Pipeline-free vacuum infusion forming method of sandwiched composite material

A technology for sandwich materials and composite materials, which is applied in the field of composite vacuum infusion molding, can solve the problems of resin waste and difficult demoulding of vacuum system, and achieve the effects of improving working environment, reducing demolding difficulty and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

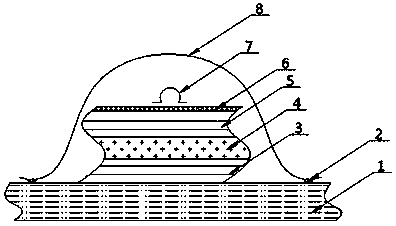

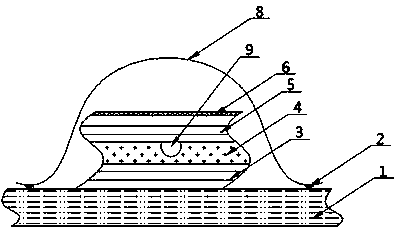

[0033] Provide the specific embodiment of the present invention below in conjunction with accompanying drawing as follows:

[0034] Such as figure 2 As shown, the specific implementation steps of a sandwich composite material without pipeline vacuum infusion molding method of the present invention are as follows:

[0035] 1) Groove the sandwich material 4 to form a filling hole 7 for the sandwich material. The filling hole 7 for the sandwich material is located on the upper surface of the sandwich material 4. The size of the slot is 5 mm to 50 mm, and the shape of the hole is circular or semicircular. shape;

[0036] 2) Lay the lower dry layup 3 on the mold 1;

[0037] 3) Lay the sandwich material 4 with the sandwich material perfusion hole 7 on the lower dry layup layer 3;

[0038] 4) Lay the upper layer of dry layup 5 on the sandwich material 4;

[0039] 5) The diversion medium 6 is laid on the upper dry laying layer 5;

[0040] 6) Paste the sealing strip 2 on the edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com