A kind of preparation technology of one-piece molded shoe

A preparation process and an integrated technology, which is applied in the field of the preparation process of integrally formed shoes, and can solve problems such as poor connection firmness between the upper and the sole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0020] Embodiments of the invention are:

[0021] A preparation process for integrally formed shoes, comprising the following steps:

[0022] 1) Select the corresponding mold according to the style of the sole to make the sole mold base by injection molding;

[0023] 2) Prepare the shoe upper 100, and sew a connecting piece with a smooth surface around its lower periphery on the outer surface of the shoe upper 100;

[0024] 3) Set the shoe upper 100 prepared in step 2 in the matching shoe last 1, and stretch the shoe upper 100 in a shoe shape;

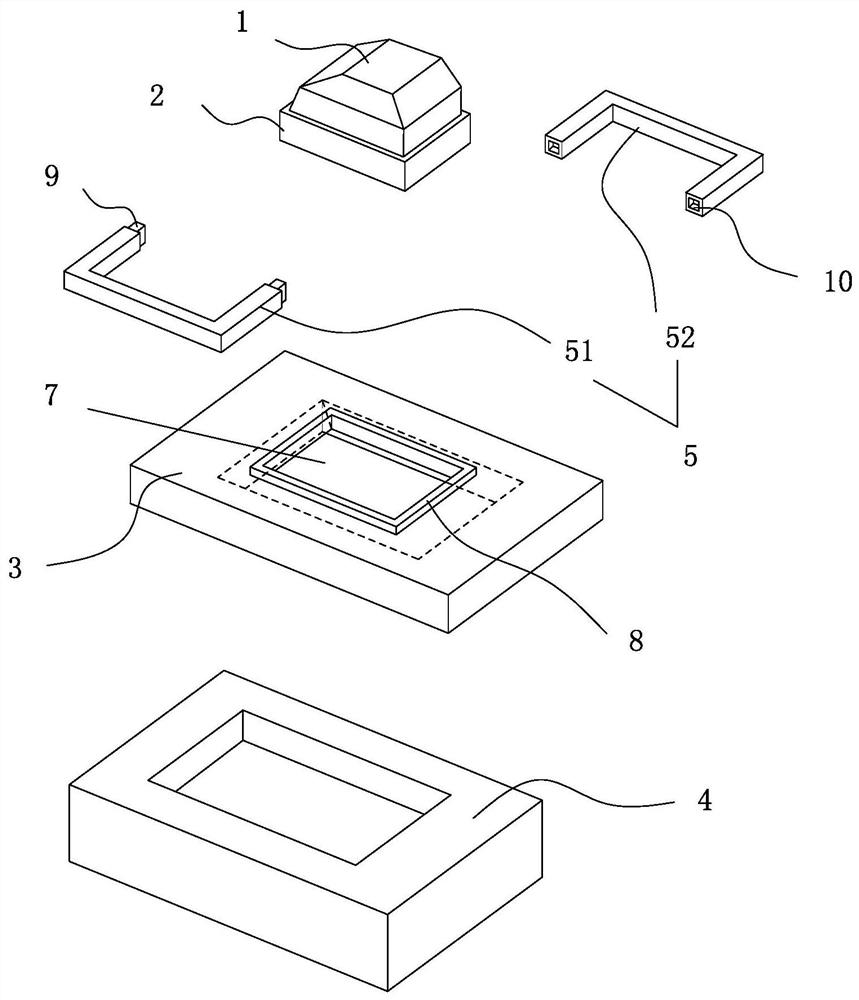

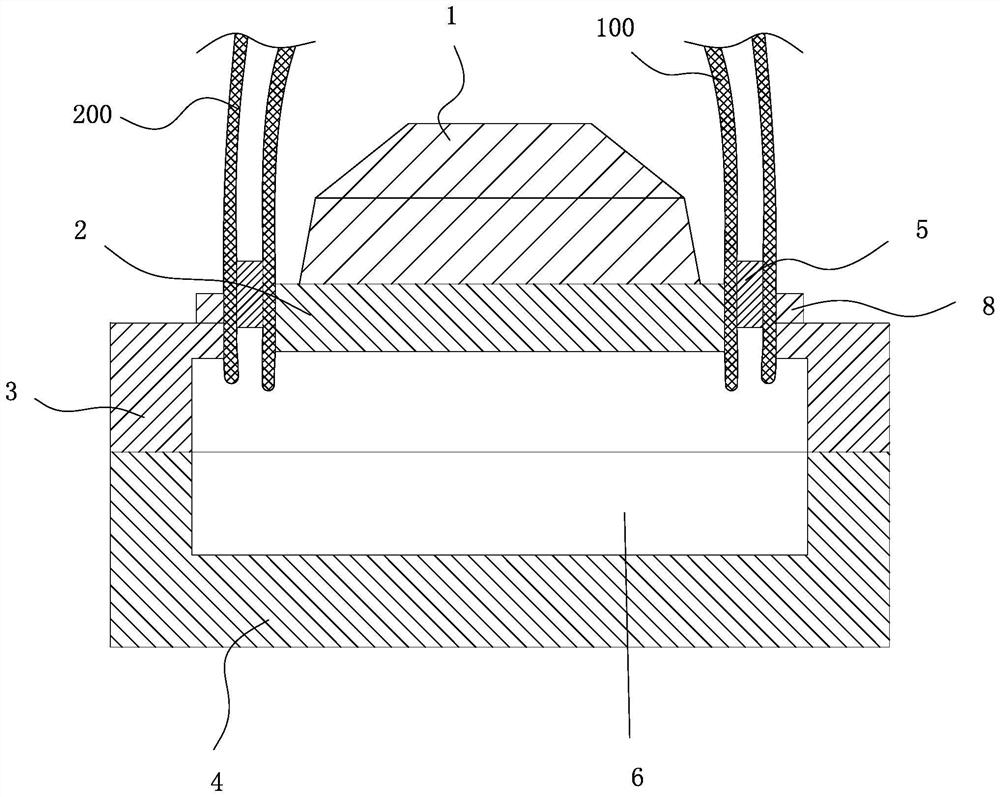

[0025] 4) Preparation of secondary molding mold, refer to figure 1 and figure 2 , the secondary molding mold includes an upper mold 2, a middle mold 3, a lower mold 4 and a fixed ring 5, and the upper mold 2, the middle mold 3 and the lower mold 4 form a mold cavity 6, and the upper part of the middle mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com