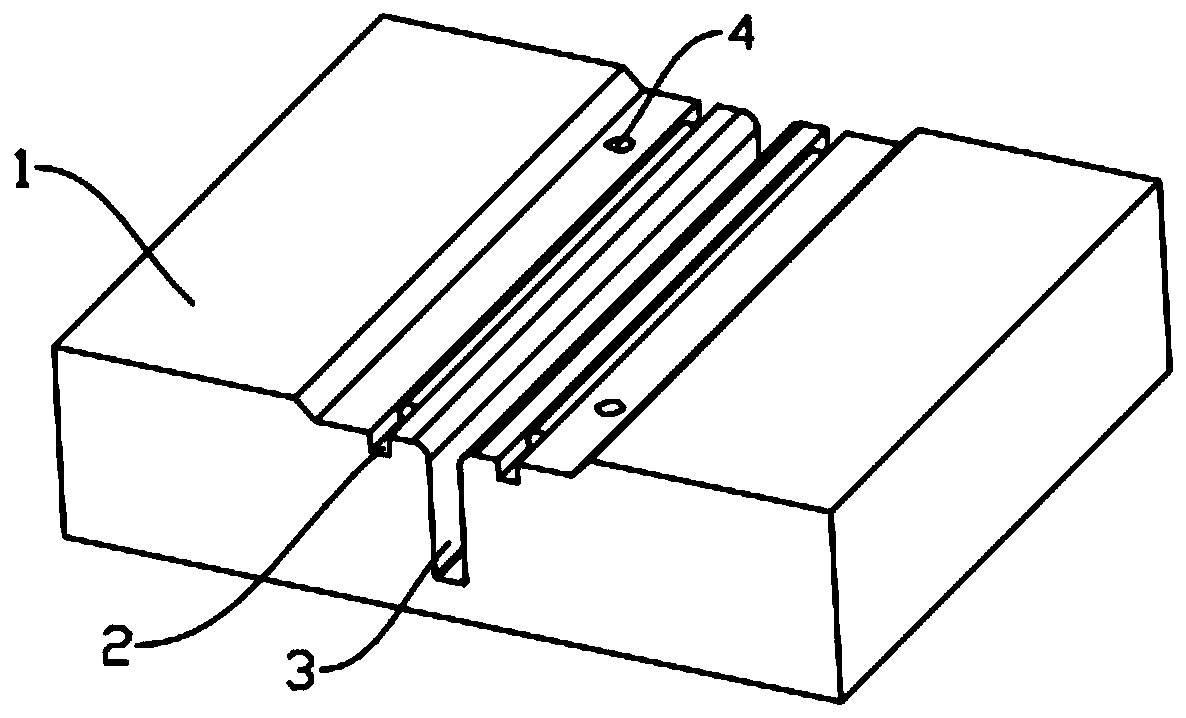

Existing tunnel lining reinforcement structure and reinforcement method

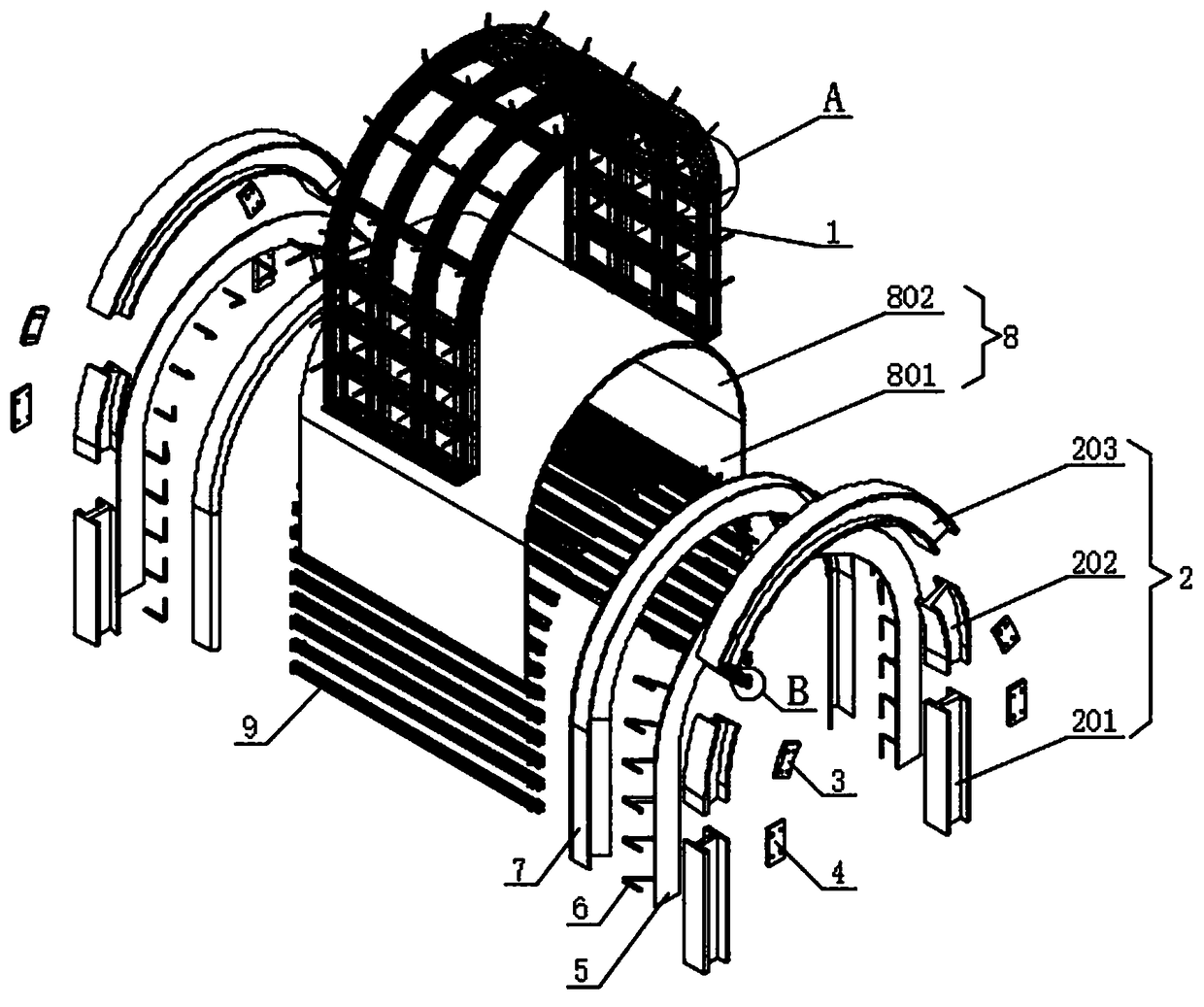

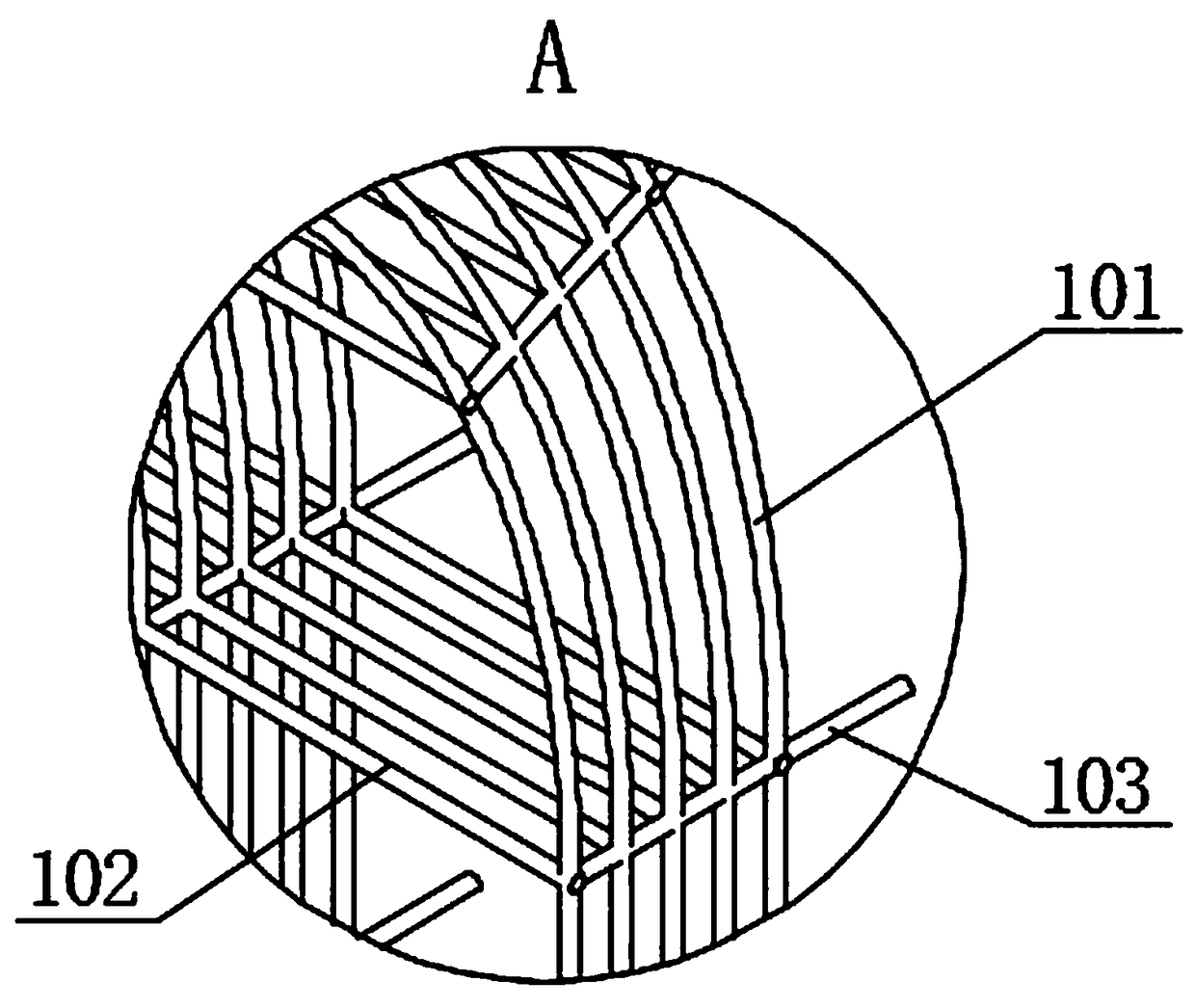

PendingCN109252875AEasy to removeReduce difficultyUnderground chambersTunnel liningStress conditionsEngineering

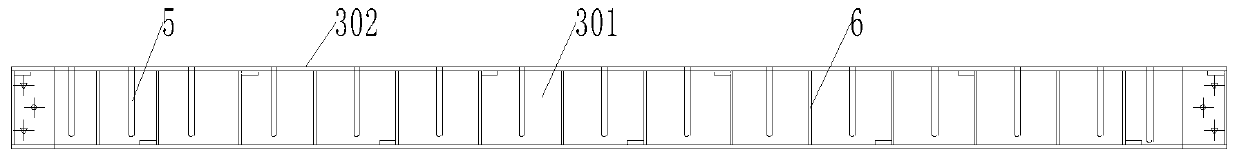

The invention discloses an existing tunnel lining reinforcement structure and a reinforcement method. The reinforcement structure is characterized in that arch lining steel frames serve as main supporting structures and are adopted for supporting formwork to form supporting units, a distance between the inner side of each supporting unit and an existing tunnel lining is smaller than 37.5cm to guarantee catenary safety and construction safety, concrete is poured to the inner side of the supporting formwork repeatedly, and the lining steel frames and the formwork are demounted after pouring is finished. According to the reinforcement method, the existing tunnel is equally segmented, segments are sequentially numbered, the supporting units are erected at intervals on odd segments, width of the supporting units is determined according to the segmenting conditions and stress conditions in a concrete pouring process, each supporting unit forms an independent concrete pouring cavity, concreteend faces of odd segments serve as end moulds of the even segments, and only inner side formwork supporting is needed; by segmented pouring, the lining steel frames can be demounted conveniently, influences on concrete service life due to pouring of the lining steel frames in concrete are avoided, and operating efficiency is greatly improved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

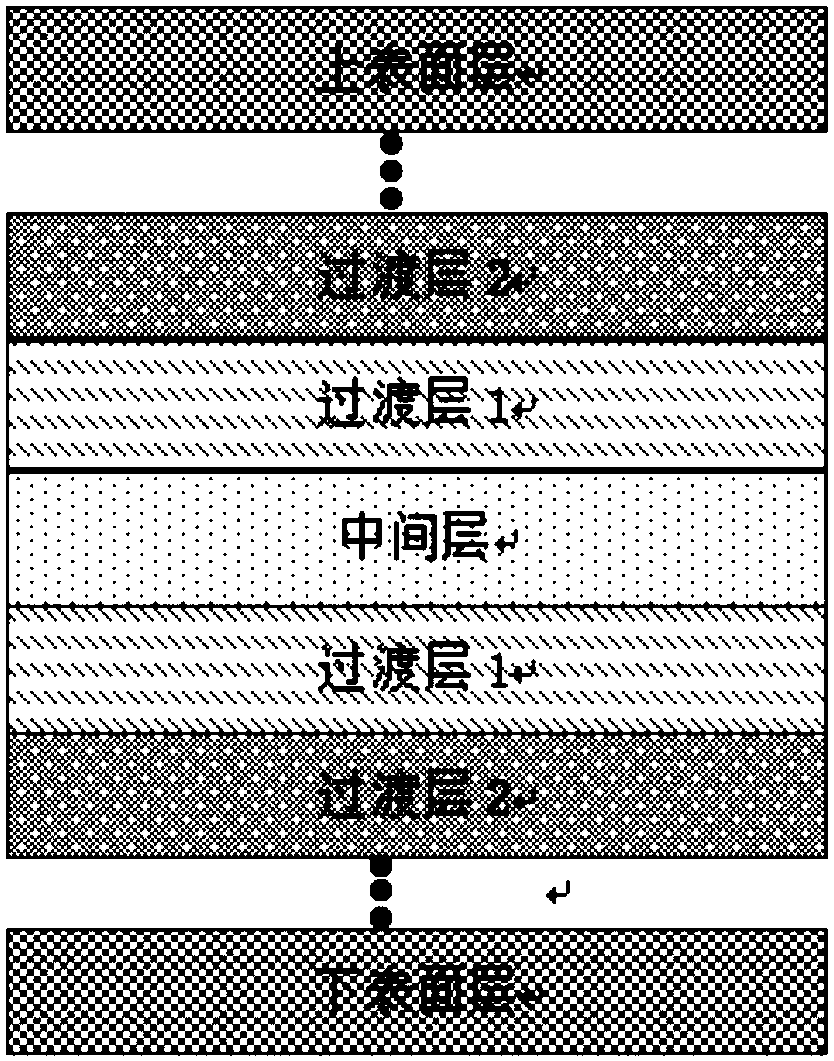

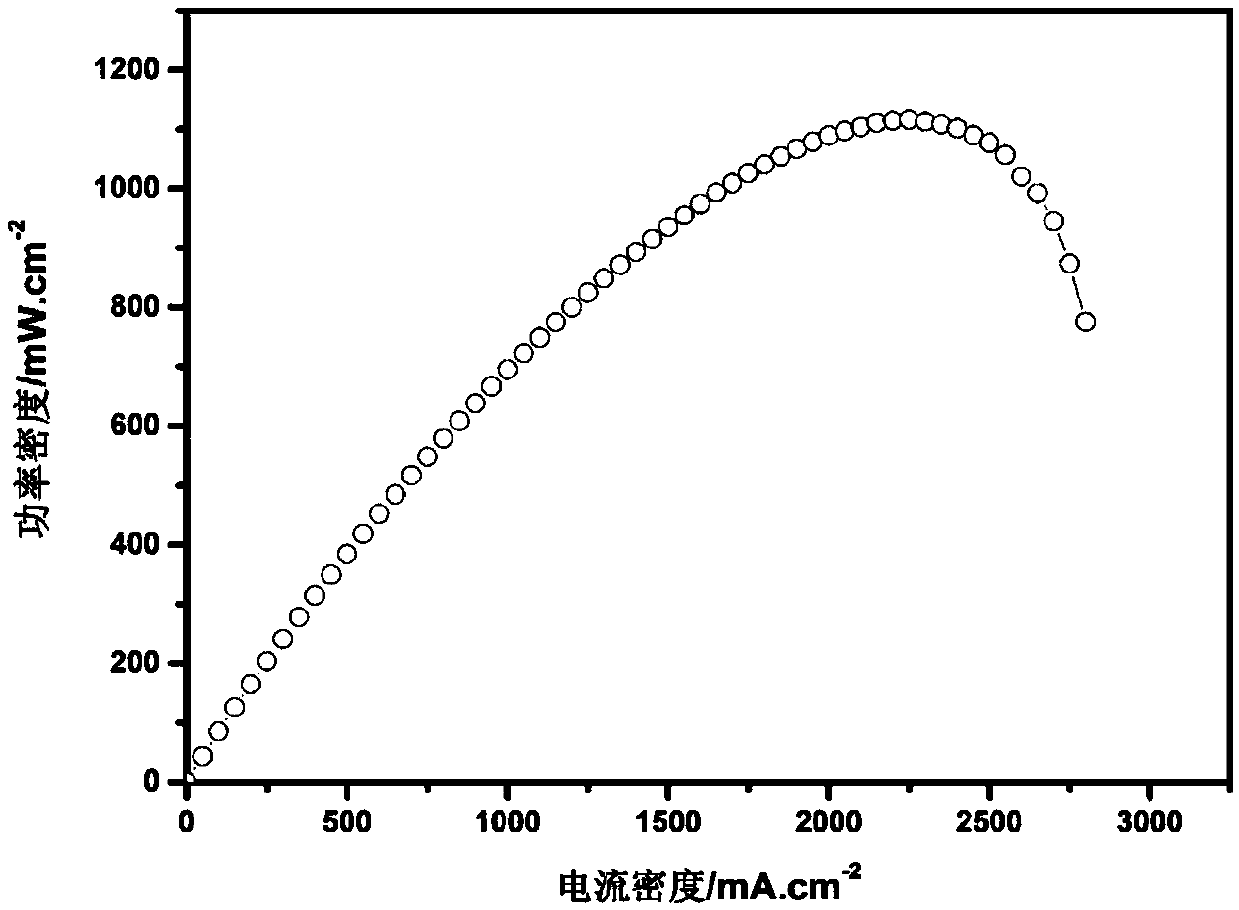

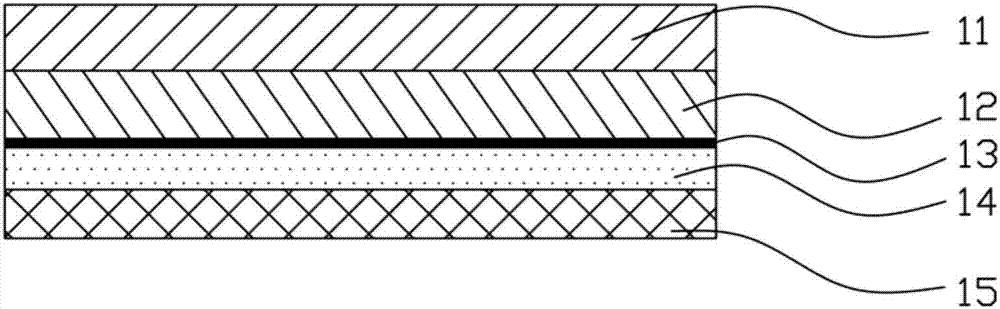

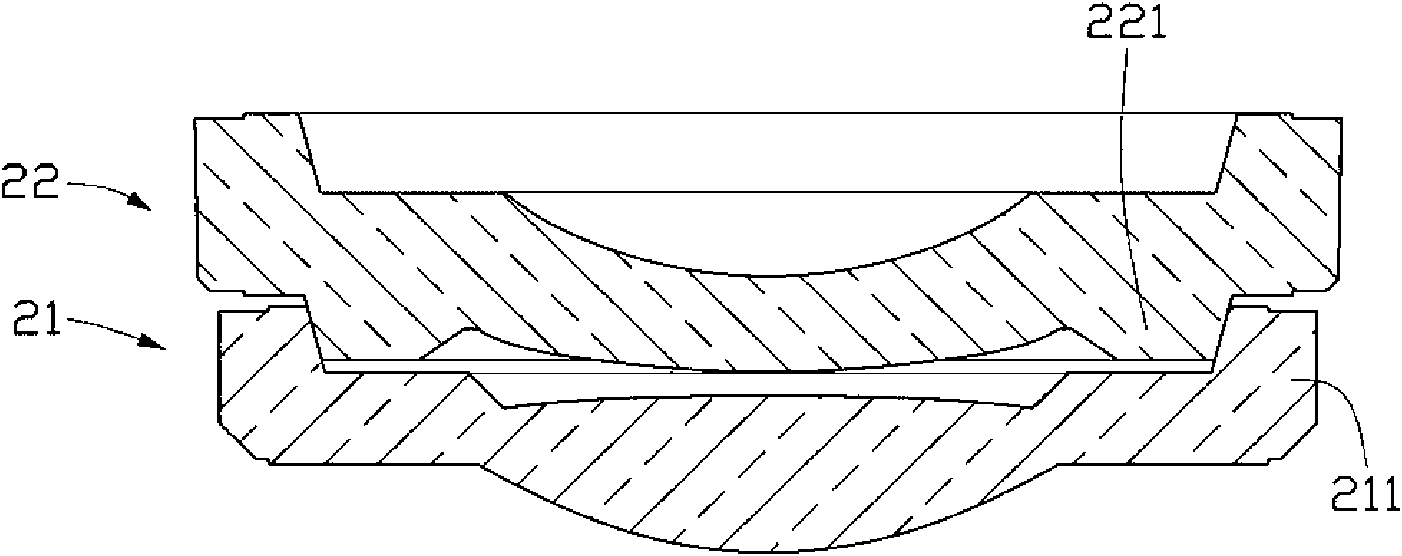

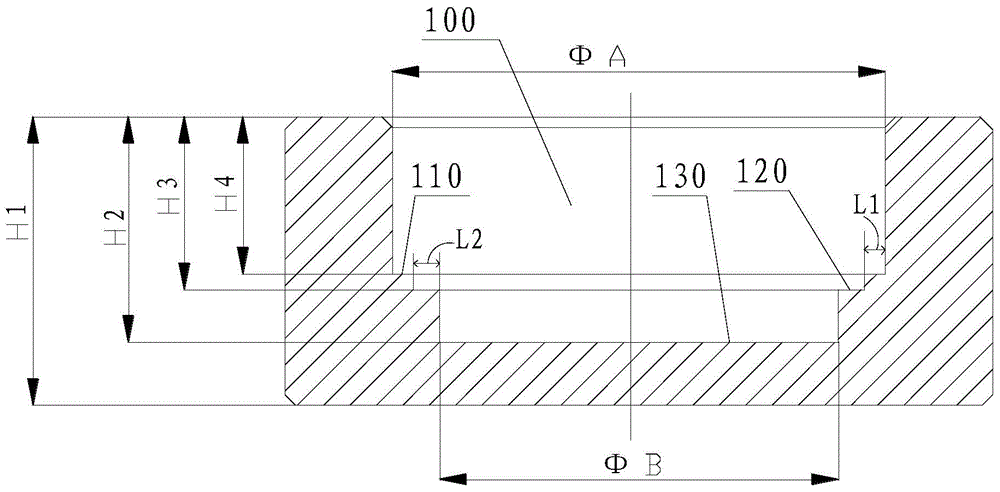

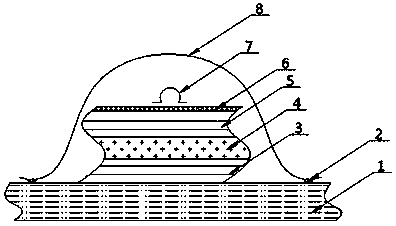

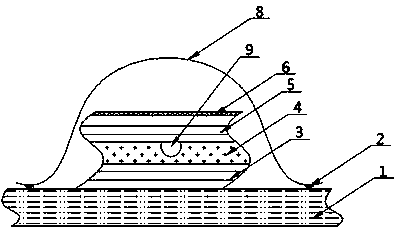

Composite bipolar plate for fuel cell as well as preparation method and application of composite bipolar plate

ActiveCN109514962AReduce the difficulty of demouldingImprove corrosion resistance and airtightnessLaminationLamination apparatusSurface layerElectrical resistivity and conductivity

The invention provides a composite bipolar plate. The composite bipolar plate comprises an upper surface layer, a lower surface layer and one or more intermediate layers, wherein one or more transition layers exist between the upper surface layer or the lower surface layer and each intermediate layer. The lower surface layer, the transition layer, the intermediate layer, the transition layer and the upper surface layer are sequentially placed into a die with a flow field and is spread and cold pressed to prepare a preform. Then, the preform is hot-pressed and is finally subjected to processessuch as demolding and aftertreatment to prepare the composite bipolar plate. The composite bipolar plate provided by the invention effectively balances the conflict between conductivity and bending strength and has good bending strength, conductivity and gas permeability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

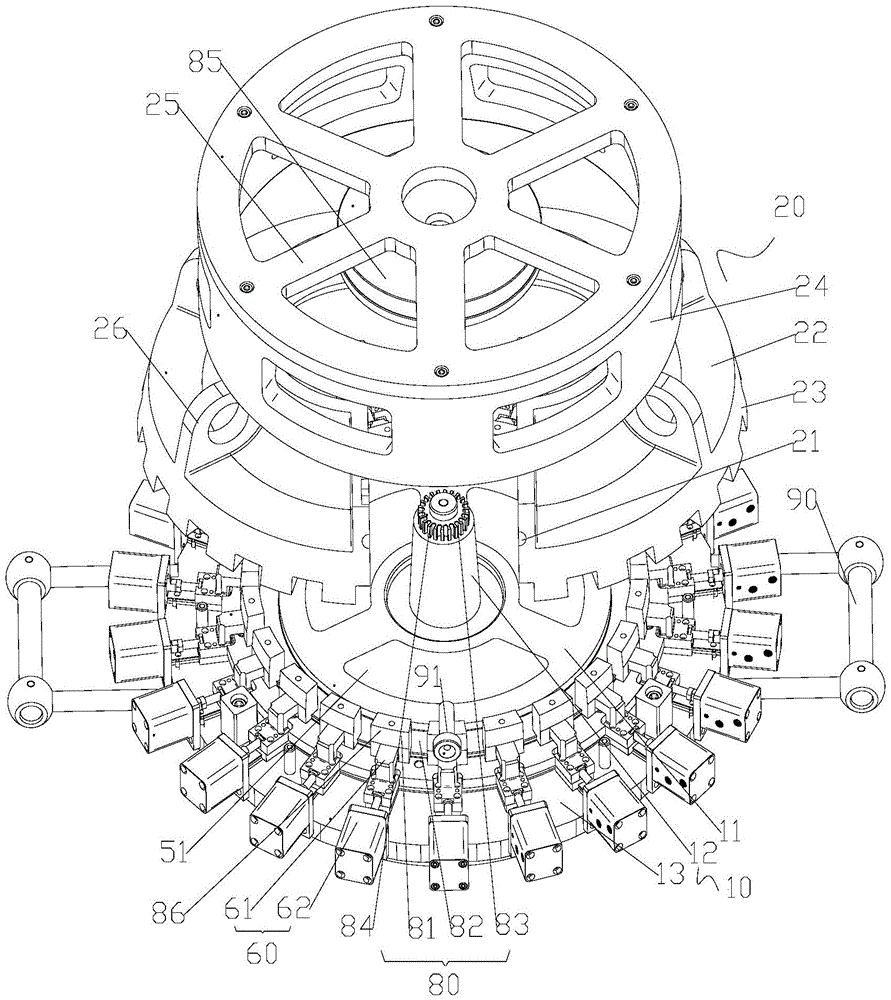

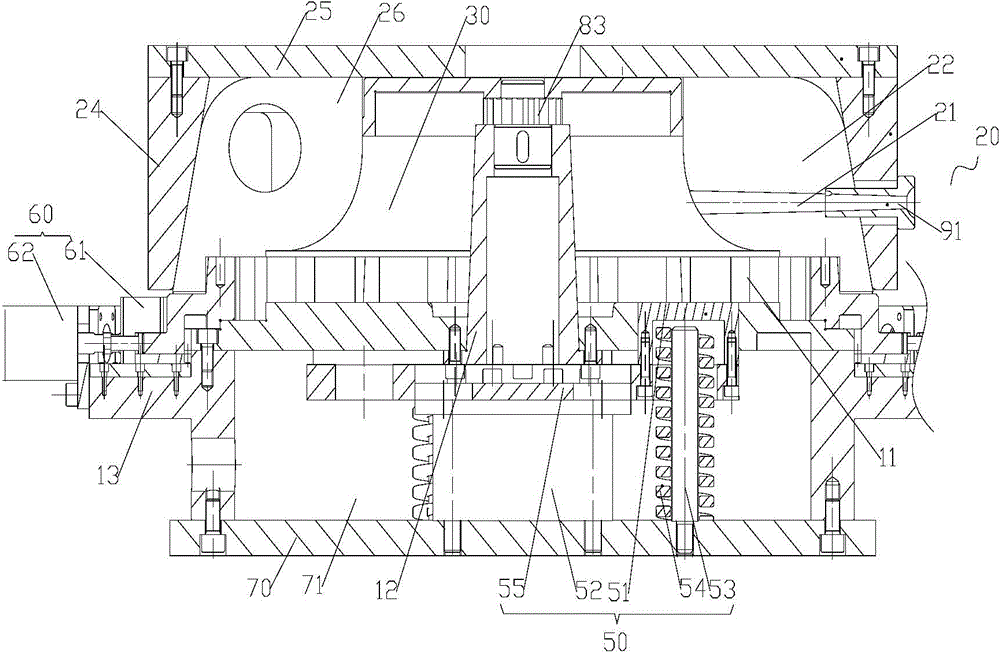

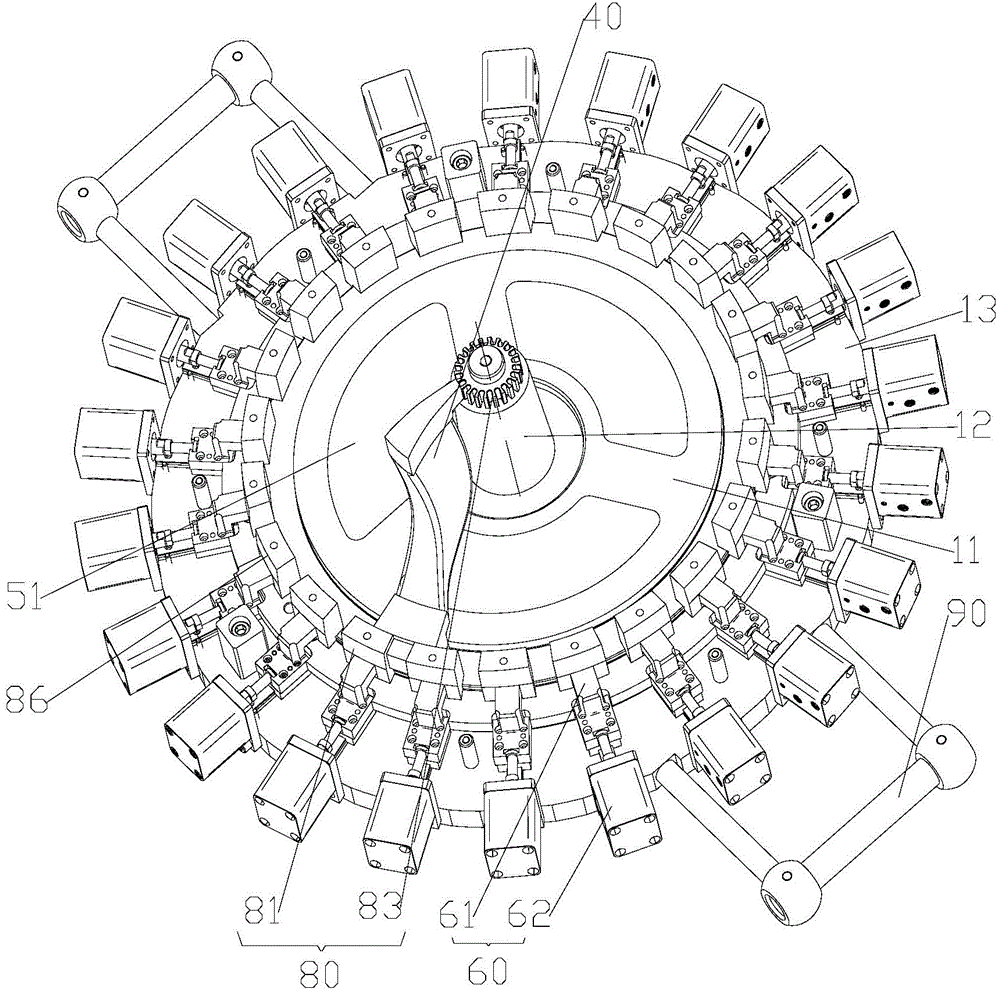

Closed type centrifugal impeller casting device

The invention provides a closed type centrifugal impeller casting device which comprises a bottom mould part, a top mould part, a plurality of carbonyl cores and an ejection part, wherein the top mould part is detachably buckled on the bottom mould part, and a cavity is formed between the bottom mould part and the top mould part; a plurality of the carbonyl cores are arranged in the cavity at intervals along the peripheral direction of the bottom mould part; and the ejection part is movably arranged on the bottom mould part, and one side, which faces the top mould part, of the ejection end of the ejection part extends to act or retracts into the bottom mould part. Because the ejection part is arranged, after the casting is completed, one side, which faces the top mould part, of the ejection end of the ejection part extends to act to eject a completely cast closed type centrifugal impeller from the bottom mould part so that the closed type centrifugal impeller is completely removed from the bottom mould part, so that the demoulding difficulty is reduced, the qualification rate of finished products is increased, and the problem of finished product damage caused by difficult demoulding is prevented.

Owner:CHINA HANGFA SOUTH IND CO LTD

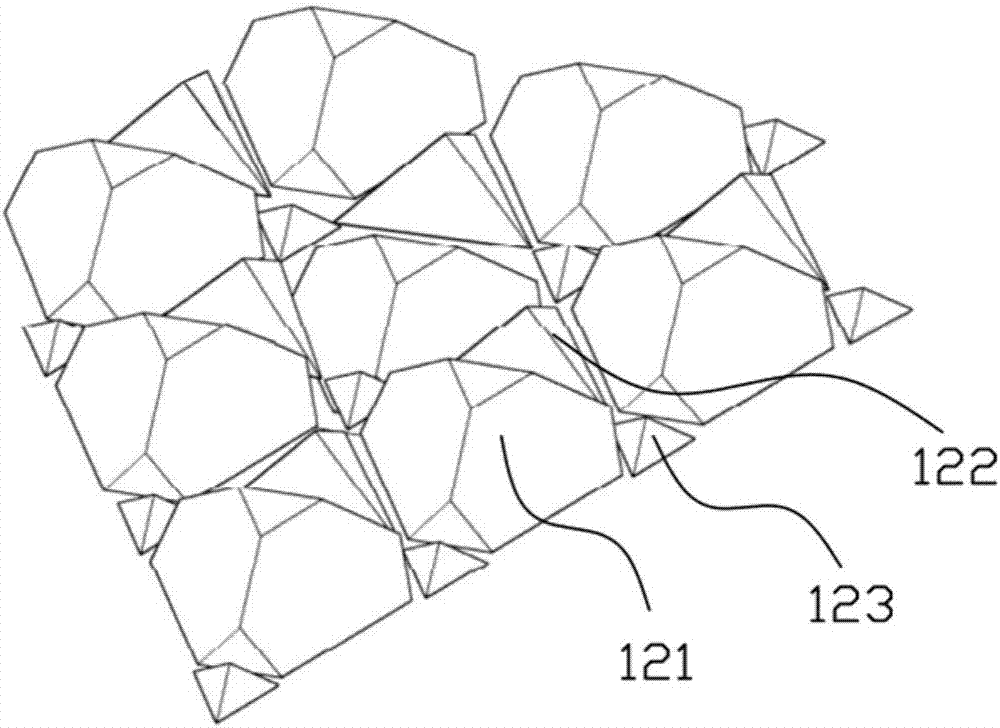

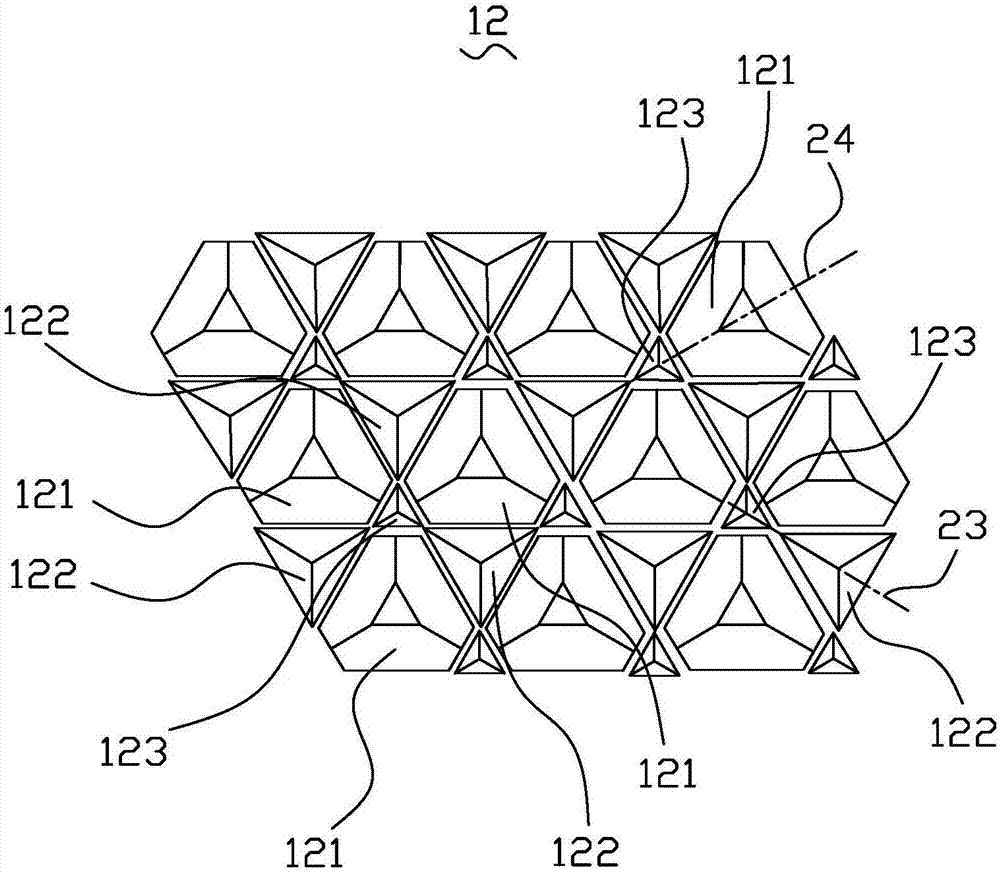

Microprism-type reflective film and manufacturing method thereof

ActiveCN106990460AImprove viewing angleReduce the difficulty of demouldingOptical elementsOptoelectronicsPrism

The invention provides a microprism-type reflective film. The microprism-type reflective film comprises a transparent basal film and a microprism layer. The microprism layer is arranged on a surface of the transparent basal film. The microprism layer is a combination of a plurality of microprism units. Each microprism unit comprises first prisms and a second prism. Each first prism is a triangular pyramid structure which is formed after cutting off one angle at a vertex angle and a base angle respectively and possesses a bottom surface, three side surfaces, three bottom cross sections and one top cross section. The second prism is a triangular pyramid structure and possesses a bottom surface, three side surfaces, one vertex angle and three base angles. A bottom surface of each first prism and a bottom surface of the second prism are combined with the transparent basal film. The second prism is arranged in a gap of the adjacent first prisms. By using the microprism-type reflective film, a viewing angle can be increased and demoulding difficulty is reduced.

Owner:SVG TECH GRP CO LTD +1

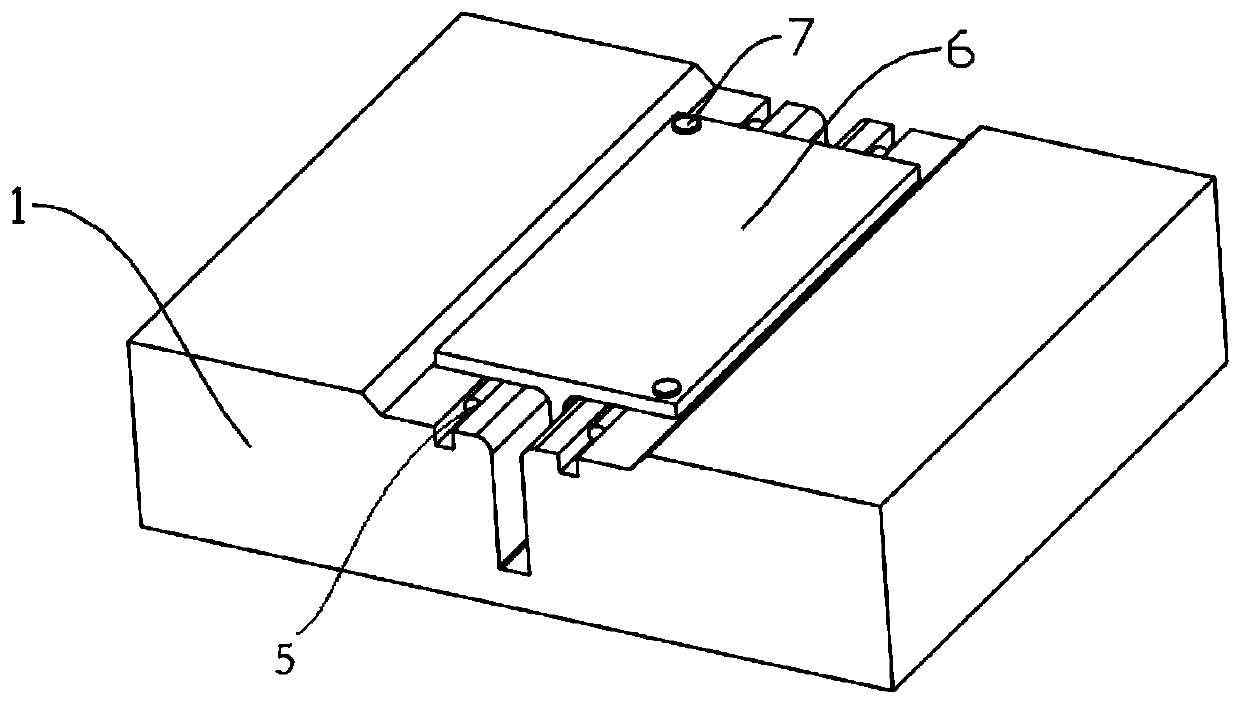

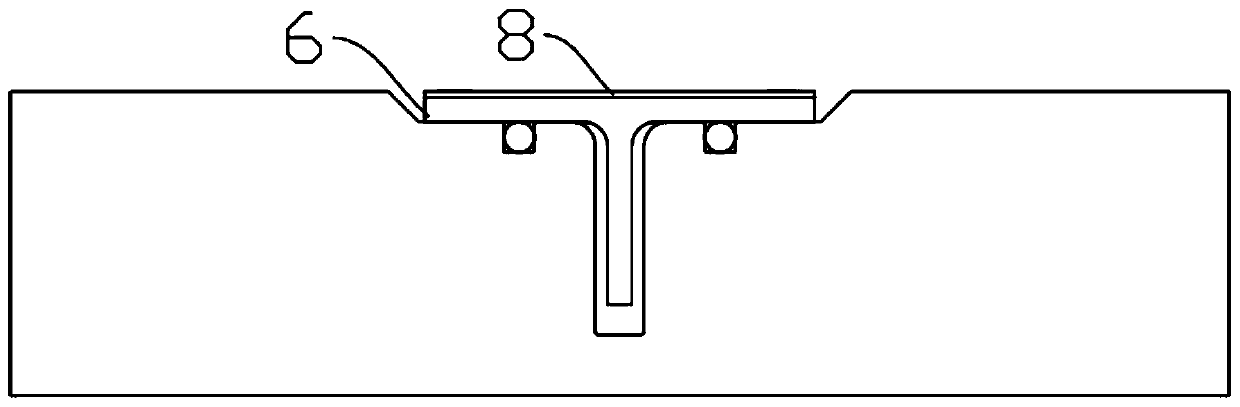

Composite material T shaped ribbed wallboard autoclave forming die structure and forming method

InactiveCN111590794APrevent inflowAvoid stickingDomestic articlesOblique angleMechanical engineering

The invention discloses a composite material T shaped ribbed wallboard autoclave forming die structure and a forming method. The structure comprises a die provided with a T shaped groove; the die is used for manufacturing a composite material T shaped ribbed wallboard; a T shaped rib is placed in the die provided with the T shaped groove and is precisely positioned through a positioning hole and the die; a sealing strip is arranged between the T shaped rib and the die and ensures that resin does not flow into the T shaped groove during the curing process; an oblique angle is designed on the Tshaped groove of the die to ensure demoulding feasibility; a dried rib and a wet skin are in glue joint to manufacture the T shaped ribbed wallboard; the rib for manufacturing the composite material ribbed wallboard is high in location degree and axis degree; and a rotary body structure provided with an internal T shaped ribbed structure also can be manufactured.

Owner:XIAN AIRCRAFT IND GROUP

Lens group

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

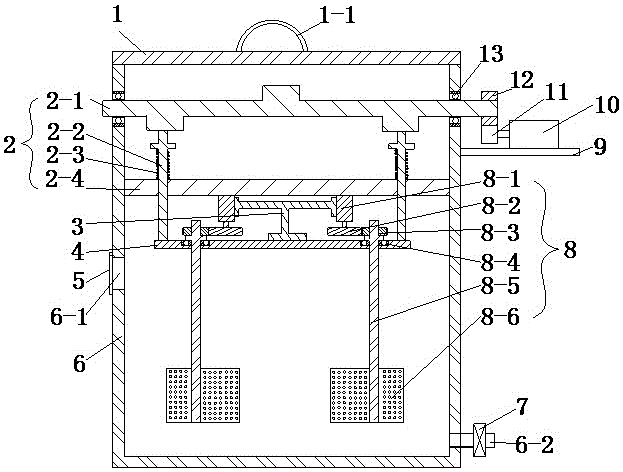

Organic silicon release agent stirring device

InactiveCN105771746AImprove the mixing effectReduce the difficulty of demouldingRotary stirring mixersTransportation and packagingMotor drivePropeller

The invention relates to the technical field of organic silicon release agents, in particular to an organic silicon release agent stirring device. The organic silicon release agent stirring device is characterized in that the bottom ends of ejecting shafts pass through springs and a guide plate sequentially to be fixedly connected with a fixing plate, each of stirring mechanisms comprises a stirring motor, a driving stirring gear, a driven stirring gear, a stirring bearing, a stirring shaft and a stirring propeller, and the lower ends of the stirring shafts pass through the stirring bearings and the fixing plates sequentially to be fixedly connected with the stirring propellers. When the organic silicon release agent stirring device is used, an external motor drives a camshaft to rotate to enable a telescoping mechanism to reciprocate up and down, then the fixing plate is driven to enable the whole stirring mechanisms to reciprocate up and down and not to stop on a fixed plane, and accordingly stirring efficiency is better and difficulty in release due to nonuniform mixing is lowered. Additionally, the organic silicon release agent stirring device is simple in structure, reasonable in design and low in manufacturing cost.

Owner:黄宇松

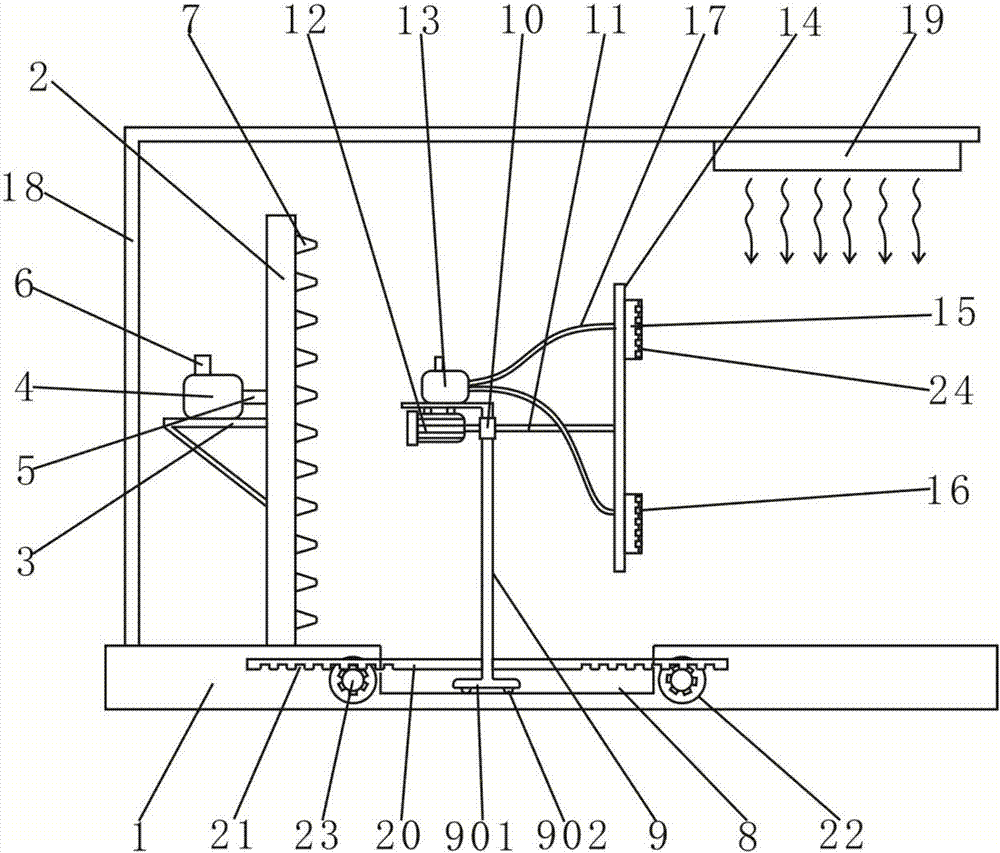

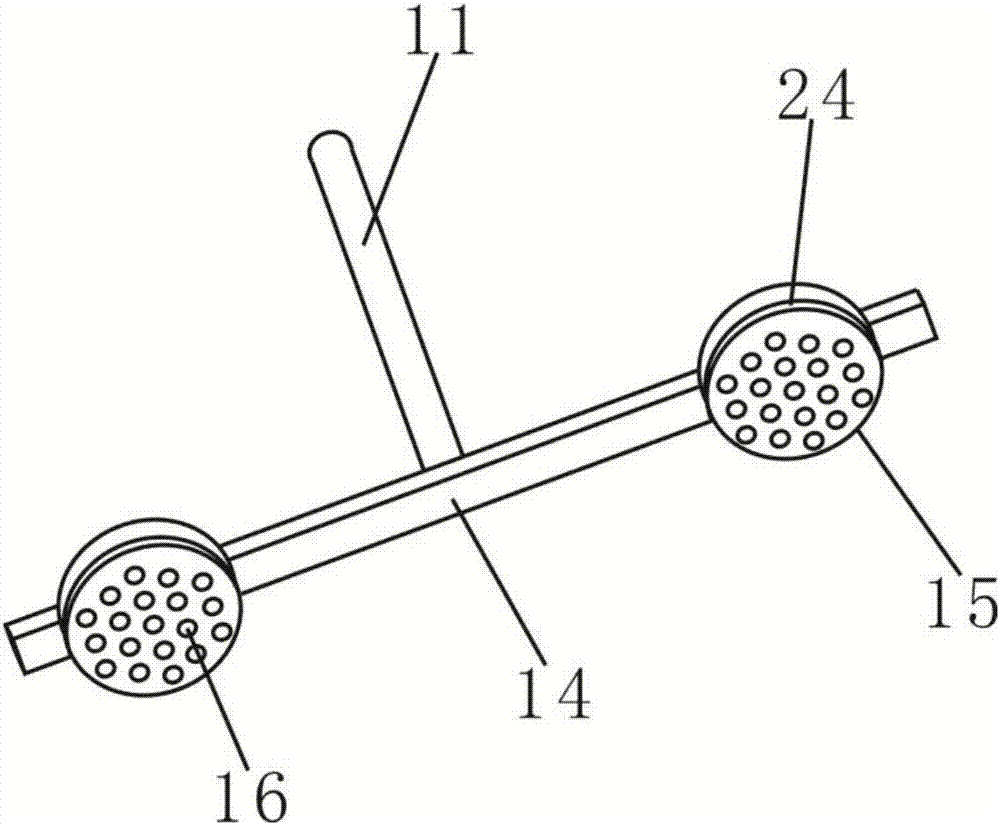

Silicone rubber insulator injection mold demolding device

ActiveCN107571470AIncrease productivityHorizontal dynamics are even and gentleDomestic articlesGas compressorEngineering

The invention discloses a silicone rubber insulator injection mold demolding device which comprises a base. The base is connected with a high-pressure cavity. The left side of the high-pressure cavityis connected with an air compressor. The surface of the right side of the high-pressure cavity is connected with horizontal jet nozzles. The base is provided with a rectangular groove. A stand columnis arranged in the rectangular groove. A bearing is arranged at the top end of the stand column. A rotary shaft is arranged in the bearing. The left side of the rotary shaft is connected with a motorand fixedly connected with a rotary frame. The two ends of the rotary frame are fixedly provided with negative-pressure cavities. Adsorption holes are formed in the right sides of the negative-pressure cavities. The left side of the base is connected with an L-shaped support. The tail end of the L-shaped support is provided with an air cooler. By arranging the high-pressure cavity and the jet nozzles, even and gentle air force is used for demolding, no pit is left in the surface of an insulator, by arranging the rotary frame and the negative-pressure cavities, rotation and forward pushing areconducted at the same time, and the demolding difficulty is lowered.

Owner:硅美德橡塑科技(昆山)有限公司

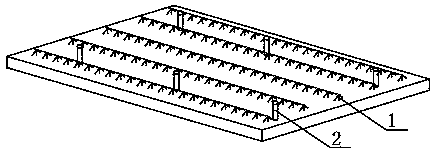

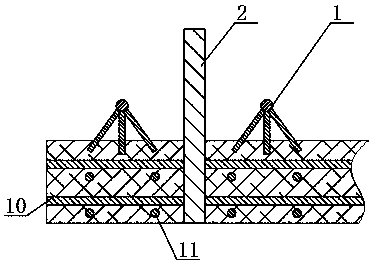

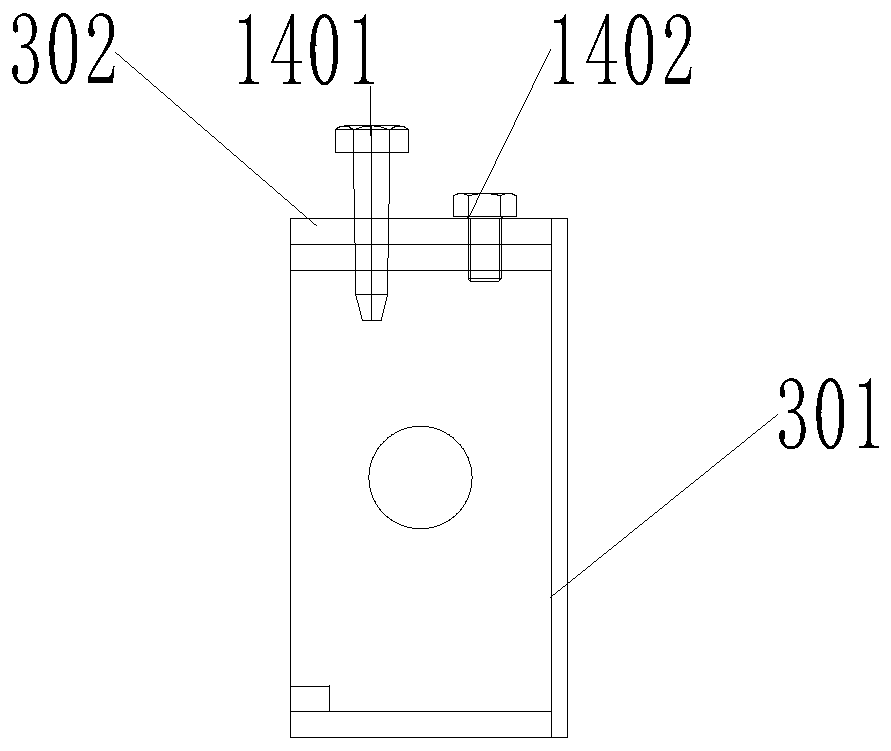

Assembling type composite floor slab with height limiting device and production process for assembling type composite floor slab

PendingCN110616838AReduce the difficulty of demouldingAvoid wastingFloorsBuilding material handlingRebarFloor slab

The invention discloses an assembling type composite floor slab with a height limiting device and a production process for the assembling type composite floor slab. Transverse steel bars and longitudinal steel bars are poured in the composite floor slab, truss steel bars are poured on the composite floor slab, the composite floor slab is further fixedly provided with a plurality of vertical heightlimiting columns, and the top ends of the height limiting columns are higher than the truss steel bars. A mold for producing the composite floor slab adopts a structure for facilitating demolding, and the detailed structure is as follows: a mold table is provided with a rectangular opening groove, and a supporting plate is hinged clinging to the inner wall of the opening groove. When side platesare installed, supporting plates are rotated to a horizontal position and are fixed, the supporting plates are rotated to a vertical state to enable the side plates to be suspended after the pouring is finished, and then the side plates are knocked downwards, so that a relatively large shearing force can be generated between the side plates and concrete, and the side plates can be accelerated to be separated from the concrete. The height limiting columns are integrally installed while the composite floor slab manufactured, the height limiting columns can be used for indicating a pouring thickness of the cast-in-place concrete, and the problem of waste caused by excessive pouring of the concrete is effectively solved.

Owner:GANSU CONSTR TECH RES & DEV CO LTD

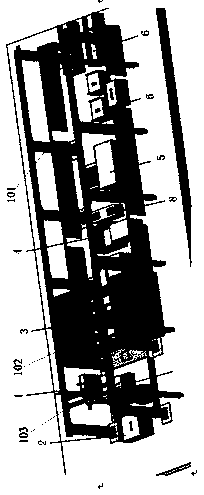

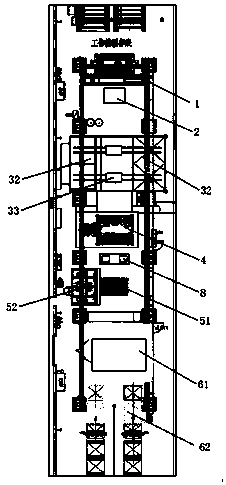

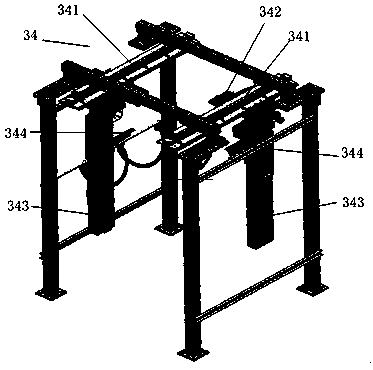

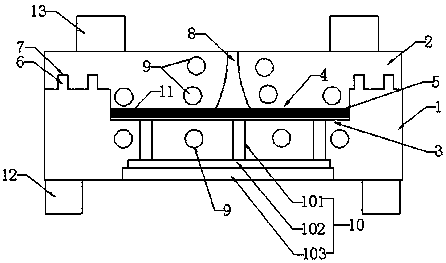

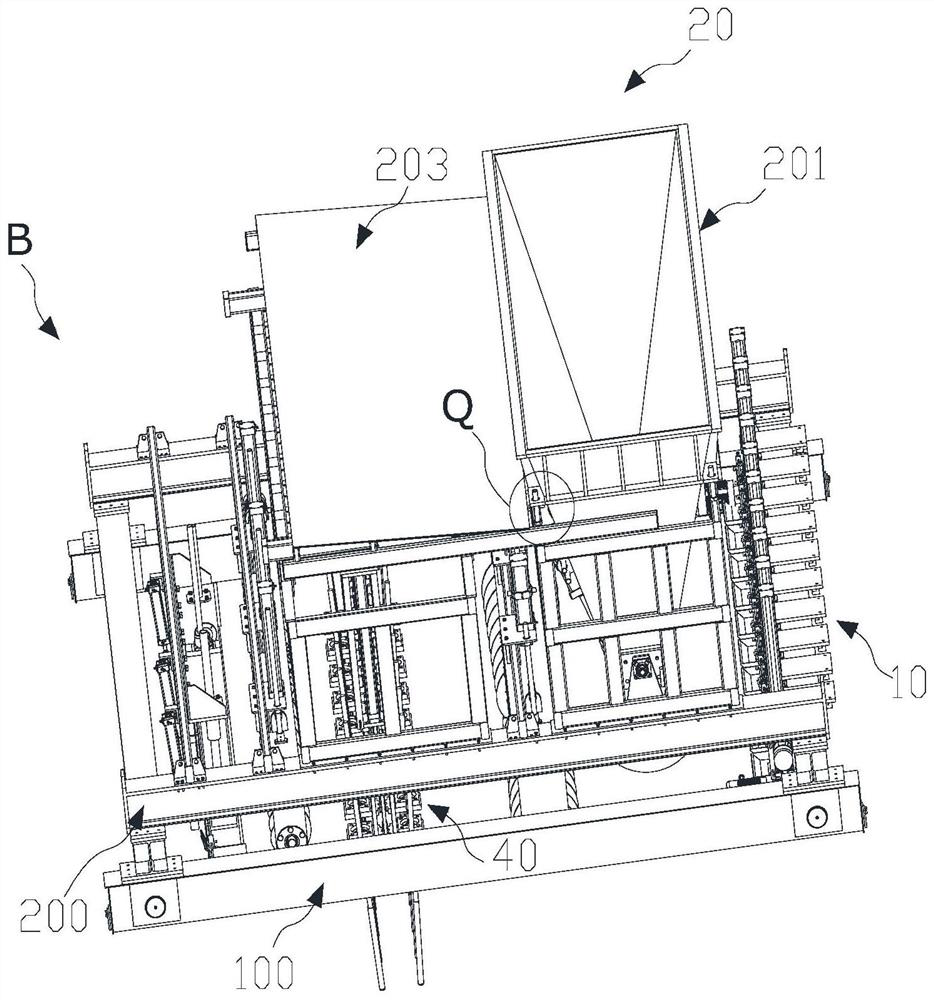

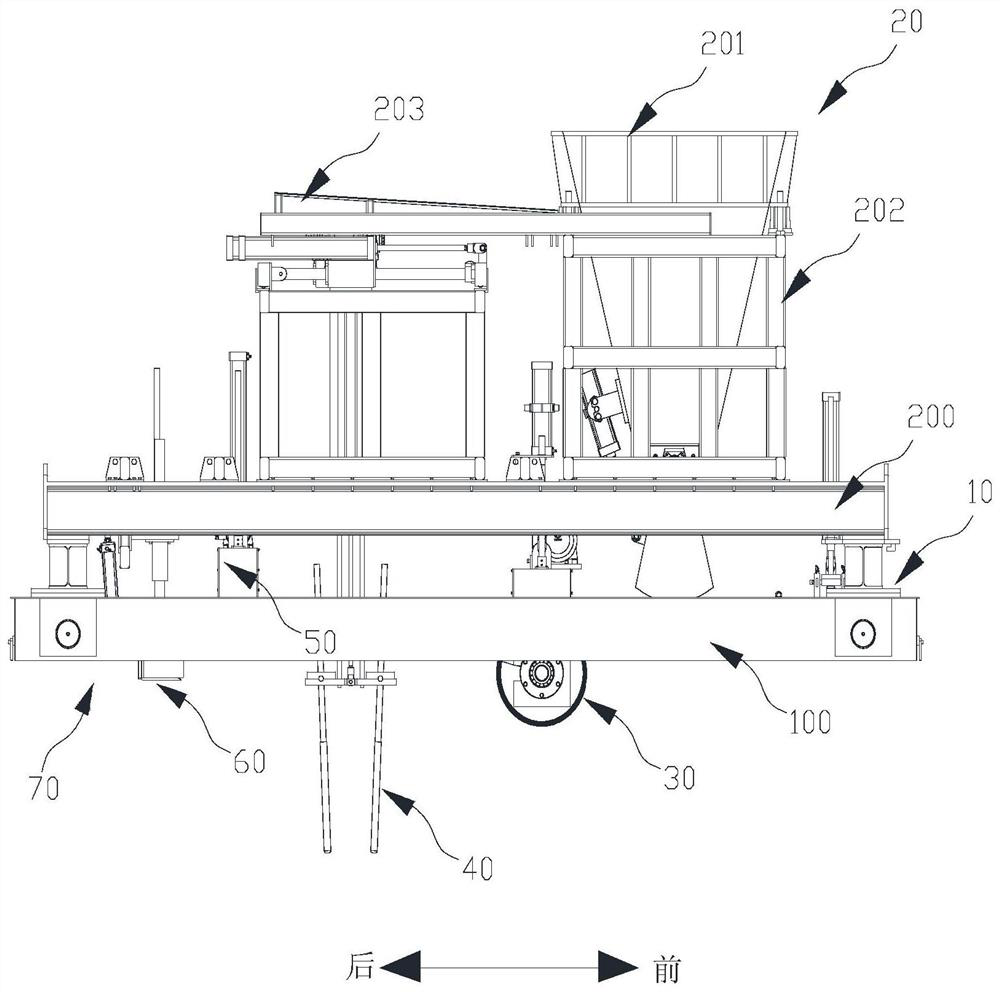

Automatic sand mold casting mold forming production line and method

InactiveCN111496198AWeight increaseGuaranteed cleanlinessMoulding toolsMoulding plantsProcess engineeringCasting mold

The invention relates to an automatic sand mold casting mold forming production line which comprises a truss robot, a feeding device, a sand removing device, a coating device, a drying device and a core assembling device. The truss robot is mounted on two parallel sliding rails, and can slide along the sliding rails, and the sliding rails are mounted on stand columns. The sand removing device comprises an automatic sand removing room, a manual sand removing room and a transferring trolley. The truss robot can place workpieces on the transferring trolley, and the transferring trolley can transfer the workpiece to the automatic sand removing room and the manual sand removing room. According to the automatic sand mold casting mold forming production line, unmanned operation can be achieved inthe whole process, the labor cost is reduced, rigid grabbing points do not need to be additionally arranged, and the demolding difficulty is reduced; the grabbing process and the like are high in repeated positioning precision, sand molds cannot be damaged, the sand core rejection rate is low, and all sand molds can be compatible; and due to the fact that sand mold production is mixed routing production, the time wasted by replacing fingers and other accessories is greatly shortened, and the production cost is reduced.

Owner:烟台冰轮智能机械科技有限公司

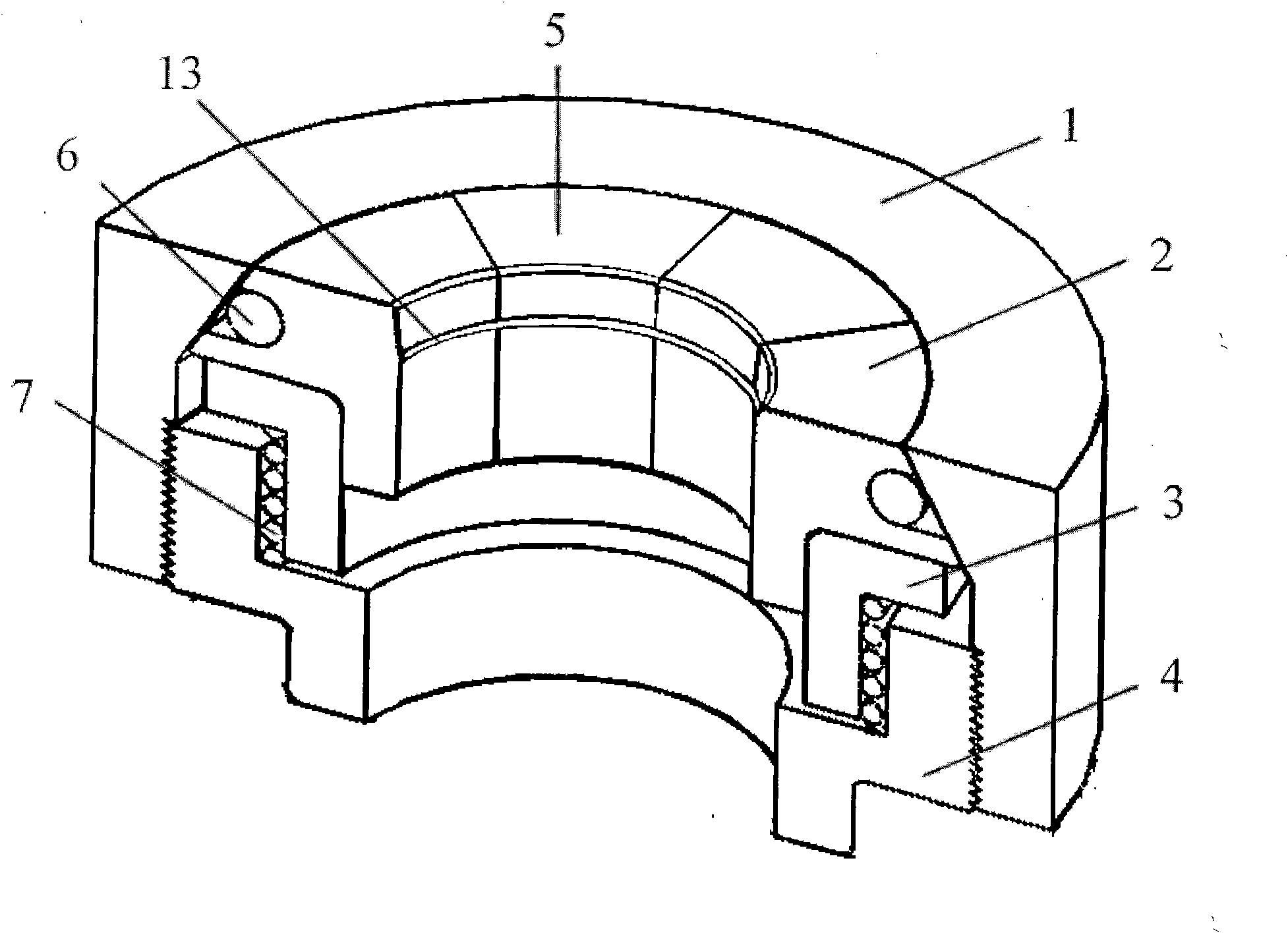

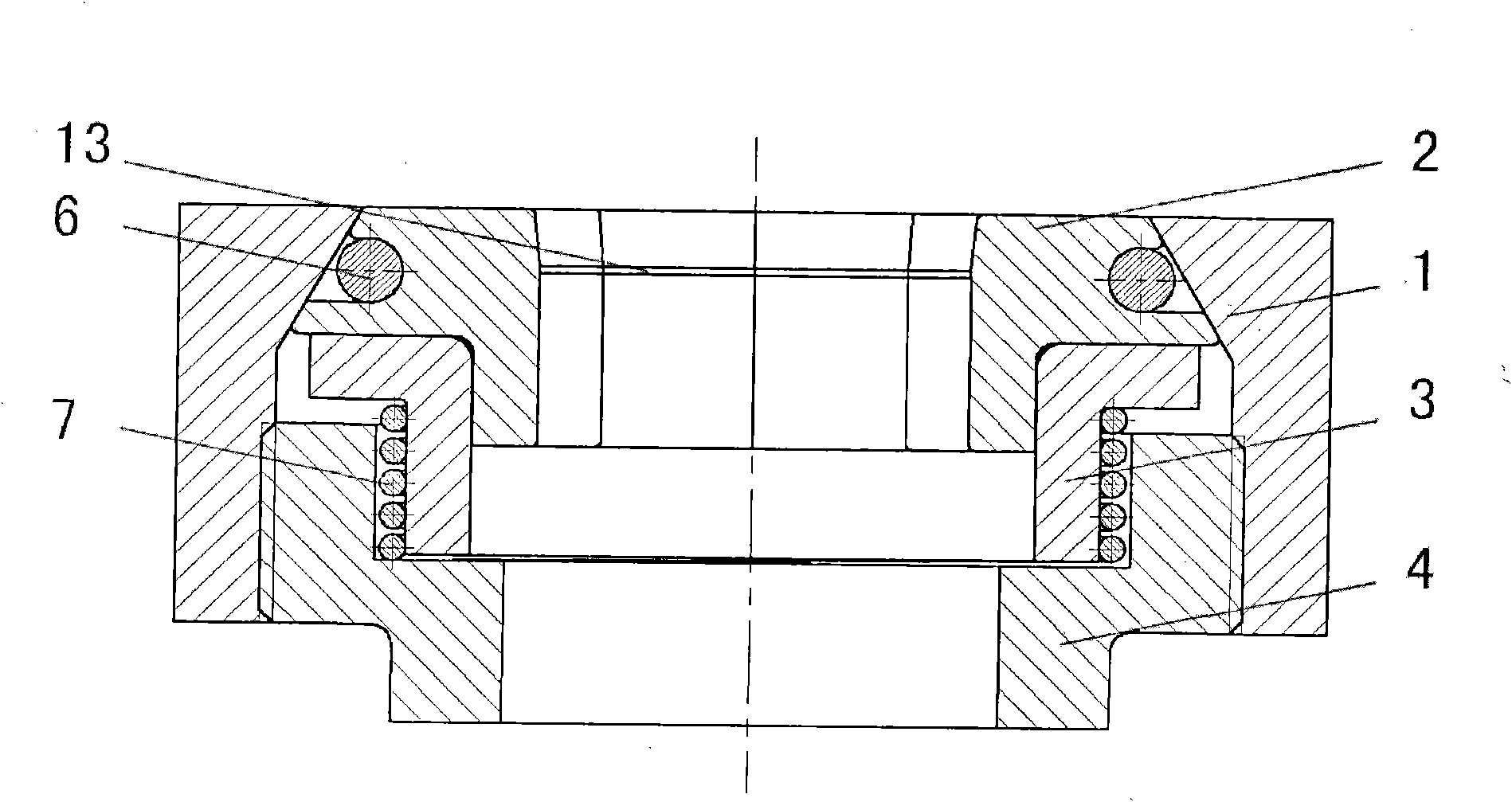

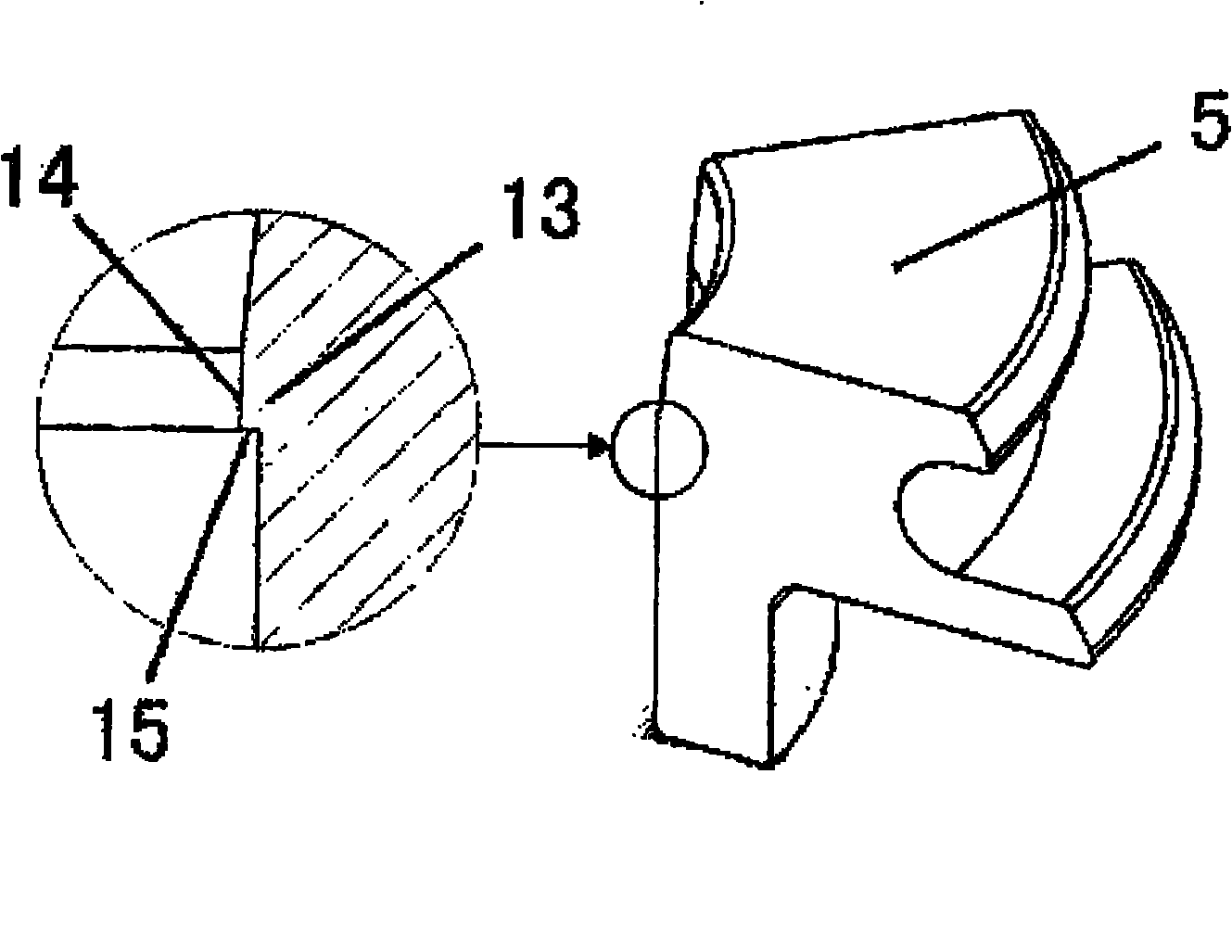

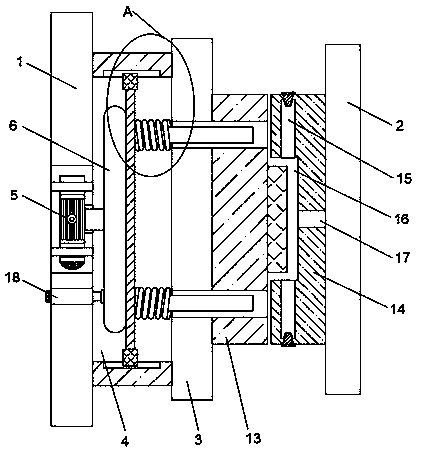

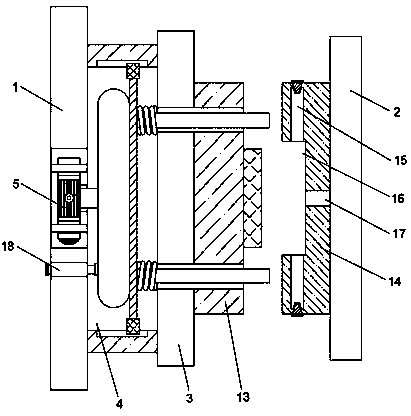

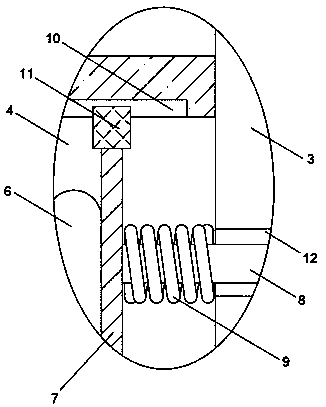

Demoulding device for thin-wall deep-drawing part process

ActiveCN102248092AReduce the difficulty of demouldingAvoid pressure instabilityStripping-off devicesRubber ringDeep drawing

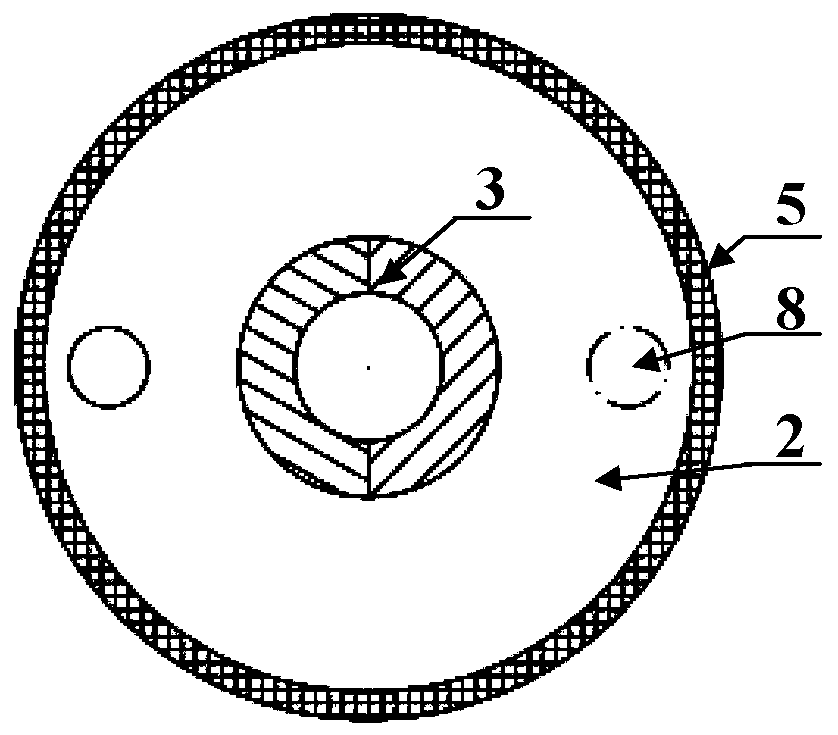

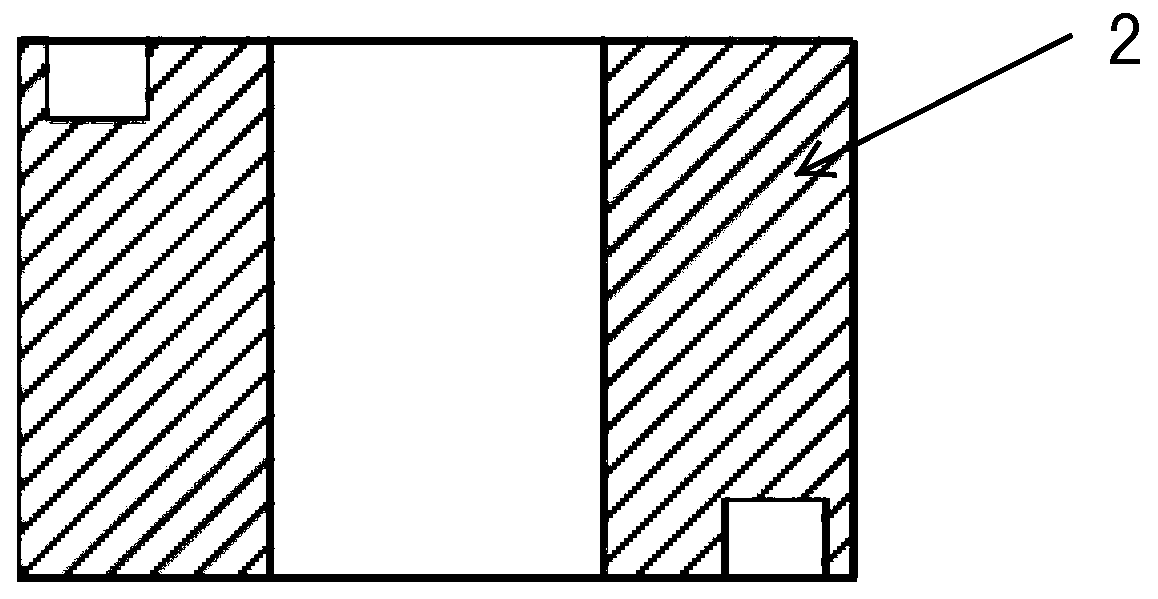

The invention relates to a demoulding device for a thin-wall deep-drawing part process. The demoulding device mainly comprises a discharging ring (2), a material guiding barrel (3) and a thread check ring (4) which are sleeved sequentially from top to bottom, wherein a rubber ring (6) is hooped in a U-shaped slot of the discharging ring (2) for fixing; a spring (7) is arranged on the thread check ring (4) and is used for supporting the material guiding barrel (3); a taper hole seat (1) is used for sleeving the components; and a thread is matched with the thread check ring (4). The demoulding device is characterized in that: a step-shaped structure (13) is arranged at the position, which is close to the upper port, on the inner wall of the discharging ring (2) to form an inner flange (14) and an auxiliary support surface (15). Due to the adoption of the unique design of spliced discharging blocks and the inner flange, the demoulding device can obviously reduce the demoulding difficulty of 500ml-steel cans and can effectively prevent the openings of the cans from being pressed and destabilized in the demoulding process.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Construction method for cover-excavation reverse method soil moulding bed

ActiveCN102433892AControl GeometryImprove appearance qualityArtificial islandsUnderwater structuresEngineeringStressed state

The invention discloses a construction method for a cover-excavation reverse method soil moulding bed, overcoming the defect of the common soil moulding bed construction method. The moulding bed can be prevented from chipping and falling angles, and is convenient to fall, demoulding cost is lowered, and safety is improved. In addition, with the construction method, materials are saved, the environment is protected, cost is lowered, and demoulding efficiency and appearance quality are improved. The construction method has the beneficial effects of simple technology, strong maneuverability, strong weather adaptability, low demoulding difficulty and small demoulding cost, saving of more materials, and effective control of physical dimension of a beam plate, and ensures that the structure is in the normal stressed state; and the forming appearance quality of the beam plate concrete is improved.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

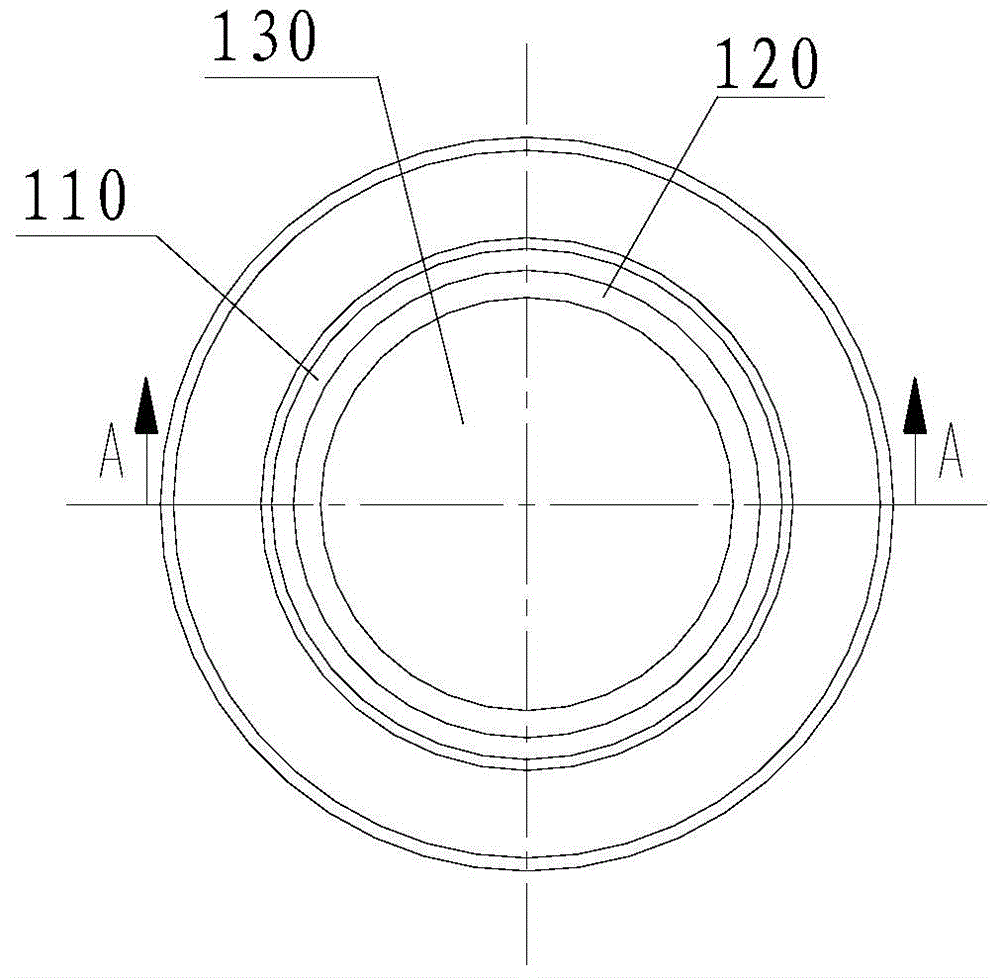

Hollow fiber membrane filtration core potting mold and use method thereof

The present invention discloses a hollow fiber membrane filtration core potting mold and a use method thereof. The potting mold is made from a hydrophobic organic material and has advantages of simple structure, easy processing and easy use, wherein the hydrophobic organic material has a low surface energy so as to effectively reduce the adhesion between the potting glue and the potting mold, such that the potted and casted filtration core can be completely demolded, the demolding difficulty is reduced, the damage on the work-piece during the demolding process is avoided, and the potting efficiency is effectively improved. According to the use method of the potting mold, with the pre-treatment process on the potting mold, the demolding difficulty is further reduced, and the potting efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Electrified sintering die

ActiveCN108748620AImprove uniformityImprove integrityMouldsCeramic shaping mandrelsEngineeringCounterbore

The invention provides an electrified sintering die which comprises an internal movable block forming die and an outer die sleeve arranged from inside to outside and further comprises an upper pressure head and a lower pressure head arranged in the internal movable block forming die, wherein a counterbore hole is formed in the outer die sleeve; a shunting flow deflector is arranged in the counterbore hole; and the inner wall of the outer die sleeve or the outer wall of the internal movable block forming die is coated with a release agent. The electrified sintering die can improve the uniformity of a sintering temperature field and reduces the demoulding difficulty of a sintered sample to improve the sintering uniformity of the sample and the integrity of the sintered sample.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

U-shaped building embedded part and construction method of anchoring component of U-shaped building embedded part

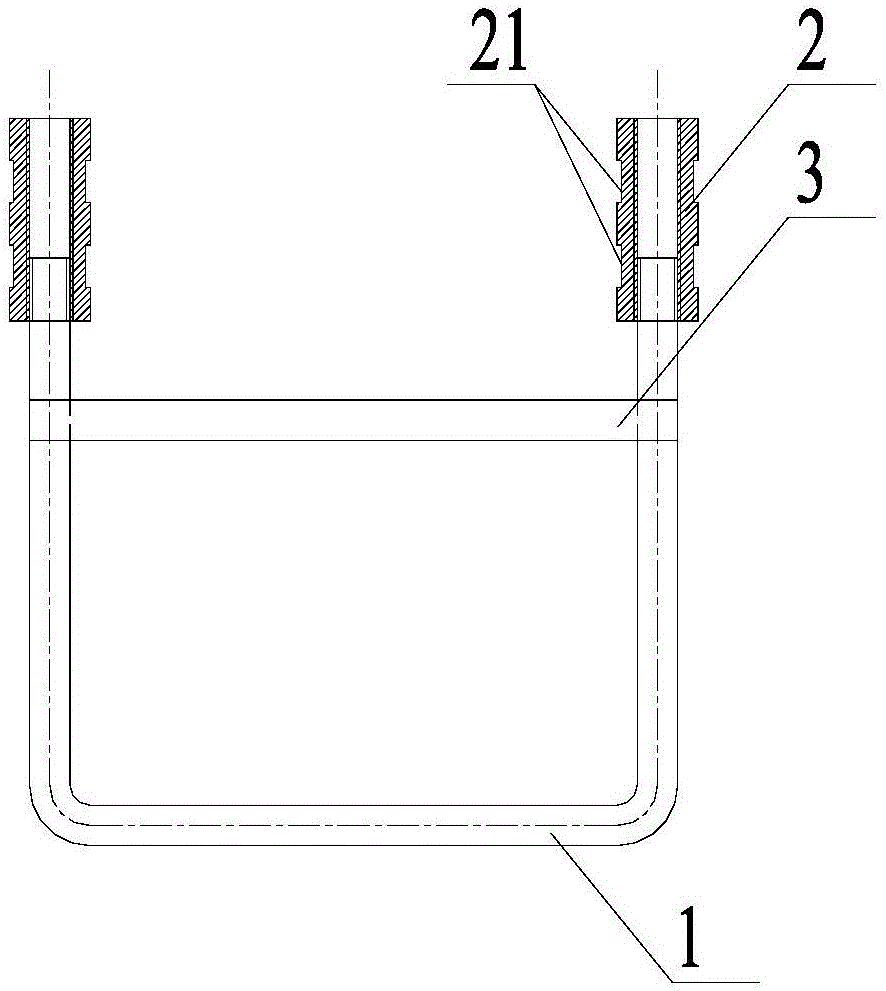

InactiveCN105888078AAvoid slurry leakageReduce the difficulty of demouldingBridge structural detailsBuilding constructionsSteel barSlurry

The invention discloses a U-shaped building embedded part and a construction method of an anchoring component applying the U-shaped building embedded part. The embedded part comprises a U-shaped bolt, two connecting sleeves and a reinforcing steel bar; the U-shaped bolt and the connecting sleeves are connected through threads, and the reinforcing steel bar and the U-shaped bolt are welded, so that the U-shaped bolt is prevented from being deformed in the carrying process. When embedding in pouring construction is conducted, the ends of the connecting sleeves abut against a whole formwork, holes do not need to be preformed in the whole formwork, the slurry leakage phenomenon cannot occur in the pouring process, and later formwork stripping is easy; in addition, accessory equipment is connected with the sleeves of the U-shaped embedded part through bolts, when the accessory equipment fails, the accessory equipment can be maintained and replaced by screwing down the connecting bolts, and therefore concrete structure ancillary facilities are greatly convenient to maintain and replace.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

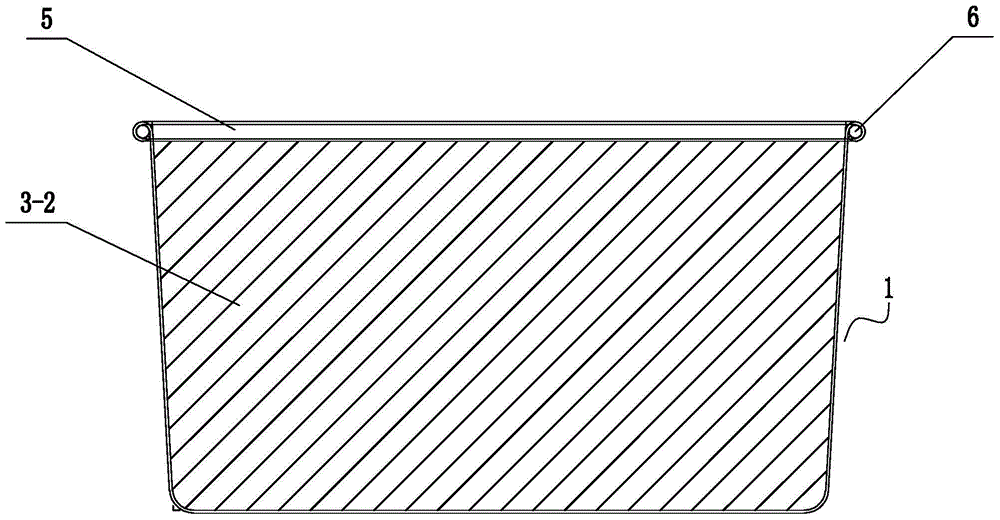

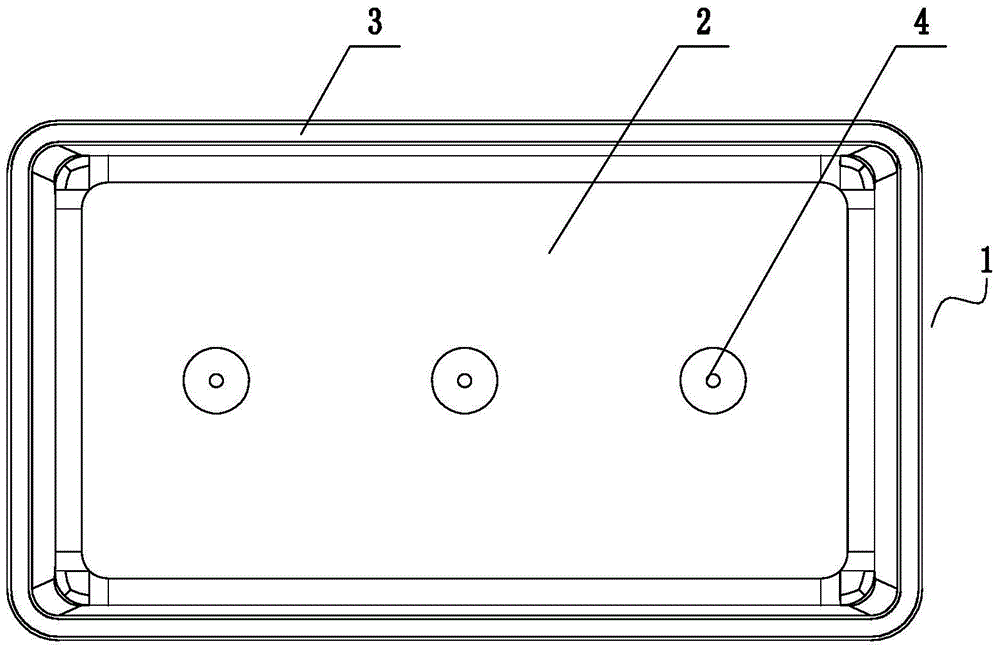

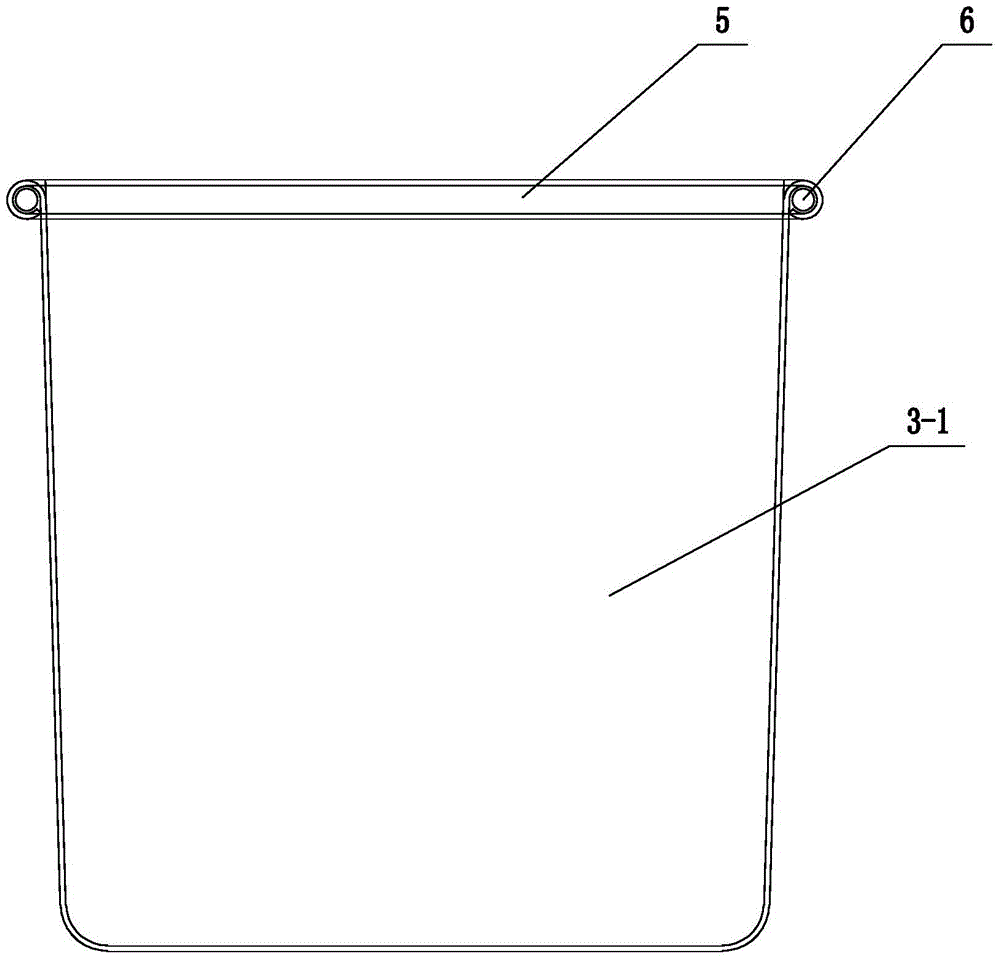

Non-stick easy demoulding toast box

InactiveCN104886195AReduce the difficulty of demouldingWill not defaceBaking-tinsDuctilityEngineering

The invention relates to a non-stick easy demoulding toast box, which comprises a toast box body, and the toast box body comprises a box bottom and a sidewall located on the edge of the box bottom; the non-stick easy demoulding toast box is characterized in that the sidewall comprises two short-side sidewalls and two long-side sidewalls, the two short-side sidewalls are of a flat plate structure, and the two long-side sidewalls are shaped like up-and-down waves. The box bottom is provided with a plurality of oil drain holes. The internal surface of the toast box body is provided with ductile non-stick coating. The upper edge of the sidewall is outwardly curled to form an edge with a round section, a solid fixed bar is fixedly welded in the cavity of the edge, and the section of the fixed bar adopts a round which is the same as the shape of the section of the cavity of the edge. The non-stick easy demoulding toast box described by the invention decreases the difficulty of demoulding a roasted product from the toast box, the non-stick easy demoulding toast box is convenient to operate, and food cannot be defaced.

Owner:SAN NENG BAKE WARE WUXI

Injection mold convenient for stable demoulding

The invention discloses an injection mold convenient for stable demoulding. The injection mold comprises a moving module and a fixed module, the moving module comprises a moving base, a supporting plate is welded to the moving base, a cavity is formed between the moving base and the supporting plate, an air pump is installed in the moving base, an air bag is connected to the output end of the airpump, a pressing plate is fixedly adhered to the air bag, two abutting rods are correspondingly welded to the pressing plate, springs are arranged on the two abutting rods in a sleeving mode, a sliding groove is formed in the inner wall of the cavity, and sliding blocks are correspondingly welded to the upper end and the lower end of the pressing plate. According to the injection mold, a water-cooling cavity is utilized to improve the cooling setting efficiency of a plastic part, and thus the waiting time of demoulding is shortened; the temperature in the injection mold is adjusted properly through the cooling effect, the temperature difference between the injection mold and the environment is advantageously reduced, and thus the air pressure adjustment in an injection module is achieved;and the air pump is utilized to inflate the air bag to achieve the horizontal movement of the abutting rods, thus the abutting rods push the forming plastic part, and the plastic part is separated from a moving mold stably.

Owner:徐州康纳高新材料科技有限公司

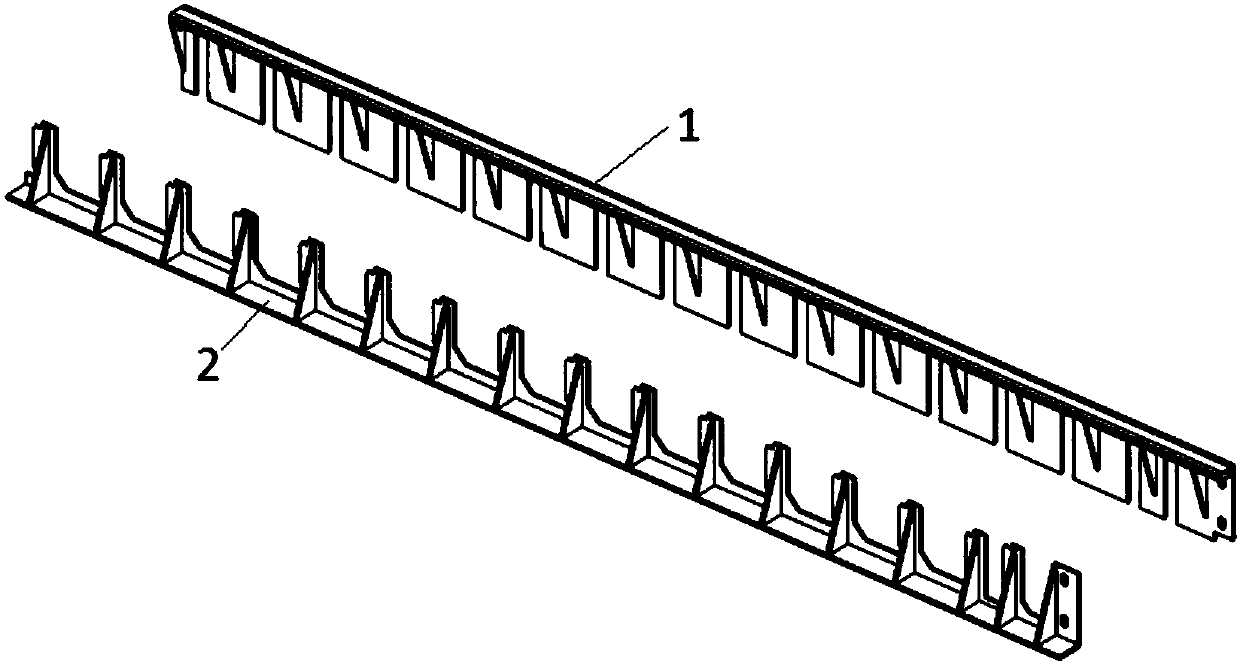

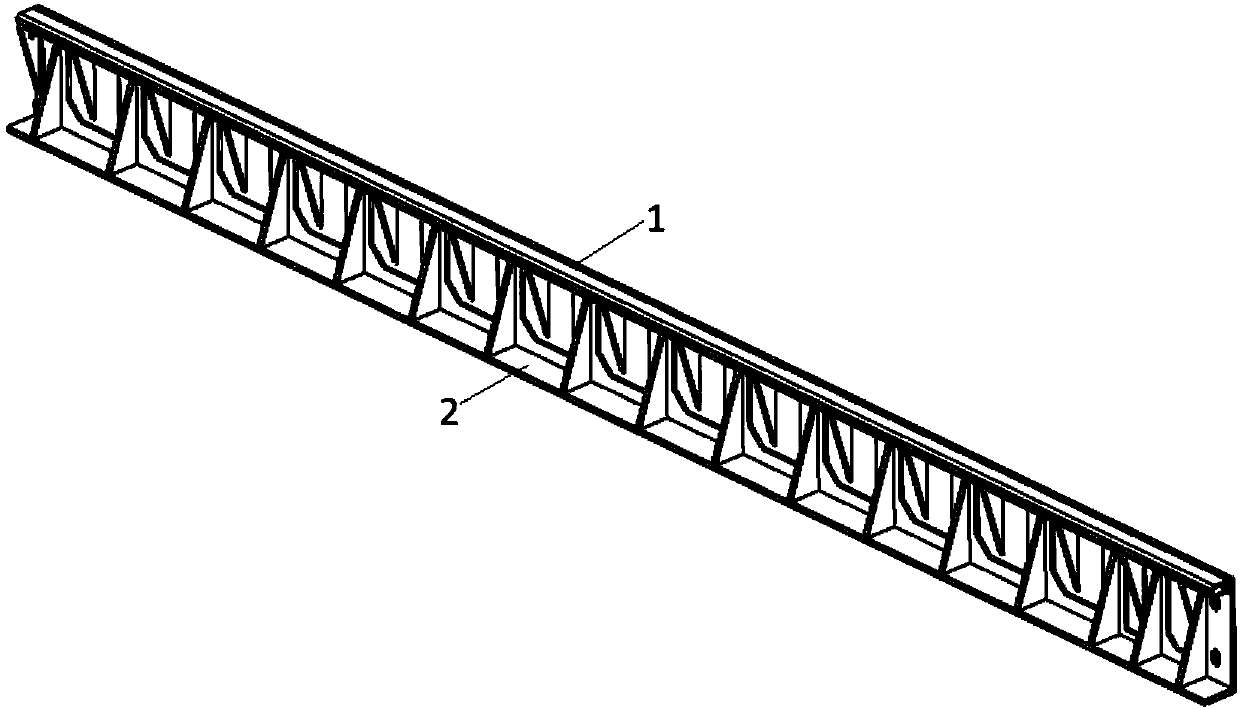

Combined mould and forming method used for bulged bar prefabricated part forming

The invention relates to a combined mould used for bulged bar prefabricated part forming. The combined mould comprises a first molding board and a second molding board, wherein slots perpendicular tothe length direction of the first molding board are formed in the first molding board; the slots communicate with the bottom side of the first molding board; baffle strips which are staggered with theslots are arranged on the second molding board; two notches for placing reinforcing steel bars are formed in one side of each baffle strip; the first molding board is combined with the second moldingboard to form an integrated molding board; and a first bar penetrating hole and a second bar penetrating hole for allowing the reinforcing steel bars to pass through are formed between each slot andthe corresponding baffle strip. After being combined, the mould is good in sealing property, and the holes for just allowing the reinforcing steel bars to pass through are formed in the formed integrated molding board, so that occurrence of leaked slurry is greatly reduced in comparison with waist-shaped holes in the prior art, building materials are favorably saved, and a prefabricated componentwith uniform components is obtained; molding and de-molding are convenient, de-molding difficulty is reduced, and de-molding efficiency is greatly improved; acting force on each molding board is relatively small in a molding process and a de-molding process; and moreover, structural strength of the molding boards is high, so that the molding boards are not liable to damage, and using and maintaining cost of the mould is reduced.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

Pipeline-free vacuum infusion forming method of sandwiched composite material

The invention discloses a pipeline-free vacuum infusion forming method of a sandwiched composite material for vacuum infusion formation of a sandwiched composite material. According to the invention, a method for forming a sandwiched material filling hole (7) by slotting a sandwiched material (4) in a sandwiched composite material structure is used for replacing a flow guide pipe used in the prior art to establish a vacuum system. Liquid resin flows through the sandwiched material filling hole (7) and infiltrates an upper dry laying layer (5), a sandwiched material (4) an a lower dry laying layer (3). After a product is cured, the slotted sandwiched material (4) is left in the product and is integrated with the product. Resin is kept in the product by pipeline-free filling; a great amount of resin waste is reduced; meanwhile, the problem of demoulding difficulty of a vacuum system on the surface of the product is solved; because of reduction of a great amount of solid waste, the environmental pollution is prevented; the working environment is improved.

Owner:LUOYANG SUNRUI WIND TURBINE BLADE

Plastic mold capable of demolding quickly

InactiveCN108673857AFast release efficiencyImprove demoulding efficiencyRubber materialInjection port

The invention discloses a plastic mold capable of demolding quickly. The plastic mold comprises a fixed mold and a movable mold, a fixed mold cavity is formed in one side, facing the movable mold, ofthe fixed mold, a movable mold core is arranged on one side, facing the fixed mold, of the movable mold, and the movable mold core is matched with the fixed mold cavity to form a mold cavity; a glue injection channel penetrating through the movable mold is installed in the middle of the movable mold core, cooling pipelines are internally arranged in the fixed mold cavity and the movable mold core,and water inlet ends and water outlet ends of the cooling pipelines extend out of the plastic mold. According to the mold, cooling devices are correspondingly arranged on the two sides of the upper surface of the mold cavity, two sides of the lower surface of the mold cavity, and the two sides of the glue injection channel so that residual rubber materials in a whole injection molding and the residual rubber materials in a glue injection port can be cooled at the same time, then the demolding efficiency of the whole injection molding is improved, and particularly, the demolding difficulty atthe glue injection opening is reduced; and by adopting the plastic mold, the demolding speed of the injection molding is high, the demolding performance is reliable, the production efficiency is high,and the practicability is high.

Owner:吴中区甪直磊鑫模具厂

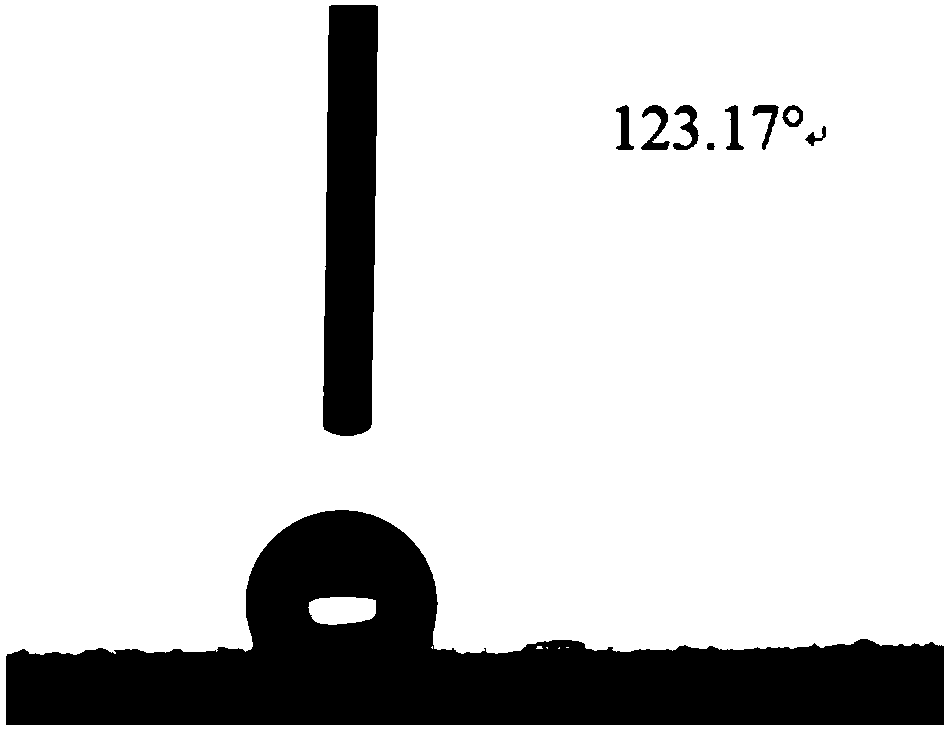

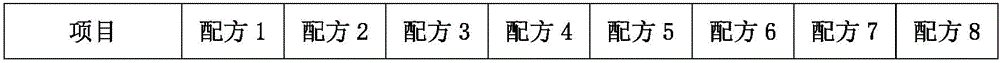

Novel epoxy resin release agent and preparation method and application thereof

The invention relates to the technical field of manufacturing of epoxy resin release agents, in particular to a novel epoxy resin release agent and a preparation method and application thereof. By means of ratio design of high vacuum silicone grease, gasoline and absolute ethyl alcohol, the novel epoxy resin release agent is reasonable in ratio, mold release is easy after the novel epoxy resin release agent is used for mold release treatment, the appearance surface of a product is full, the film forming speed is moderate, and formed films are evenly distributed in a mold; and no film sticking phenomenon happens, the mold release difficulty is reduced, the mold release efficiency is improved, and the product quality is improved.

Owner:黄超

RTM mold for composite workpiece with reinforcing ribs

Owner:HENGSHEN

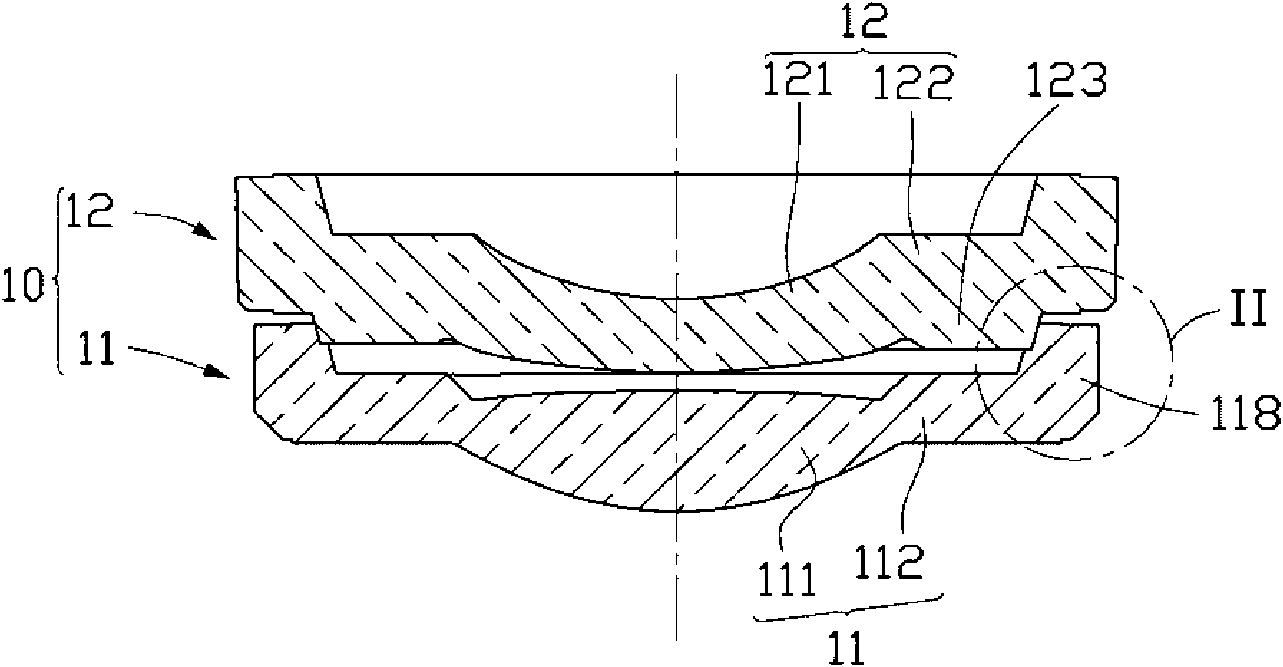

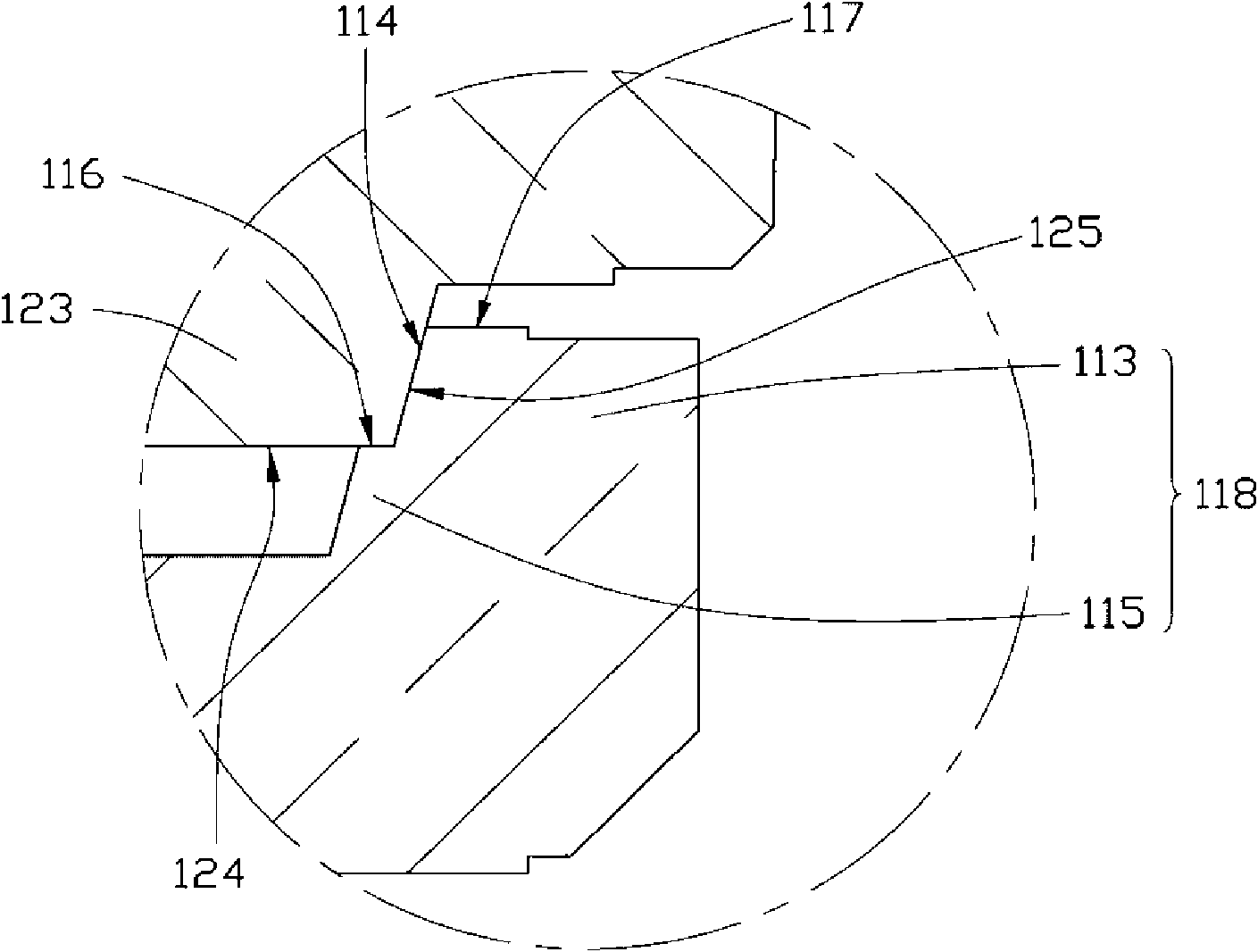

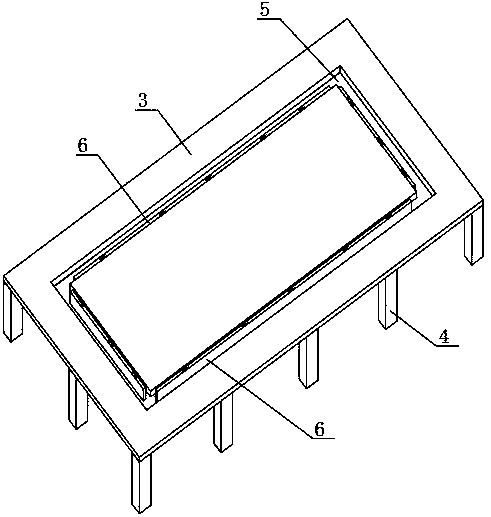

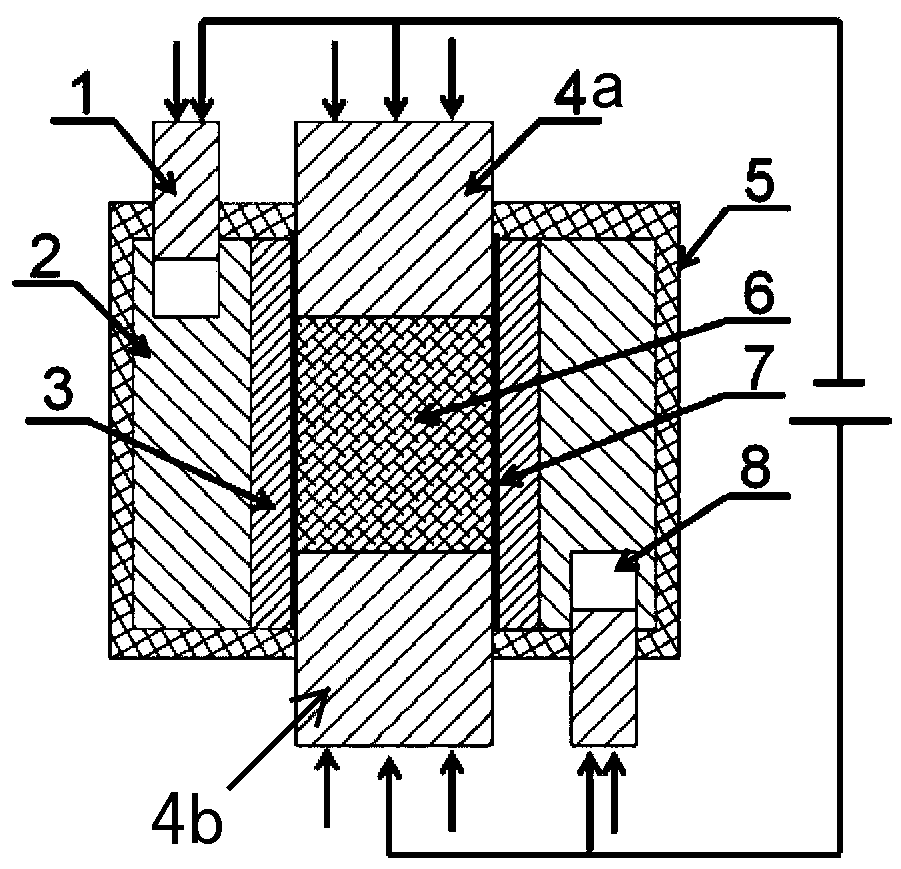

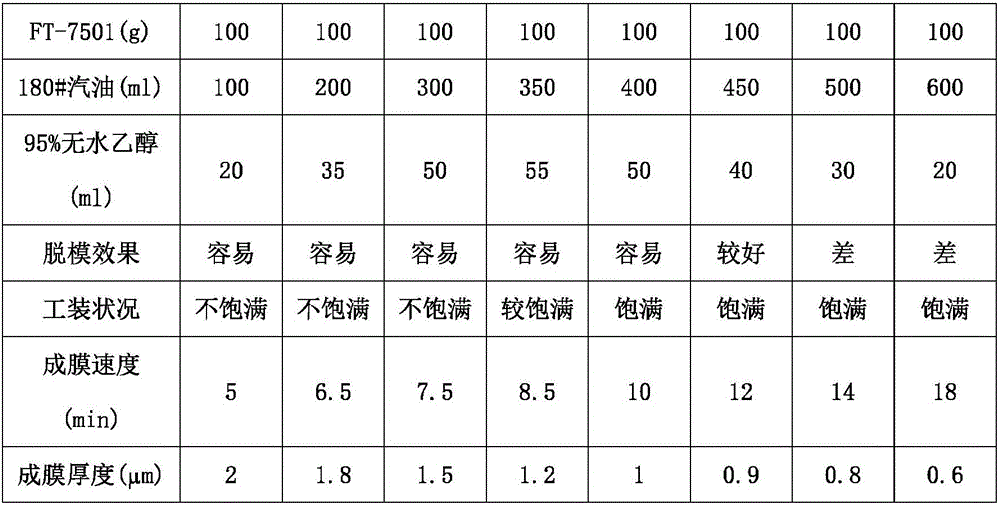

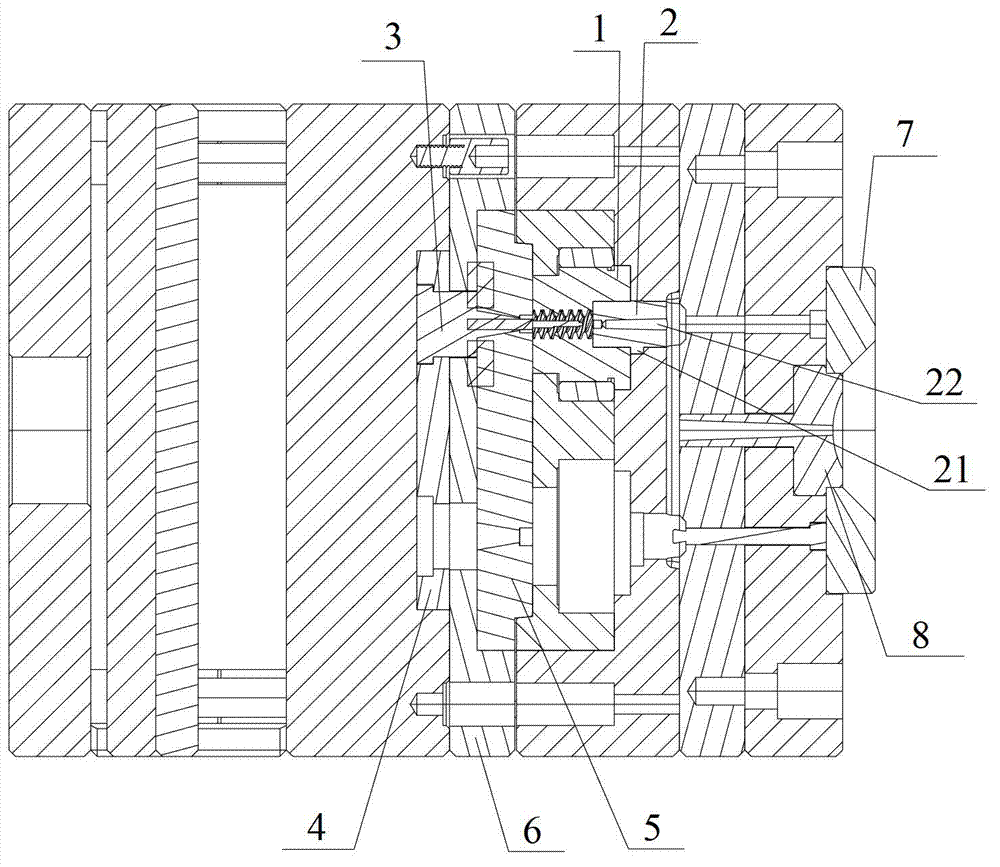

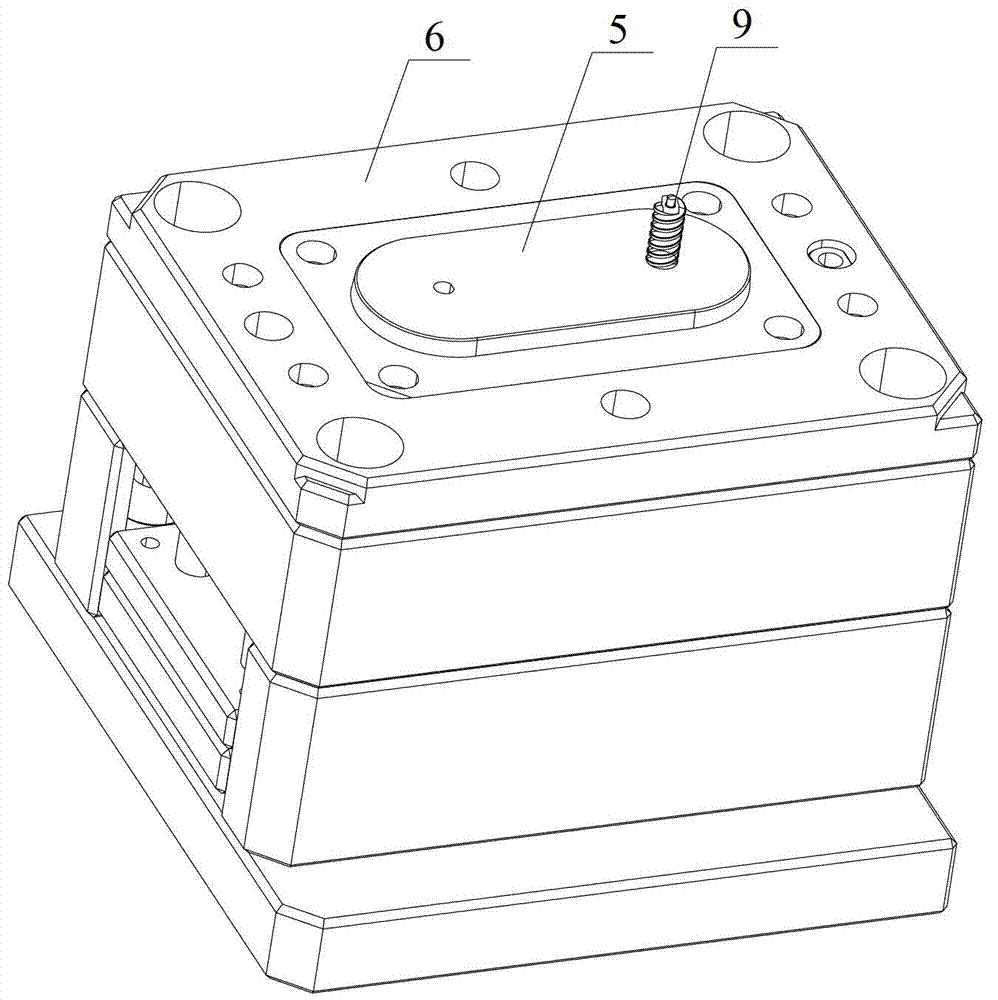

Autoclave die for forming parts with reinforcing ribs

The invention provides an autoclave die for forming parts with reinforcing ribs. The autoclave die comprises a die main body, a border and a boss group, wherein the die main body is provided with an annular groove and a rectangular groove; the border is embedded in the annular groove; the border and the boss group are provided with die release bolt holes, and further provided with fastening bolt holes; die release bolts are arranged in the die release bolt holes, and fastening bolts are arranged in the fastening bolt holes; the boss group is embedded in the rectangular groove, and comprises more than two bosses; and each boss is provided with an upper die release corner above the upper surface of the die main body, and provided with a lower die release corner below the upper surface of the die main body. According to the autoclave die, the boss group and the die main body are of a separated structure and can be independently detached, and during die release, the parts can be separated from the die main body with the boss group, thus die release difficulty for the parts with reinforcing ribs is greatly reduced; and the boss group is capable of controlling the dimensional accuracy of the holes, and the border is capable of controlling the overall dimensions of the parts, so that after-treatment is not required for the formed parts.

Owner:HENGSHEN

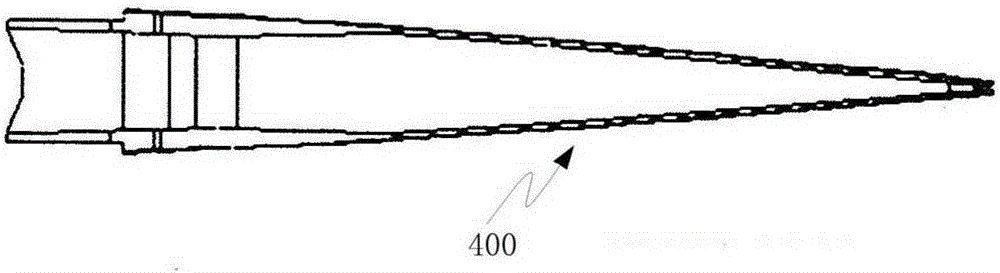

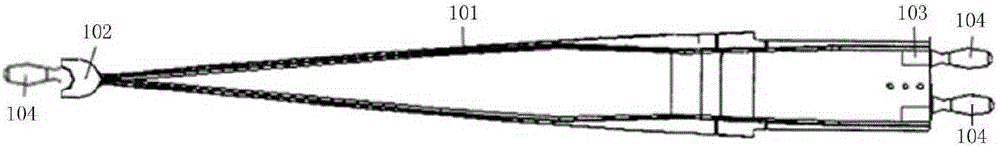

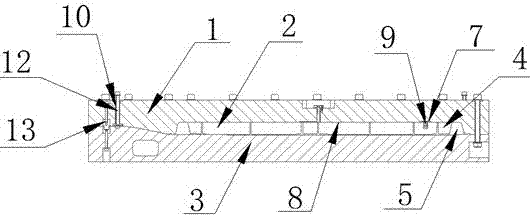

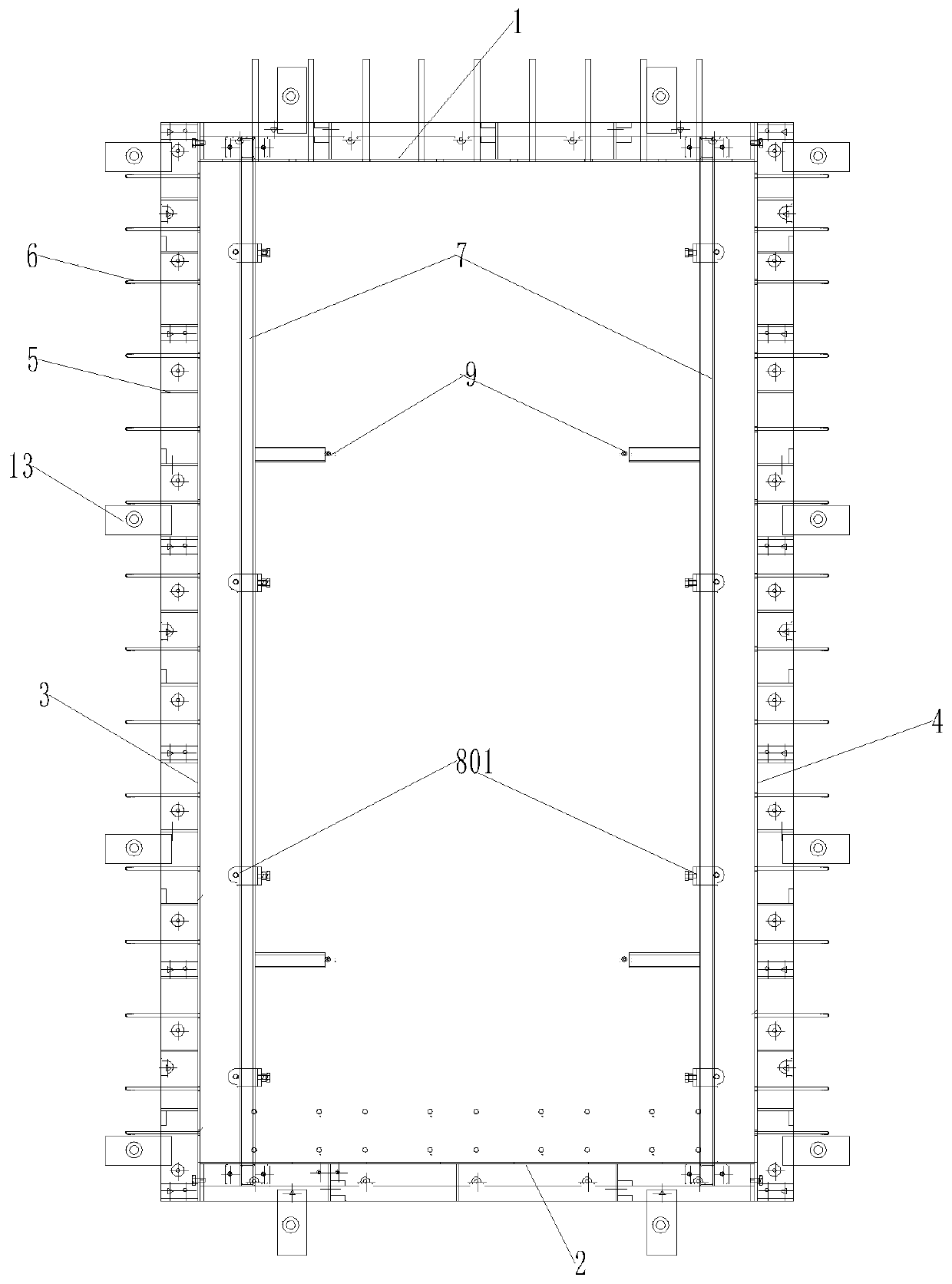

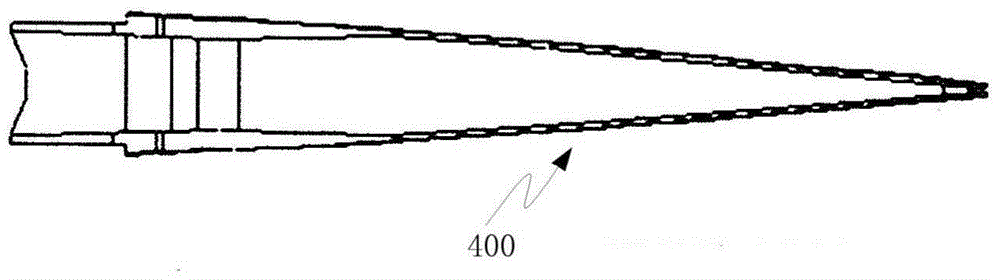

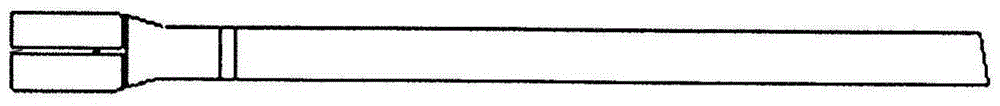

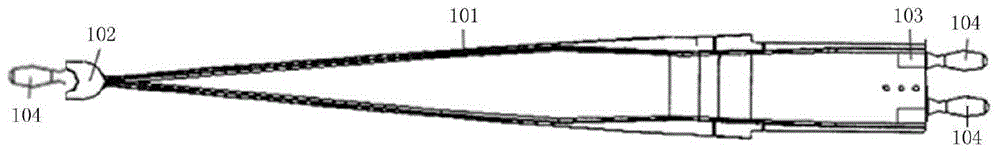

Spiral pulling-out type demolding tool for composite products and demolding process thereof

ActiveCN104723584AReduce Delamination DefectsImprove surface qualityDomestic articlesStructural engineeringMechanical engineering

The invention provides a spiral pulling-out type demolding tool for composite products and a demolding process thereof. The demolding tool comprises a spiral pulling-out assembly, a positioning assembly and a fixed part assembly, wherein the spiral pulling-out assembly is used for drawing a metal baffle, the positioning assembly is used for fixing the current position of the metal baffle, and the fixed part assembly is used for fixing a composite product, and the three assemblies are sequentially respectively fixed on a metal substrate. According to the demolding process based on the demolding tool, a stable tensile force is provided by using a screw rotating device, a stable vertical pulling-out force is applied to the metal baffle in the product, and finally, the metal baffle clamped in the composite product is perfectly taken out.

Owner:SHENYANG AIRCRAFT CORP

Combined prefabricated shear wall mold assembly and using method thereof

InactiveCN111070380AImprove molding qualityReduce manufacturing costDischarging arrangementMouldsMechanical engineeringShear wall

The invention belongs to the technical field of improvement of building prefabricated components, and discloses a combined prefabricated shear wall mold assembly and a using method thereof. The mold assembly comprises a pair of end molds and a pair of side molds, wherein the side molds and the end molds are alternately connected and fixed to form a prefabricated shear wall frame, each side mold comprises an upper pressing plate and a lower side mold, and the upper pressing plate is buckled and fixed on the lower side die. According to the technical scheme, the mold assembly has the advantagesof simplicity, convenience and rapidness in operation, good component forming quality and low mold manufacturing cost, the process is simplified, and the production efficiency is improved.

Owner:ZHONGTIAN CONSTR GROUP +1

Mold of worm with gears

Owner:CIXI SANPEI MACHINE

Plastic well injection molding device with wall thickness adjusting function

The invention discloses a plastic well injection molding device with a wall thickness adjusting function, and relates to the technical field of plastic well injection molding, the plastic well injection molding device comprises a feeding assembly, an outer mold, an inner mold, a thickness adjusting assembly, a cooling assembly, a lower rack and a discharging assembly, the feeding assembly, the outer mold and the lower rack are in fastening connection, and the inner mold and the outer mold are in fastening connection; one end of the thickness adjusting assembly is arranged on the inner surface of the outer mold, the other end of the thickness adjusting assembly is arranged on the outer surface of the inner mold, one end of the cooling assembly is fixedly connected with the lower rack, and the other end of the cooling assembly is embedded into the outer mold and the inner mold. According to the feeding assembly, temperature difference energy is converted into continuous vibration energy, the uniform heating effect of injection molding materials is promoted, the heating speed is increased, and energy loss is reduced. The wall thickness of the plastic well can be intelligently adjusted through the thickness adjusting assembly, and products of various specifications can be produced through one forming device.

Owner:上海泓伟新材料有限公司

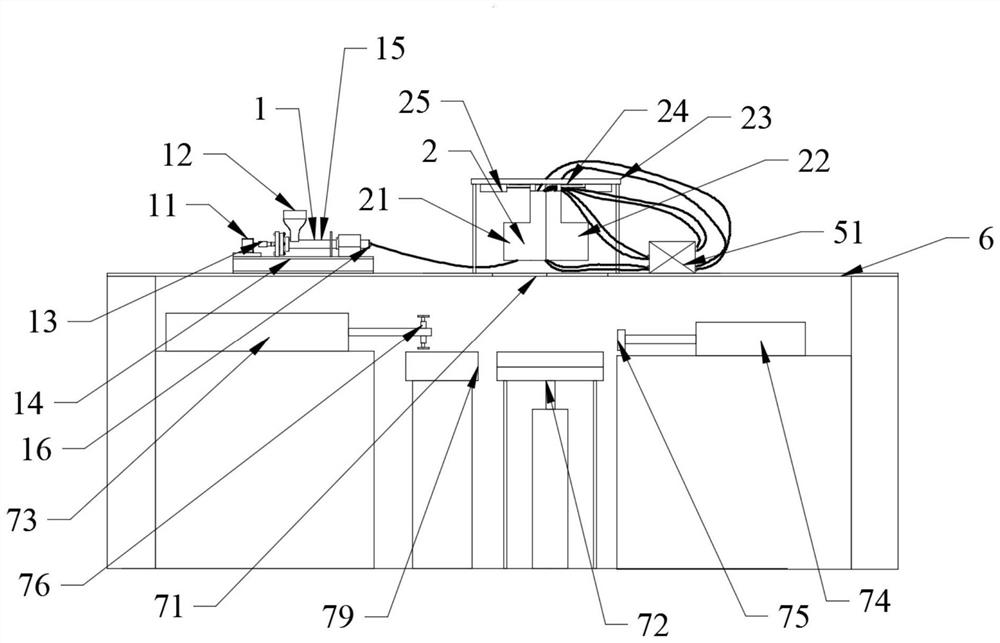

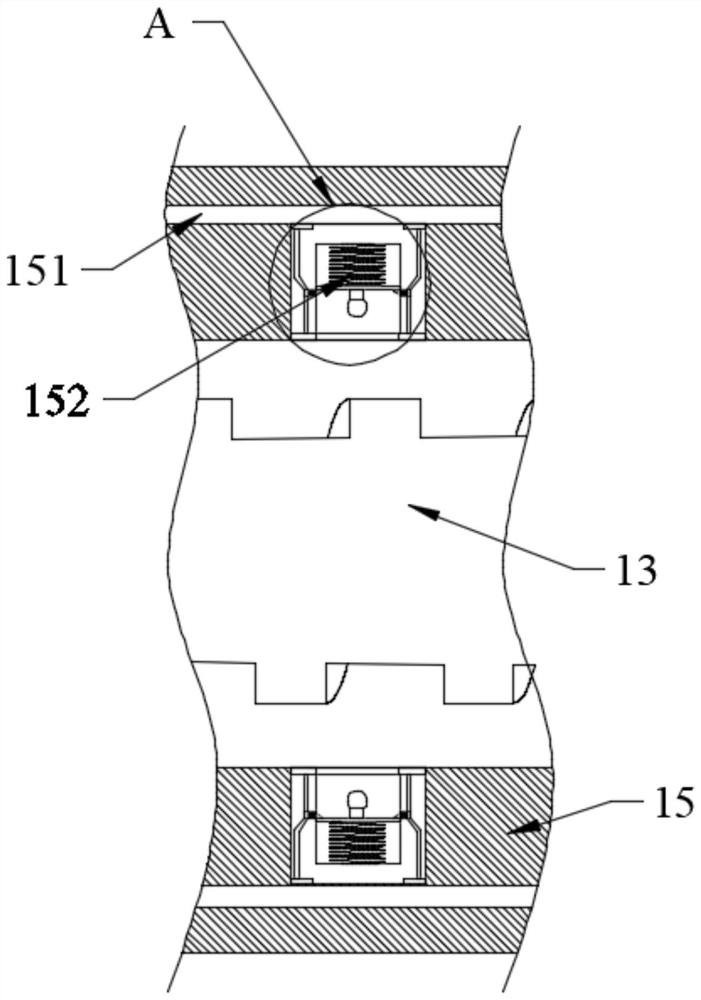

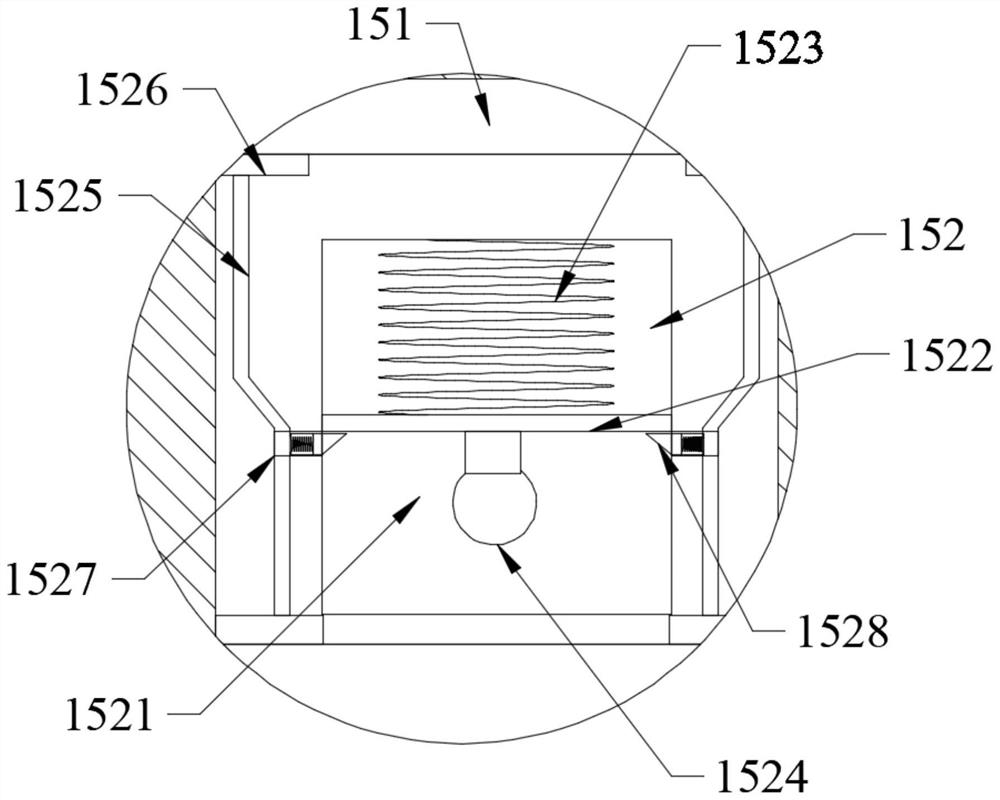

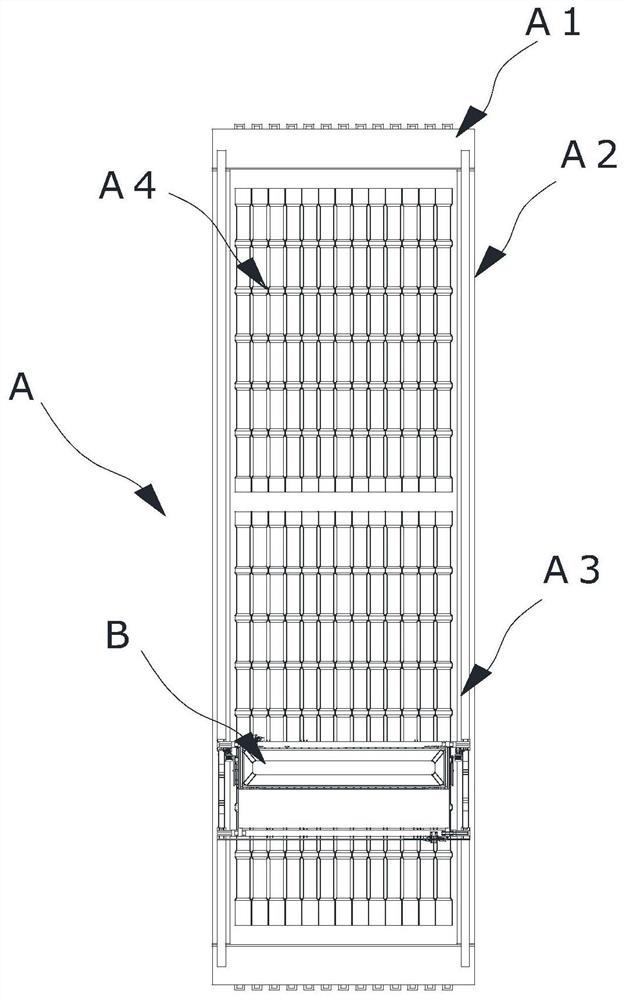

Production method and production equipment of variable cross-section precast pile

PendingCN114102818ASimple structureIncrease productivityMouldsFeeding arrangmentsRoughcastStructural engineering

The invention discloses a production method and production equipment of a variable-cross-section precast pile, and the method comprises the following steps: injecting concrete into mold cavities with openings in the tops of a plurality of molds so as to carry out primary material distribution; pushing the uniform material in the width direction of the mold; the vibrating mechanism is used for vibrating and compacting the uniformized concrete; the scraping mechanism is used for scraping redundant concrete inside and outside the die cavity so as to perform primary scraping; forming a variable cross-section prefabricated blank; secondary material distribution is conducted on the top of the variable cross-section prefabricated blank in a spaced mode, so that at least one top protrusion distributed in the length direction at intervals is molded on the top, and the top protrusion corresponds to the large-diameter section of the mold cavity; redundant concrete on the top protrusion is scraped off; and the variable-cross-section precast pile is formed. According to the scheme, the variable-cross-section prefabricated blank is firstly formed in the mold cavity through casting, then the top of the variable-cross-section prefabricated blank is modeled through the modeling procedure, finally, the variable-cross-section prefabricated pile is formed, and the demolding difficulty is greatly reduced.

Owner:周兆弟

Tooling and manufacturing method for manufacturing variable-section I-shaped composite material parts

The invention relate to a tool and production method for producing a variable cross-section type I-shaped composite part. According to the technical scheme, the tool is composed of an upper male die, a lower male die, a middle spacer plate and composite even pressing plates on the two sides. The production method comprises the steps that firstly, the composite even pressing plates are made; then, carbon fiber prepregs cut into fixed sizes are laid on a forming tool; finally all parts of the carbon fiber prepregs laid well are transferred from the forming tool to an assembly solidification tool for integral assembly, and packaged in a vacuum bag; the fully sealed prepreg blank is subjected to solidification forming under the conditions of 120-180 DEG C and 0.3-0.8 mpa for 1-3 hours; and after cooling, the composite even pressing plates, the middle spacer plate, the upper male die and the lower male die are detached to obtain the variable cross-section type I-shaped composite part. According to the production process, the pressure transmission efficiency of the part in the solidification process can be improved; generation of the structure defect of the part is reduced; the shape and the internal quality of the part are ensured.

Owner:SHENYANG AIRCRAFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com