Composite bipolar plate for fuel cell as well as preparation method and application of composite bipolar plate

A bipolar plate and reinforcing material technology, which is applied in fuel cells, chemical instruments and methods, circuits, etc., can solve the problems of mechanical strength and electrical conductivity being difficult to take into account at the same time, low mechanical strength, and decreased electrical conductivity of bipolar plates. The effect of reducing the difficulty of demolding, high mechanical strength, and reducing the interface contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

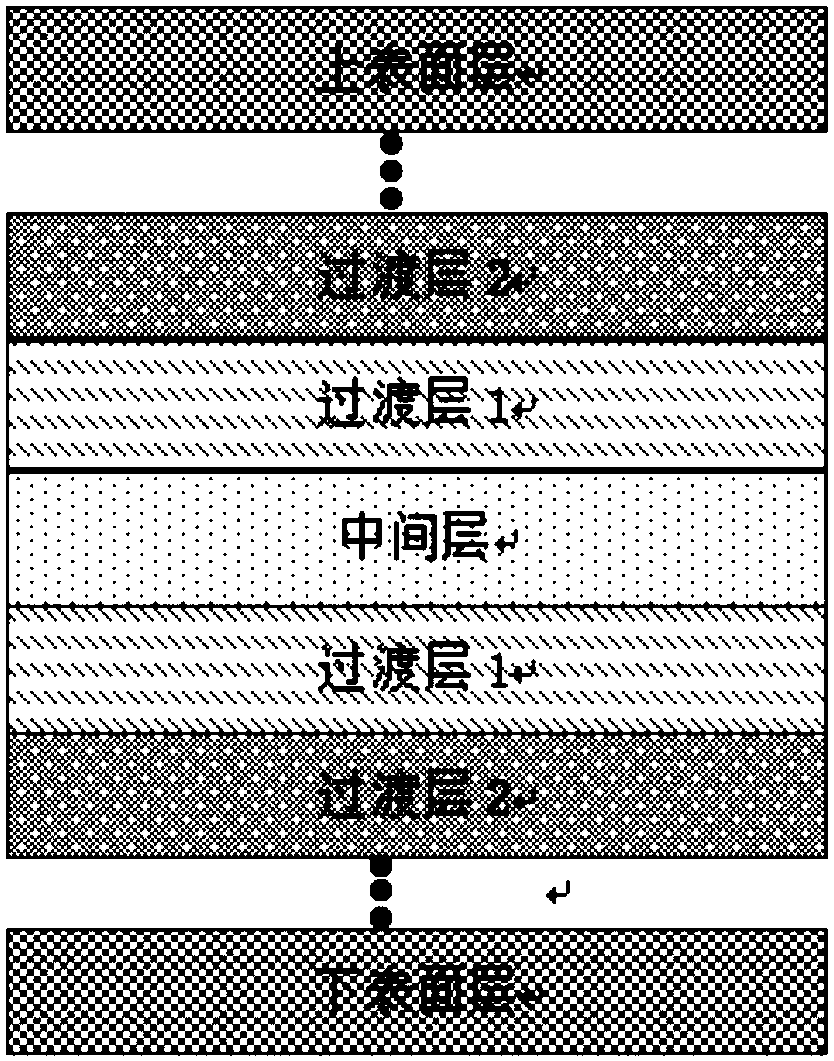

[0032] (1) Weigh 0.3kg polyvinylidene fluoride resin, 2.7kg flake graphite, 0.1kg carbon fiber and carry out ball milling, the ball milling time is 10min, prepare the surface layer of the composite board; weigh 0.5kg phenolic resin, 2.1kg flake graphite, 0.15kg The carbon fiber was ball milled for 15 minutes to prepare the middle layer of the composite board; 0.15 kg polyvinylidene fluoride resin, 0.2 kg phenolic resin, 1.8 kg flake graphite, and 0.2 kg carbon fiber were weighed for ball milling, and the ball milling time was 15 min to prepare the composite board transition layer 1; weigh 0.18 kg polyvinylidene fluoride resin, 0.18 kg phenolic resin, 1.8 kg flake graphite, and 0.2 kg carbon fiber for ball milling, and the ball milling time is 15 minutes to prepare the transition layer 2 of the composite plate;

[0033] (2) after the lower surface layer raw material that step (1) is made is evenly tiled, after cold pressing, then transition layer 1, transition layer 2, intermedi...

Embodiment 2

[0037] (1) Weigh 0.1kg polytetrafluoroethylene resin, 0.2kg polyvinylidene fluoride resin, 2.8kg flake graphite, and 0.1kg carbon fiber for ball milling. The ball milling time is 20min to prepare the surface layer of the composite board; weigh 0.5kg epoxy Resin resin, 2.0kg flake graphite, 0.15kg carbon fiber are ball milled, and the ball milling time is 15min to prepare the middle layer of the composite board; weigh 0.05kg polytetrafluoroethylene resin, 0.1kg polyvinylidene fluoride resin, 0.2kg epoxy resin, 1.8kg of flake graphite and 0.2kg of carbon fiber were ball milled for 15 minutes to prepare the transition layer 1 of the composite board; weighed 0.08kg of polytetrafluoroethylene resin, 0.1kg of polyvinylidene fluoride resin, 0.18kg of epoxy resin, and 1.8kg of Flake graphite and 0.1kg carbon fiber were ball milled for 20 minutes to prepare the transition layer 2 of the composite board; weighed 0.06kg polytetrafluoroethylene resin, 0.12kg polyvinylidene fluoride resin, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com