Spiral pulling-out type demolding tool for composite products and demolding process thereof

A technology for composite materials and parts, which is applied in the field of composite material manufacturing, can solve problems such as difficult removal of insert-type metal molds, and achieve the effects of avoiding tooling deformation and scrapping, improving pass rate and production efficiency, and reducing delamination defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

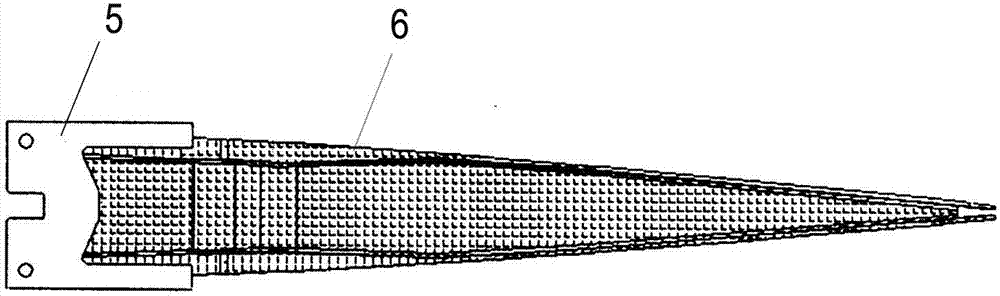

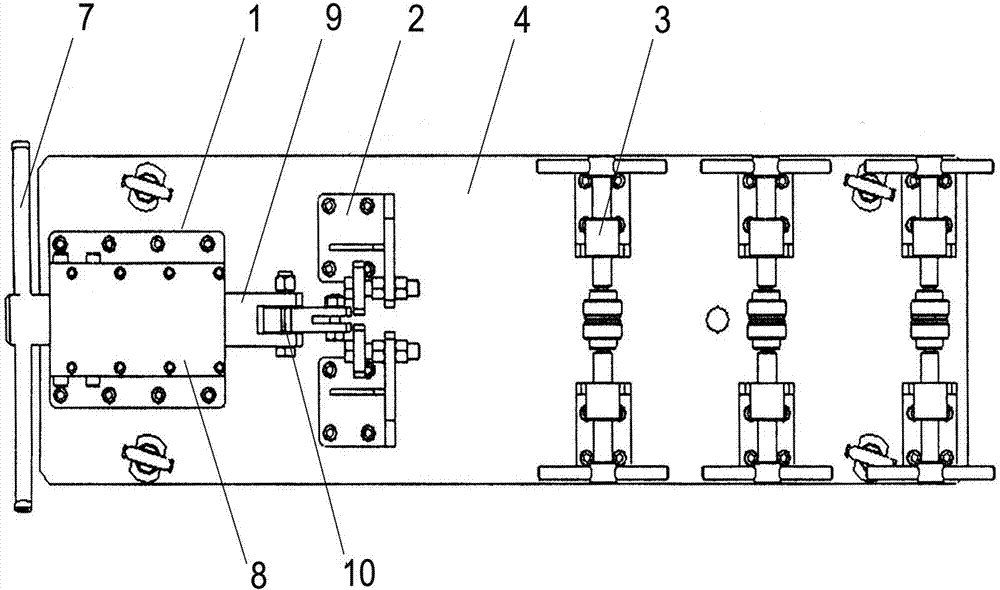

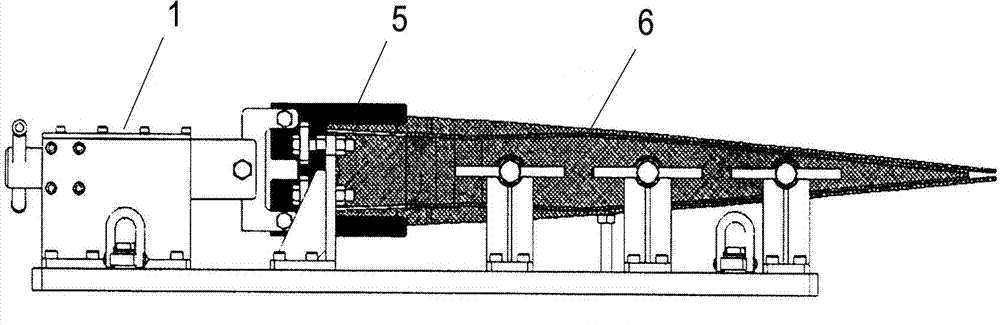

[0024] like figure 2 As shown, taking the I-shaped reinforcing rib in the rudder of a certain model as an example, the spiral pull-out type demoulding tooling used includes a screw pull-out assembly 1 for pulling the metal baffle 5, a screw pull-out assembly 1 for fixing the metal baffle 5 The positioning component 2 at the current position and the fixing component component 3 for fixing the composite material part 6 are three parts. The above-mentioned three part components are respectively fixed on the metal substrate 4 in sequence, and the distance between the components depends on the size of the composite material part. depends.

[0025] In the described spiral extraction assembly 1, the rotating handle 7 is fixedly connected with the screw rod in the metal box 8, the position of the screw rod relative to the metal box 8 is fixed, and the end of the screw rod is connected with the threaded stretching assembly 9, stretching The component 9 is connected with the metal baf...

Embodiment 2

[0040] Continuing to take the I-shaped reinforcing rib in the rudder of a certain model as an example, the spiral pull-out type demoulding tooling used includes a screw pull-out assembly 1 for pulling the metal baffle 5, and a screw pull-out assembly 1 for fixing the current position of the metal baffle 5. The positioning assembly 2 and the fixing assembly 3 used to fix the composite material part 6 are three parts. The above three parts are respectively fixed on the metal substrate 4 in sequence, and the distance between the components is determined according to the size of the composite material part. .

[0041] In the screw extraction assembly 1, the hexagon socket nut is fixedly connected to the screw rod in the metal box 8, the position of the screw rod relative to the metal box 8 is fixed, and the end of the screw rod is connected to the threaded stretching assembly 9, stretching The component 9 is connected with the metal baffle 5 positioned on the positioning component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com