Production method for improving yield of low-Si alloy steel plate

A production method and yield technology, which is applied in the production field of improving the yield of low-Si alloy steel sheets, and can solve the problems of low yield of low-Si alloy steel sheets, loss of yield of low-Si alloy steel, difficulty in floating slag and inclusions, etc. , to achieve the effect of reducing the amount of steel passing, improving the quality and reducing the tail delamination defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

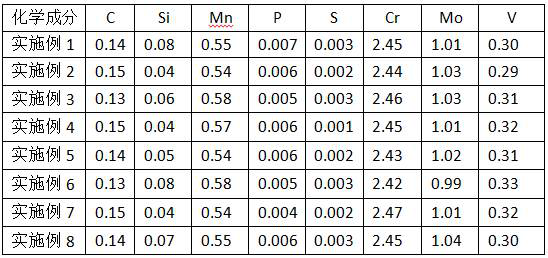

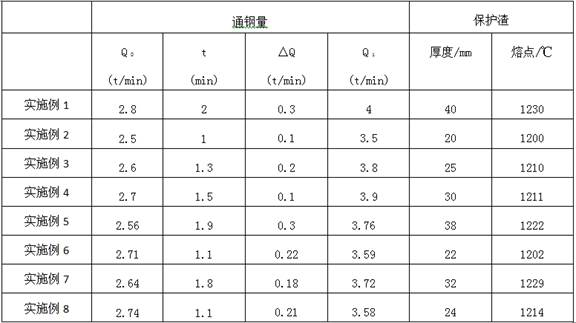

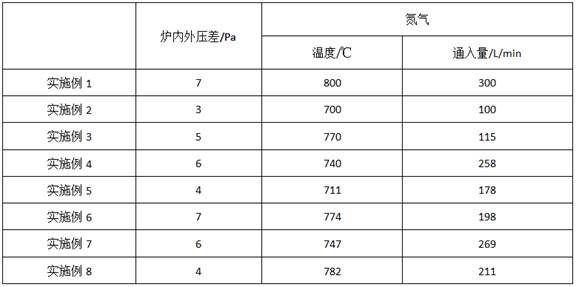

[0017] Examples 1-8 The molten steel is refined in the LF furnace, using the deoxidation method of weak deoxidation first, and then strong deoxidation. The deoxidizer in the weak deoxidation process uses carbon powder and calcium carbide, and the strong deoxidation process uses Al deoxidation, and then in the VD furnace Vacuum treatment is carried out, and the composition and content of the obtained molten steel are shown in Table 1, and then the molten steel is mold-cast, and then the obtained steel ingot is heated in a heating furnace. The amount of deoxidizer added to the LF furnace, the vacuum degree of the VD furnace and the holding time under this vacuum degree are shown in Table 2. 0 , at each time t, the increase value of steel flow is △Q, and the maximum steel flow is Q 1 , Die casting pass steel parameters and mold flux parameters are shown in Table 3. During the heating process of the steel ingot in the heating furnace, a slight positive pressure is maintained. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com