Assembled mould structure with self-contained sliding core power

A combined mold and sliding core technology, applied in the field of injection molds, can solve the problems affecting product processing quality, lack of support block mechanism, and unreliable cores, and achieve the effects of flexible operation of the overall structure, fast maintenance, and novel design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

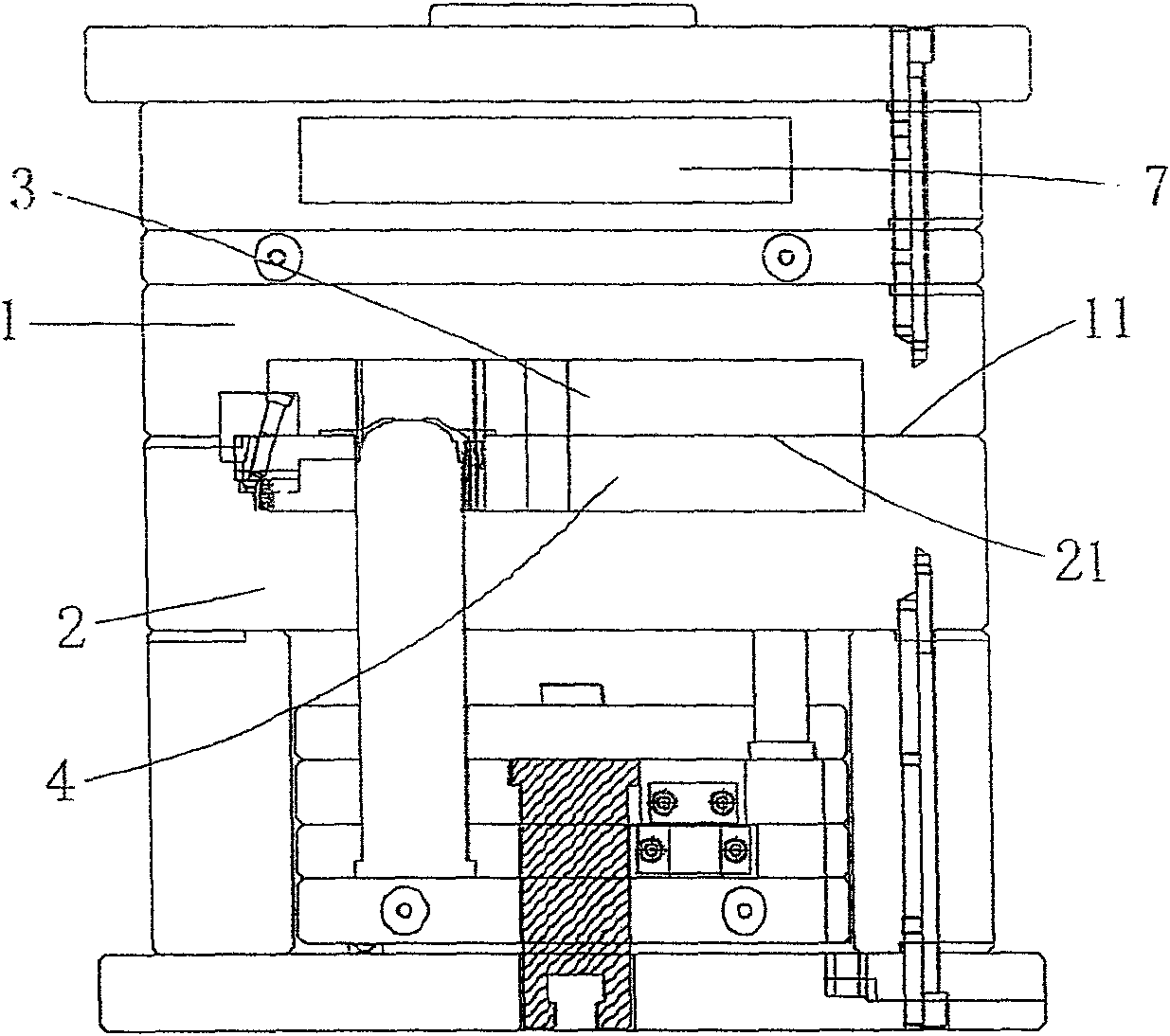

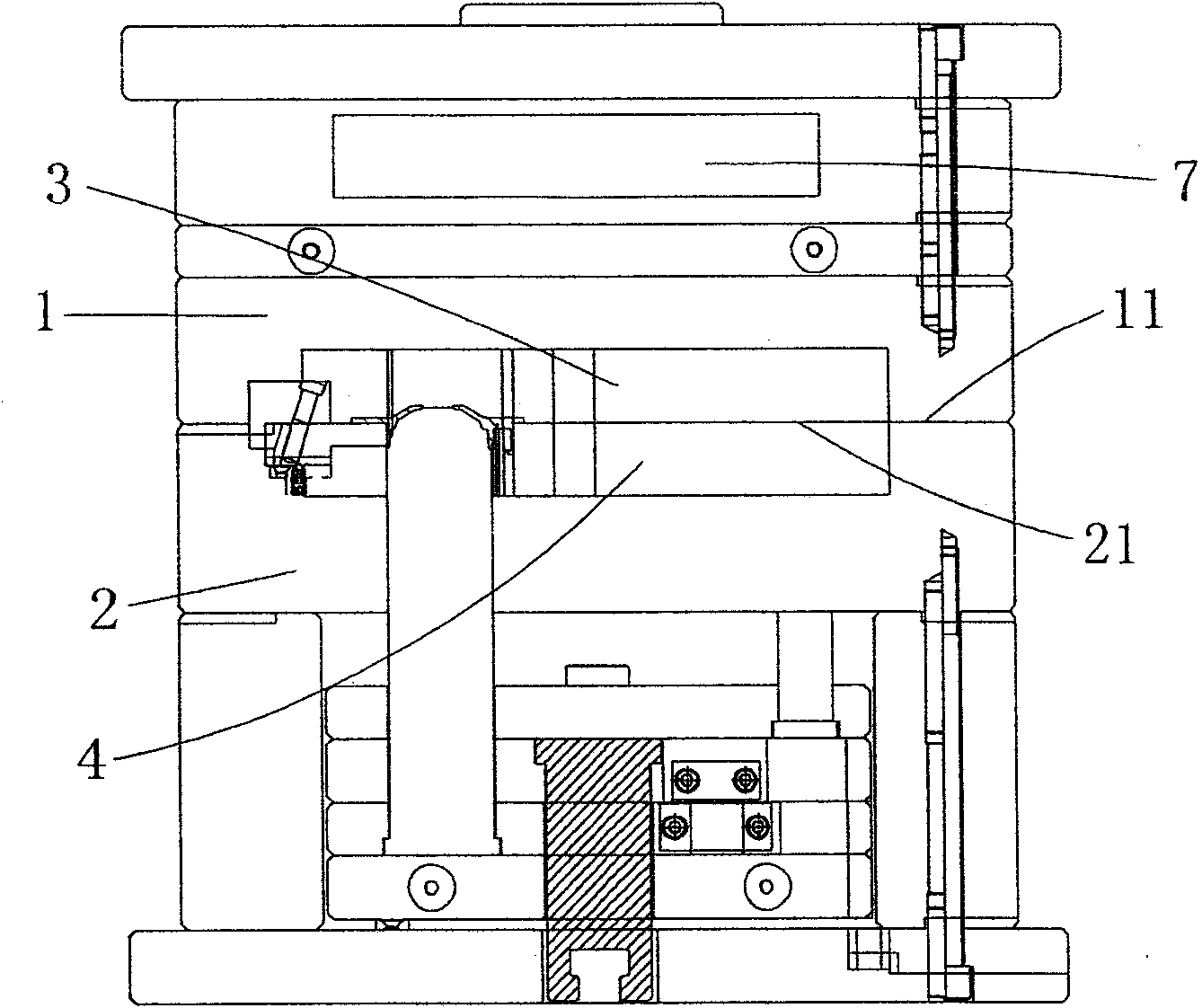

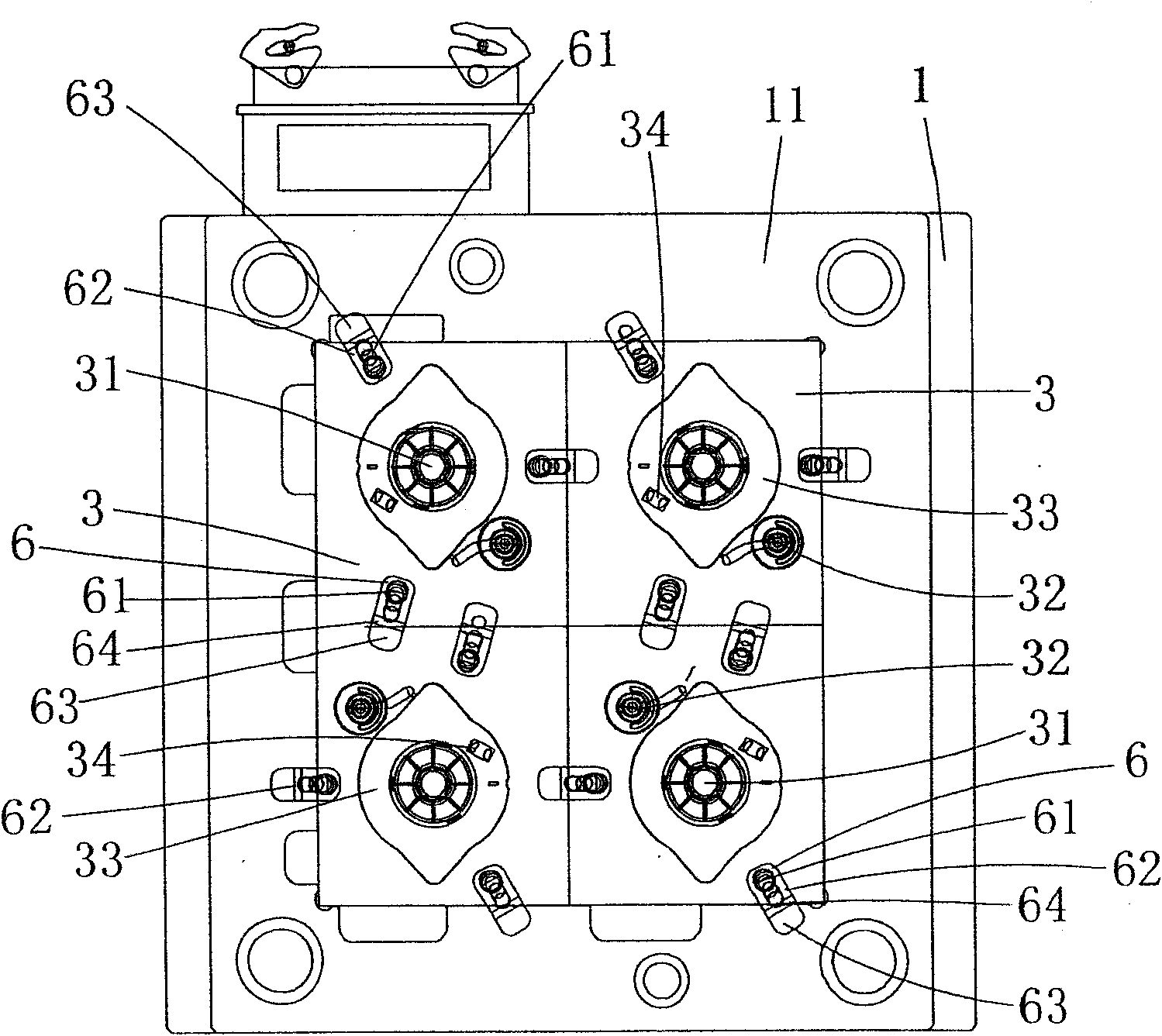

[0020] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

[0021] As shown in Figures 1 to 4, the icon numbers are explained as follows: fixed mold 1, contact surface 11, movable mold 2, working surface 21, fixed module unit 3, molded cavity 31, gate 32, sinker 33, fixed Insert hole 34, movable module unit 4, movable mold cavity 41, movable mold unit body 42, movable insert hole 43, sliding core unit 5, slider 51, inclined end surface 51a, hollow collar 52, positioning block 53, The groove 53a, the driving unit 6, the driving shaft 61, the driving seat 62, the convex body 63, the positioning slope 64, the hot runner system 7.

[0022] In the embodiment of the present invention, the combined mold structure with sliding core power includes a fixed mold 1 and a movable mold 2 that are matched. The working surface 21 of the movable mold 2 is embedded with a movable module unit 4, and each movable module unit 4 is made i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com