Automatic sand mold casting mold forming production line and method

A casting mold forming and production method technology, which is applied in the field of sand mold casting, can solve problems such as size and weight restrictions, unreasonable setting of sand cleaning devices, and inability to automatically clean sand for large workpieces, so as to achieve the effect of ensuring cleanliness and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

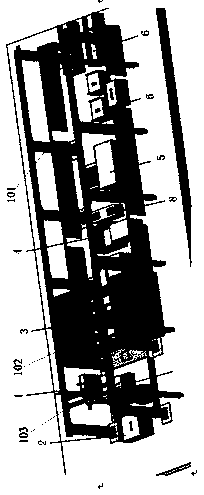

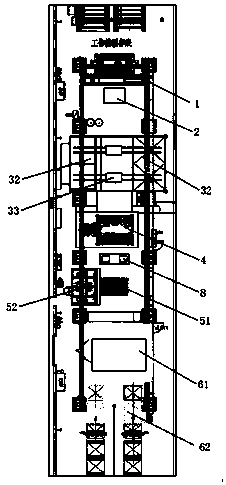

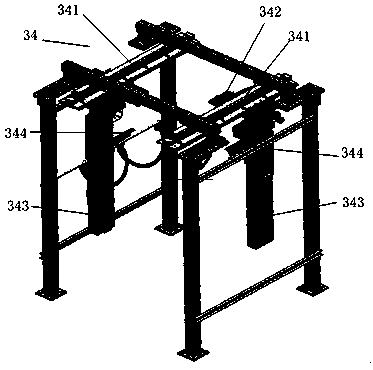

[0031] Such as figure 1 and figure 2 As shown, the automatic sand mold forming production line of the present invention includes a truss robot 1 , a feeding device 2 , a sand cleaning device 3 , a dipping device 4 , a drying device 5 and a core assembly device 6 . The core assembly device includes a core assembly platform 61 and a three-dimensional warehouse 62 .

[0032] Such as figure 1 As shown, two rows of columns 101 are set on both sides of the production line, slide rails 102 are installed on the columns 101, the truss robot 1 is installed on two parallel slide rails 102, and the truss robot 1 can slide along the slide rails 102, so that the truss robot 1 can move along the direction of the production line. The beam 103 installed between the two slide rails 102, the robot can move on the beam 103 in the direction perpendicular to the production line, so that the truss robot 1 can handle sand core workpieces of various shapes, which is more flexible than the gripper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com