Efficient spray processing method for spray room

A treatment method and spray booth technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of secondary pollution, prone to odor, adhesion, etc., to ensure the life of the equipment, easy to use, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

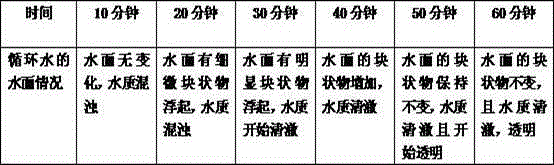

Embodiment 1

[0029] Select the polydimethyldiallyl ammonium chloride with a solid content of 15% of the stock solution, an ionization degree of 45%, and a molecular weight of 3,000,000, and dilute it to 50ml of an aqueous solution with a dry powder mass percentage of 1.2%, and select the aluminum oxide mass percentage content as 32%. Polyaluminum chloride with a basicity of 85% is diluted with water to 25ml of an aqueous solution with a dry powder mass percentage of 20%, and the selected montmorillonite content is 50%, the pH value is 5, the expansion multiple is 10, and the particle size is 50 mesh sodium bentonite , and diluted with water to 25ml of an aqueous solution with a mass percentage of dry powder of 0.5%, poured into the circulating water of a 10L air pressure-water washing spray booth, it can be found that the paint in the water loses its viscosity quickly, and the paint is condensed into crisp clumps floating on the water surface , easy to salvage, ensure the normal operation o...

Embodiment 2

[0051] The only difference between this example and Example 1 is that the components and proportions of the paint mist coagulant are different. Polyacrylamide with a molecular weight of 6 million and a solid content of the stock solution of 0.2% is selected and diluted to 200ml of an aqueous solution with a mass percentage of dry powder of 2%. Aluminum sulfate with a mass percentage content of 11% and a basicity of 50% is diluted with water to 100ml of an aqueous solution with a dry powder mass percentage of 10%. The montmorillonite content is 95%, the pH value is 9, and the expansion factor is 50. Calcium-based bentonite with a particle size of 3000 meshes, diluted with water to 100ml of an aqueous solution with a dry powder mass percentage of 20%, added to 200L of circulating water produced after spraying with 820-BSG-338 black solvent-based paint primer, wherein polyacrylamide and The volume ratio of the paint is 1:30. After stirring for half an hour, a large number of massi...

Embodiment 3

[0053] The only difference between this example and Example 1 is that the components and proportions of the paint mist coagulant are different, and polydimethyldiallyl chloride with a solid content of 12% of the stock solution, an ion degree of 48%, and a molecular weight of 4 million is selected. Ammonium, diluted to 100ml of an aqueous solution of 1.1% by mass percentage of dry powder, aluminum sulfate with a mass percentage of alumina content of 11% and a basicity of 50%, diluted with water to 50ml of an aqueous solution of 11% by mass of dry powder, and the selected montmorillonite content is 98%, the pH value is 9, the expansion multiple is 50, and the particle size is 3000 mesh lithium-based bentonite, and diluted with water to 50ml of an aqueous solution with a dry powder mass percentage of 20%. In the 80L circulating water produced, the volume ratio of polydimethyldiallylammonium chloride to paint is 1:10. After stirring for half an hour, a large number of blocky holes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com