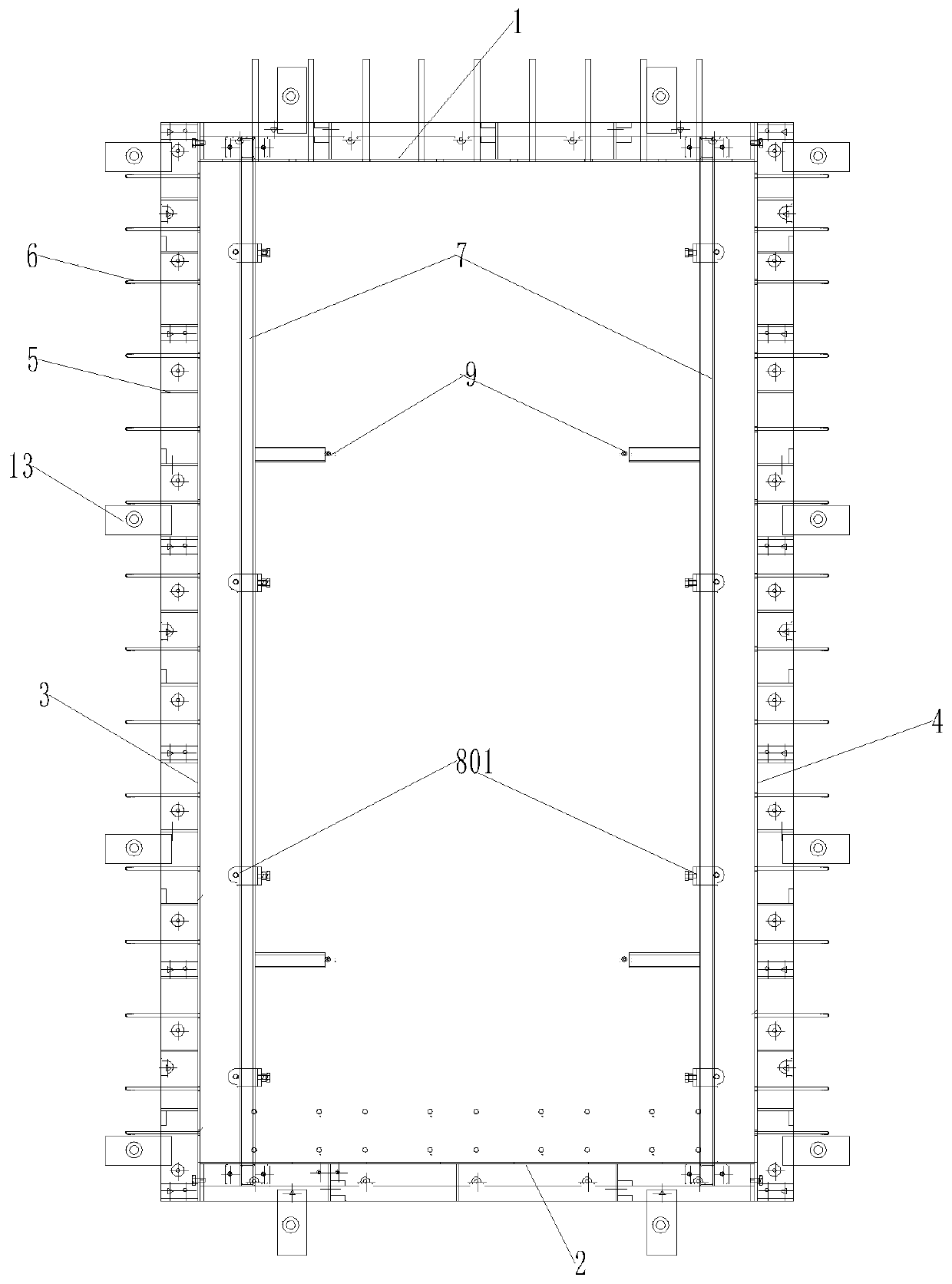

Combined prefabricated shear wall mold assembly and using method thereof

A prefabricated shear force and combined technology, applied in the direction of molds, manufacturing tools, unloading devices, etc., can solve the problems of high overall comprehensive cost, complex mold structure, difficult quality assurance, etc. Low, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

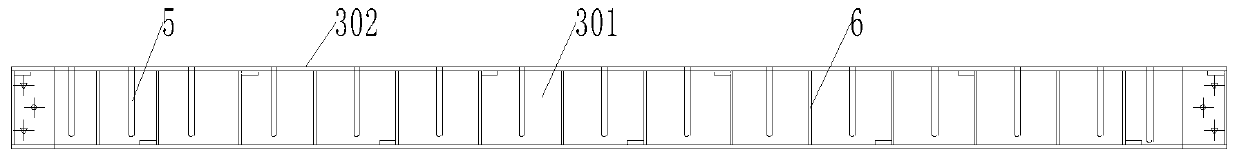

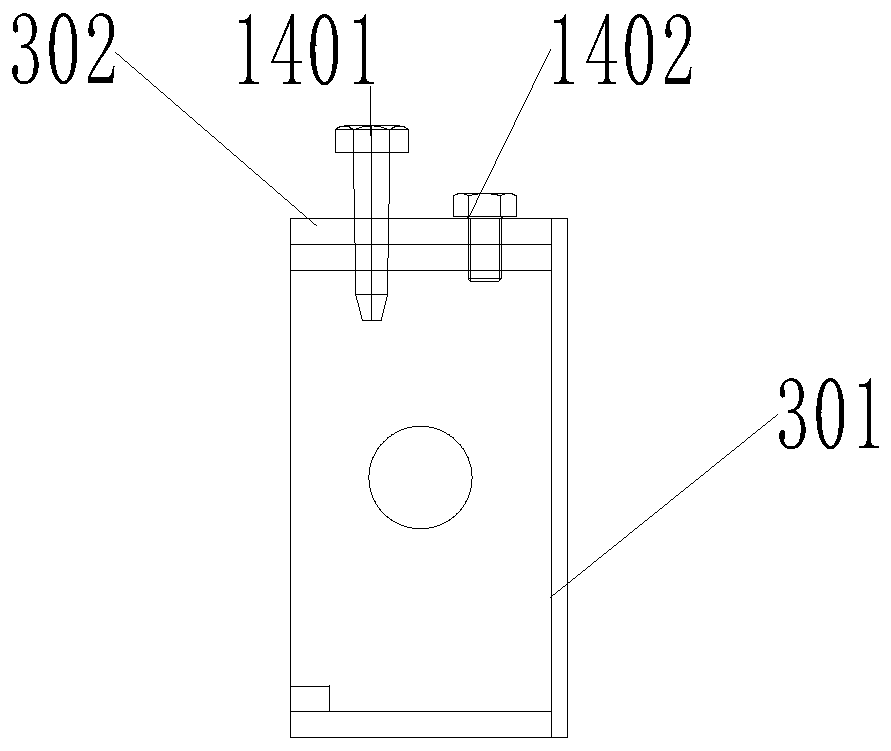

Method used

Image

Examples

Embodiment 2

[0062] Embodiment two, such as Figure 10 Shown:

[0063] A method applicable to the above combined prefabricated shear wall mold assembly, the method includes the following steps:

[0064] Step S01, processing the above-mentioned mold according to the shape, size and reinforcement arrangement of the prefabricated component to be formed;

[0065] Step S02, fixing the lower side molds of the left mold 3 and the right mold 4, the upper mold 1, and the lower mold 2 on the mold table with a fixed magnetic box 13, and each part of the mold is fixedly connected with bolts;

[0066] Step S03 Apply the adjusted mold release agent or exposed aggregate retarder (when there is a requirement for exposed coarse aggregate rough surface) evenly on the concrete contact surface of the mold to avoid missing coating and uneven

[0067] Step S04, according to the design drawing of the prefabricated shear wall, install stirrups and vertically stressed steel bars in the assembled mold, and after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com