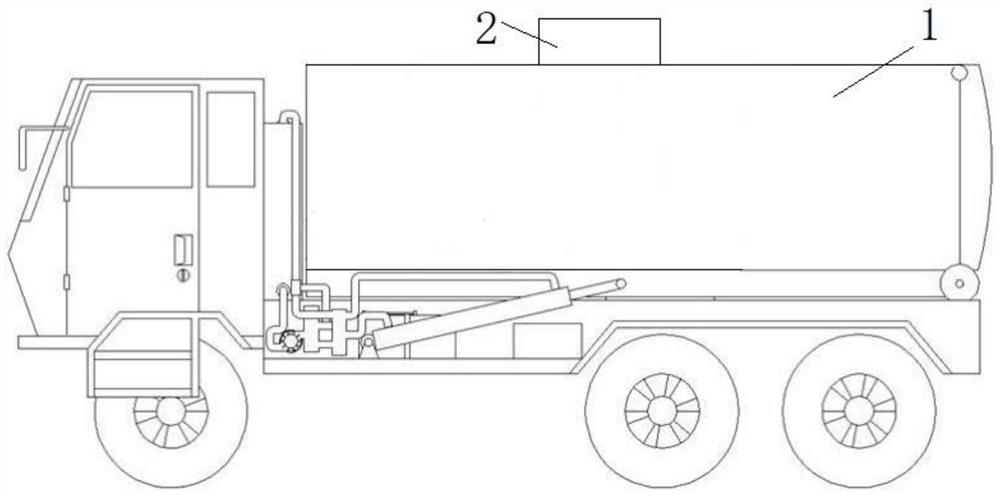

Compression type garbage truck

A garbage truck and compression technology, which is applied in the directions of garbage receptacle, transportation and packaging, can solve the problems of odor, unfavorable environmental protection and cleanliness of the compartment, and inconvenient garbage discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

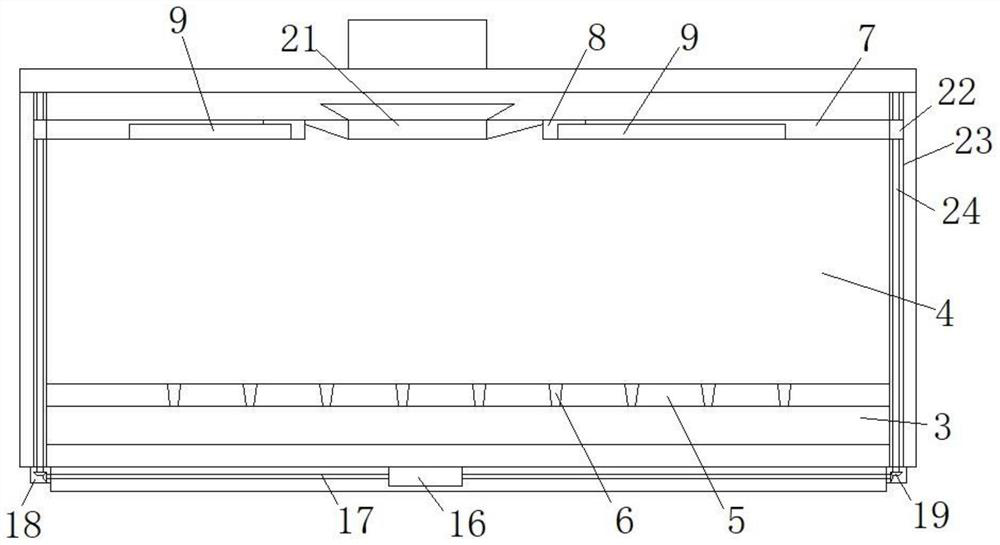

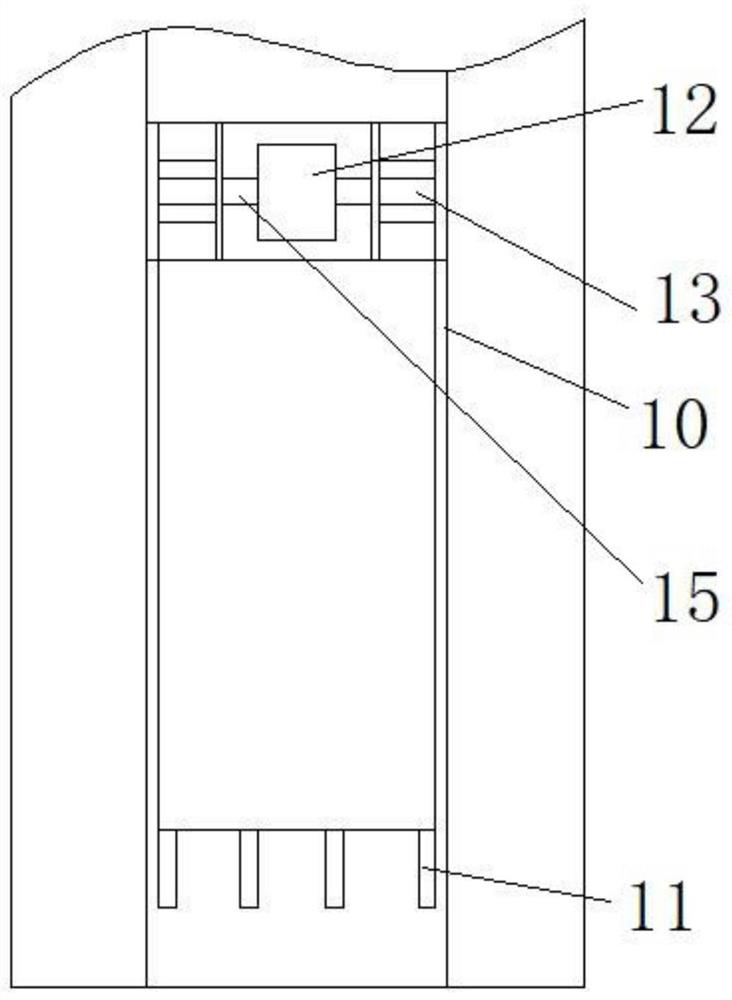

[0028] Such as Figure 2 to Figure 4 As shown, the guide toggle mechanism includes a drive box 8 and a toggle plate 9, one end of the toggle plate 9 is provided with a plurality of toggle teeth 11, the other end of the toggle plate 9 is provided with a concave bayonet 14, and the concave shape Both sides of the bayonet socket 14 are provided with rotating shafts 13, the drive box 8 is clamped in the concave bayonet socket 14, and the drive box 8 is connected to the rotating shafts 13 on both sides, and the drive box 8 is driven by The rotating shafts on both sides rotate to drive the toggle plate 9 to rotate into and out of the receiving groove 10 of the pressing plate 7 . The setting of a plurality of toggle teeth facilitates the rubbish to be toggled during the toggle process of the toggle plate, so that the rubbish can be better moved to the other side. During setting, one end of the rotating shaft is fixedly connected with the toggle plate, and the other end is in transmi...

Embodiment 2

[0036] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the lifting mechanism includes a hydraulic rod and a hydraulic cylinder 20 that drives the hydraulic rod to move up and down, and the hydraulic cylinder 20 is arranged on the top inner wall of the solid waste collection box 4, The hydraulic cylinder 20 is connected with the pressing plate 7 through a hydraulic rod. By starting the hydraulic cylinder, the hydraulic rod is driven to expand and contract, and then the pressure plate is driven to compress the garbage.

[0037] In order to prevent excessive sewage in the sewage collection box from spreading into the solid waste collection box, the modified garbage truck also includes a spare water tank located at the bottom of the compartment main body 1, and the spare water tank is connected to the sewage collection box 3 through a drain pipe. connect. The backup water tank initiates the buffer pooling action.

[0038] As a further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com