Patents

Literature

37results about How to "Easy demoulding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

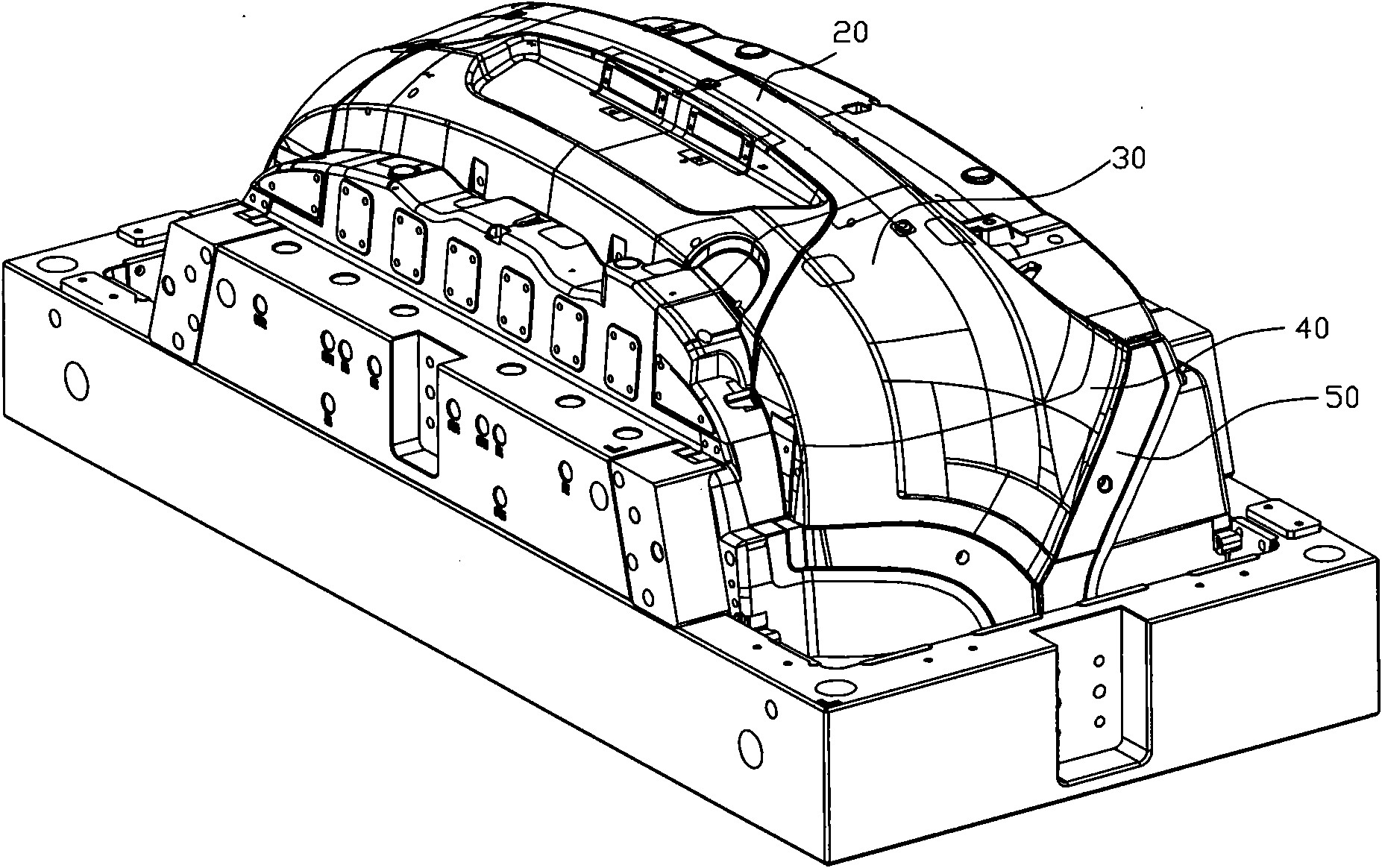

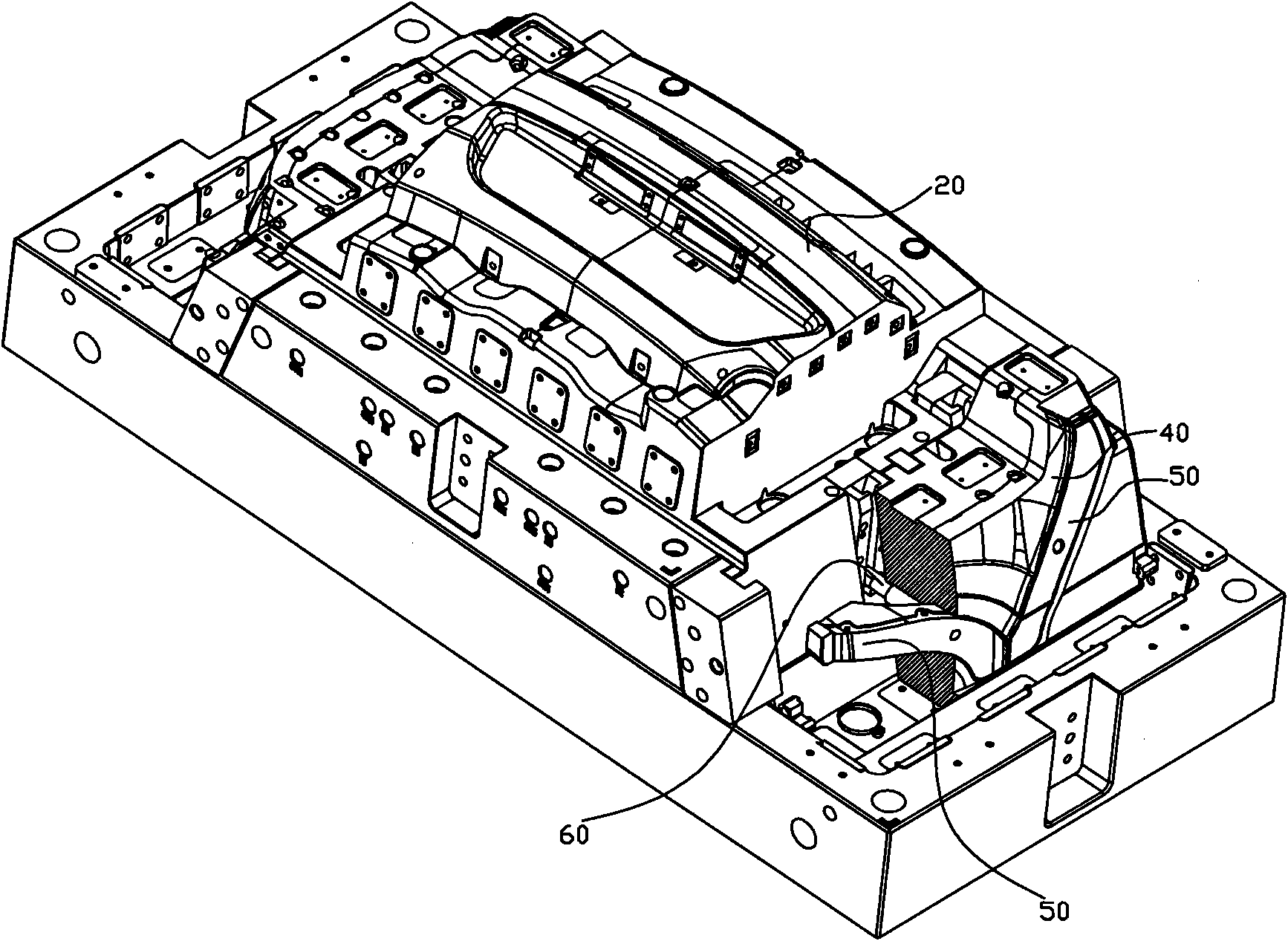

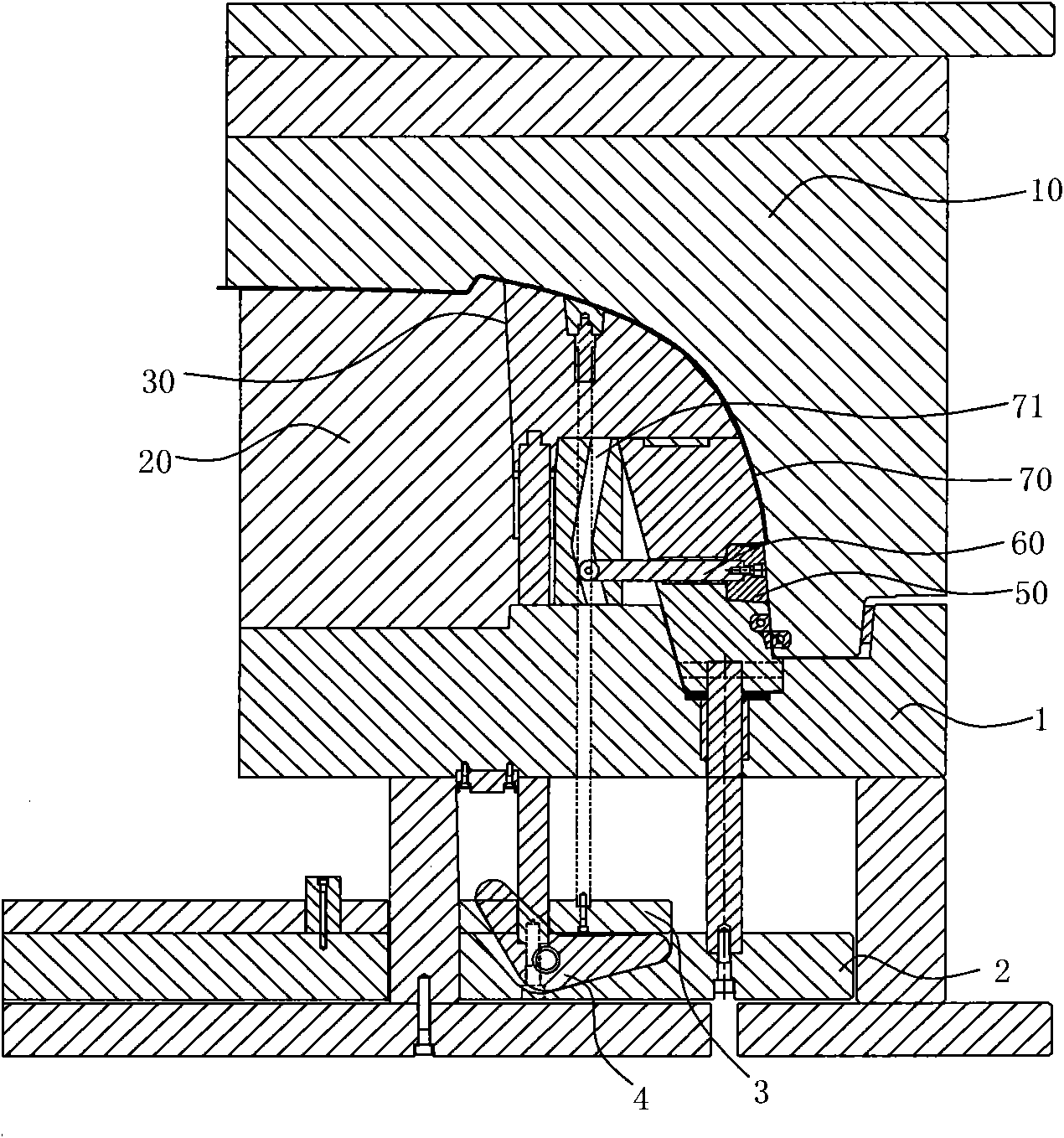

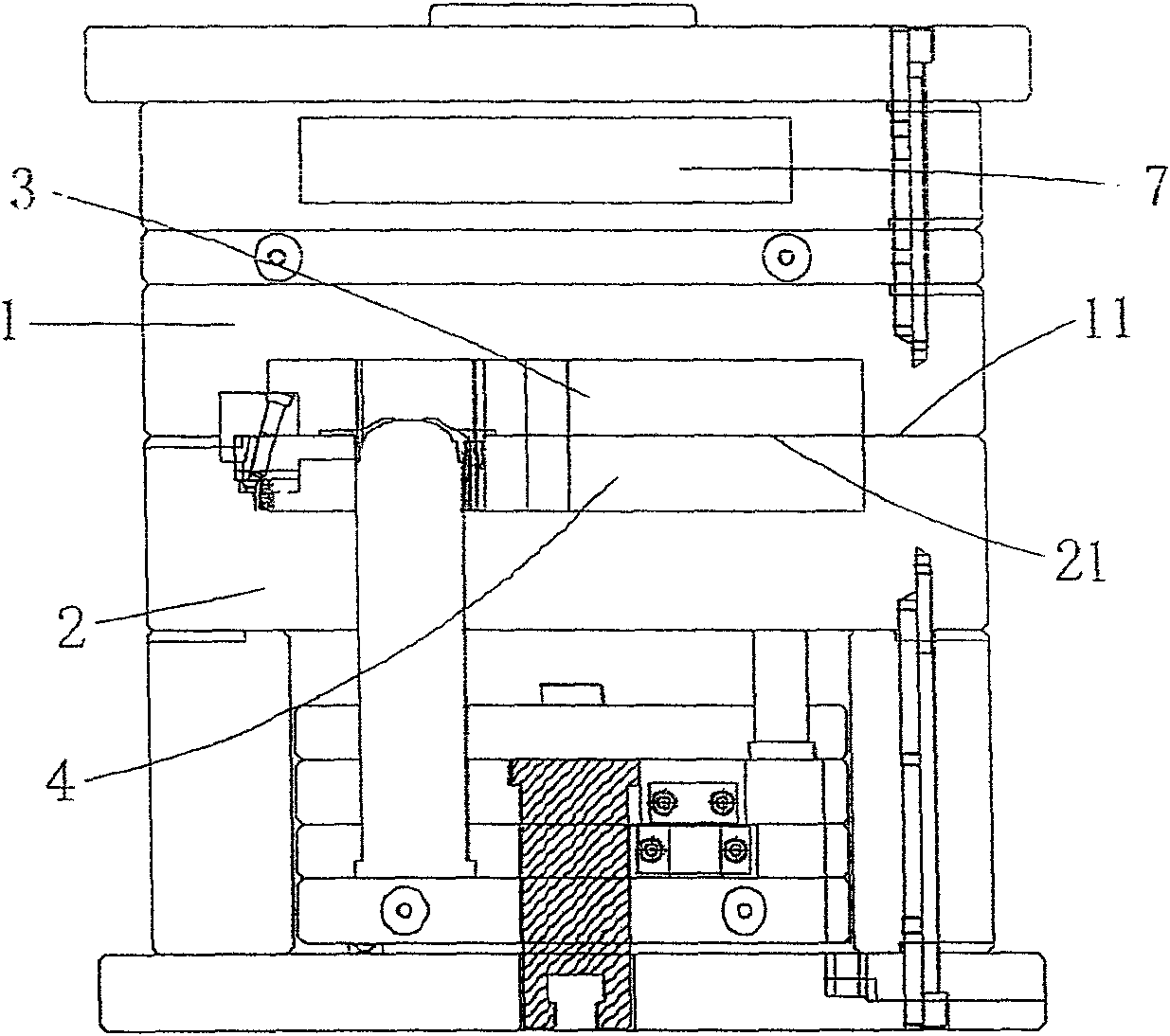

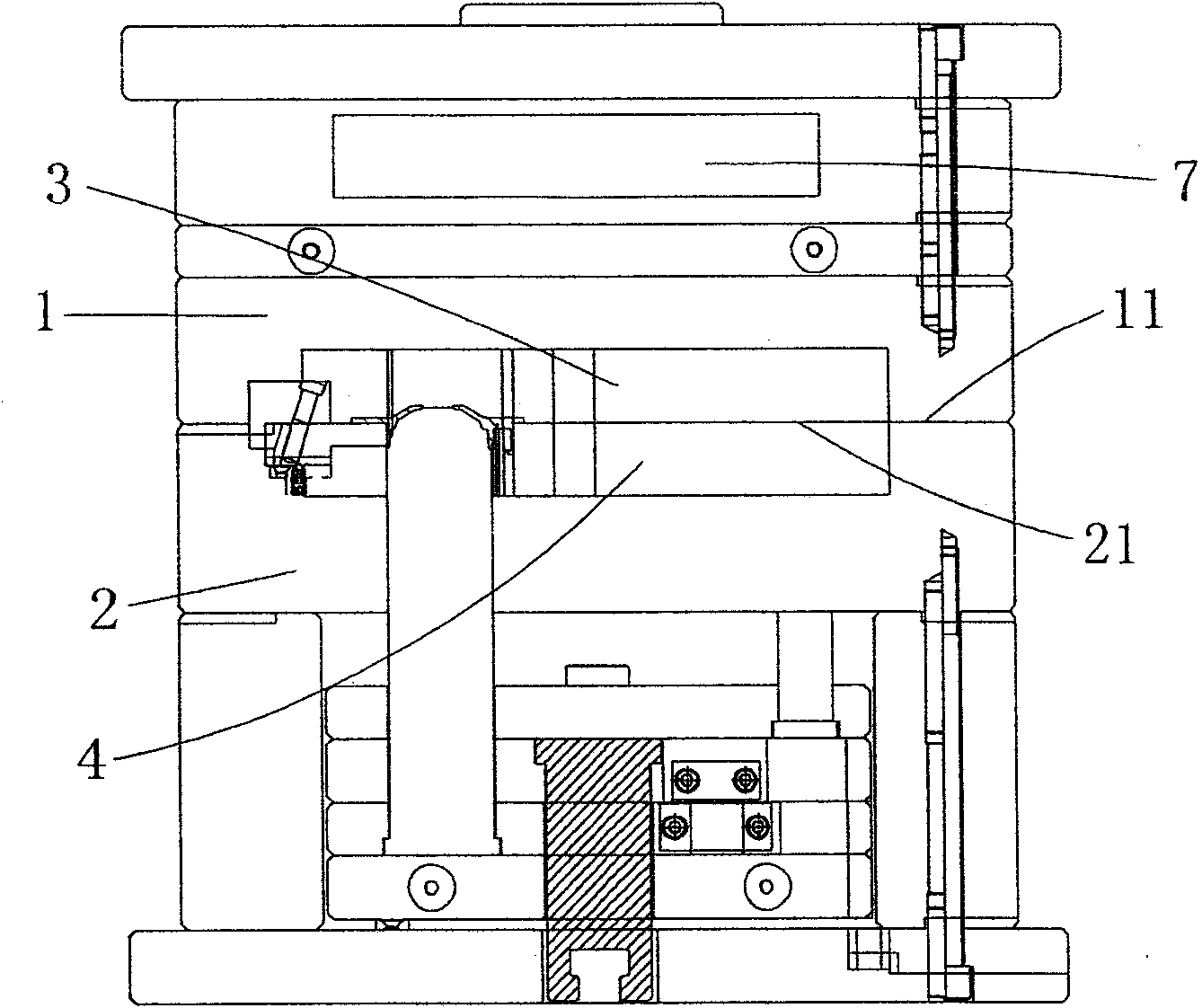

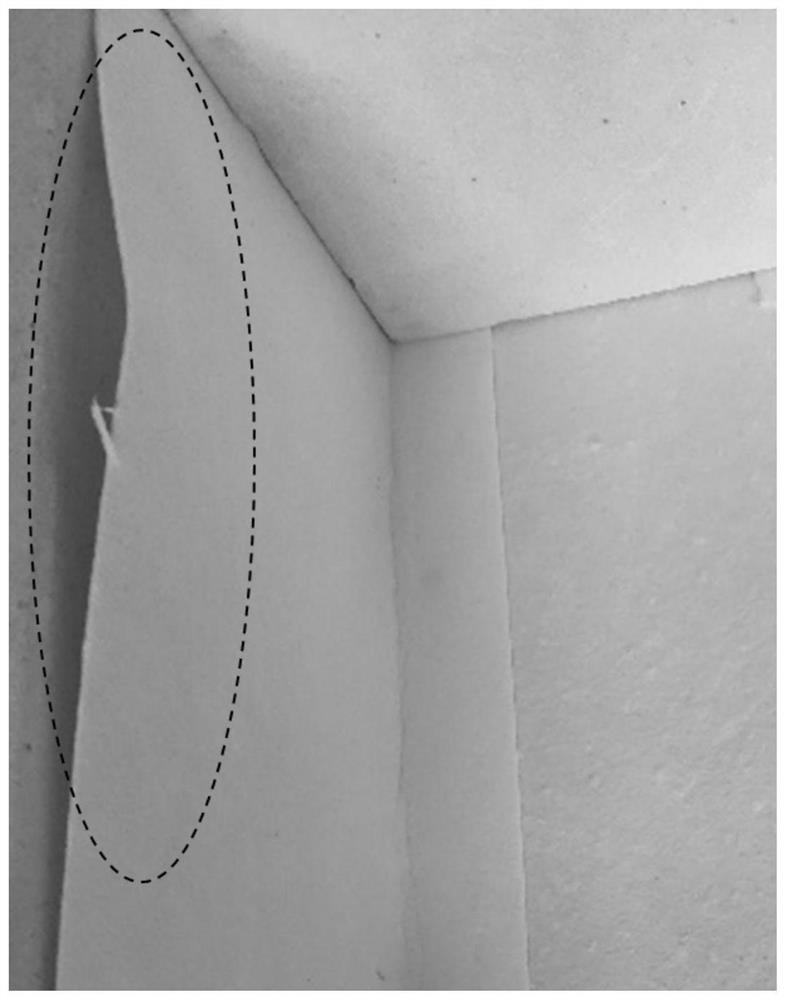

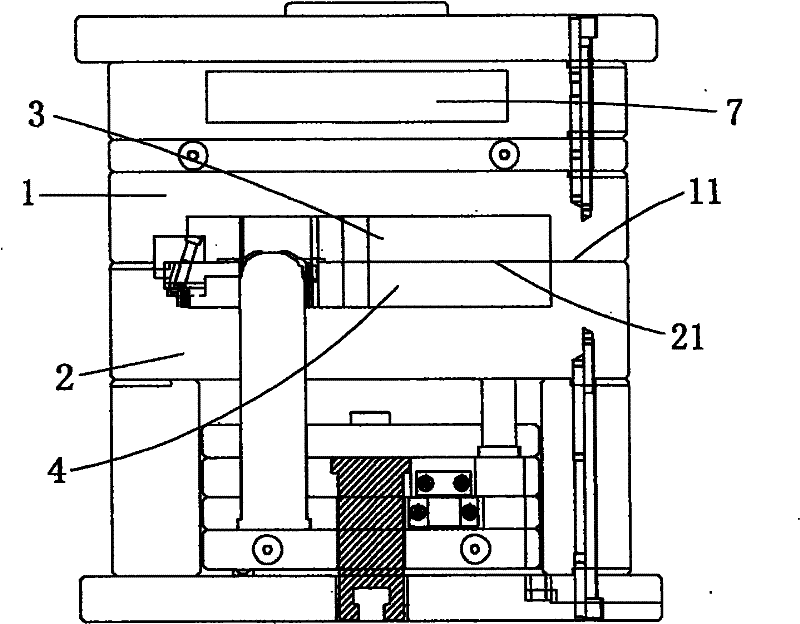

Mould

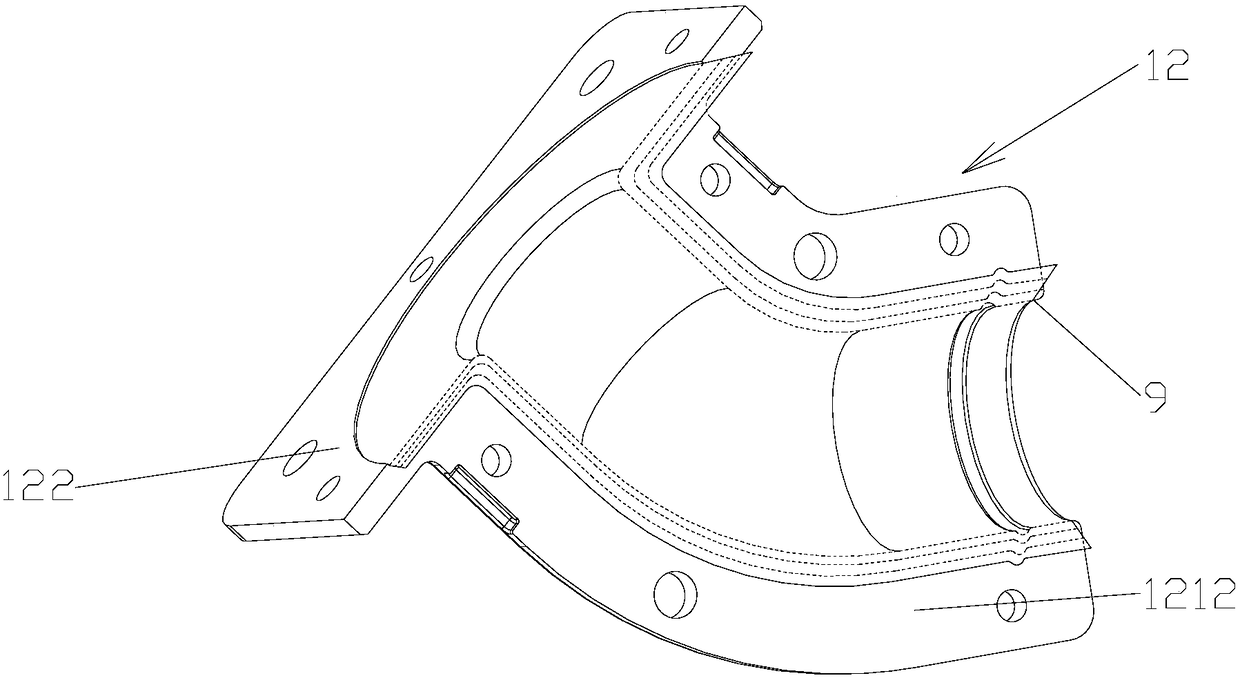

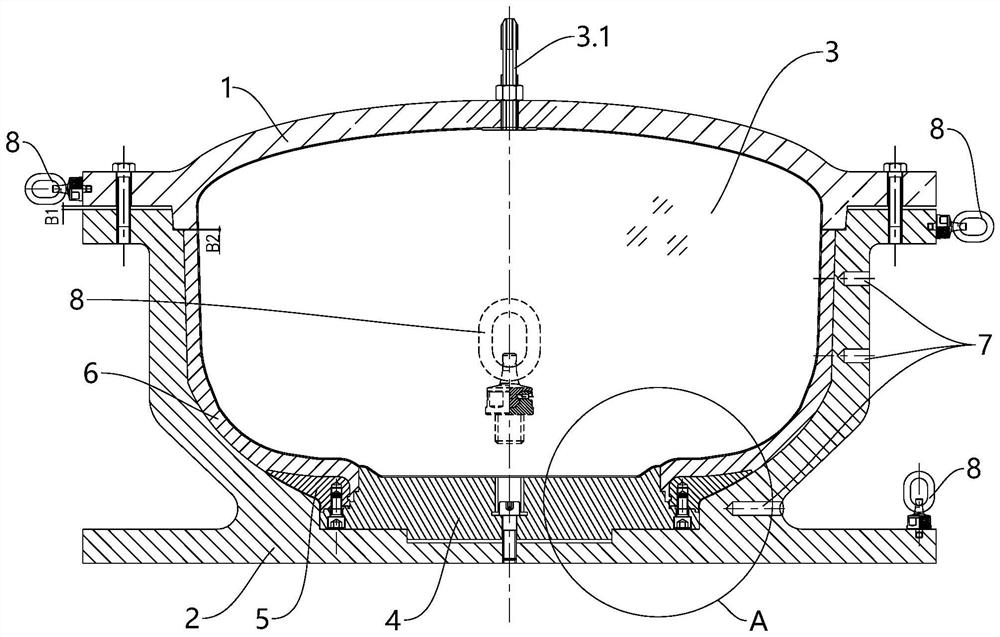

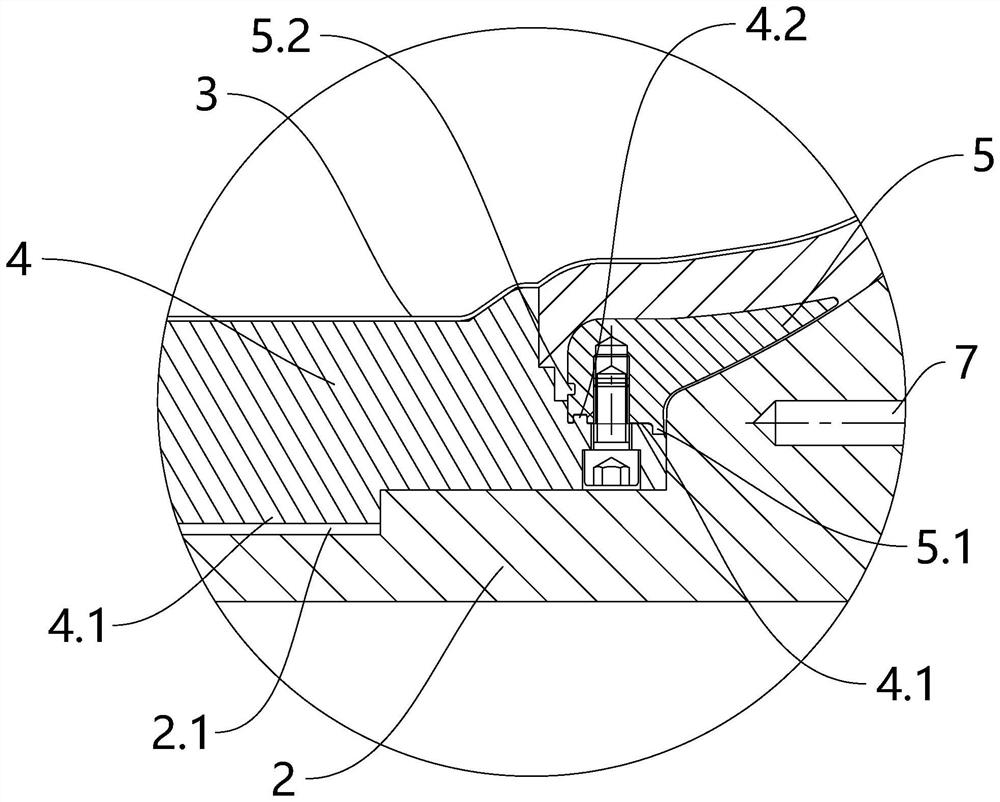

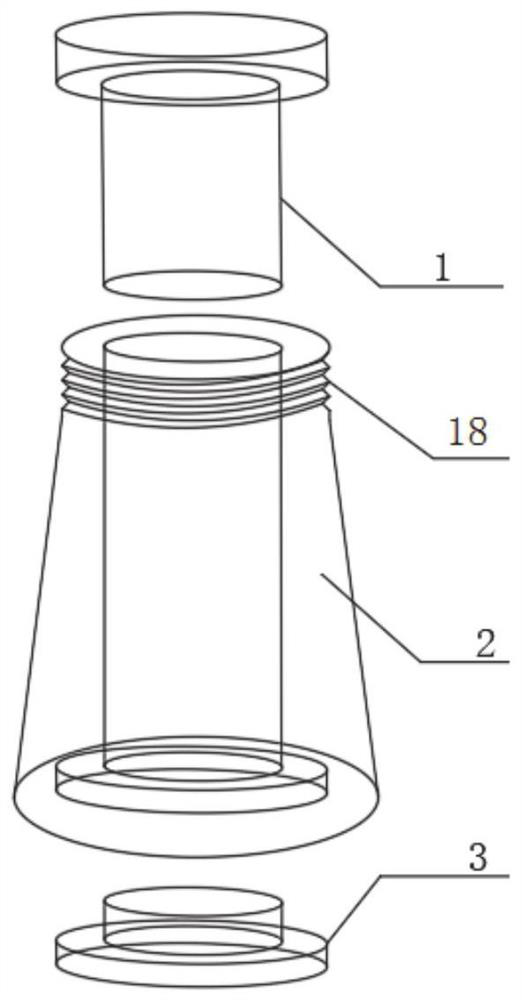

InactiveCN101823320AIncrease productivityEasy demoulding processDomestic articlesFlangingMaterials science

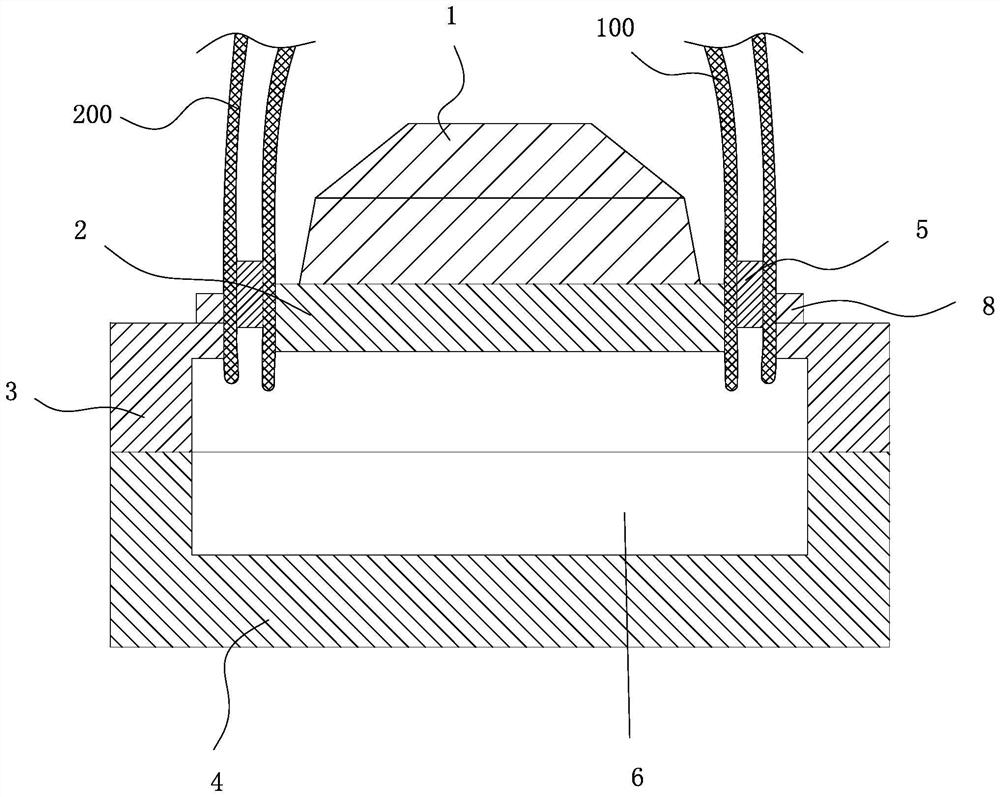

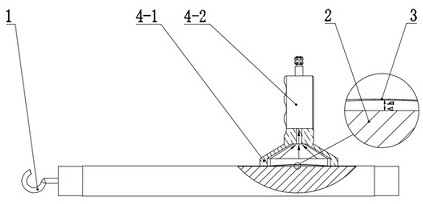

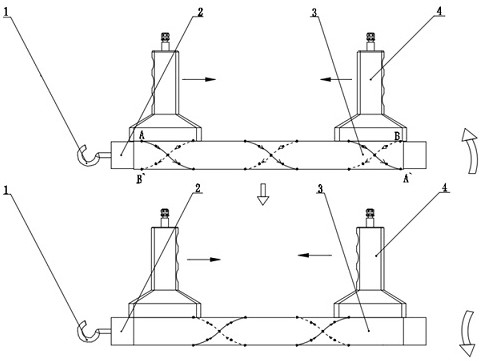

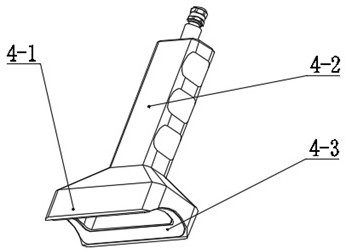

The invention aims to provide a mould, which is convenient for demoulding and ensures a product parting line located at the side of a veneer to improve the smoothness and flatness of the veneer. The mould comprises an integrative front mould component and a rear mould component, the edge of the moulding surface of the front mould component extends to the side of the veneer of the product to be processed, the rear mould component comprises a rear mould mold core, a rear mould straight-acting mold core, a tilt-acting mold core, a flanging moulding block and the like; the rear mould mold core, the straight-acting mold core and the tilt-acting mold core of the rear mould are combined and the flanging moulding block is matched with the flanging moulding slot arranged on the tilt-acting mold core mutually to conveniently realize the demoulding process, and the outer surface of the produced product is smooth and trim, namely the veneer, thereby avoiding the phenomena of flashing and burr on the outer surface of the product, having no need of implementing finishing and polishing treatment on the outer surface and significantly improving production efficiency.

Owner:合肥星通橡塑有限公司

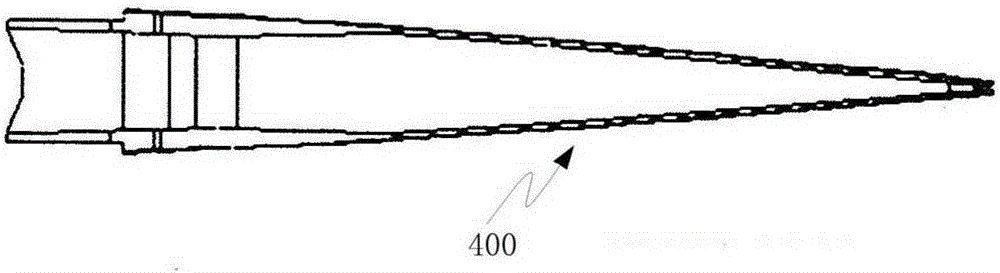

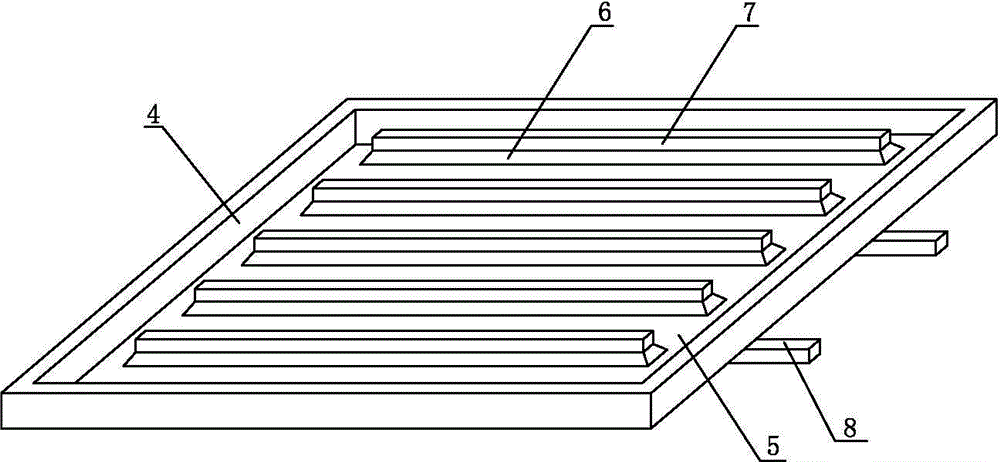

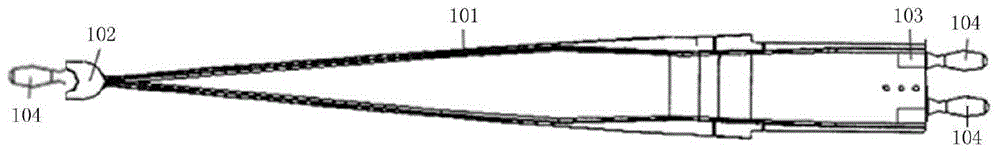

Tool and production method for producing variable cross-section type I-shaped composite part

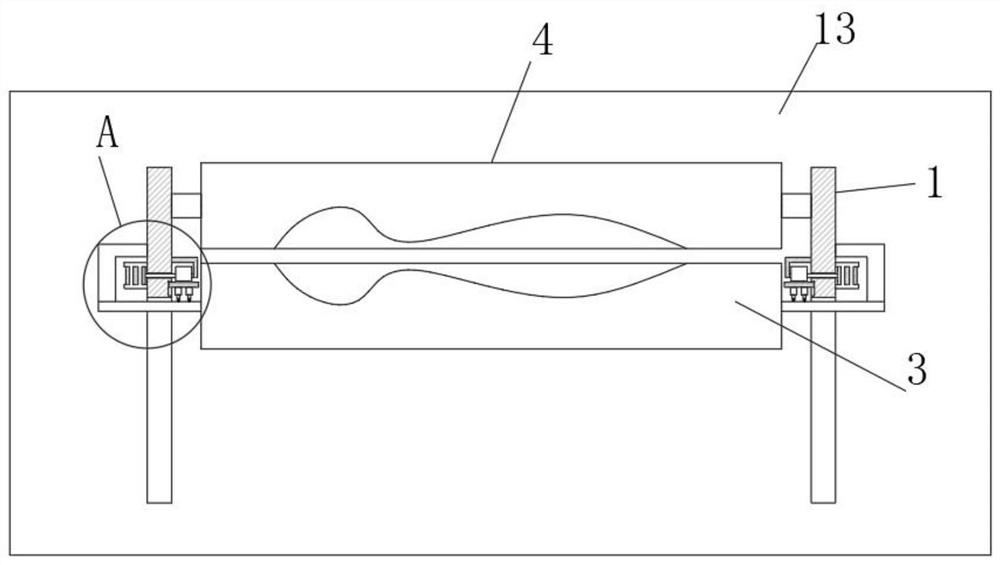

The invention relate to a tool and production method for producing a variable cross-section type I-shaped composite part. According to the technical scheme, the tool is composed of an upper male die, a lower male die, a middle spacer plate and composite even pressing plates on the two sides. The production method comprises the steps that firstly, the composite even pressing plates are made; then, carbon fiber prepregs cut into fixed sizes are laid on a forming tool; finally all parts of the carbon fiber prepregs laid well are transferred from the forming tool to an assembly solidification tool for integral assembly, and packaged in a vacuum bag; the fully sealed prepreg blank is subjected to solidification forming under the conditions of 120-180 DEG C and 0.3-0.8 mpa for 1-3 hours; and after cooling, the composite even pressing plates, the middle spacer plate, the upper male die and the lower male die are detached to obtain the variable cross-section type I-shaped composite part. According to the production process, the pressure transmission efficiency of the part in the solidification process can be improved; generation of the structure defect of the part is reduced; the shape and the internal quality of the part are ensured.

Owner:SHENYANG AIRCRAFT CORP

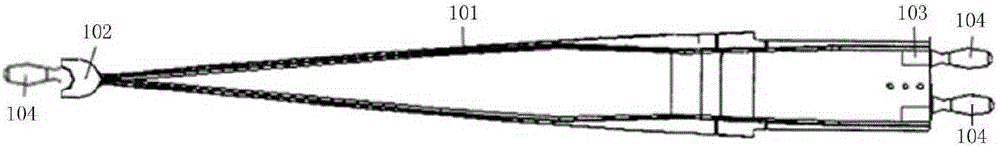

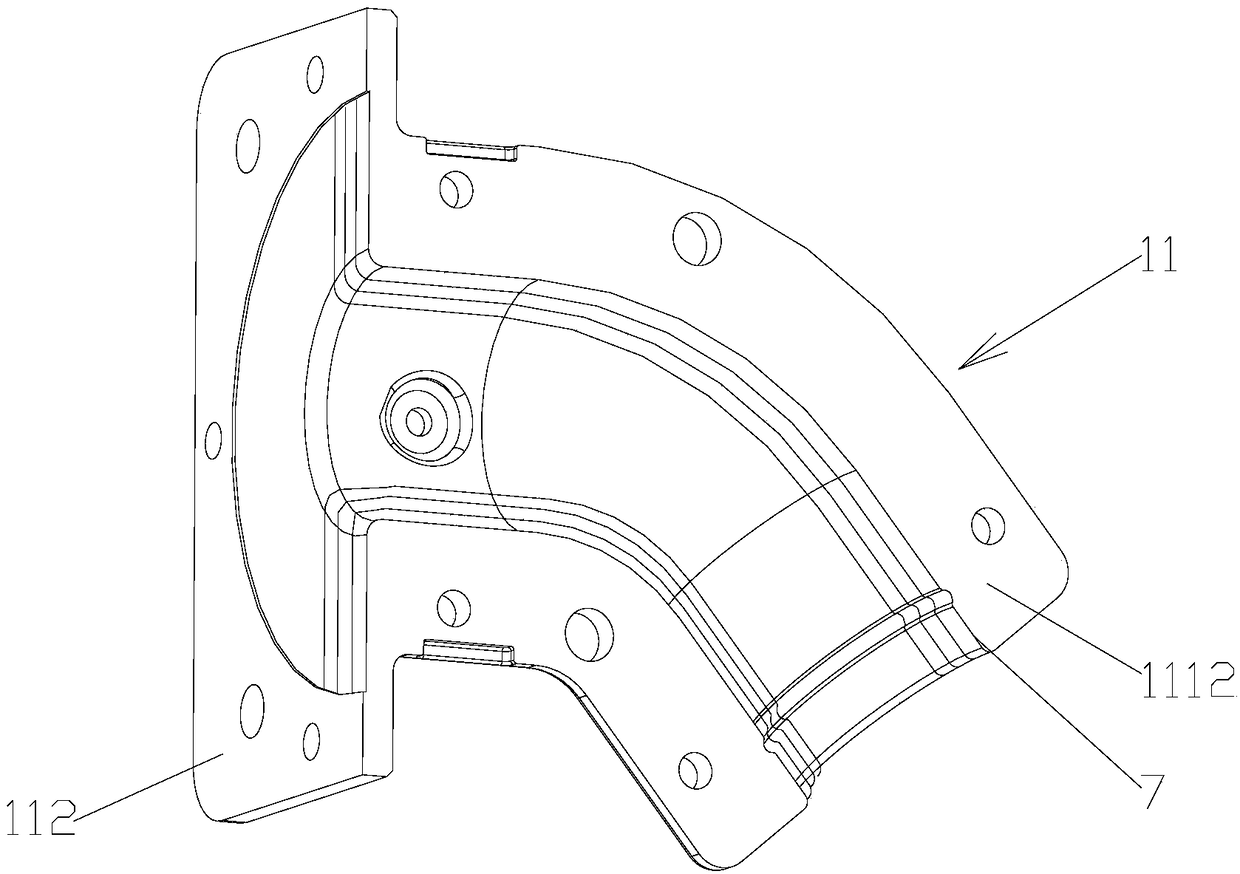

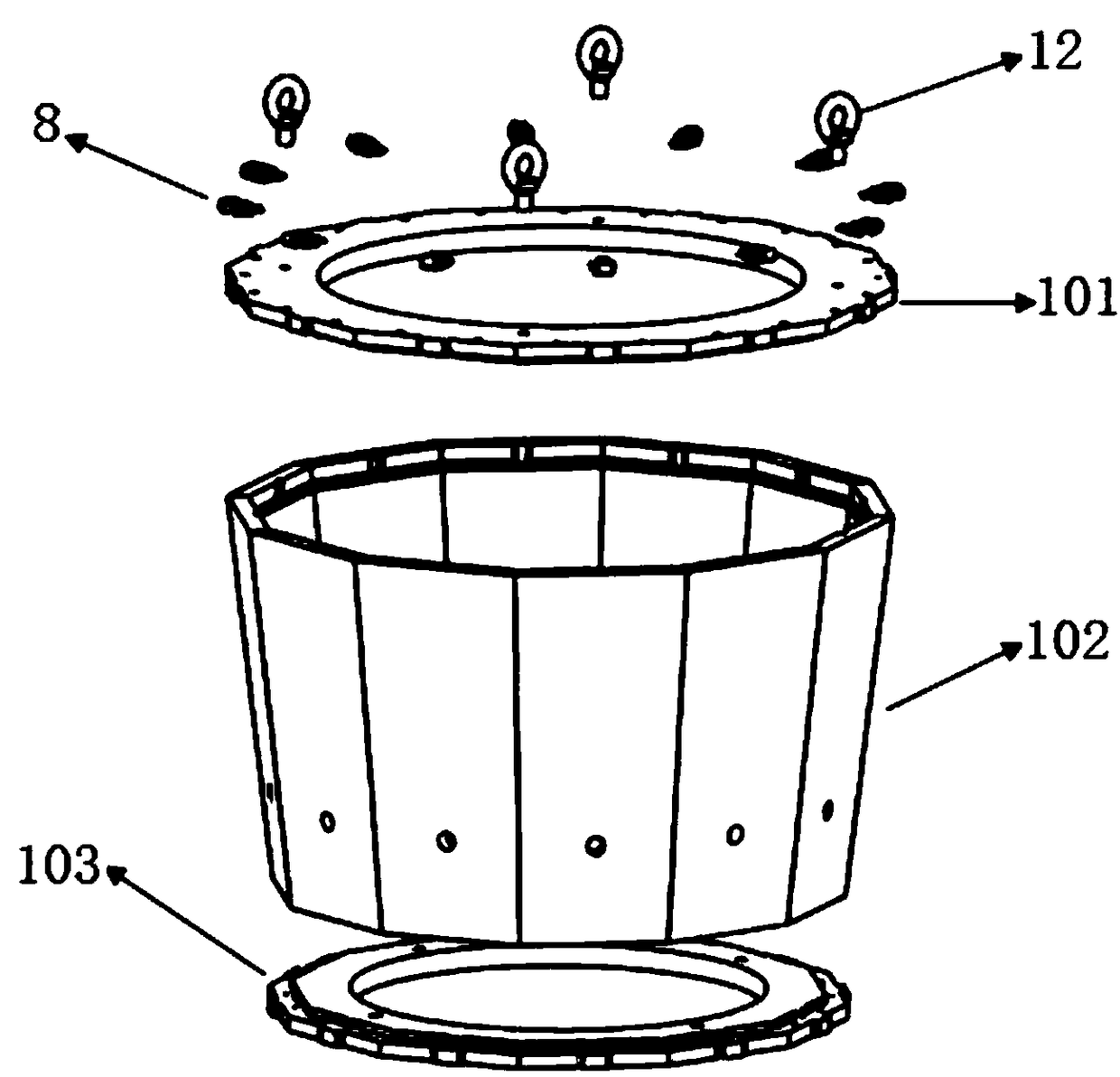

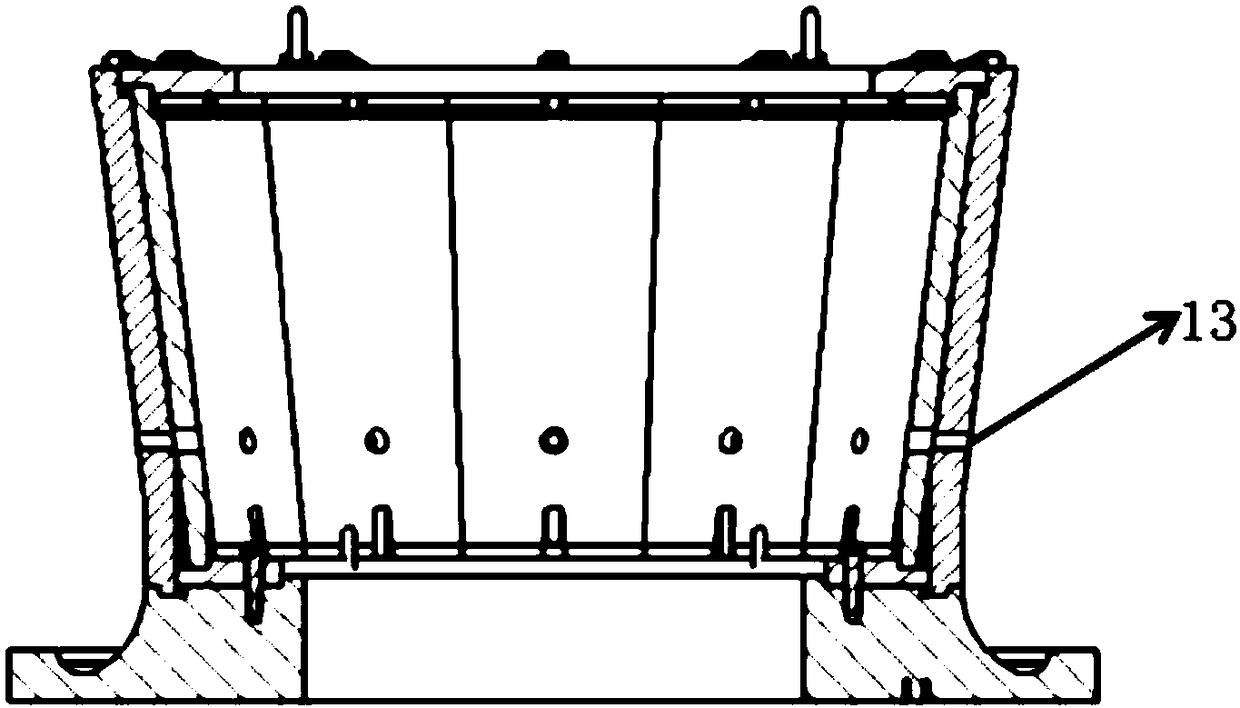

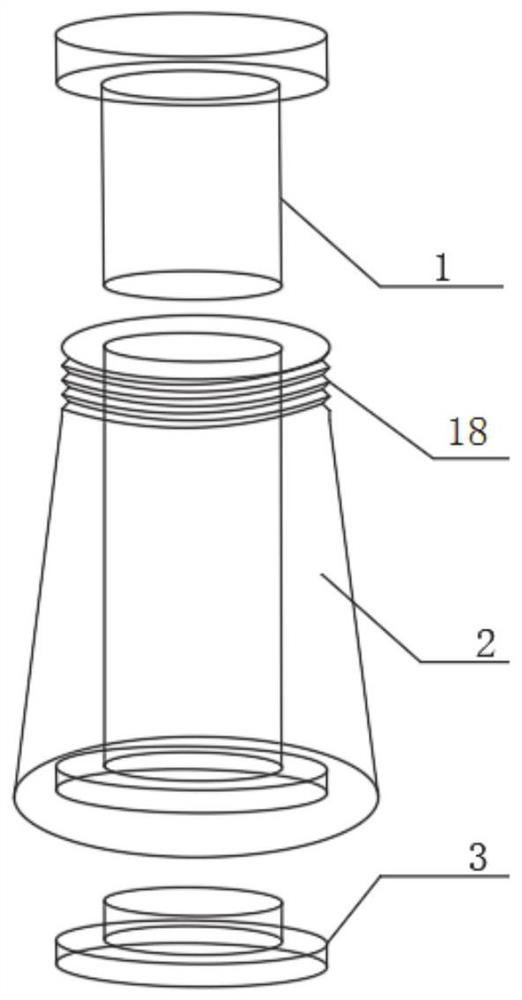

Forming mold and forming method for composite material tubular parts with flanges

InactiveCN108407323AEasy demoulding processLaying is simple and quickDomestic articlesPipeMold removal

The invention discloses a forming mold for composite material tubular parts with flanges. The forming mold for the composite material tubular parts with the flanges comprises a first combined mold anda second combined mold; the first combined mold is provided with a first pipe cavity and a first annular cavity; the first pipe cavity and the first annular cavity communicate with each other at theposition of a pipe port in one end of the first pipe cavity; the second combined mold is provided with a second pipe cavity and a second annular cavity; the second pipe cavity and the second annular cavity communicate with each other at the position of a pipe port in one end of the second pipe cavity; the first combined mold and the second combined mold are subjected to mold closing, and the firstannular cavity is made to communicate with the second annular cavity; and a forming method for using the forming mold to machine the composite material tubular parts with the flanges is disclosed. The forming mold has the beneficial effects that by performing combined design on the forming mold, in the forming process of the composite material tubular parts with the flanges, paving and pasting ofprepreg can be easier and faster, and operation is convenient; after curing molding of the tubular parts, demolding of the forming mold can be achieved easily, and operation is easy and convenient; and the production efficiency is improved, and practicability is high.

Owner:JIANGSU MEILONG AVIATION COMPONENTS

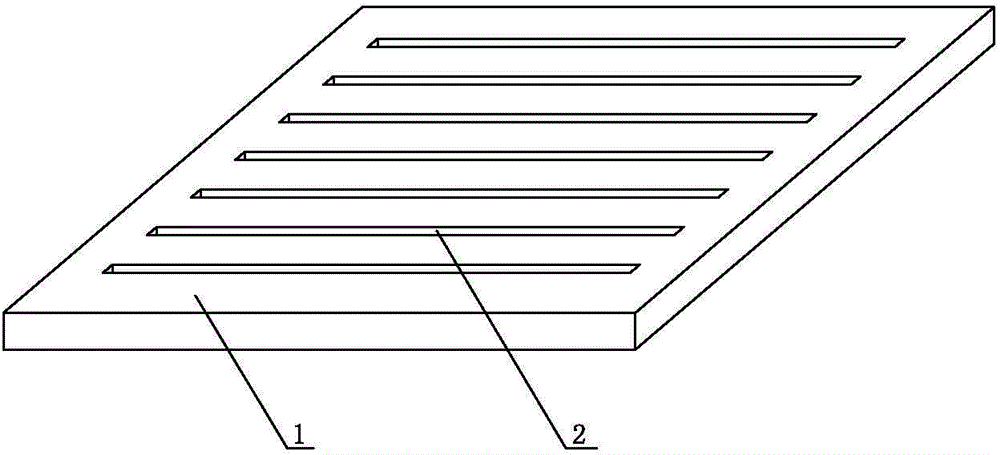

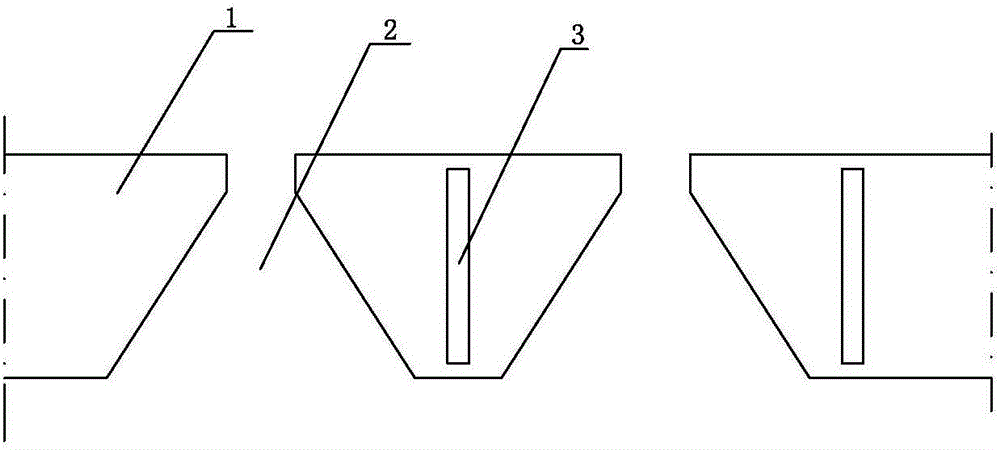

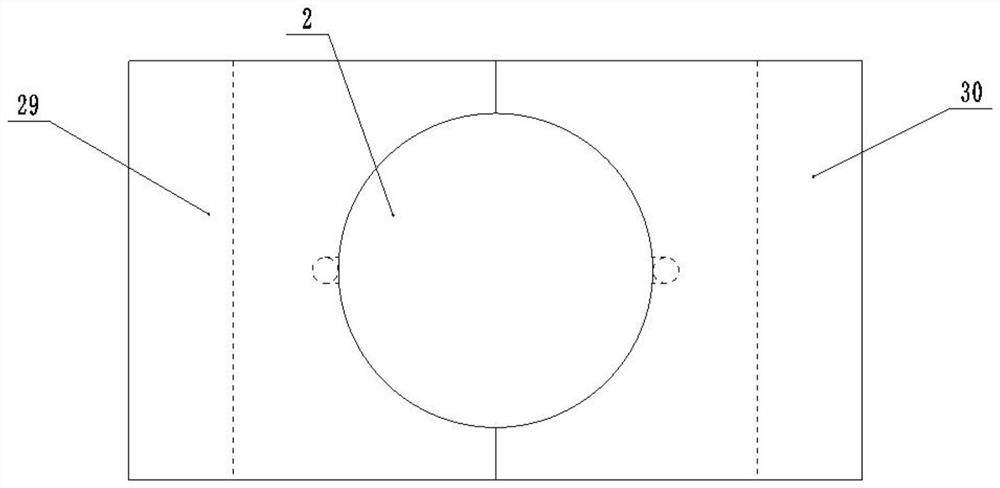

Trapezoid manure leaking floor and manufacturing mold assembly thereof

ActiveCN105104214ADesign scienceReasonable structureDischarging arrangementMouldsUltimate tensile strengthManure

The invention discloses a trapezoid manure leaking floor and a manufacturing mold assembly thereof, and relates to a pig house. The trapezoid manure leaking floor and the manufacturing mold assembly are characterized in that a plurality of manure leaking seams are formed in the trapezoid manure leaking floor at equal intervals, the cross section of each manure leaking seam is in a trapezoid shape with a small upper opening and a big lower opening, and a reinforcing steel bar frame is arranged in the portion, between every two adjacent manure leaking seams, of the manure leaking floor and buried vertically so that the strength of the manure leaking floor can be improved. The manufacturing mold assembly comprises a manure leaking floor mold and a demolding tool. The trapezoid manure leaking floor is manufactured through the manure leaking floor mold, and the demolding procedure is rapidly completed through the demolding tool. By means of the trapezoid manure leaking floor and the manufacturing mold assembly, concrete is directly poured into the mold, the manure leaking floor with the trapezoid seams is manufactured through the mold with trapezoid protrusions, the demolding tool is used in cooperation with a forklift, and demolding work can be rapidly conducted.

Owner:YUNNAN SHENNONG AGRI IND GROUP

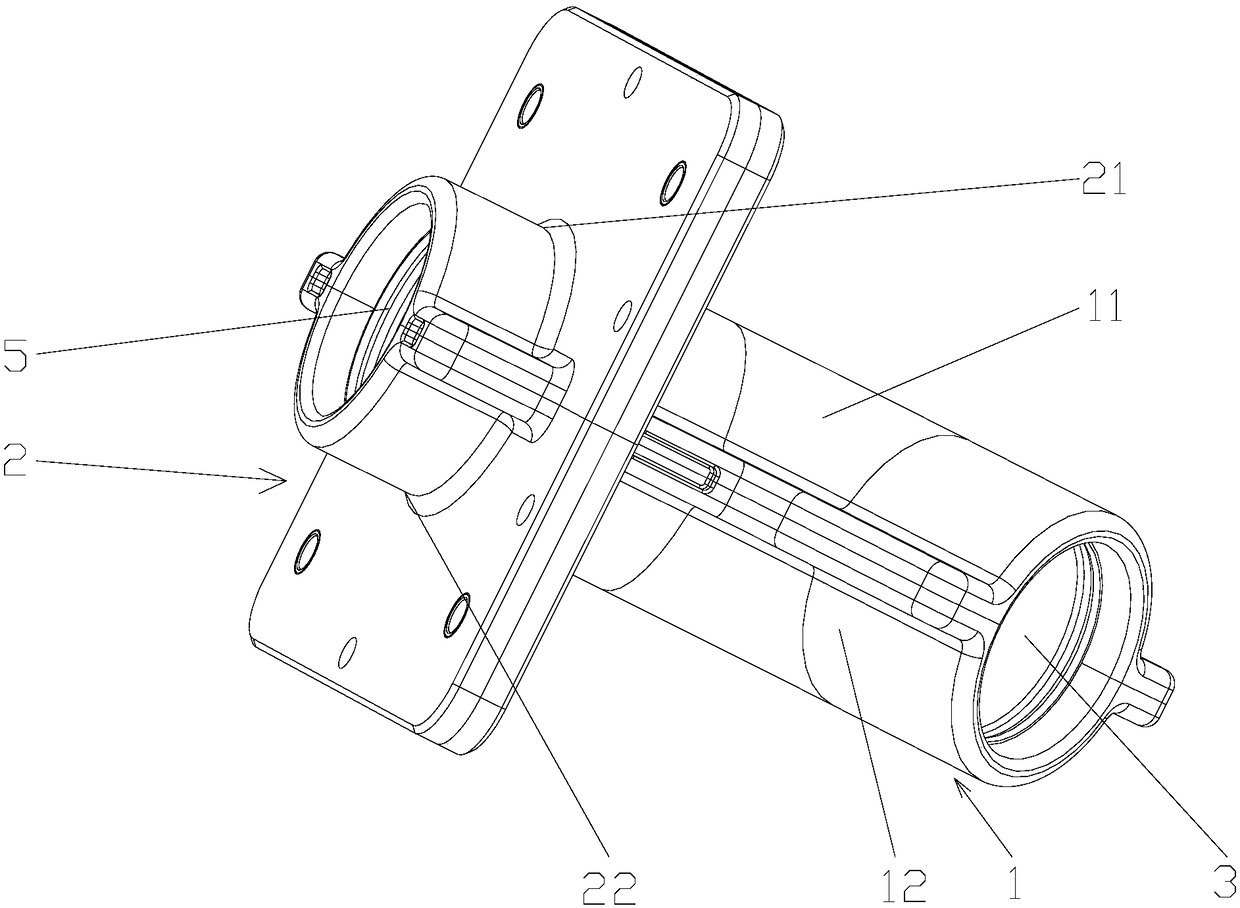

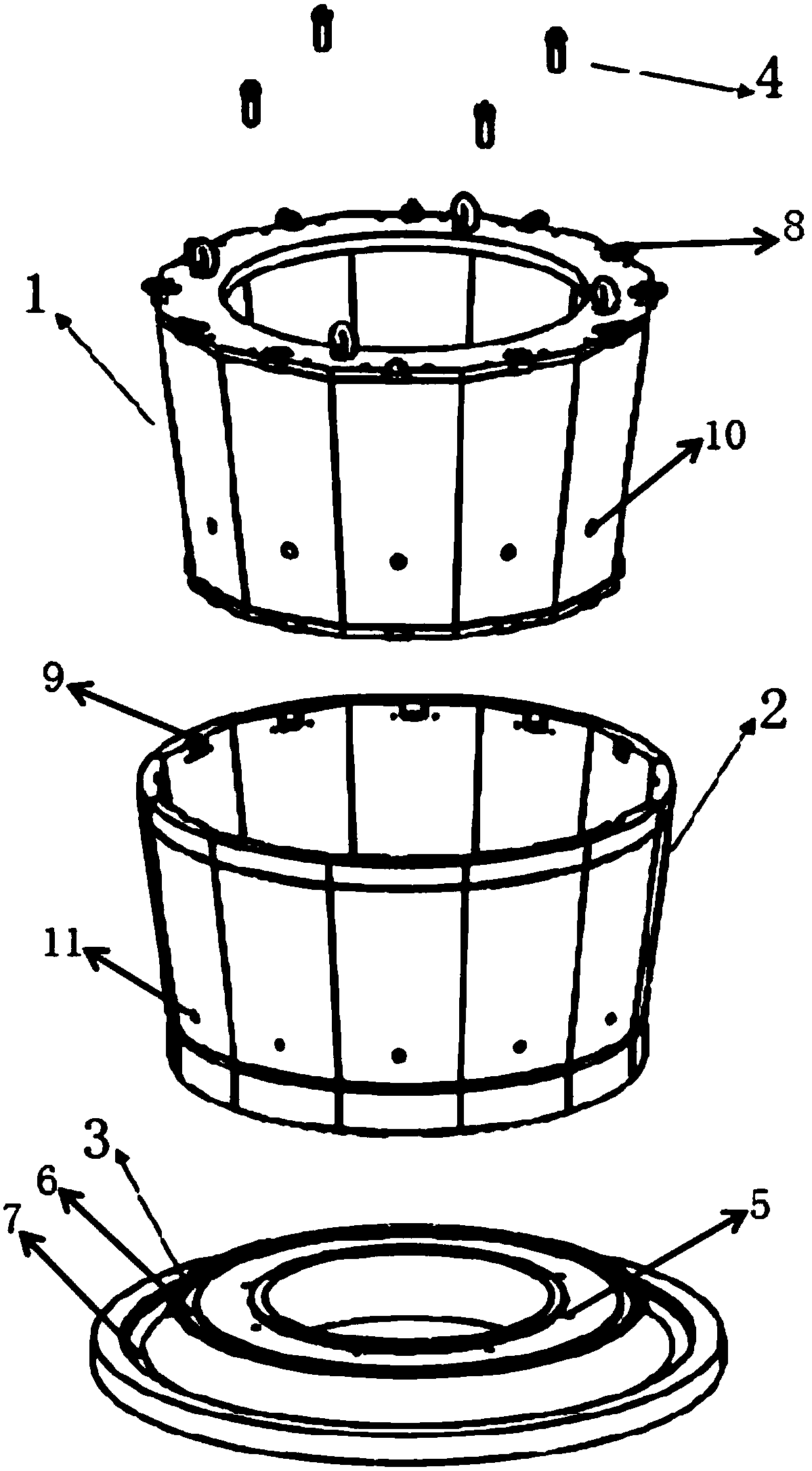

Combined mold and duct wall molding method

The invention provides a combined mold and a duct wall molding method. The combined mold for molding a duct wall comprises a core mold, a tile mold and a lug sheet mold, wherein the core mold is attached to the inner side surface of the tile mold, and the lower side of the core mold is tightly and fixedly connected to the lug sheet mold so as to carry out layer stacking molding on a prepreg. According to the present invention, through the combined mold, the whole mold is divided into the core mold, the tile mold and the lug sheet mold, and the core is attached to the inner side surface of thecore so as to retain the shape and ensure the rigidity of the whole mold through the core mold, such that the integrated molding of the duct wall can be completed by combing the core mold, the tile core and the lug sheet cold; and the demolding process is easy through the form of the combined mold.

Owner:SHEN ZHEN KUANG CHI HEZHONG TECH LTD

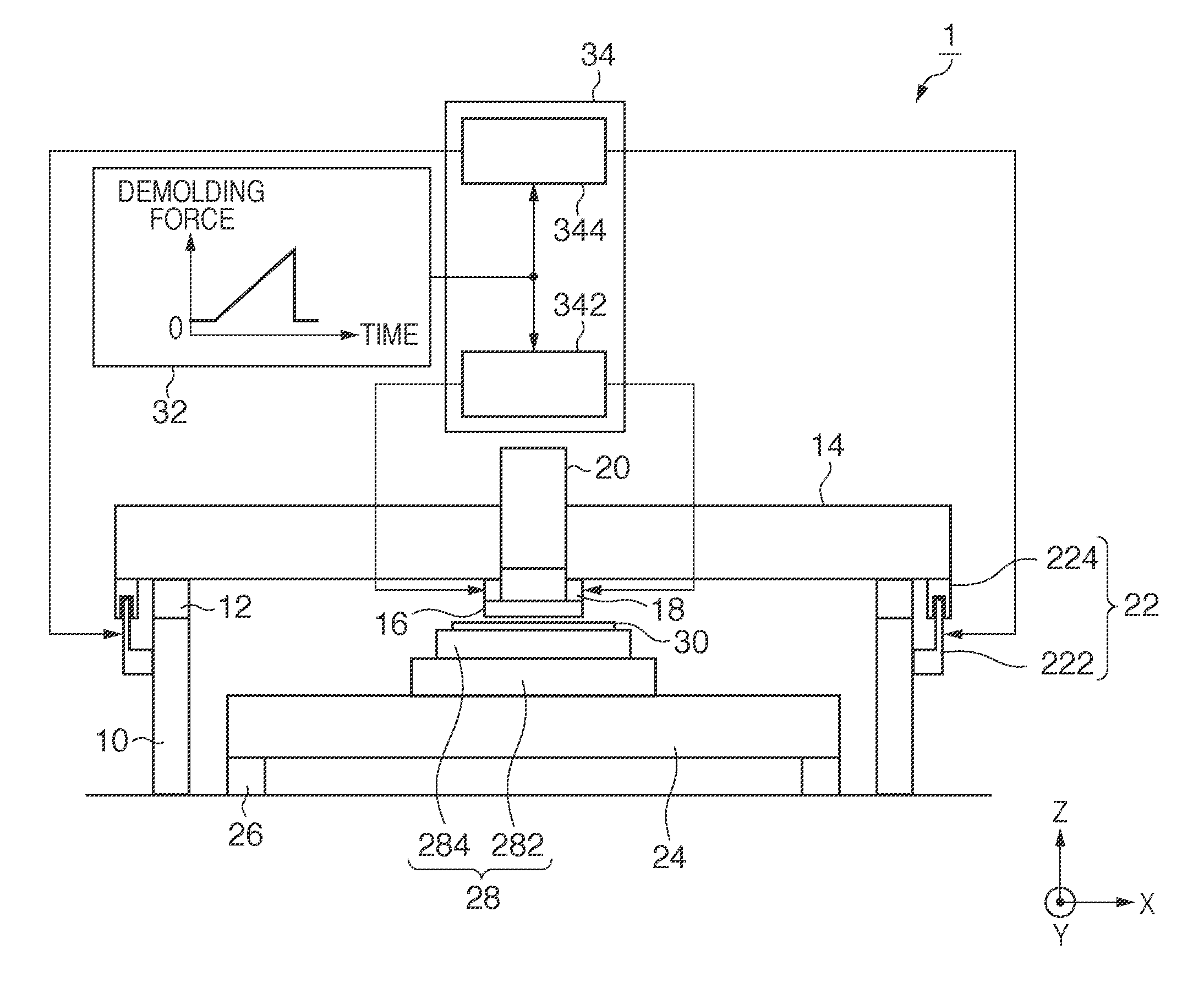

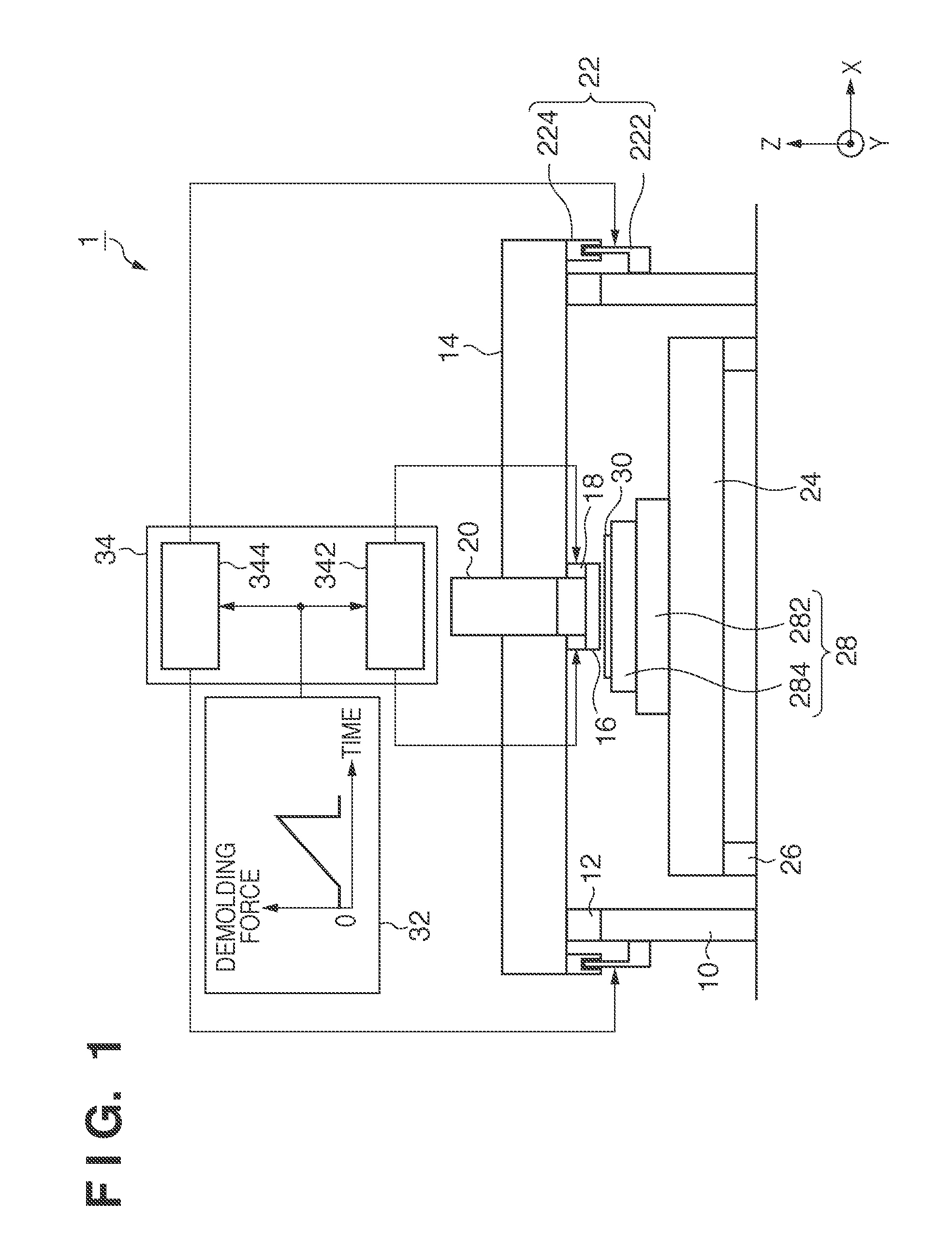

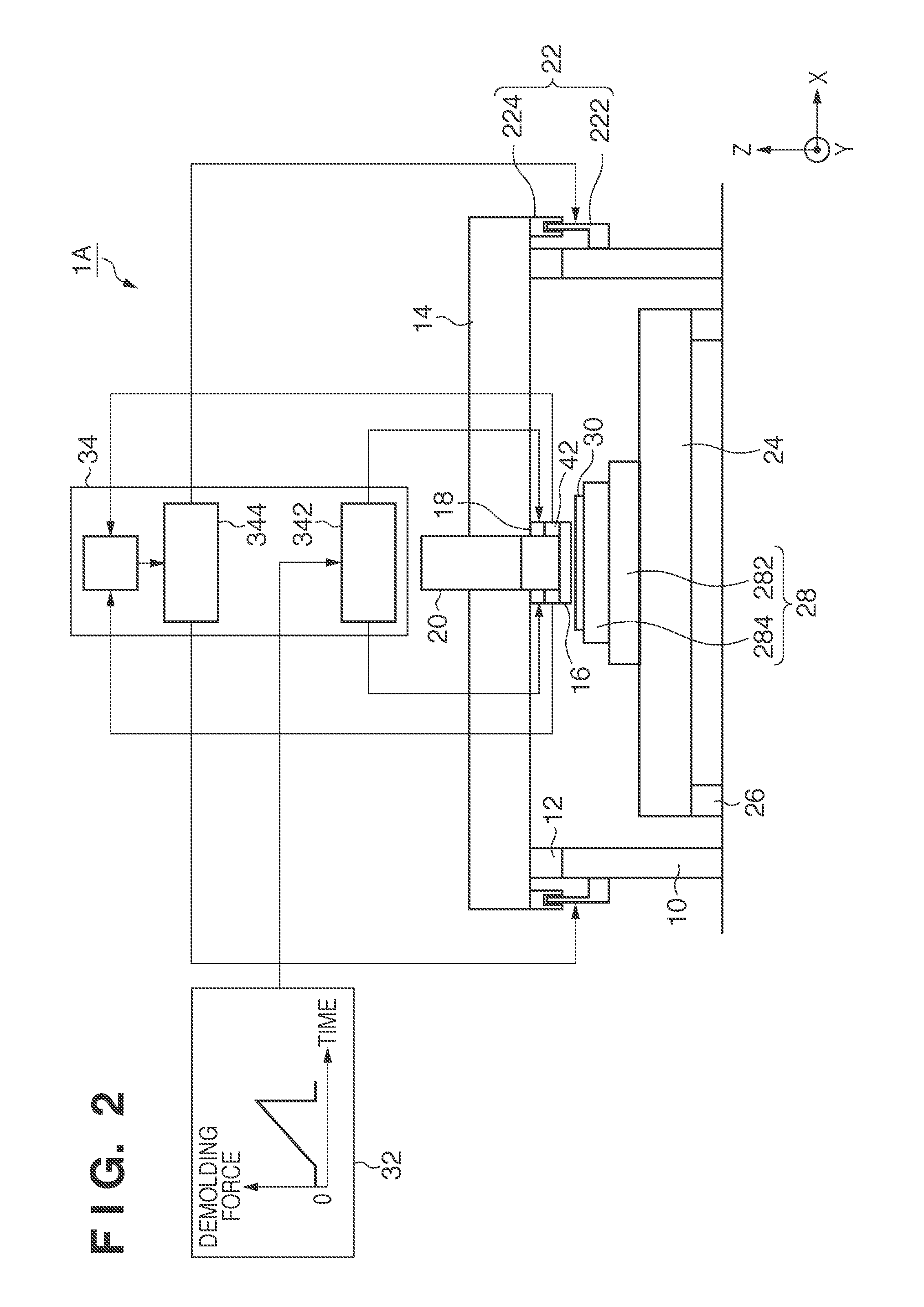

Imprint apparatus and manufacturing method of commodities

InactiveUS20110084423A1Easy demoulding processHigh pattern accuracyNanoinformaticsConfectioneryEngineeringMechanical engineering

The present invention provides an imprint apparatus including a mold and a stage that holds a substrate, the imprint apparatus executing a curing process of curing a resin while the mold and the resin applied to the substrate contact and a demolding process of releasing the mold from the resin cured in the curing process, the imprint apparatus including a structure that holds the mold, a pillar that supports the structure mechanically independently from the stage through an anti-vibration mount that reduces propagation of vibration, and a force providing unit that provides, to the structure, force in an opposite direction from a direction of force generated in the structure by providing demolding force to the mold during the demolding process.

Owner:CANON KK

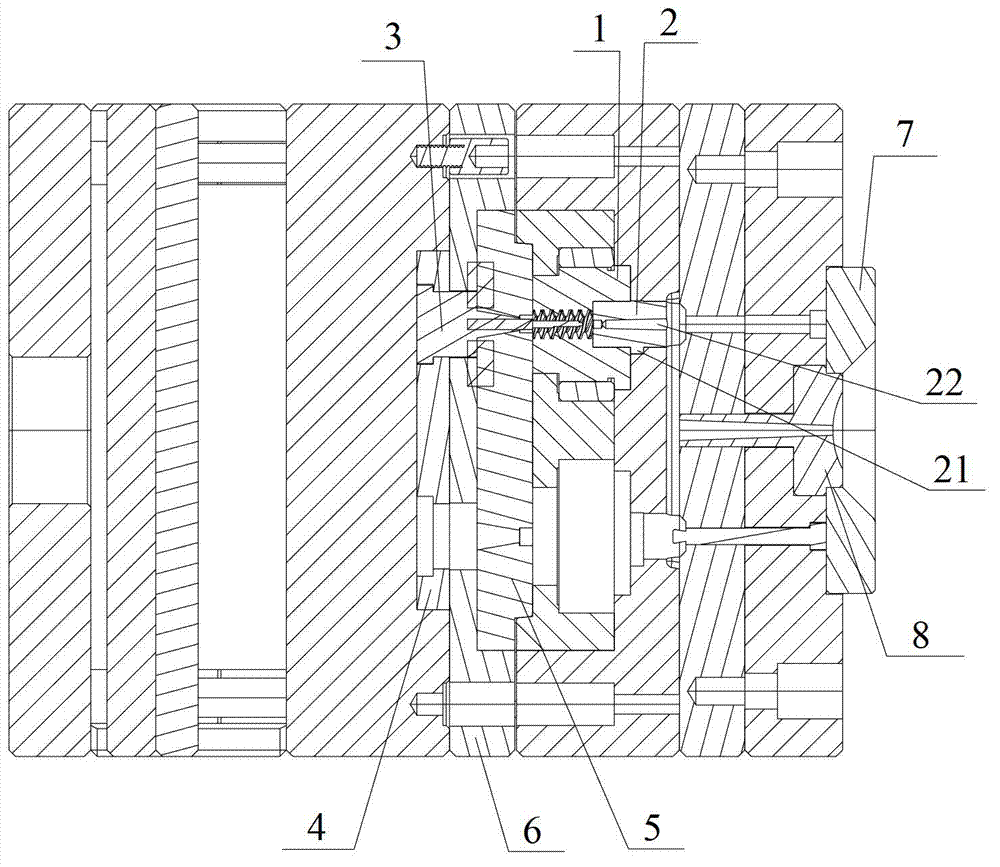

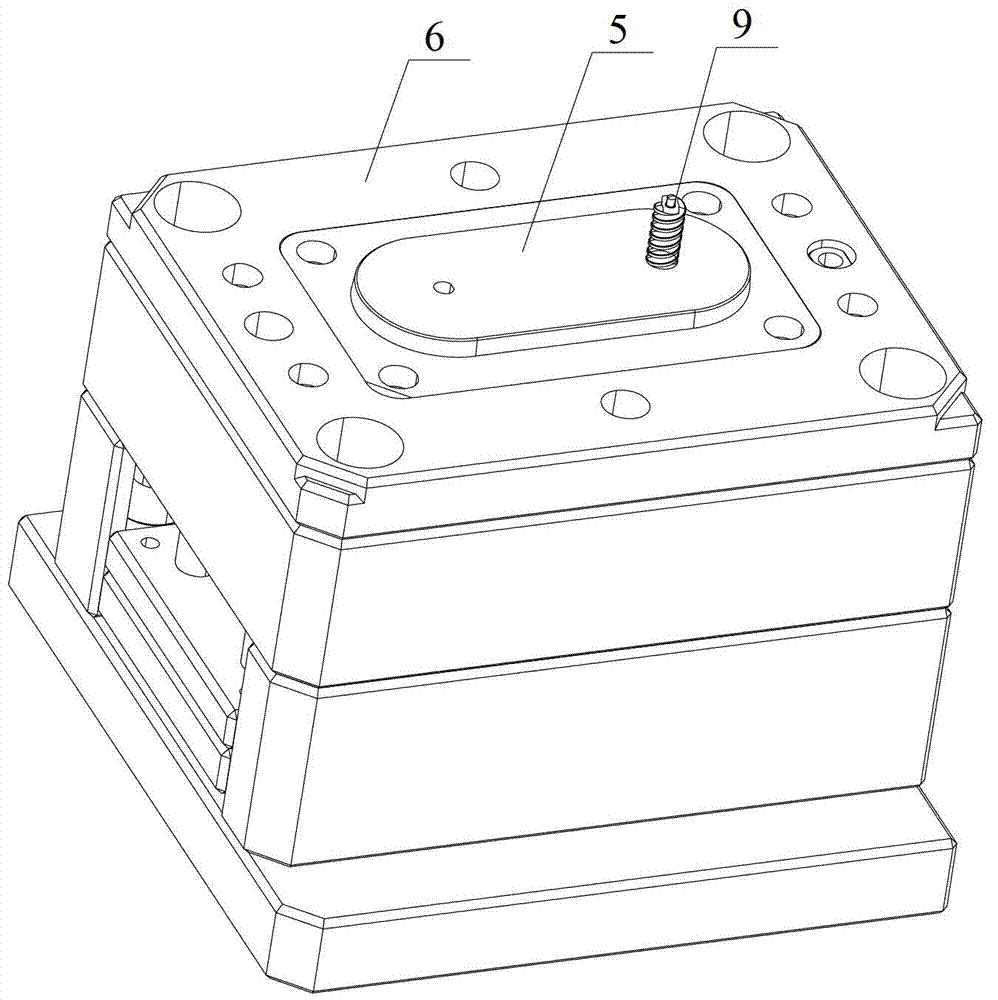

Mold of worm with gears

Owner:CIXI SANPEI MACHINE

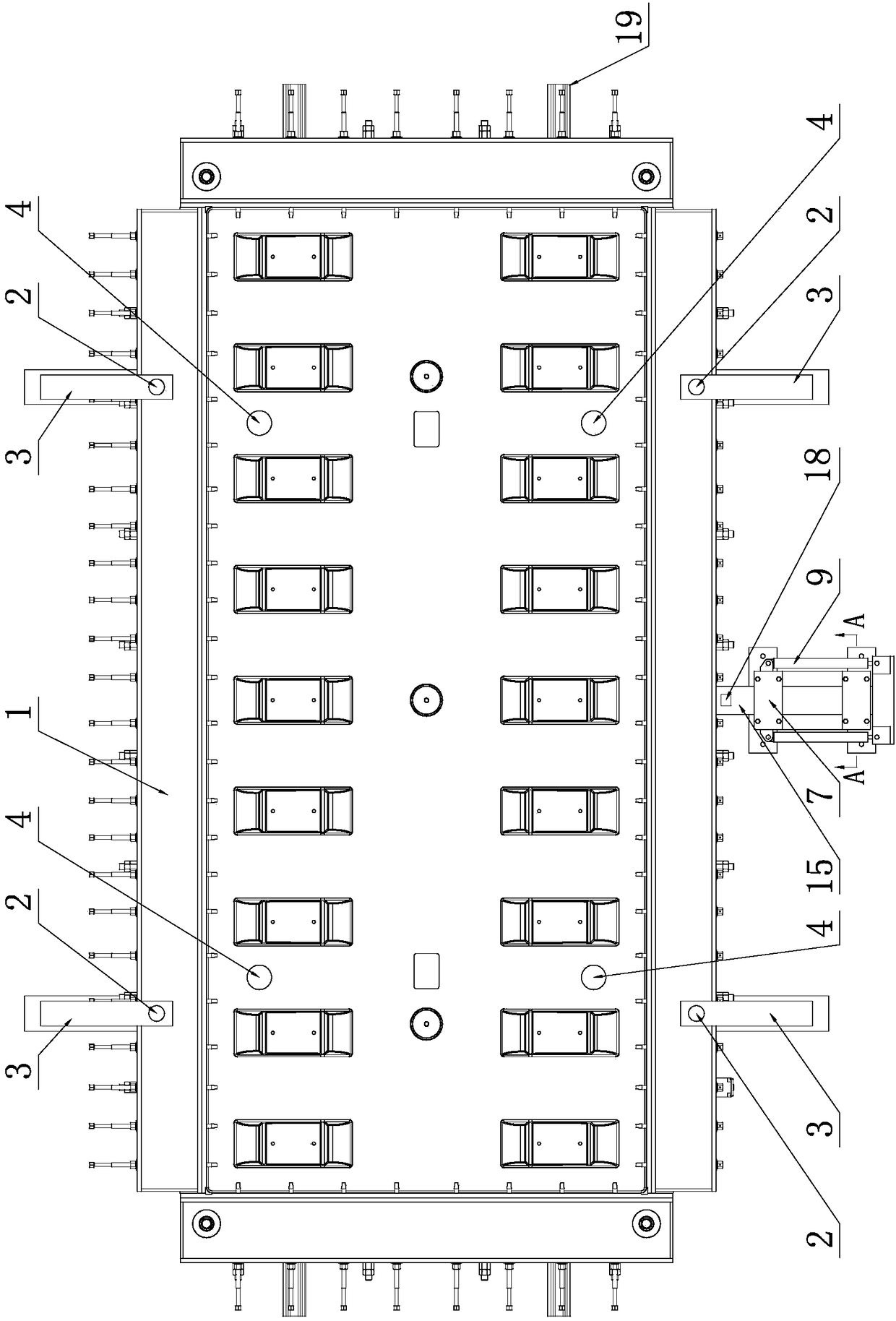

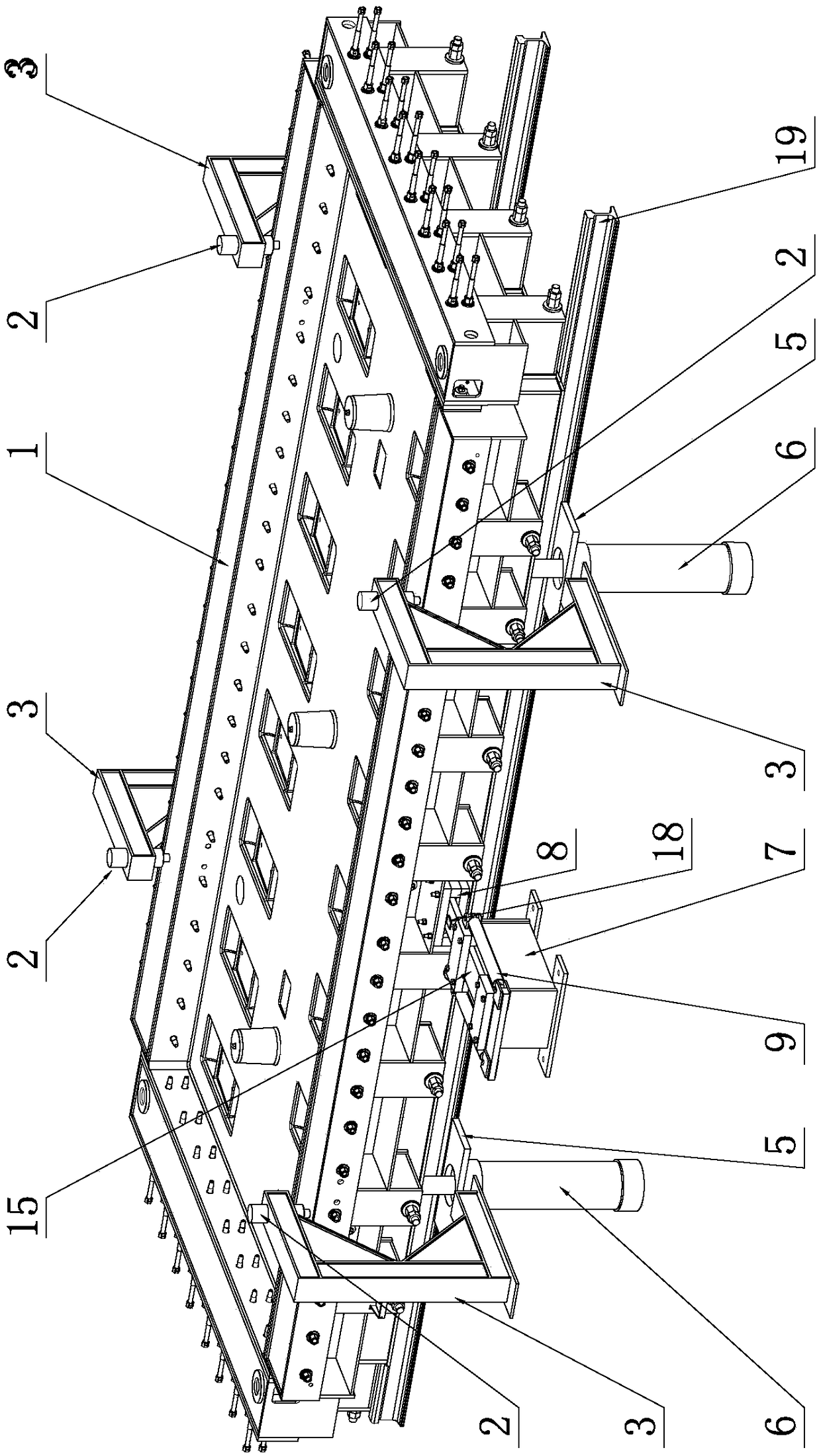

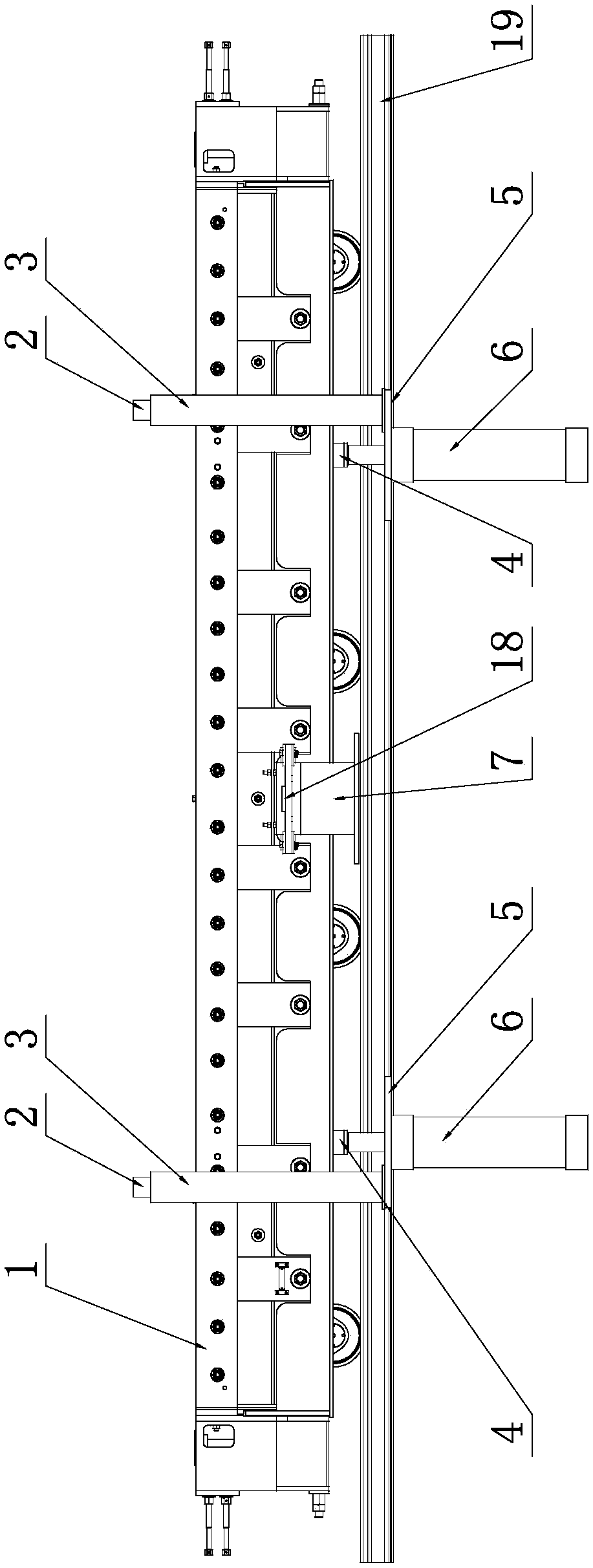

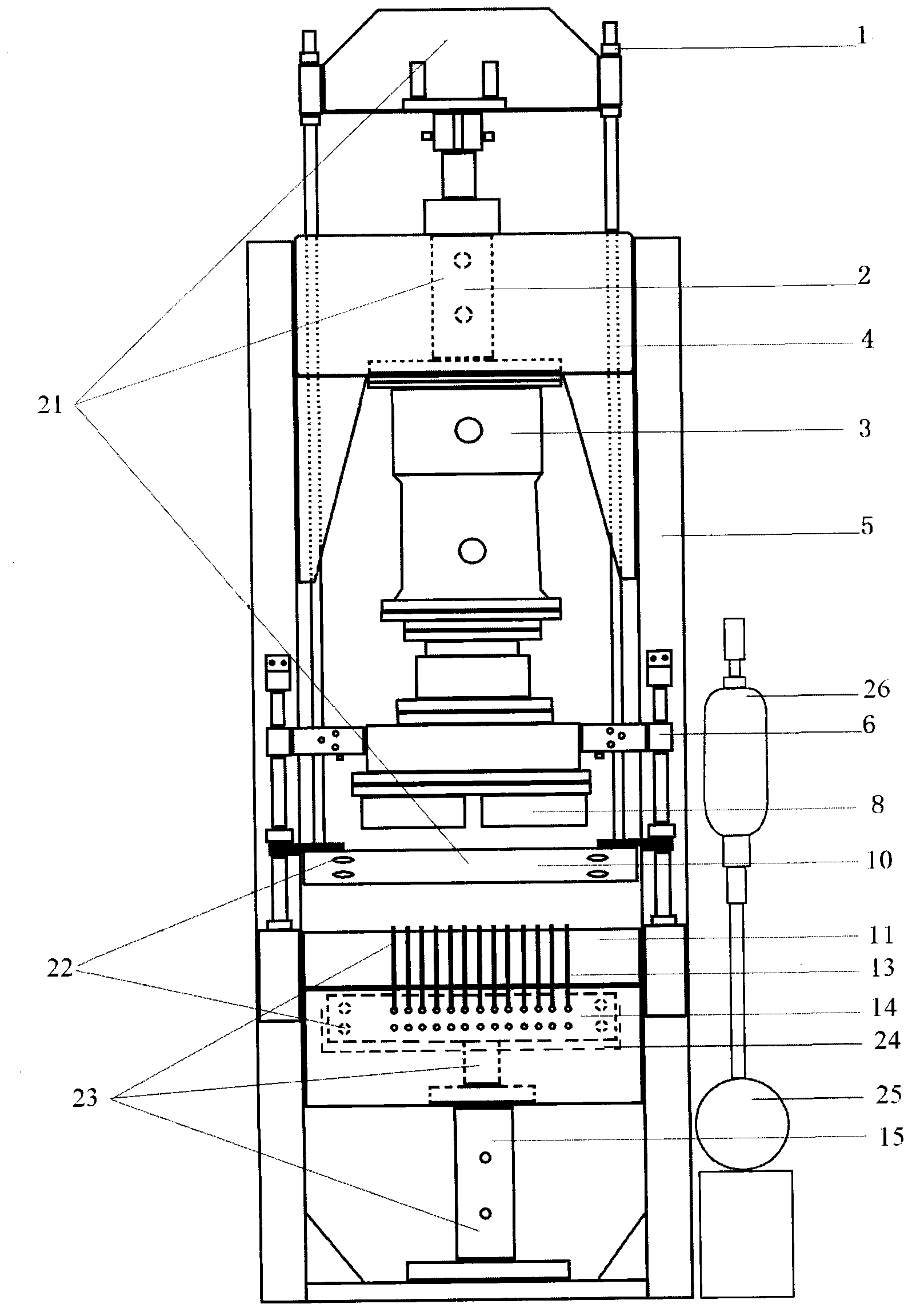

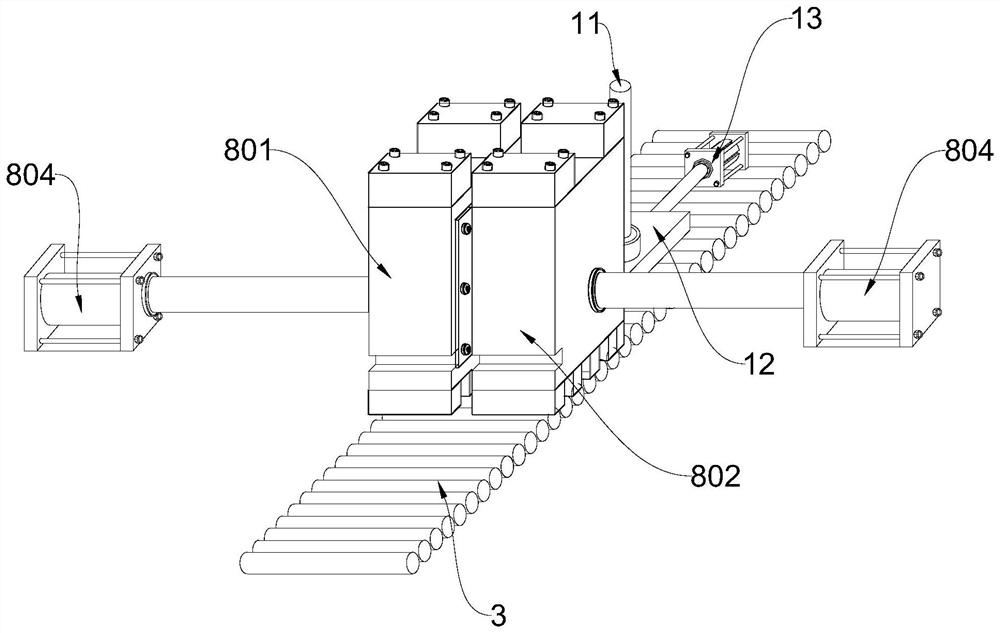

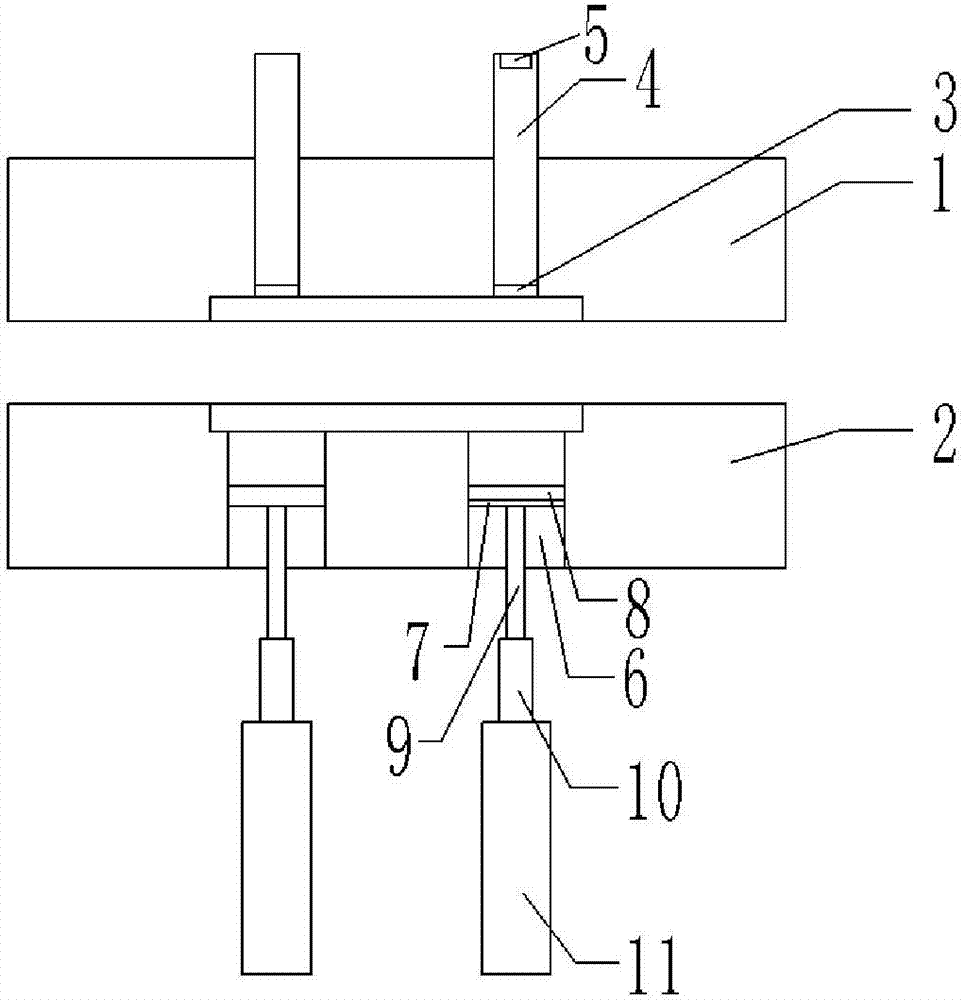

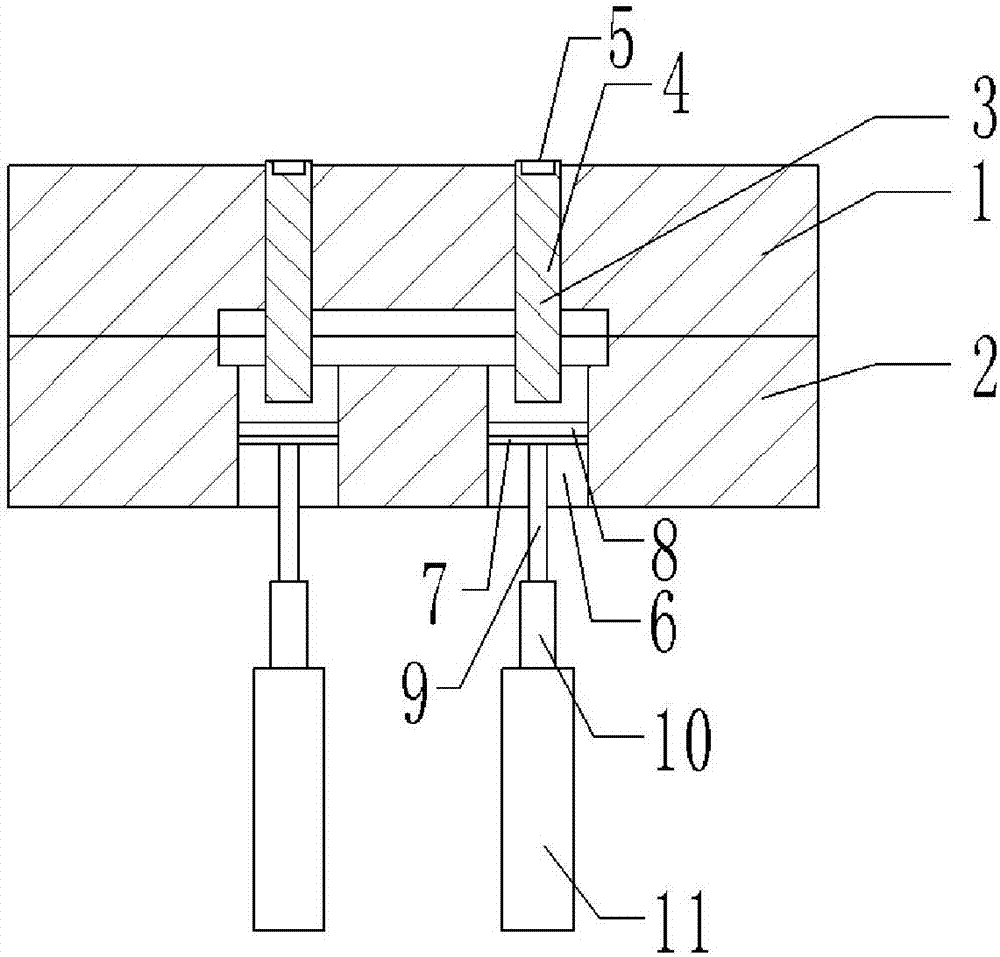

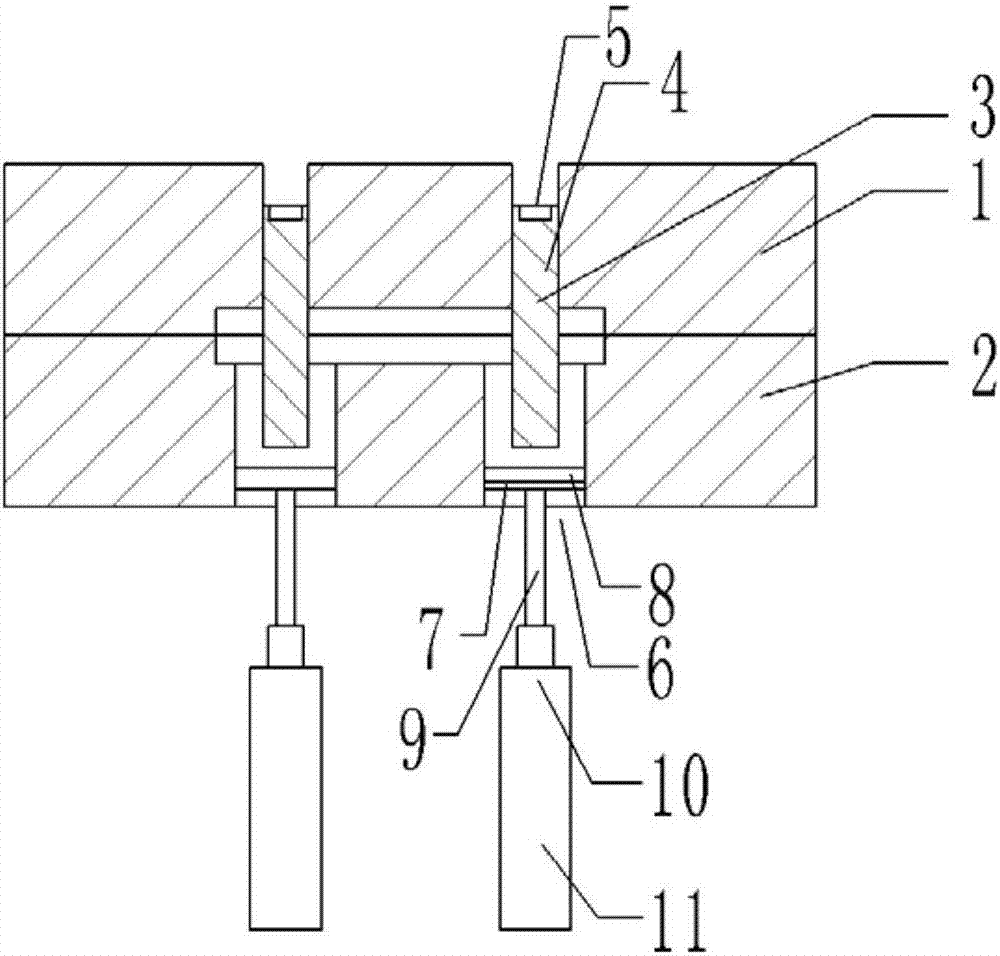

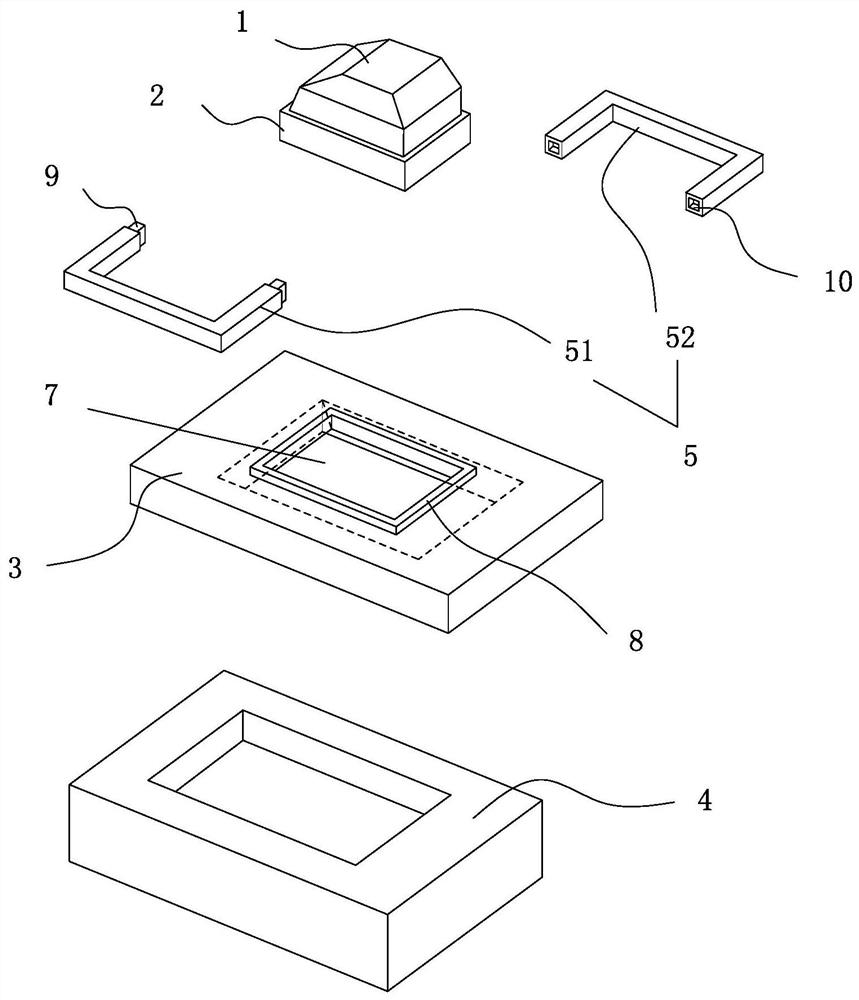

Demolding jacking system for pre-tensioning method prestressed concrete track board production line and application thereof

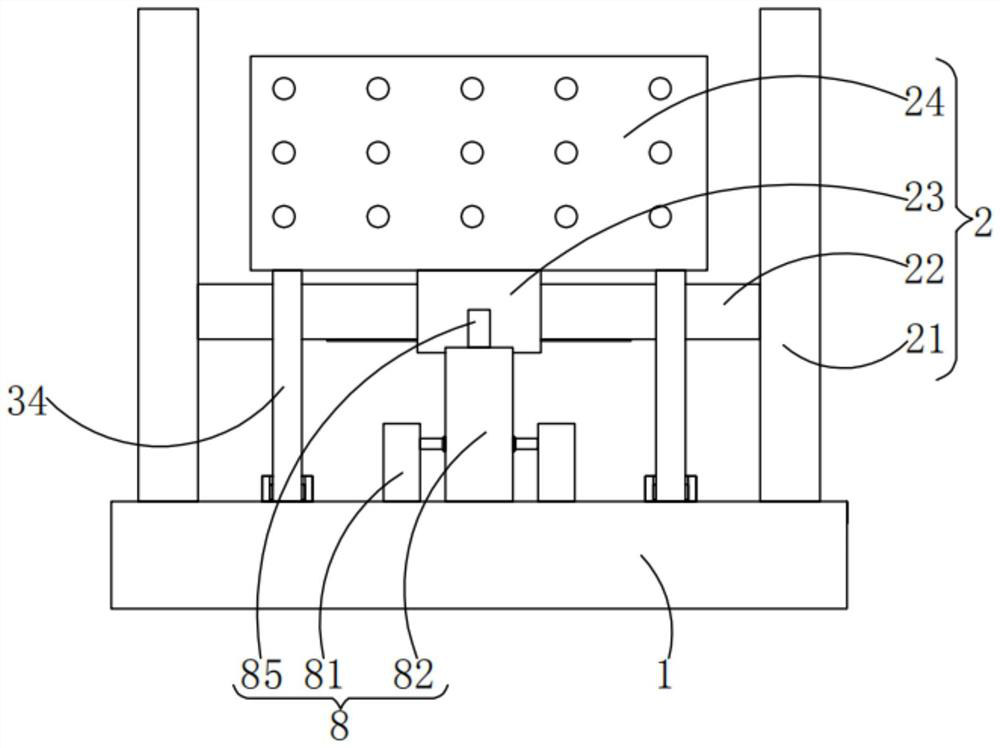

PendingCN108214857AAvoid repeated disassemblySimplify the process steps of repeated disassembly and assemblyDischarging arrangementProduction lineAutomatic control

The invention belongs to a demolding device, and in particular relates to a demolding jacking system for a pre-tensioning method prestressed concrete track board production line and an application thereof. The demolding jacking system comprises a control device, a locking mechanism, jacking mechanisms and a precise positioning mechanism, wherein the control device receiving collected signals in mold moving and mechanism working processes controls actions of the mechanisms; the jacking mechanisms are arranged on the inner side of the locking mechanism and are symmetrically distributed along thecenter line of a mold to form a rectangular supporting face concentric to the center of a track board for the track board in the mold; each of the jacking mechanisms comprises a jacking jack which isfixed to a base and corresponds to the lower end of a demolding jacking column in the mold, and a displacement sensor and a hydraulic sensor are separately arranged on the jacking jack and a hydraulic loop thereof. The demolding jacking system provided by the invention solves the technical problems that the technical demands of existing standards are unlikely to meet in the prior art, the productquality is hard to guarantee and the like effectively, and has the advantages of meeting the existing standard demands better, being compact in structural layout, high in demolding success rate, easyto implement automatic control and the like.

Owner:河北益铁机电科技有限公司 +3

Tooling and manufacturing method for manufacturing variable-section I-shaped composite material parts

The invention relate to a tool and production method for producing a variable cross-section type I-shaped composite part. According to the technical scheme, the tool is composed of an upper male die, a lower male die, a middle spacer plate and composite even pressing plates on the two sides. The production method comprises the steps that firstly, the composite even pressing plates are made; then, carbon fiber prepregs cut into fixed sizes are laid on a forming tool; finally all parts of the carbon fiber prepregs laid well are transferred from the forming tool to an assembly solidification tool for integral assembly, and packaged in a vacuum bag; the fully sealed prepreg blank is subjected to solidification forming under the conditions of 120-180 DEG C and 0.3-0.8 mpa for 1-3 hours; and after cooling, the composite even pressing plates, the middle spacer plate, the upper male die and the lower male die are detached to obtain the variable cross-section type I-shaped composite part. According to the production process, the pressure transmission efficiency of the part in the solidification process can be improved; generation of the structure defect of the part is reduced; the shape and the internal quality of the part are ensured.

Owner:SHENYANG AIRCRAFT CORP

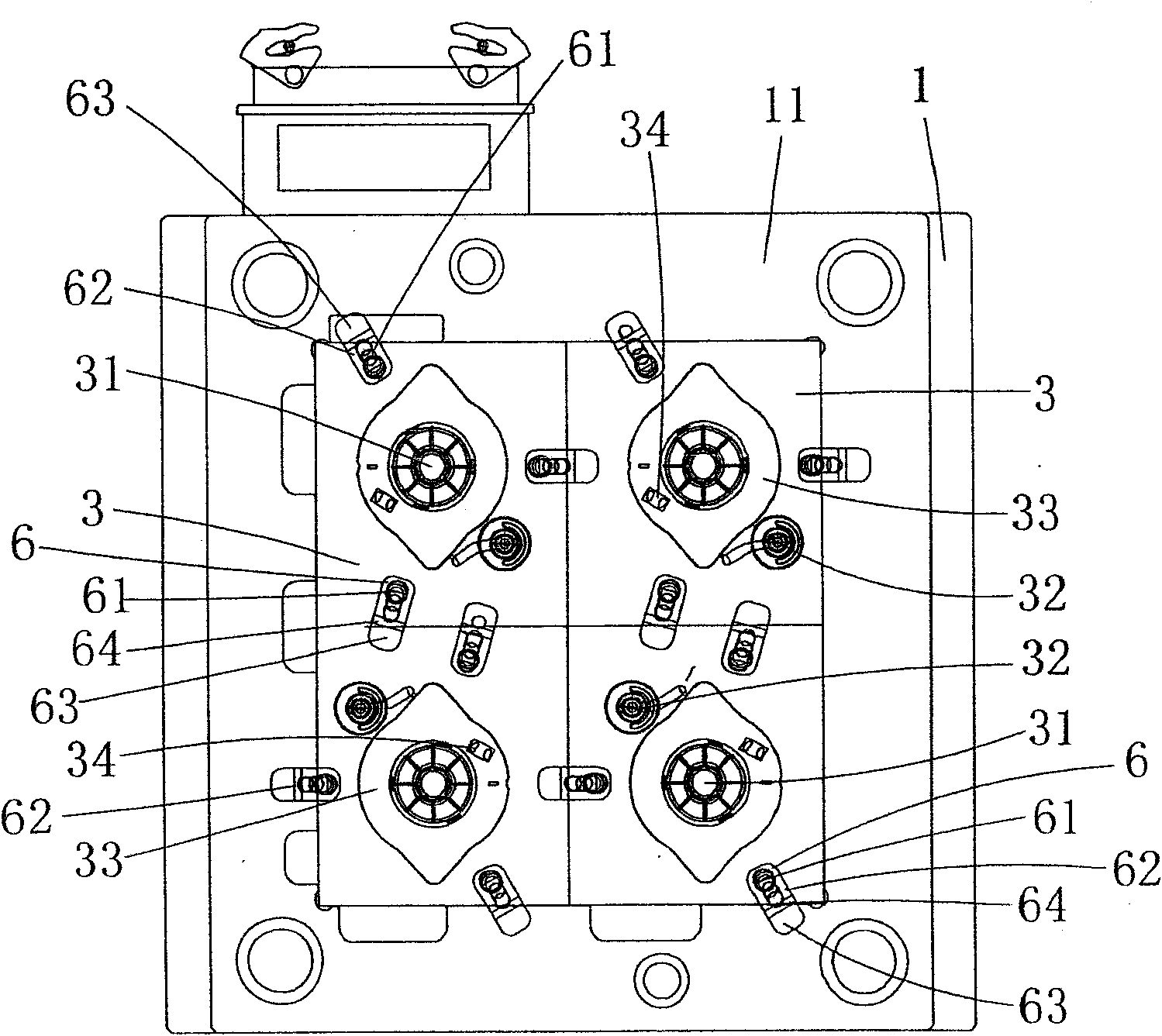

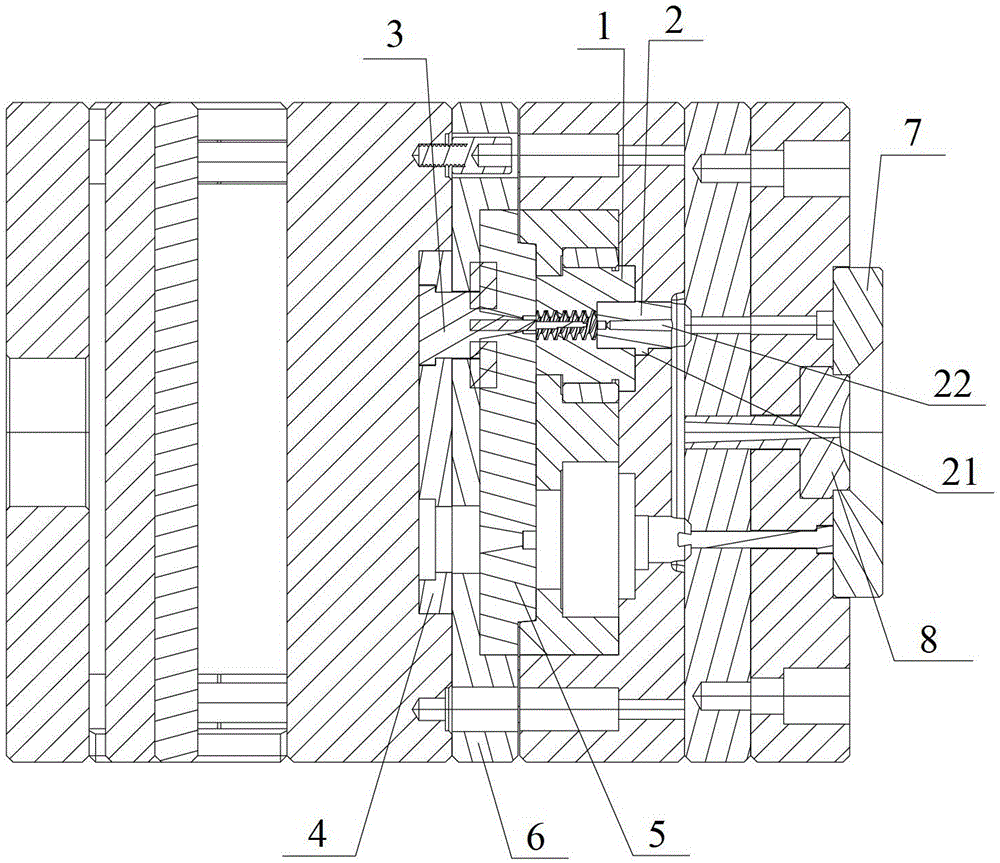

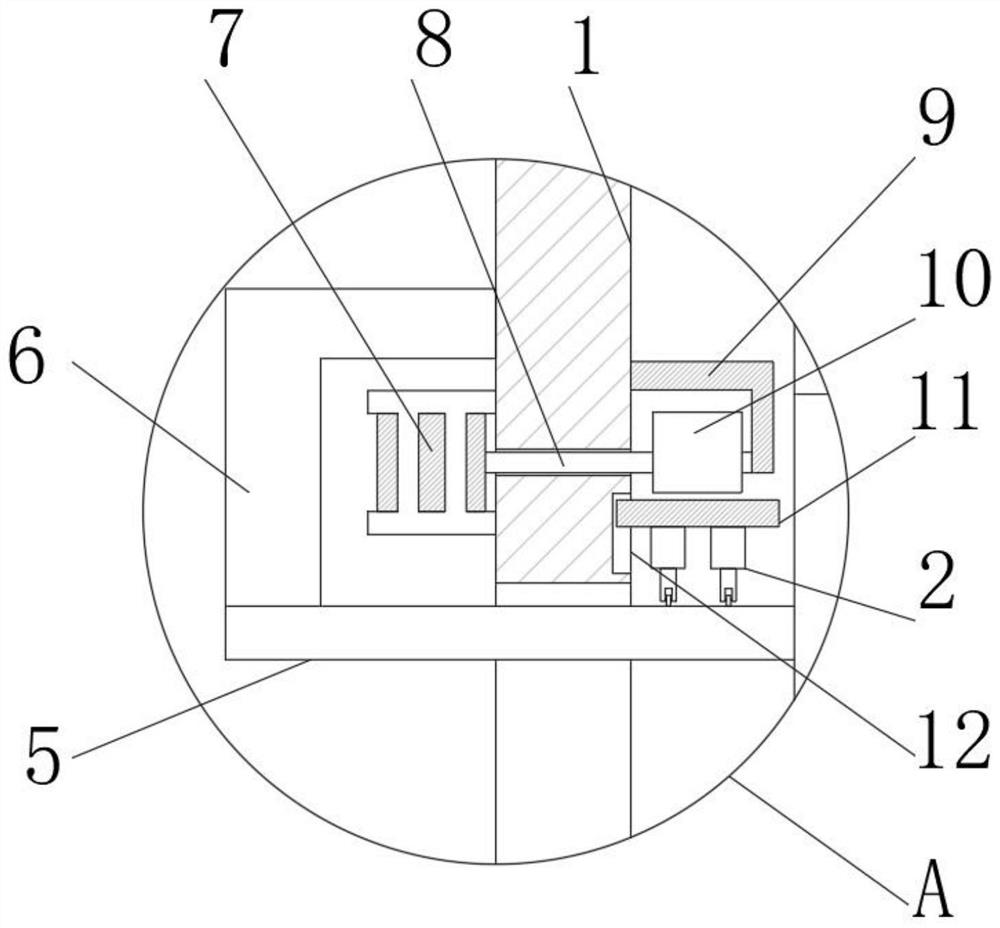

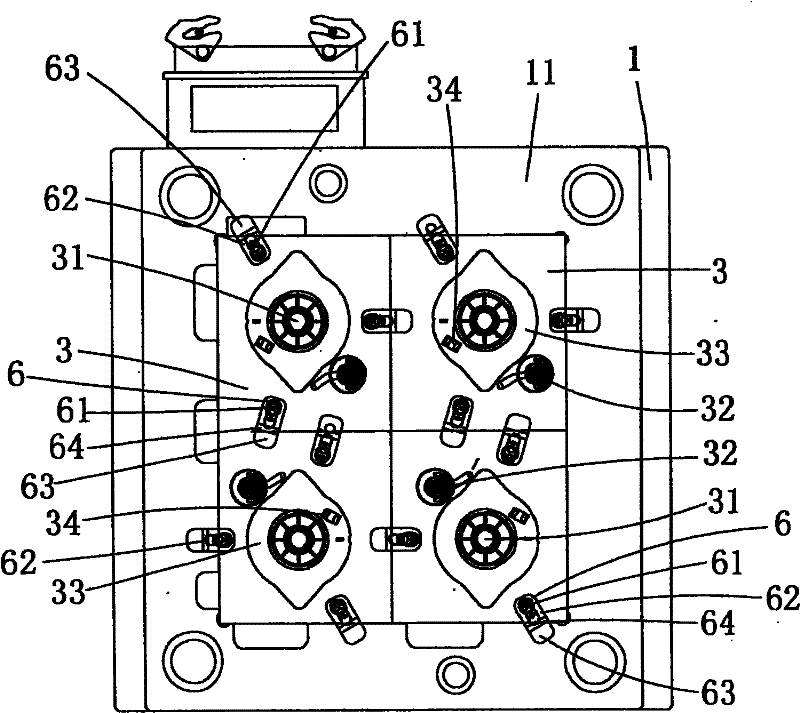

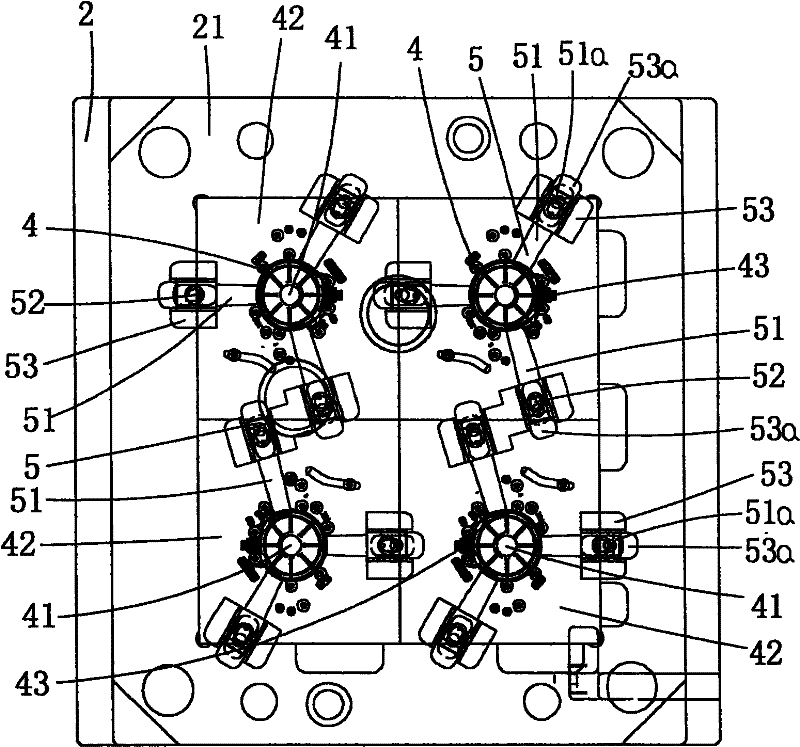

Assembled mould structure with self-contained sliding core power

The invention discloses an assembled mould structure with self-contained sliding core power, which comprises a fixed mould and a movable mould matched with each other, wherein the working face of the movable mould is encrusted with movable mould units, the middle part of each movable mould unit is provided with a movable cavity, and the periphery of each movable mould unit is provided with three sets of sliding core units at an interval of equal radian along the center of the movable cavity; each sliding core unit is equipped with a slide block, and the external end side of the slide block is provided with an obliquely arranged hollow lantern ring; the contact face of the fixed mould is embedded with fixed mould units, the middle part of each fixed mould unit is provided with a fixed cavity, and the periphery of each fixed mould unit is provided with three sets of driving units at an interval of equal radian along the center of the fixed cavity; and each driving unit is internally equipped with a protruded and obliquely arranged driving shaft. The assembled mould structure of the invention has the advantages that: by using the structure of splicing inclined shafts and sleeves, the operation of the slide blocks can be realized without other external power; the same module is equipped with four sets of module units; the processing efficiency is high; and all units are in bolted connection, so the maintenance is quick and convenient.

Owner:NINGBO HUASHUO MOLDING & MACHINE

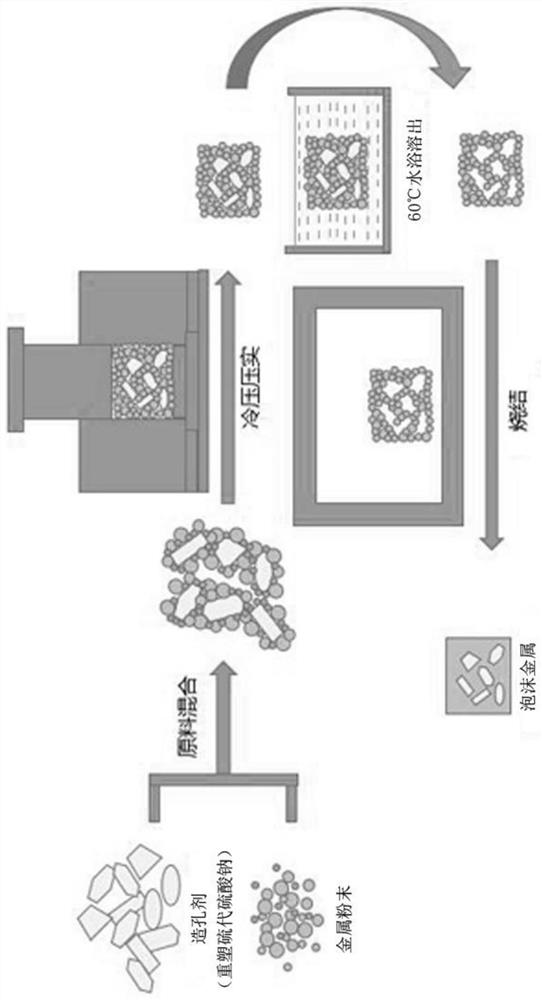

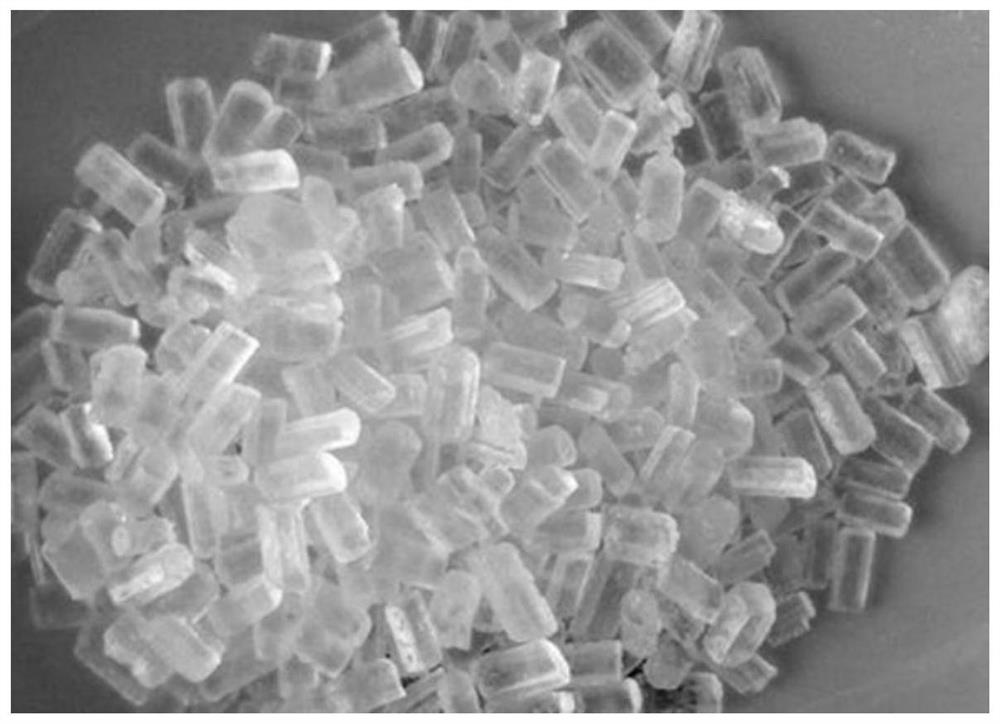

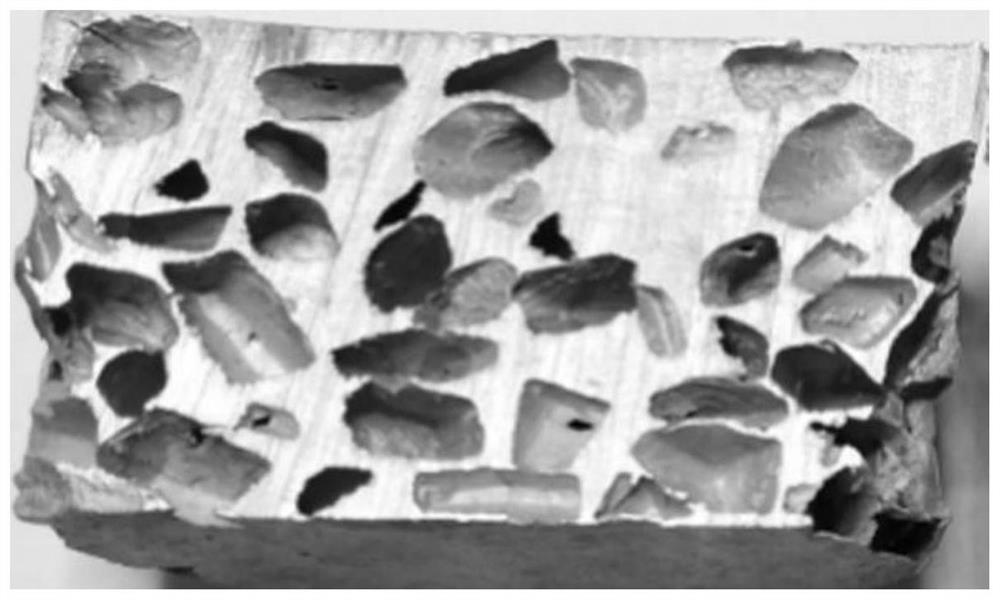

Method for preparing foam metal with controllable pore structure

ActiveCN112264621ASave raw materialsEasy to getAdditive manufacturing apparatusAdditive manufacturing processesSodium thiosulfateMetallic materials

The invention relates to a method for preparing foam metal with a controllable pore structure, belongs to the technical field of foam metal material preparation, and solves the technical problems thata pore-forming agent is not completely dissolved out in the forming process of a foam metal sample by a sintering dissolution method, and a matrix is easy to corrode when the pore-forming agent is dissolved. According to the solution scheme, sodium thiosulfate is adopted as the pore-forming agent to prepare foam metal with the controllable pore structure, and by designing pore shape, determiningthe weight of required sodium thiosulfate particles and metal powder, preparing the pore-forming agent, powder mixing, cold pressing, pore-forming agent dissolving, drying and sintering, so that the foam metal with the controllable pore structure is prepared; and sodium thiosulfate is used as the pore-forming agent, a 3D printing technology is used for processing a plastic mold, sodium thiosulfatecan be reshaped as required to obtain sodium thiosulfate particles of any shape and structure, the prepared sodium thiosulfate particles are used as the pore-forming agent, and foam metal of variousuniform and regular pore structures can be obtained by adopting a space-occupying sintering method.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

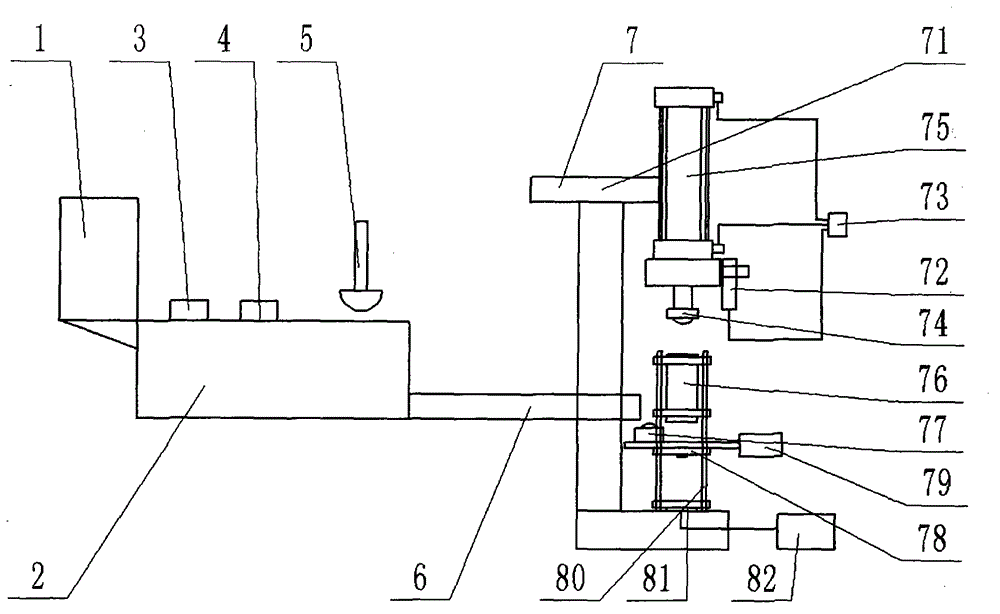

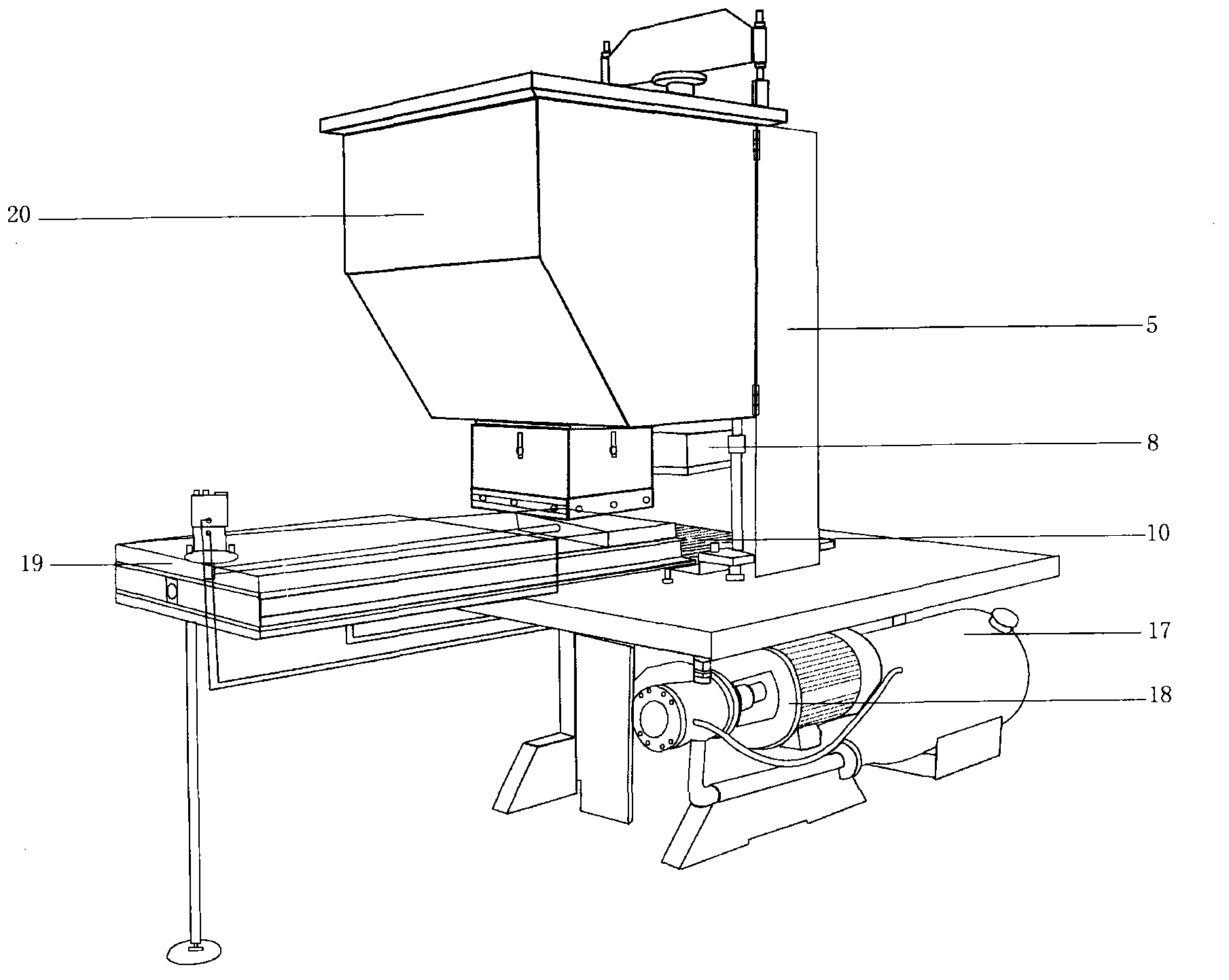

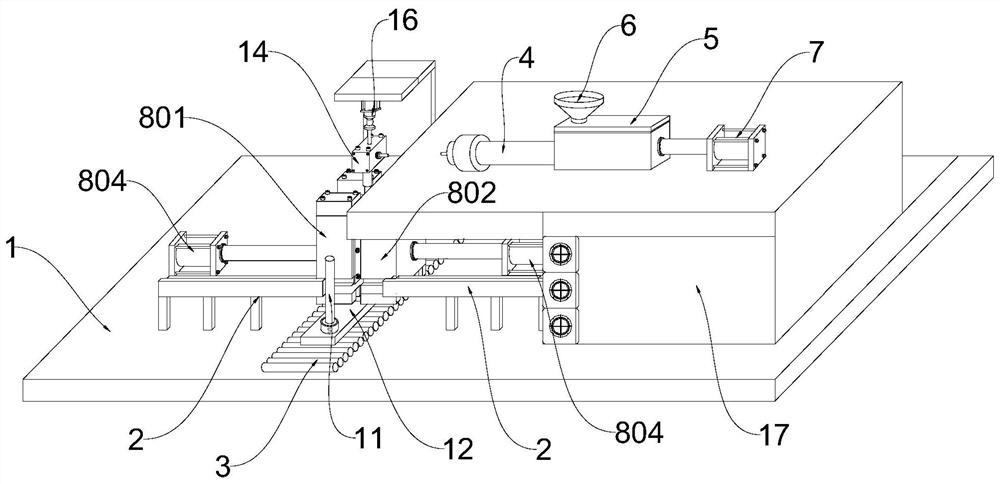

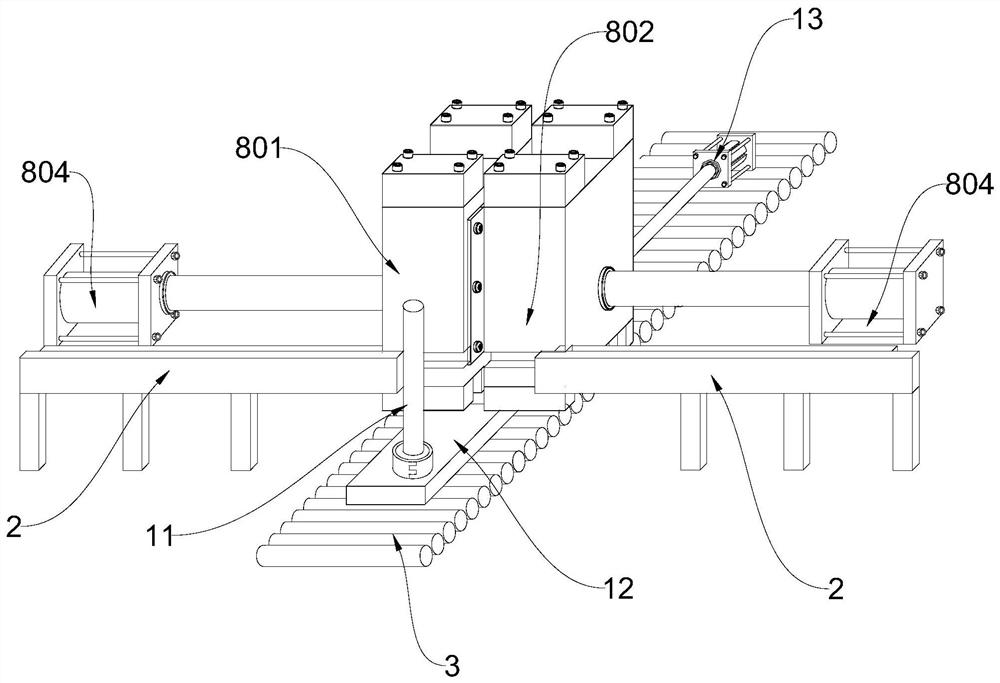

Household garbage bar making device

The invention discloses a household garbage bar making device. The household garbage bar making device comprises a hopper, a blender, an additive adding device, a quick lime adding device, a humidifying device, a conveying device, a bar making machine body, and a die cavity installing frame, wherein the blender is an upper opening type double-shaft blender with the transmission function, and the hopper is arranged on the front portion of the blender; the additive adding device, the quick lime adding device and the conveying device are all belt conveyors; the additive adding device, the quick lime adding device and a mist spraying water pipe are arranged on the upper space of the blender behind the hopper; one end of the conveying device is arranged under a discharging port of the blender, the other end is arranged above a filling port of the bar making machine body, and the bar making machine body comprises a rack. By means of the household garbage bar making device, smashed household garbage is blended and sterilized by adding quick lime, water and an additive are added into the household garbage to achieve a certain humidity and viscosity, then the household garbage is uniformly blended again to be conveyed to the bar making machine body and made into rod materials, meanwhile, the structure is simple, and the implementation is easy.

Owner:施婷婷

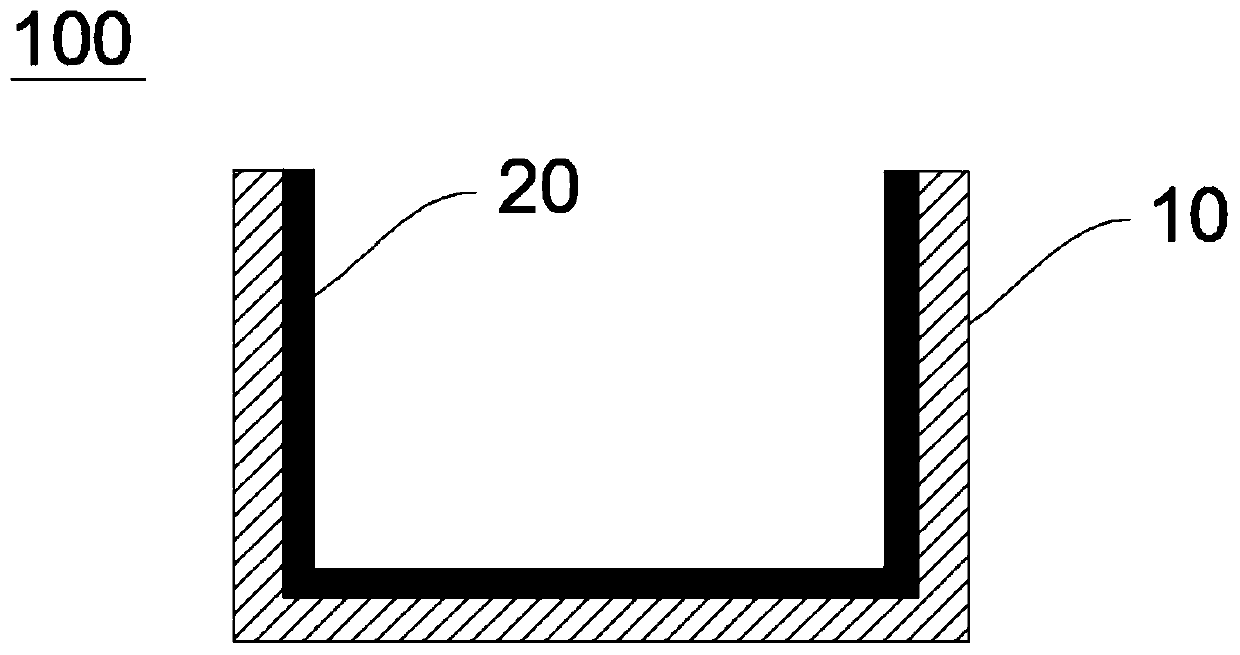

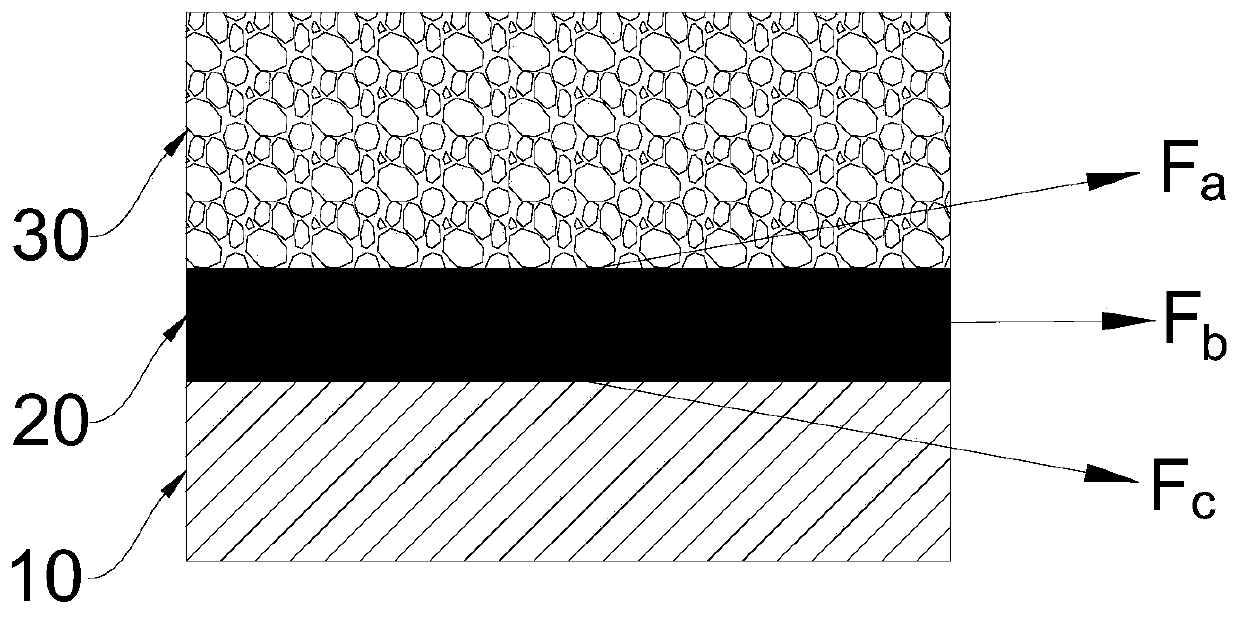

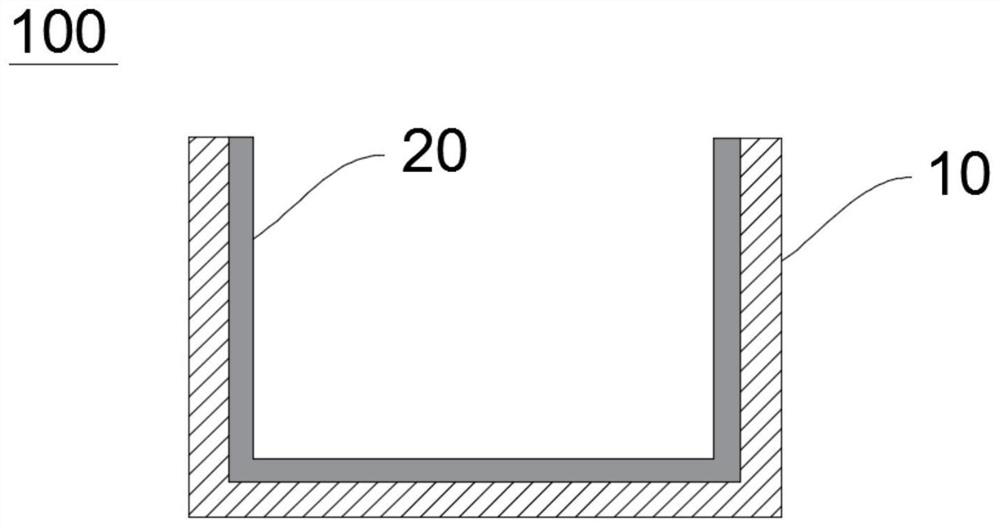

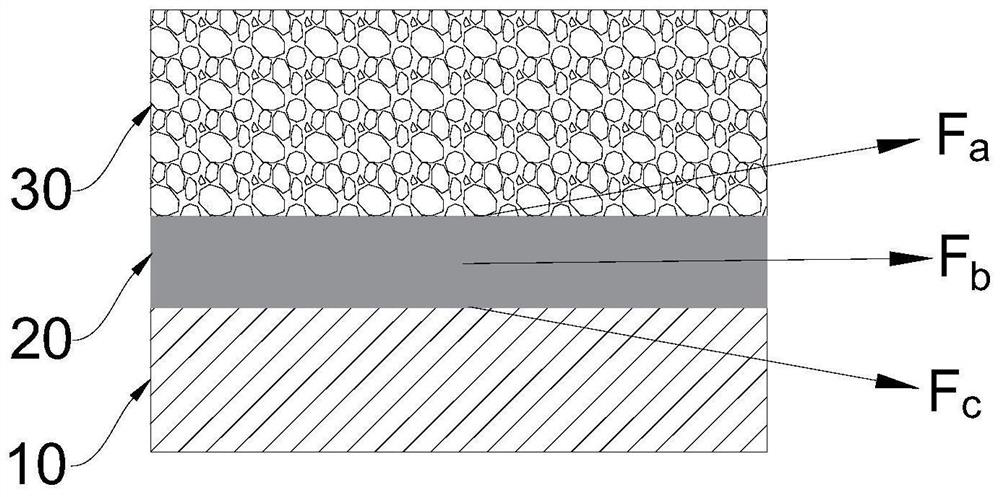

Barrier layer, sintering mold and preparation method thereof

ActiveCN110723964AGood high temperature resistanceEasy to demouldCeramic shaping liningsTungsten nitrideCarbide silicon

The invention provides a barrier layer. The barrier layer is used for being arranged on the surface of a sintering mold for preparing foamed ceramic, wherein the composition of the barrier layer comprises quartz sand, zirconia, alumina, a carbide, and a nitride, the carbide comprises one or more of silicon carbide, tungsten carbide, and boron carbide, and the nitride comprises one or more of silicon nitride, boron nitride, and tungsten nitride. The barrier layer is used for being arranged on the surface of the sintering mold for preparing foamed ceramic, and the barrier layer is characterizedin that the composition of the barrier layer comprises quartz sand, zirconia, alumina, the carbide, and the nitride, wherein the carbide comprises one or more of silicon carbide, tungsten carbide, andboron carbide, and the nitride comprises one or more of silicon nitride, boron nitride, and tungsten nitride. The invention also provides the sintering mold and a preparation method of the sinteringmold.

Owner:江西中材新材料有限公司 +2

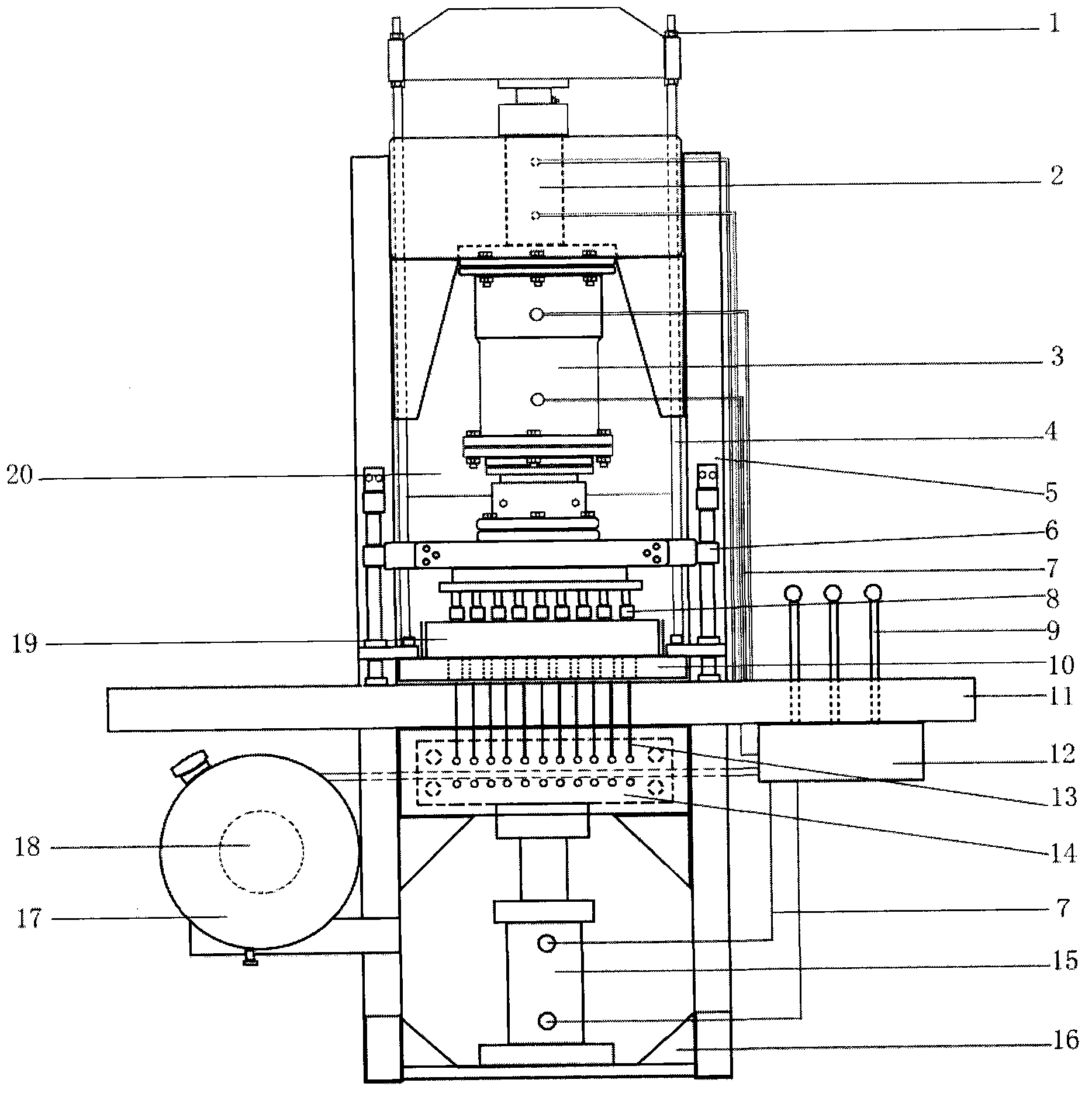

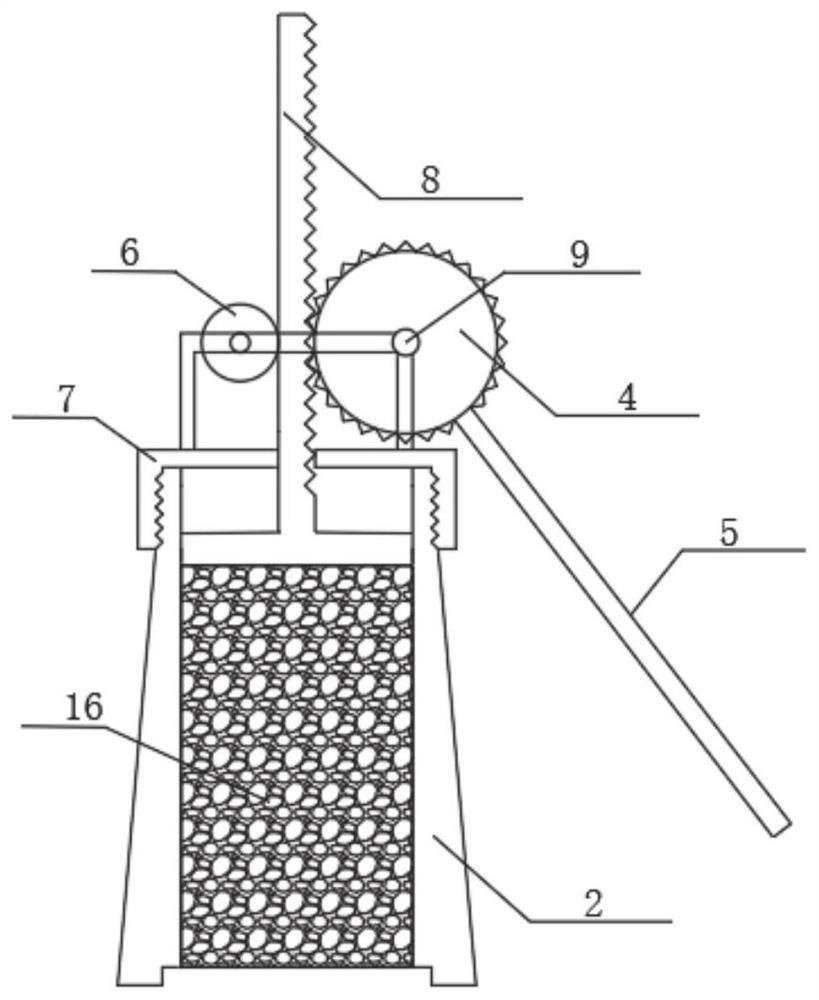

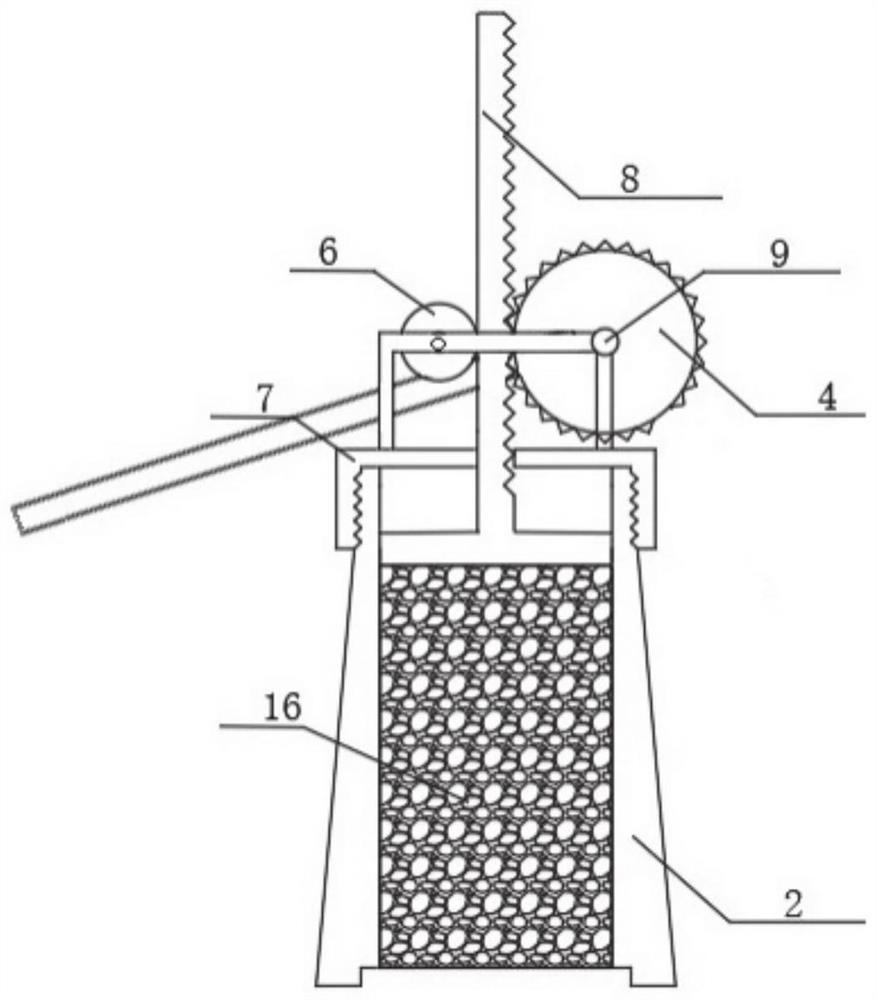

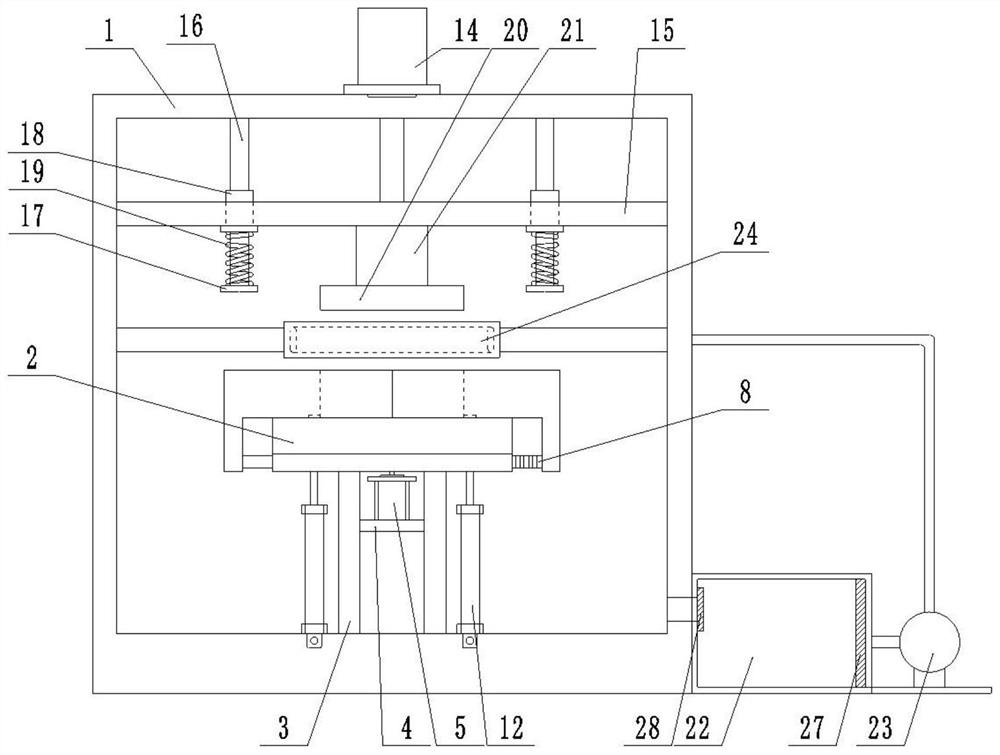

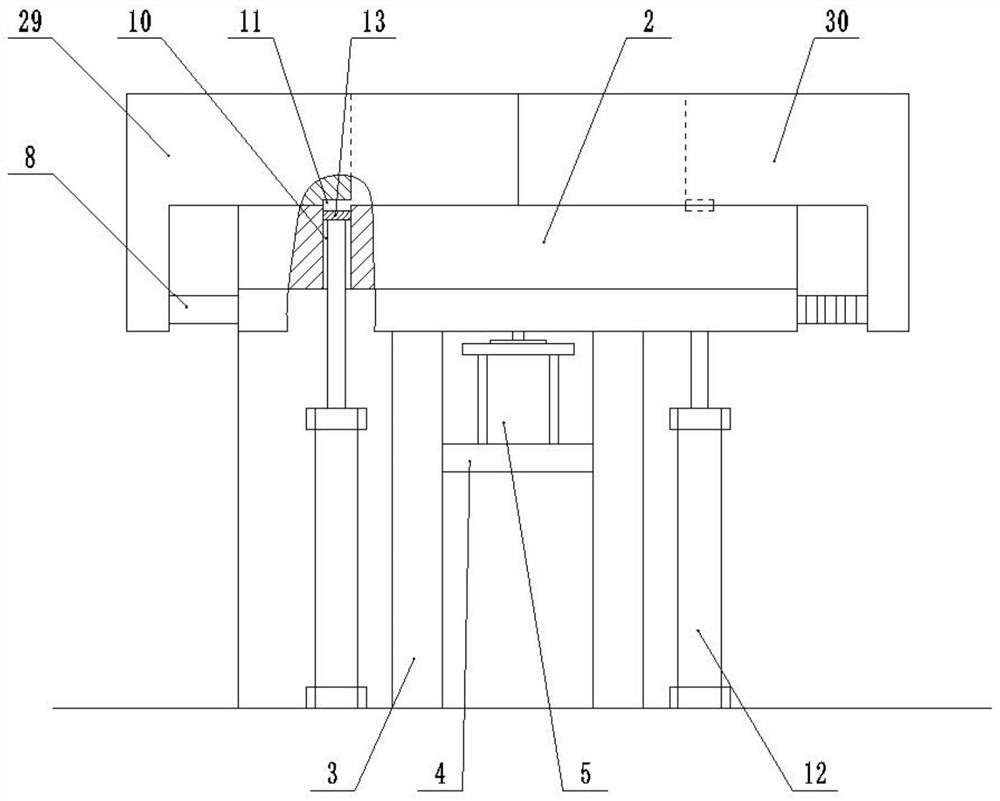

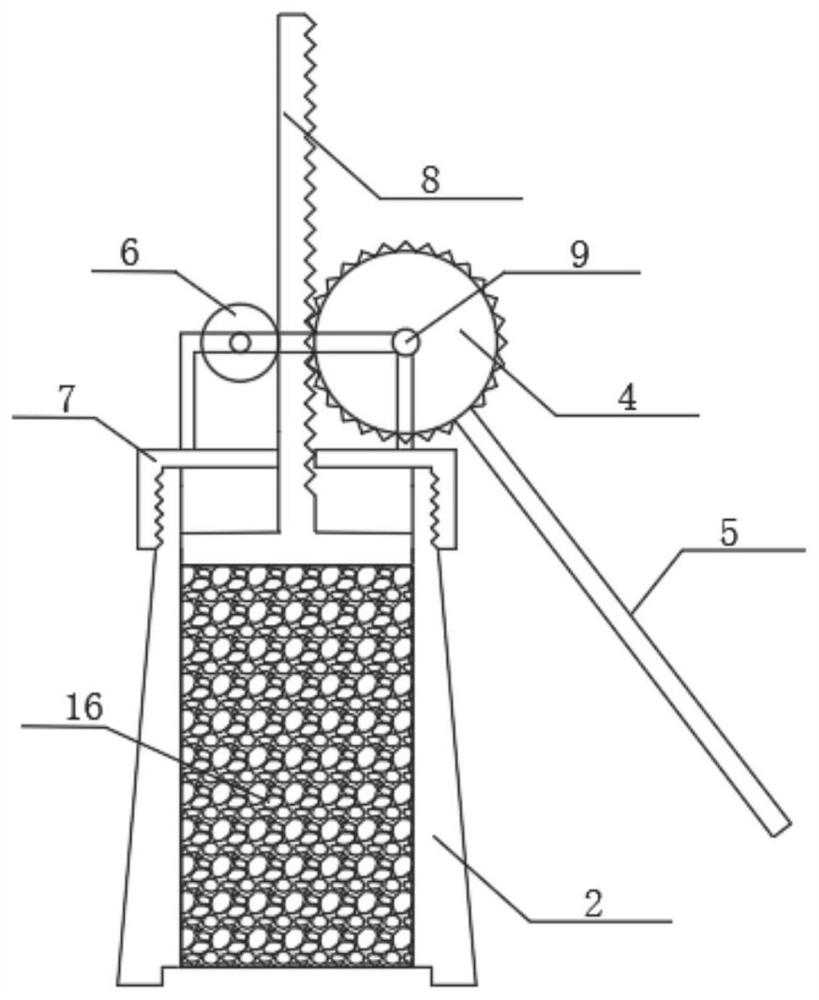

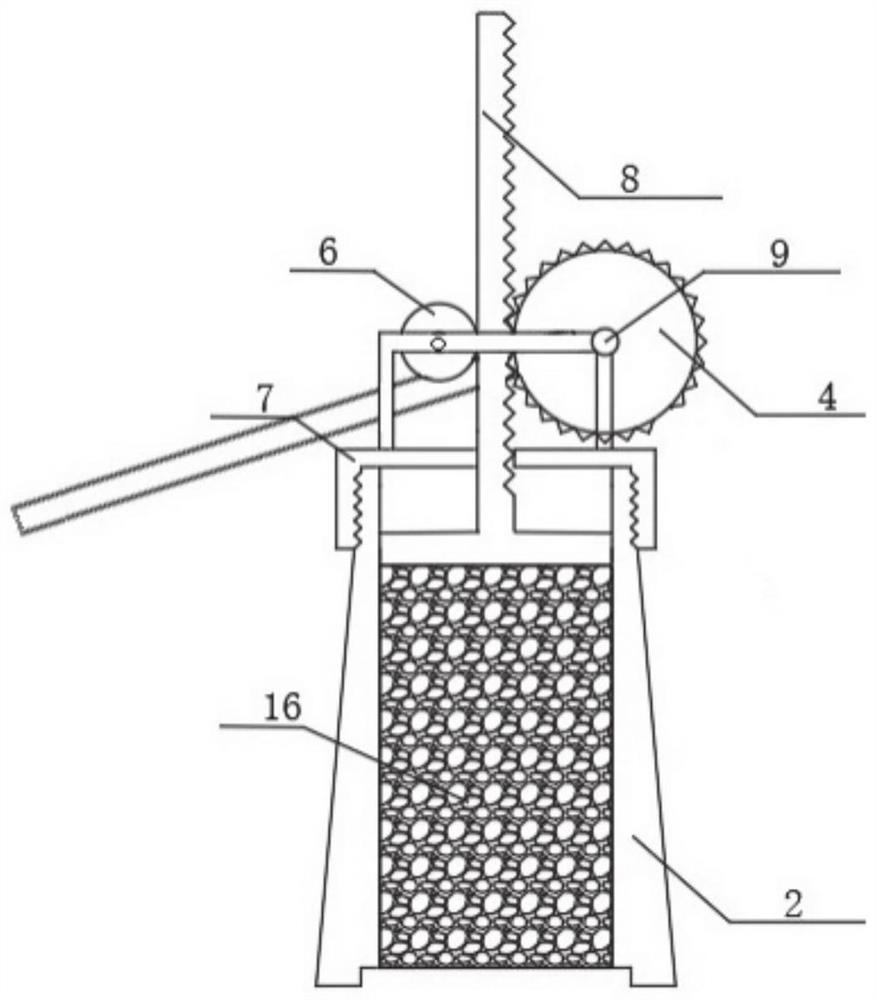

Brick molding machine for producing prefabricated drilling cement

InactiveCN103302726AEasy to achieve compressionEasy demoulding processDischarging arrangementBrickMolding machine

The invention relates to a brick molding machine for producing prefabricated drilling cement, which comprises a brick molding main machine, a gantry frame, a chute, an operating platform, a raw material pusher and a hydraulic system, wherein the operating platform is fixed on the gantry frame, the brick molding main machine is fixed mounted on the inner side of the gantry frame and comprises an ejector, a mould assembly and a cement hydraulic hole former assembly, the ejector and the mould assembly are mounted on the inner side of the machine frame above the operating platform, and the cement hydraulic hole former assembly is fixedly mounted on the inner side of the machine frame below the operating platform. According to the brick molding machine provided by the invention, the ejector is arranged at the top of the machine frame of the brick molding machine, the cement hydraulic hole former device is arranged at the bottom of the machine frame so as to realize prefabricated drilling cement suppressing and demolding conveniently, and improve the degree of automation of prefabricated drilling cement producing greatly.

Owner:王庆起

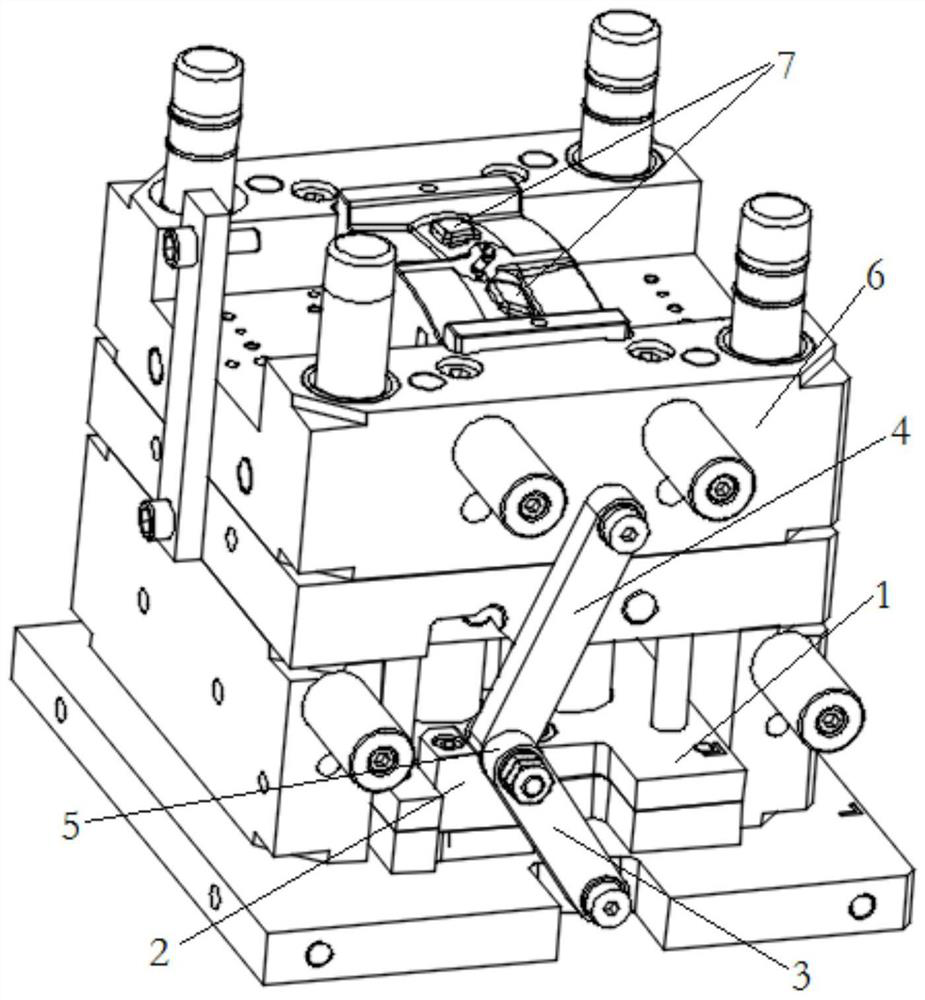

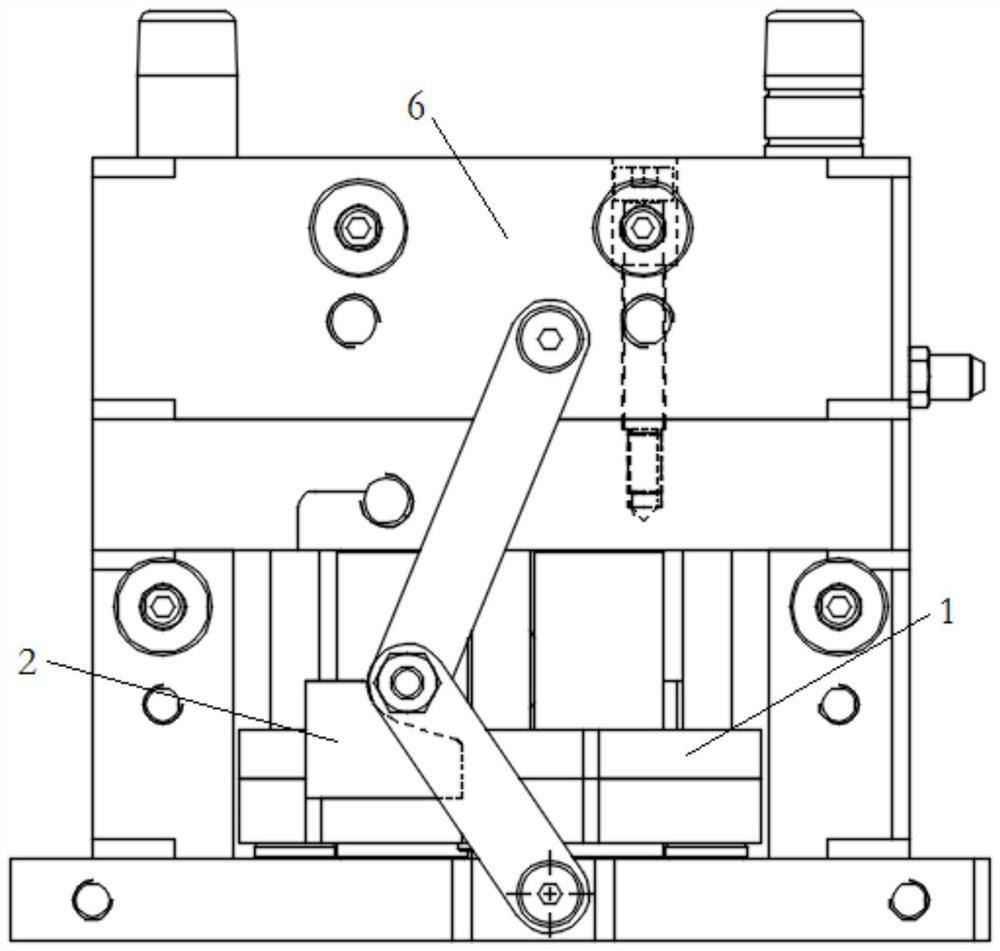

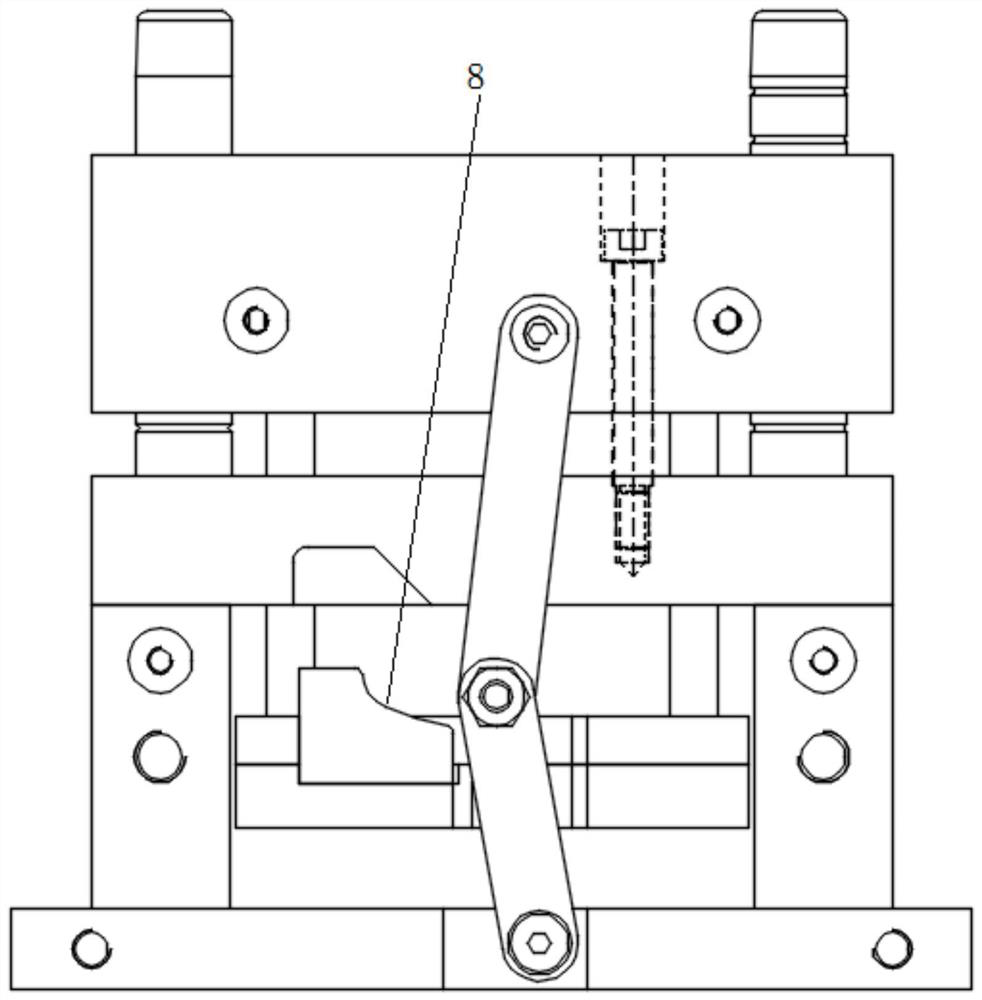

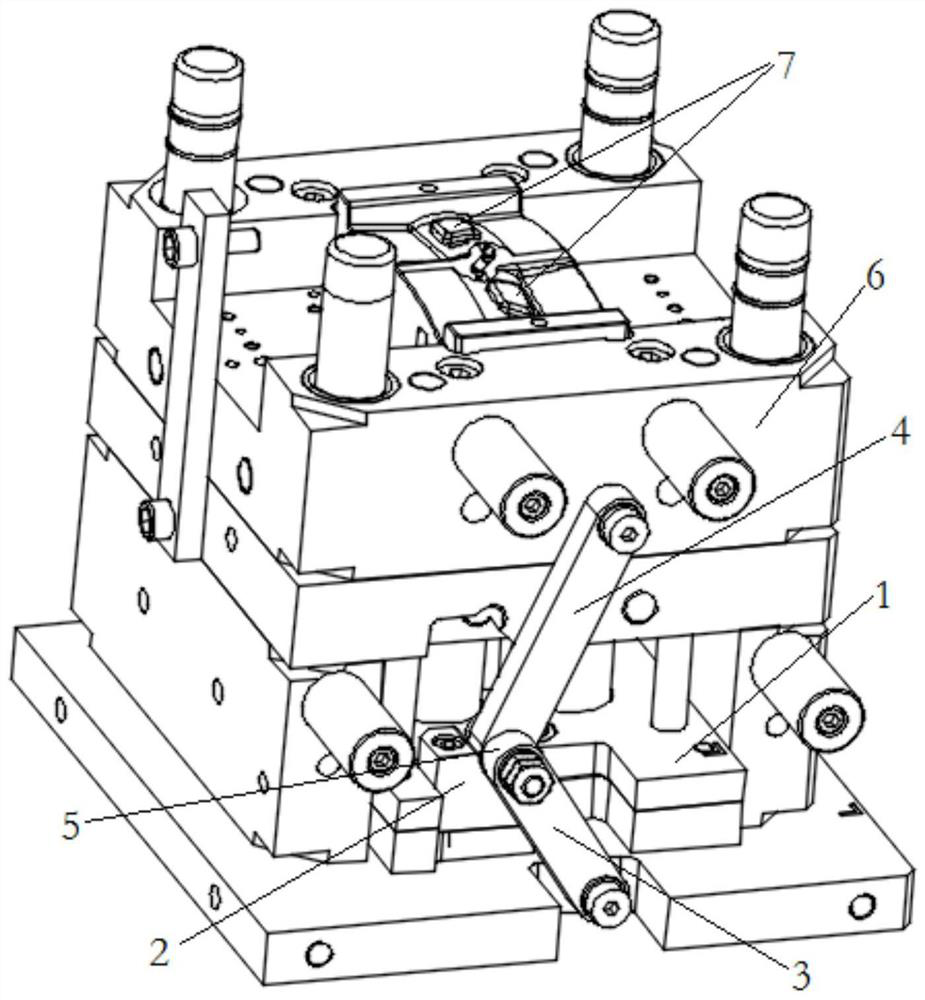

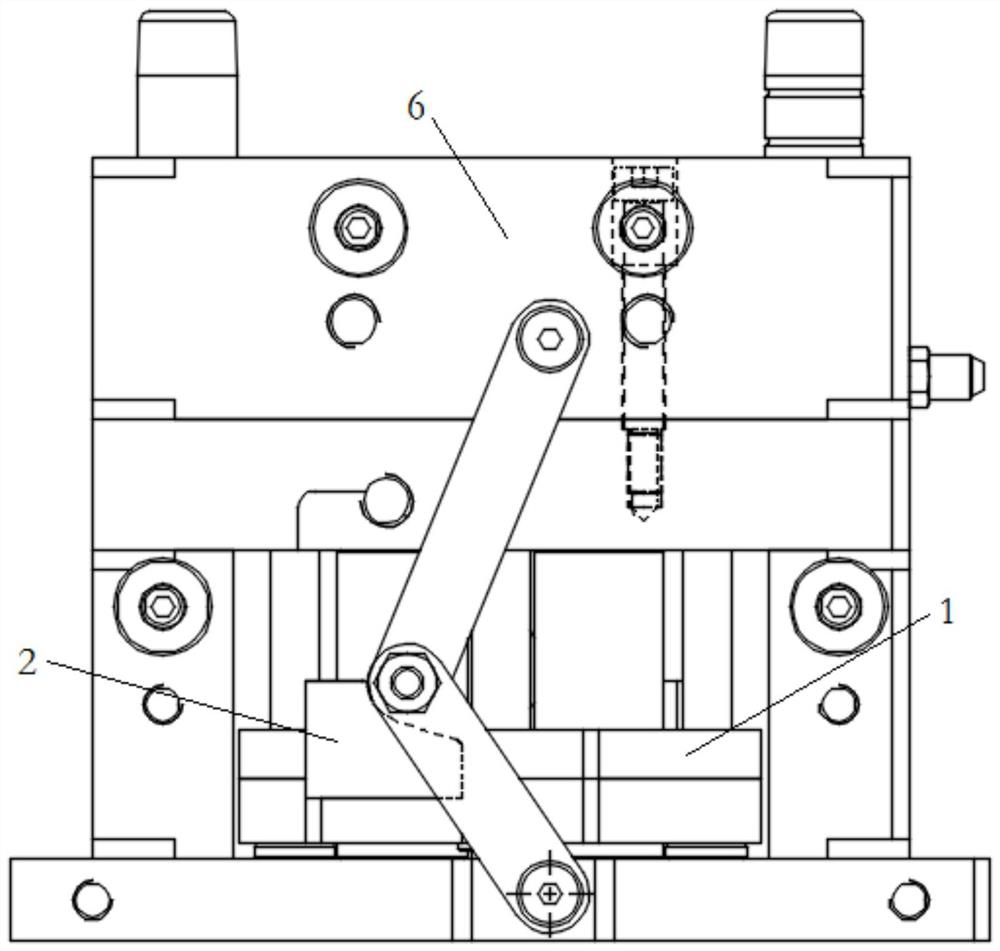

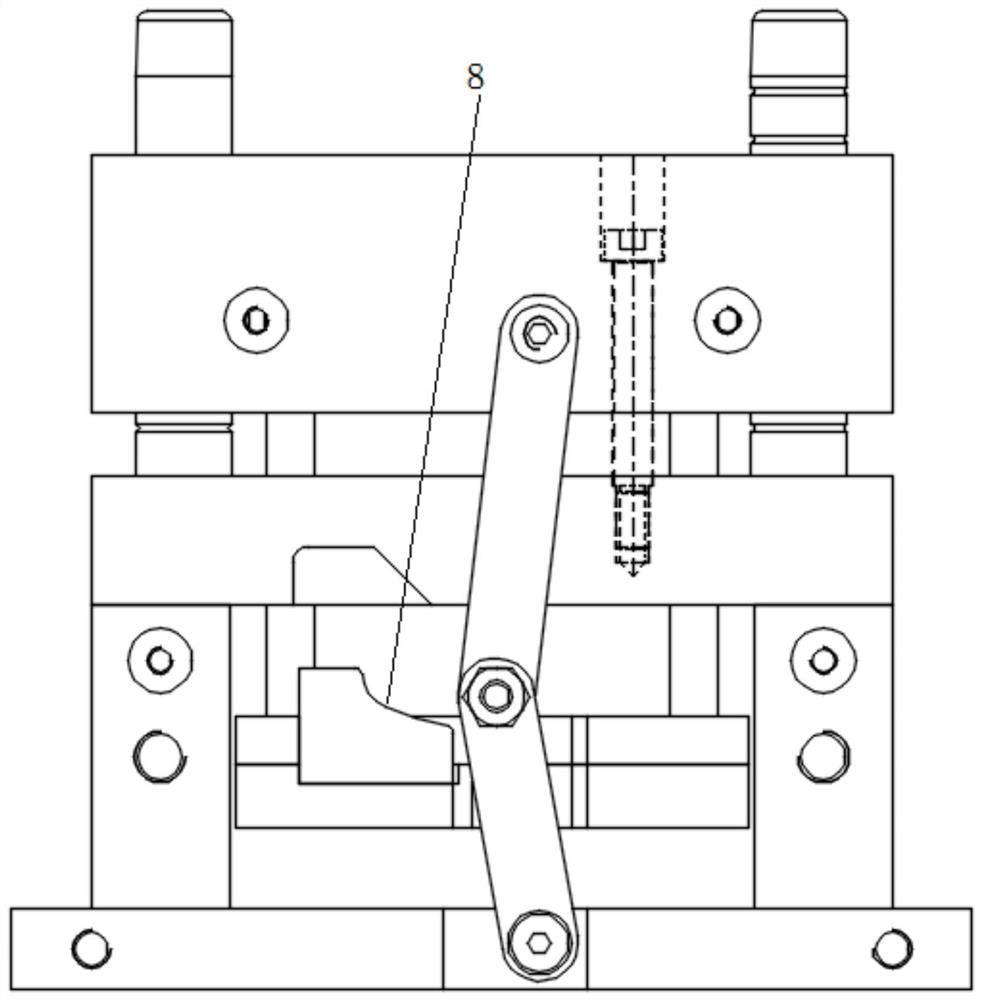

Injection mold slider-crank secondary ejection structure

The invention relates to the technical field of injection molds, in particular to an injection mold slider-crank secondary ejection structure and method. The injection mold slider-crank secondary ejection structure comprises a slider-crank mechanism, a push plate used for pushing a movable mold to move upwards so as to eject a product to a first distance, a shifting block and an ejector pin block,wherein the slider-crank mechanism comprises a first connecting rod and a second connecting rod; one end of the first connecting rod is hinged to a base; the other end of the first connecting rod ishinged to one end of the second connecting rod through a hinge; the other end of the second connecting rod is hinged with the push plate; the hinge is slidably located in a half-crescent-shaped sliding groove of the shifting block; the shifting block is fixedly connected with the ejector pin block; and the ejector pin block is fixedly provided with an ejector pin used for ejecting a product out bya second distance. When a plastic product has a deep glue position on the movable mold side, the secondary ejection structure is simple, the product demolding is convenient to realize, the cost is low, the simplicity in maintenance is achieved, and the universality is high. Secondary ejection is realized under the condition of adding a small number of parts. The added parts are simpler and more convenient to process and assemble. Therefore, the effect of saving the mold cost is achieved.

Owner:武汉华升源模具有限责任公司

Injection molding machine

PendingCN113815181ADoes not affect tightnessImprove finished product qualityHydraulic cylinderMolding machine

The invention relates to the technical field of injection molding, in particular to an injection molding machine. The injection molding machine comprises a mold fixing seat, wherein the mold fixing seat comprises a first mold plate and a second mold plate, and the first mold plate and / or the second mold plate are / is installed on a first sliding rail and connected with a first hydraulic cylinder; a mold comprises a first mold body and a second mold body, the first mold body is installed in the first mold plate, and the second mold body is installed in the second mold plate; and a mold inner container is installed on a fixing frame, the fixing frame is installed on a second sliding rail, and the fixing frame is connected with a third hydraulic cylinder. According to the injection molding machine, the problem that an injection molding mechanism in the prior art can only perform injection molding for a product in one shape is solved. The injection molding mechanism of the injection molding machine comprises the mold fixing seat, an outer mold and the mold inner container, so that hollow structures in different shapes can be formed through injection molding. The mold fixing seat is detachably connected with the outer mold, so that only the outer mold and the mold inner container need to be replaced for products in different shapes, and the mold fixing seat does not need to be replaced.

Owner:昆山秀美丰电子科技有限公司

A barrier layer, sintering mold and preparation method thereof

ActiveCN110723964BEasy demoulding processImprove yieldCeramic shaping liningsCarbide siliconTungsten nitride

The invention provides a barrier layer for being arranged on the surface of a sintered mold for preparing foamed ceramics, the composition of the barrier layer includes quartz sand, zirconia, aluminum oxide, carbide and nitride, wherein the carbide It includes one or more of silicon carbide, tungsten carbide and boron carbide, and the nitride includes one or more of silicon nitride, boron nitride and tungsten nitride. The barrier layer is used to be arranged on the surface of a sintered mold for preparing foamed ceramics, and is characterized in that the components of the barrier layer include quartz sand, zirconia, aluminum oxide, carbides and nitrides, wherein the carbides include One or more of silicon carbide, tungsten carbide and boron carbide, and the nitride includes one or more of silicon nitride, boron nitride and tungsten nitride. The invention also provides a sintering mold and a preparation method of the sintering mold.

Owner:江西中材新材料有限公司 +2

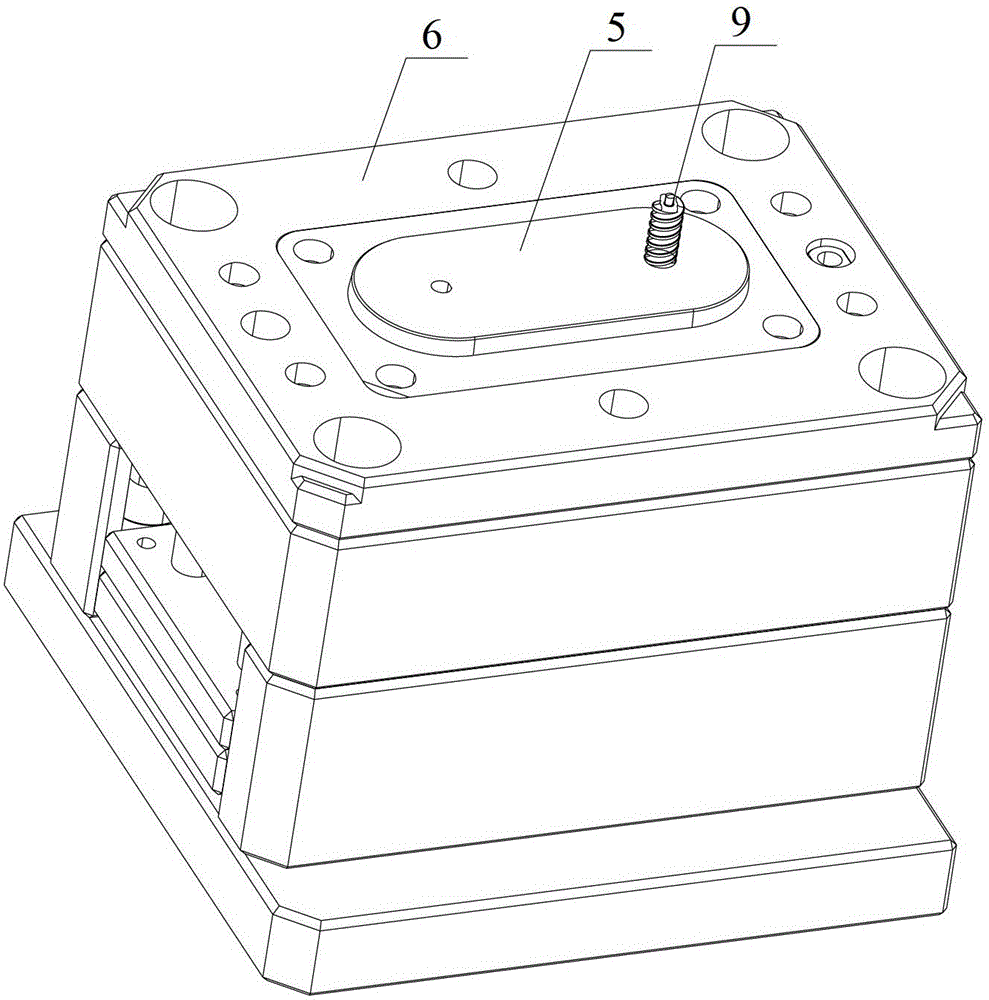

Tray mold capable of achieving injection molding of multiple bottom feet

Owner:重庆市魏来雄鑫橡塑制品有限责任公司

A kind of preparation technology of one-piece molded shoe

ActiveCN110421882BFirmly connectedImprove integrityDomestic footwearMolding machineUltrasonic welding

The invention relates to the field of shoe preparation, in particular to a preparation process for integrally formed shoes, which mainly solves the problem of poor connection firmness between the upper of the shoe and the sole in the prior art, and comprises the following steps: preparing the mold base of the shoe sole by injection molding; preparing the upper of the shoe ; set the upper of the shoe in the matching shoe last; prepare a secondary molding mold, which includes an upper mold, a middle mold, a lower mold and a fixing ring, put the shoe sole mold base into the lower mold, and fix the shoe last on the On the upper mold, set the fixing ring on the outside of the upper, and attach the fabric on the outer ring surface of the fixing ring, and finally push the upper mold to move downward and insert it into the through hole; through the secondary molding machine, the secondary The forming mold is vulcanized and heated, so that the sole mold base is foamed and formed; the upper part of the fabric and the connecting piece are welded by ultrasonic welding to form an integrated shoe.

Owner:QUANZHOU QUANYONG MACHINERY DEV

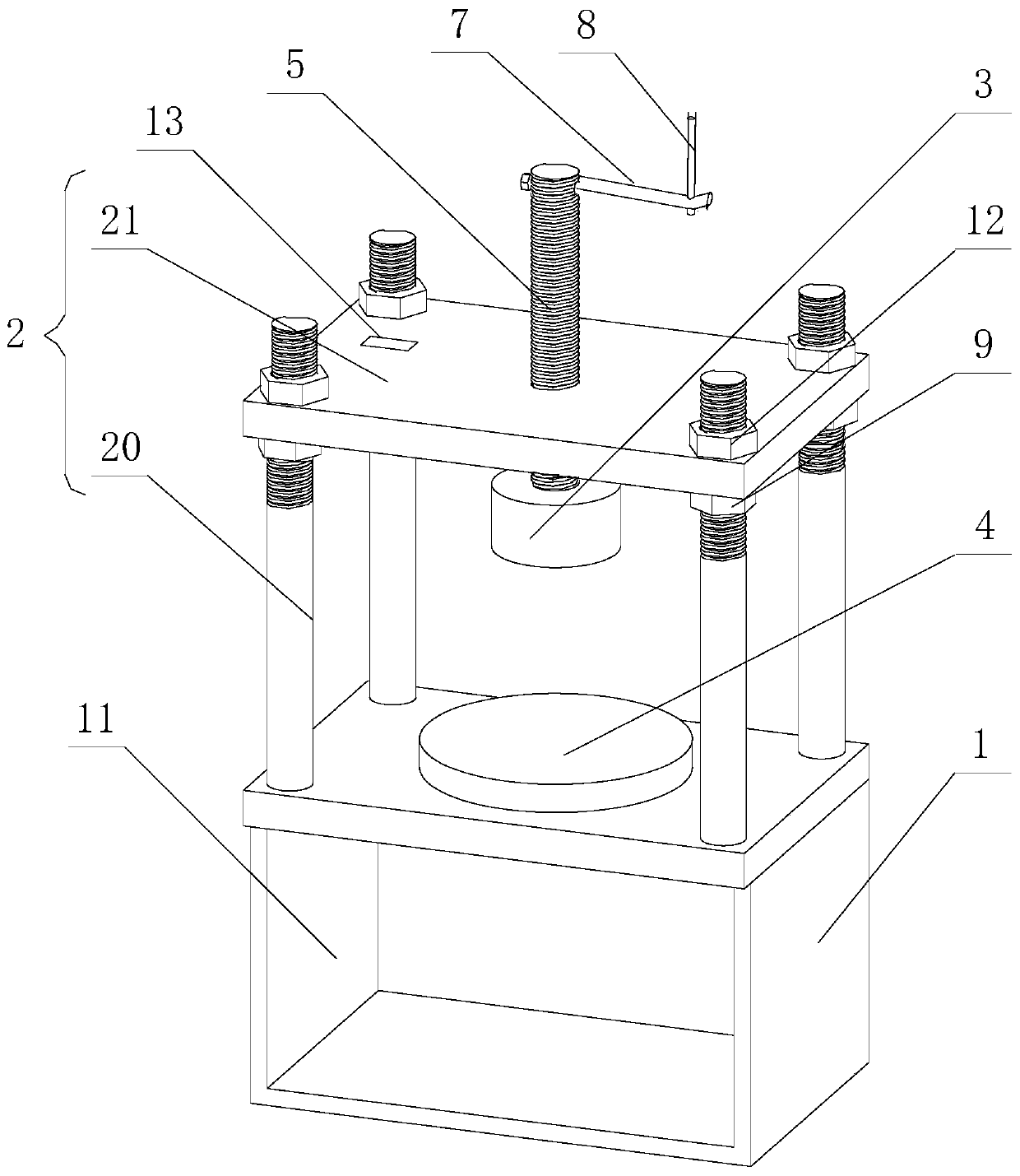

Demolding device capable of being used for molding

PendingCN111060438APrevent rotationEasy demoulding processPreparing sample for investigationPermeability/surface area analysisStructural engineeringMechanical engineering

Owner:安徽省建筑工程质量监督检测站有限公司皖南分站

Forming device for heat insulation end socket air bag

The invention discloses a heat insulation end socket air bag forming device which comprises an upper die and a lower die, and an air bag is arranged in a space defined by the upper die and the lower die. A middle mold is arranged between the air bag and the lower mold, and the middle mold is detachably connected with the lower mold; a detachable metal joint is arranged on the middle mold; and the heat insulating layer is filled in a space enclosed by the air bag, the lower die, the middle die and the metal joint. The sealing head is integrally formed in an air bag pressurization mode. In addition, the pressure of the air bag is uniform, and the device is more suitable for bonding forming of the root of an artificial debonding layer of the end socket at the equatorial line. Compared with compression molding, air bag forming has flexibility, integral forming of complex structural parts is easy to achieve, assembling and disassembling are easy, convenient and fast, cost is low, and a large amount of working hours can be saved. The forming device can achieve forming of various heat insulation end sockets, and is particularly suitable for forming of heat insulation end sockets of large-scale and ultra-large-scale solid rocket engines.

Owner:湖北三江航天江北机械工程有限公司

Gear Worm Mold

Owner:CIXI SANPEI MACHINE

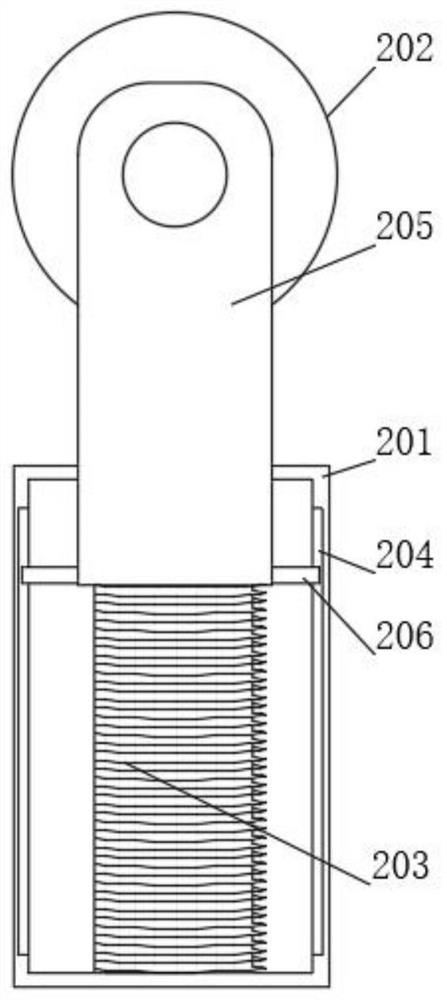

Demolding device and method for electroforming thin-wall metal fixing tube

ActiveCN113322498AEasy to demouldEasy demoulding processElectroforming processesEngineeringElectrochemistry

The invention discloses a demolding device and method for an electroforming thin-wall metal fixing tube, and belongs to the technical field of electro-chemical machining. The device mainly comprises a fixed hook, a master mold, a metal fixing tube, a suction pull head, a negative pressure generating unit, a supporting shaft and a base. Based on the device, firstly, the master mold with the metal fixing tube on the outer side surface is rotationally and detachably fixed on the base through the fixed hook and the supporting shaft; secondly, the negative pressure generating unit is started, and a handle is held by hand to tightly adsorb the suction pull head to the surface of the metal fixing tube; thirdly, the suction pull head is horizontally moved and the master mold is rotated until the adsorption point positions are completely distributed on the surface of the metal fixing tube; and finally, the metal fixing tube is pulled away from the master mold, demolding is completed, and the negative pressure generating unit is closed. The demolding device is simple, demolding is easy to achieve, the demolding effect is good, the efficiency is high, and the process cost is low.

Owner:HENAN POLYTECHNIC UNIV +1

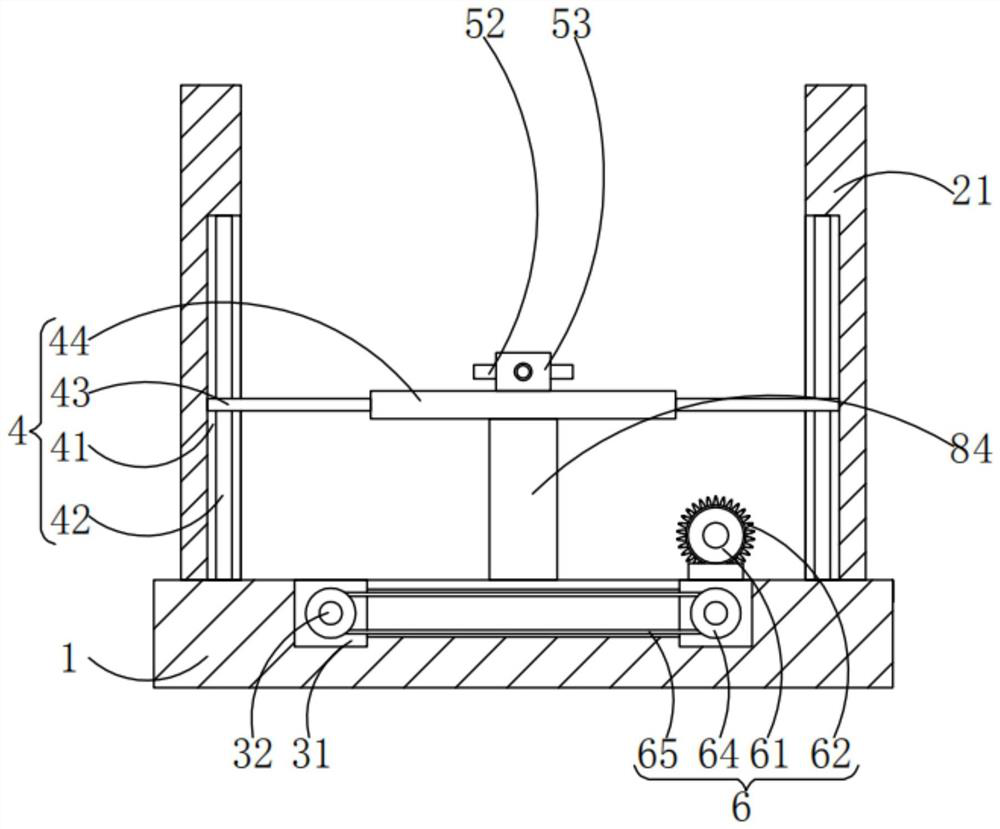

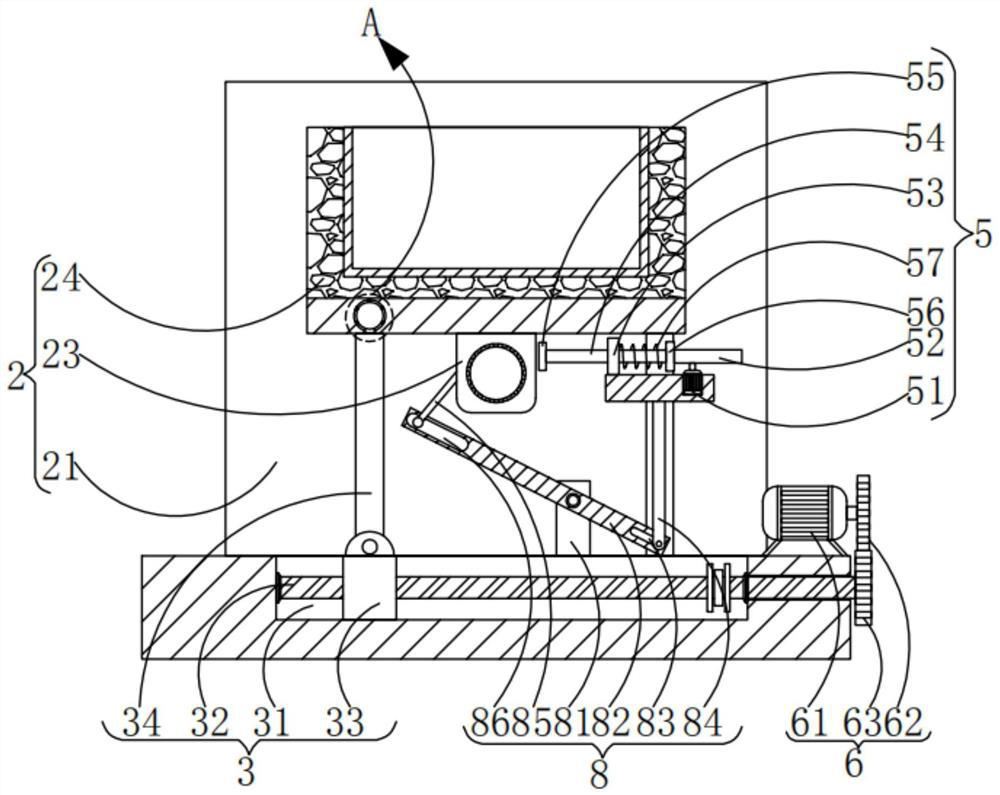

Demolding device for kit injection mold production

The invention discloses a demolding device for kit injection mold production. The demolding device comprises a base plate; two mounting plates are fixedly connected to the top end of the base plate; afixed mold is fixedly connected to the opposite ends of the two mounting plates jointly; a movable mold is arranged on the sides, close to the fixed mold, of the two mounting plates; moving rods arefixedly connected to the two sides of the movable mold correspondingly; the ends, away from the movable mold, of the two moving rods penetrate through the corresponding mounting plates correspondingly; the opposite sides of the two mounting plates are fixedly connected with limiting frames correspondingly; and the limiting frames are connected with the corresponding moving rods in a buckled mode.According to the demolding device for the kit injection mold production provided by the invention, an extrusion mechanism is arranged, due to the arrangement of a sliding block and a sliding groove inthe extrusion mechanism, a spring and the moving rods can be better limited, better use is facilitated, a demolding procedure can be better carried out, due to the arrangement of the sliding block and the sliding groove, the spring can be better protected, the spring is prevented from being damaged due to excessive deviation, and the device is easy to operate and better in use effect.

Owner:SUZHOU HAOJUN AUTOMATION EQUIP TECH CO LTD

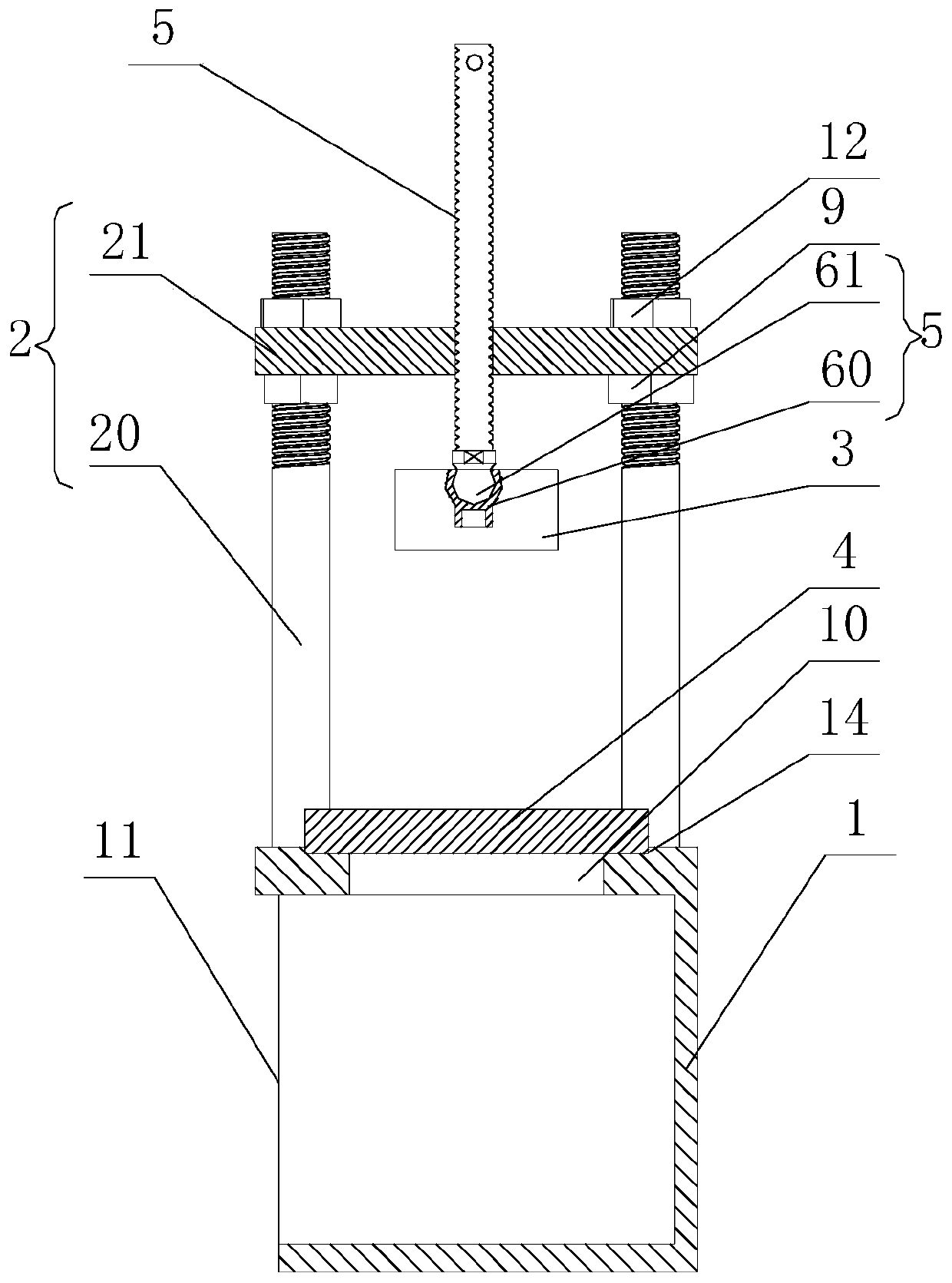

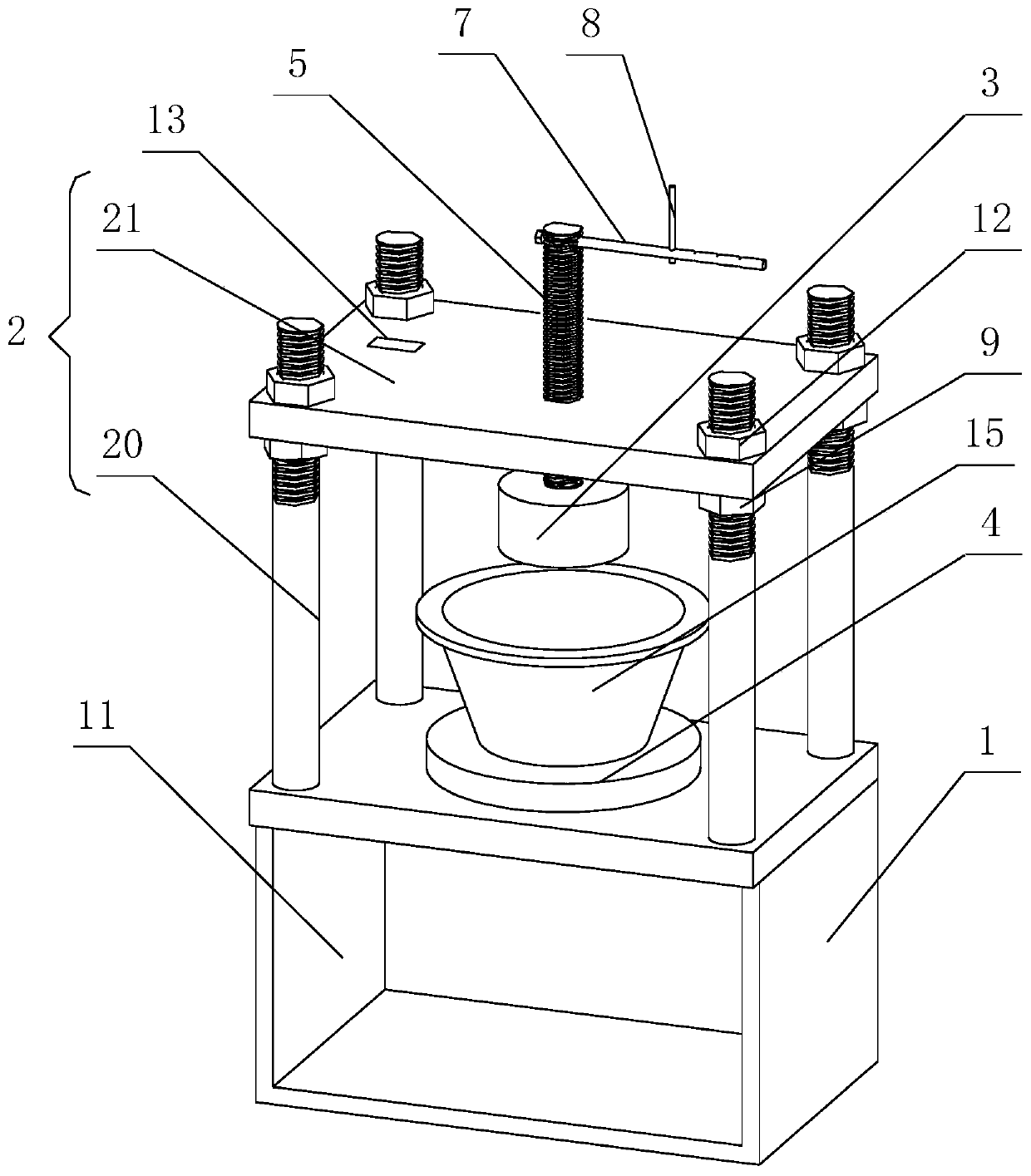

A preparation device and method for a rock-soil model test piece

ActiveCN113029719BSolve the problem of gap leakageGuaranteed accuracyPreparing sample for investigationModel testTop cap

The disclosure relates to a preparation device and method for a rock-soil model test piece, which includes a mold barrel, a hammering piece that can be inserted through the opening of the first end of the mold barrel, and a base that is detachably installed at the opening of the second end; it also includes a top The ejection mechanism, the ejection mechanism includes a top cover detachably fixed at the opening of the first end, the top cover is pierced with a ejector rod, driven by the linear drive mechanism, the ejector rod can extend into the mold barrel and move along the central axis of the mold barrel Do reciprocating linear motion. The disclosure can reduce the difficulty of preparing rock-soil model test pieces and improve the preparation quality of the test pieces.

Owner:SHANDONG UNIV

Rapid demolding mold for machining of mechanical parts

PendingCN114762893AImprove processing efficiencyEasy to demouldMould handling equipmentsEngineeringMachining

The invention discloses a rapid demolding mold for machining of mechanical parts. The rapid demolding mold comprises a base plate. The supporting device is arranged at the top of the base plate, the supporting device comprises two vertical plates, the opposite sides of the two vertical plates are fixedly connected with round rods, the outer surfaces of the round rods are rotationally connected with rotating blocks, and one sides of the tops of the rotating blocks are fixedly connected with a mold frame; the limiting device is arranged in the vertical plate, and the limiting device comprises two sliding grooves; according to the rapid demolding mold for machining of the mechanical parts, the supporting device is arranged to drive the mold frame to rotate, after the mold frame rotates, the demolding device is arranged to intermittently impact the mold frame to loosen a casting part in the mold frame, and therefore demolding of the mold is facilitated; and the supporting device moves and drives the demolding device to move at the same time, so that demolding of the mold frame is conveniently achieved, and the machining efficiency of the mechanical parts is improved.

Owner:泰兴市凯力特弹簧有限公司

A Secondary Ejection Structure of Injection Mold Crank Slider

Owner:武汉华升源模具有限责任公司

Assembled mould structure with self-contained sliding core power

The invention discloses an assembled mould structure with self-contained sliding core power, which comprises a fixed mould and a movable mould matched with each other, wherein the working face of the movable mould is encrusted with movable mould units, the middle part of each movable mould unit is provided with a movable cavity, and the periphery of each movable mould unit is provided with three sets of sliding core units at an interval of equal radian along the center of the movable cavity; each sliding core unit is equipped with a slide block, and the external end side of the slide block isprovided with an obliquely arranged hollow lantern ring; the contact face of the fixed mould is embedded with fixed mould units, the middle part of each fixed mould unit is provided with a fixed cavity, and the periphery of each fixed mould unit is provided with three sets of driving units at an interval of equal radian along the center of the fixed cavity; and each driving unit is internally equipped with a protruded and obliquely arranged driving shaft. The assembled mould structure of the invention has the advantages that: by using the structure of splicing inclined shafts and sleeves, theoperation of the slide blocks can be realized without other external power; the same module is equipped with four sets of module units; the processing efficiency is high; and all units are in bolted connection, so the maintenance is quick and convenient.

Owner:NINGBO HUASHUO MOLDING & MACHINE

Aluminum alloy workpiece extrusion forming device

ActiveCN114160643AHigh precisionPrevent stress concentration and deformationShaping toolsEjection devicesEngineeringAluminium alloy

The aluminum alloy workpiece extrusion forming device comprises a rack, an upper pressing die structure, a lower pressing die structure, a water cooling structure and a controller, the upper pressing die structure is fixedly installed at the top of the rack, the lower pressing die structure is fixedly installed at the bottom of the rack, and the lower pressing die structure comprises a lower die platform; two supporting legs are fixedly mounted at the bottom of the lower die platform; two demolding holes are formed in the top of the lower mold platform; a left side mold and a right side mold are installed on the left side and the right side of the lower mold platform in a sliding mode, the left side mold and the right side mold are fixedly connected with the two sliding gears correspondingly, demolding grooves are formed in the bottoms of the left side mold and the right side mold, and the left side mold and the right side mold have the mold closing state and the mold opening state. When the left side mold and the right side mold are in a mold closing state, the demolding grooves formed in the bottoms of the left side mold and the right side mold directly face the demolding holes formed in the top of the lower mold platform; the extrusion forming device is provided with the demolding structure and the water cooling structure, the demolding and cooling effects are good, and the forming quality of an aluminum alloy workpiece can be guaranteed.

Owner:SHANDONG UNIV

Preparation device and method for rock-soil model test piece

ActiveCN113029719ASolve the problem of gap leakageGuaranteed accuracyPreparing sample for investigationLinear motionSoil model

The invention relates to a preparation device and method for a rock-soil model test piece. The preparation device comprises a mold barrel, a hammering piece capable of being inserted from an opening in the first end of the mold barrel, and a base detachably installed at an opening in the second end of the mold barrel. The device further comprises an ejection mechanism, the ejection mechanism comprises a top cover detachably fixed to the opening of the first end, an ejection rod is arranged in the top cover in a penetrating mode, and the ejection rod can be driven by a linear driving mechanism to stretch into the mold barrel and do reciprocating linear motion along the central axis of the mold barrel. The preparation difficulty of the rock-soil model test piece can be reduced, and the preparation quality of the test piece is improved.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com