Demolding jacking system for pre-tensioning method prestressed concrete track board production line and application thereof

A track plate, prestressing technology, applied in the direction of unloading devices, manufacturing tools, etc., can solve the problems of large specific volume of the complete set of demolding machines, unstable demoulding process of the track plate, and inability to demould, so as to improve the success rate of demoulding and work efficiency, automatic control for easy synchronous locking, and the effect of easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the examples, but it should not be interpreted as a limitation of the present invention. The protection scope of the present invention is based on the contents recorded in the claims. protection scope of the present invention.

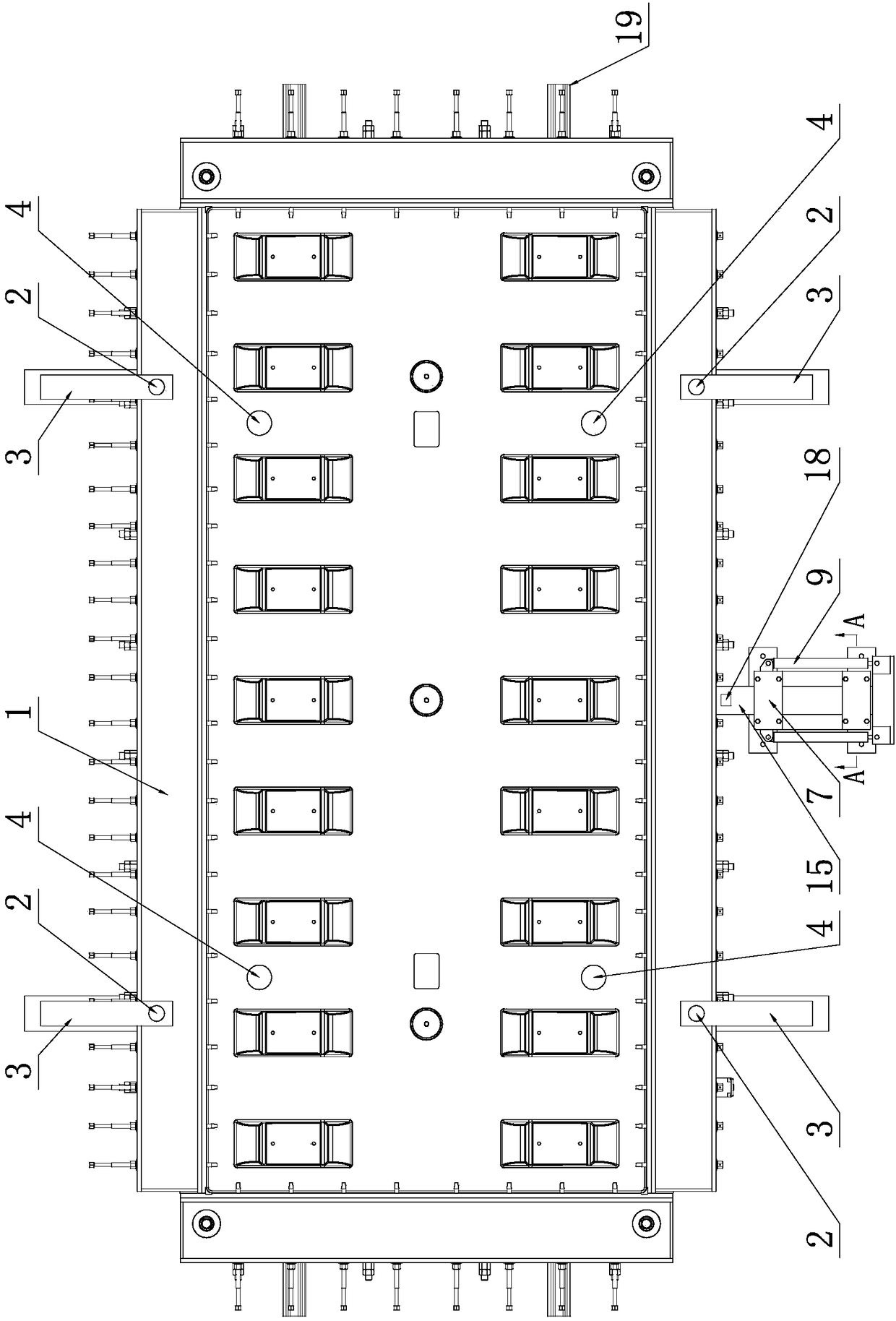

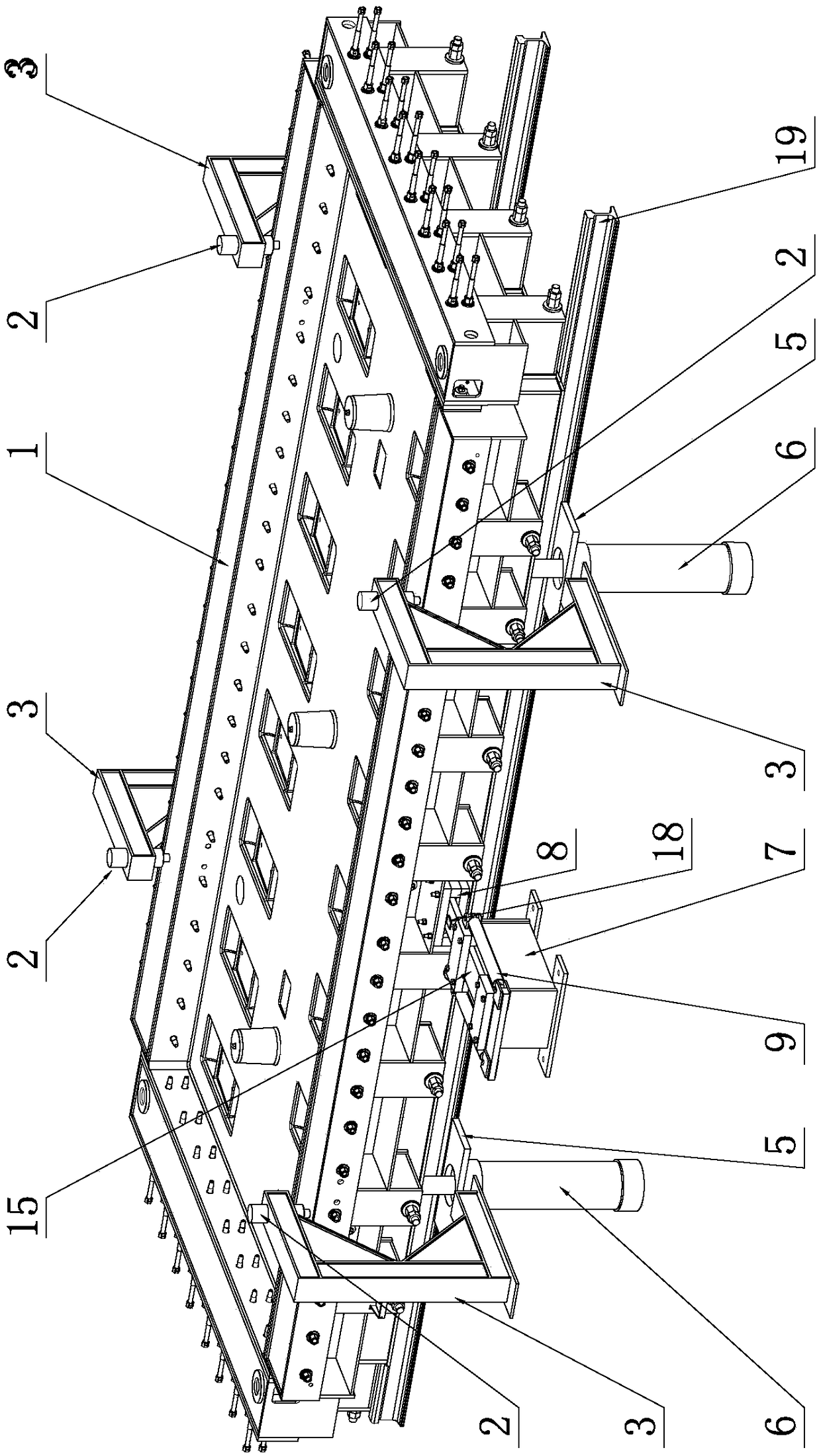

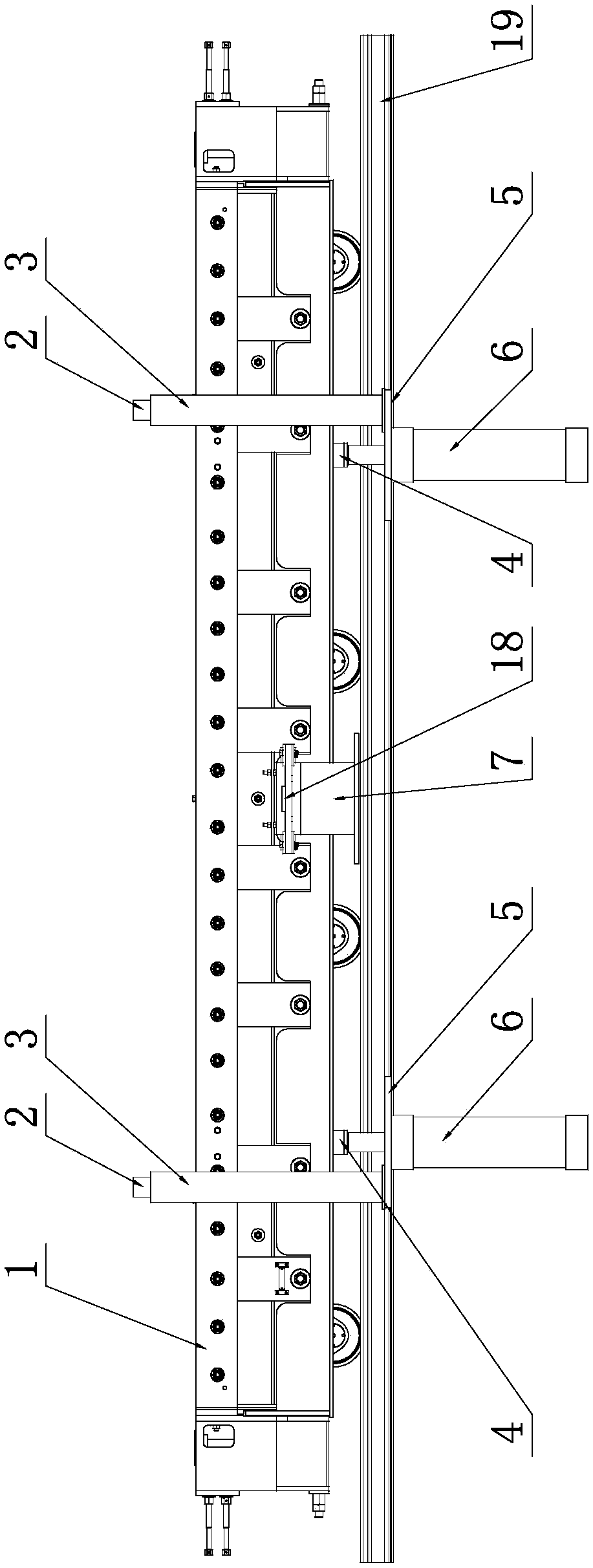

[0061] The overall concept of this embodiment is shown in the figure, wherein the demoulding and lifting system of the pretensioned prestressed concrete track slab production line includes a control device, which is arranged on both sides of the working track 19 and forms a clamping and locking lock for the track slab mold 1 The mechanism, which corresponds to the demoulding lifting column 4 in the track plate mold 1 and realizes the lifting mechanism of the track plate, is arranged on one side of the working track 19 and can be adapted to the precise positioning hole 8 opened on the track plate mold 1 The precise positioning mechanism, the control device controls the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com