Brick molding machine for producing prefabricated drilling cement

A brick making machine and cement technology, applied in the direction of manufacturing tools, ceramic forming machines, unloading devices, etc., can solve the problems of poor integration of mold devices, difficulty in adapting, and few functions, and achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

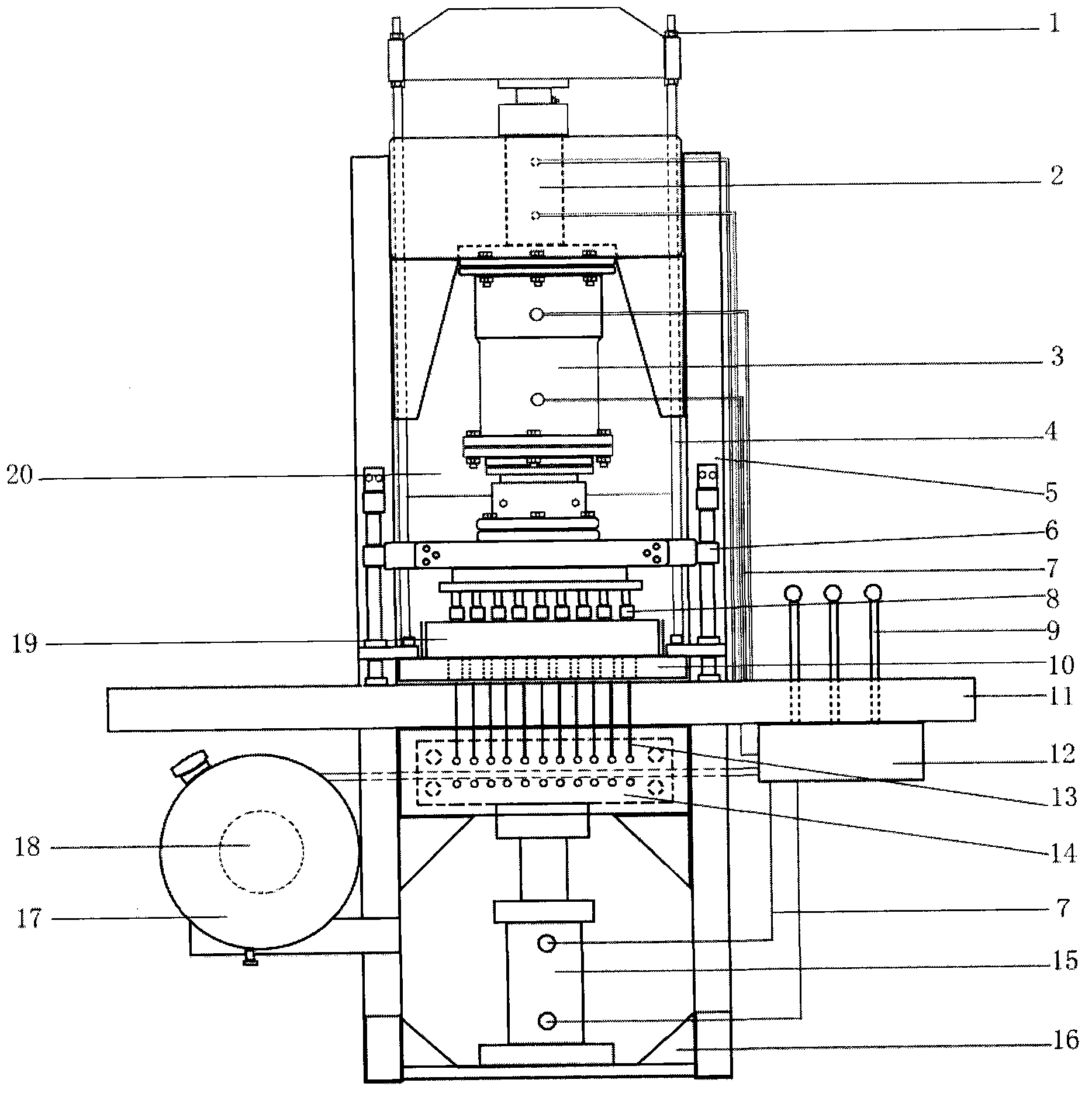

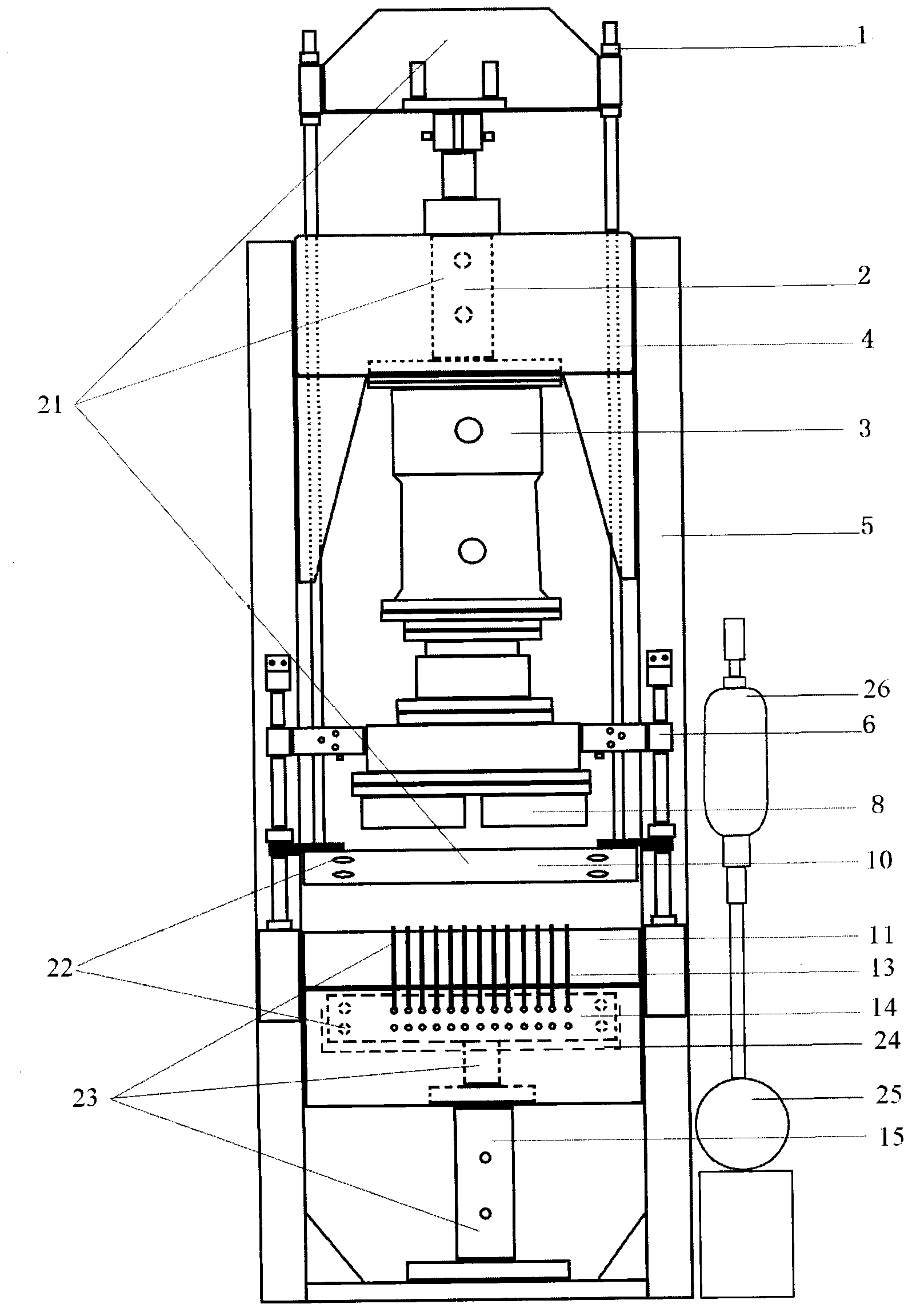

[0020] The composition structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

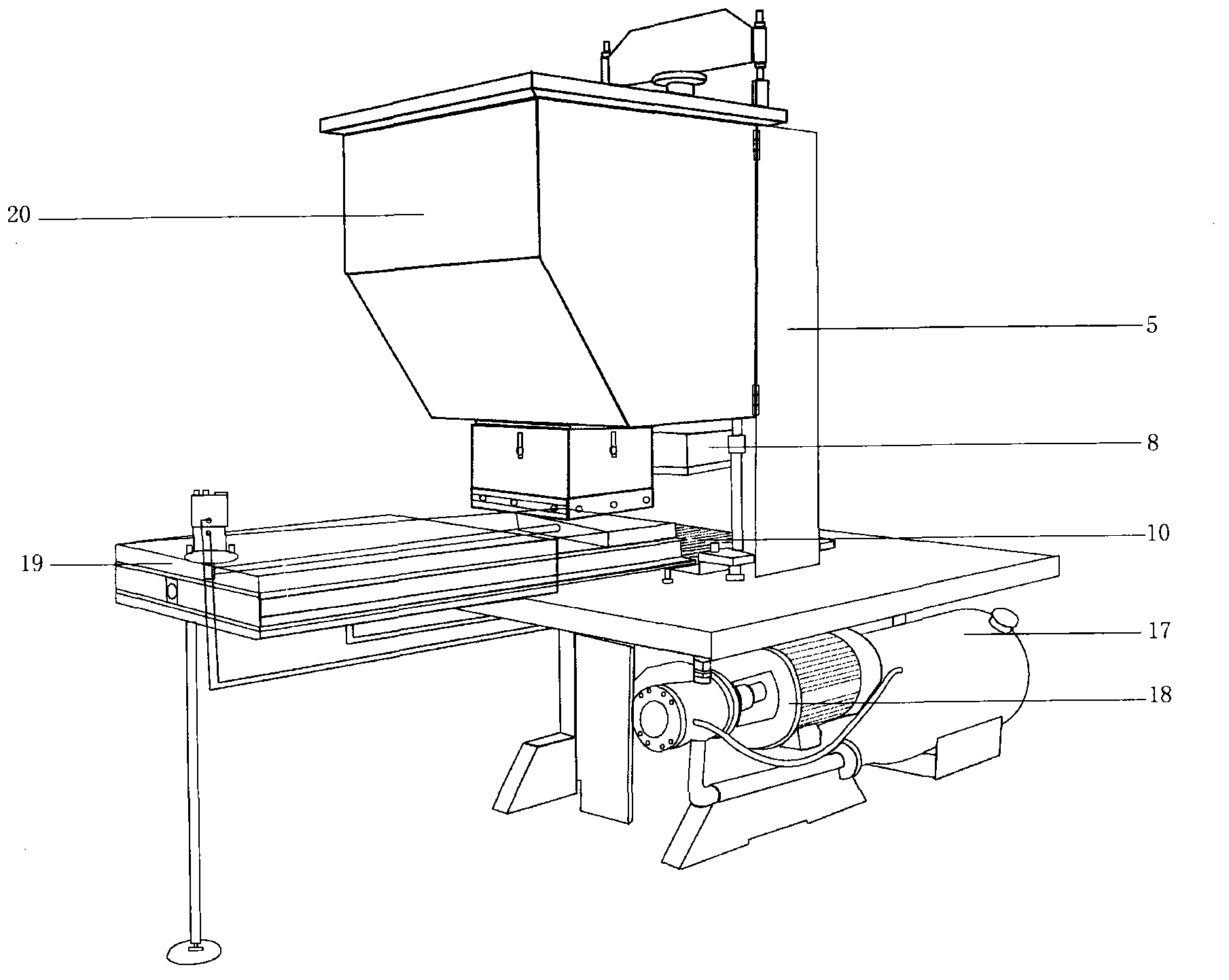

[0021] refer to Figure 1-2 , The brick making machine for producing perforated cement prefabricated products of the present invention mainly includes a brick making machine host, a gantry frame 5, a hopper 20, an operating platform 11, a raw material pusher 19 and a hydraulic oil pump system. Wherein the operating platform 11 is fixed on the gantry frame, and the main frame of the brick making machine is fixedly installed on the inside of the gantry frame, which includes a stripper and mold assembly 21 and a cement hydraulic hole maker assembly 23, wherein the stripper and mold The assembly is installed on the inside of the frame above the operating platform 11 , and the cement hydraulic hole maker assembly 23 is installed on the inside of the frame below the operating platform 11 .

[0022] The stripper and mold a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com