Demolding device and method for electroforming thin-wall metal fixing tube

A demoulding device, metal technology, applied in the direction of electroforming, electrolysis process, etc., can solve the problems of unable to achieve smooth demoulding, easy to damage the structure of the fixing tube, complex demoulding operation, etc., to achieve high demoulding efficiency and low process cost , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

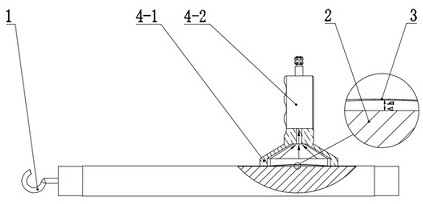

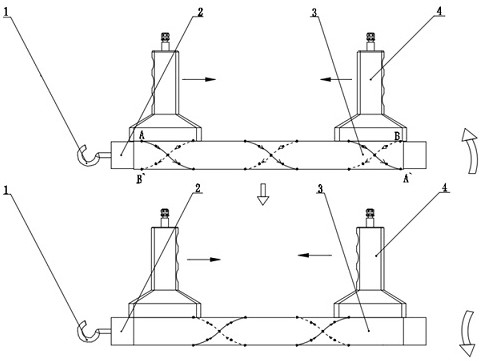

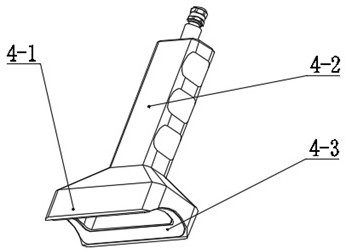

[0026] Such as figure 1 As shown, a demoulding device for electroformed thin-walled metal fixing tube, it includes a fixed hook 1 made of SUS316 stainless steel and an original mold 2, wherein the diameter of the original mold 2 is D=30mm, the length is L=360mm, And after quenching + high temperature tempering treatment, metal fixing tube 3, suction head 4, negative pressure generating unit 5, support shaft 6 and base 7; the original mold 2 is equipped with a fixed hook 1 at one end and a support shaft at the other end 6, and the rotation center axes of the original mold 2, the fixed hook 1 and the support shaft 6 coincide; the negative pressure generating unit 5 includes a suction head 4 provided with a suction nozzle 4-1, and a vacuum pump governor 5-2 installed Vacuum pump 5-1 and hose 5-3, wherein the length and width of suction nozzle 4-1 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com