RTM mold for composite workpiece with reinforcing ribs

A technology of reinforcing ribs and molds, applied in the field of RTM molds, can solve problems such as difficulty in molding and demoulding, and achieve the effects of easy demoulding, easy molding, and avoidance of demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

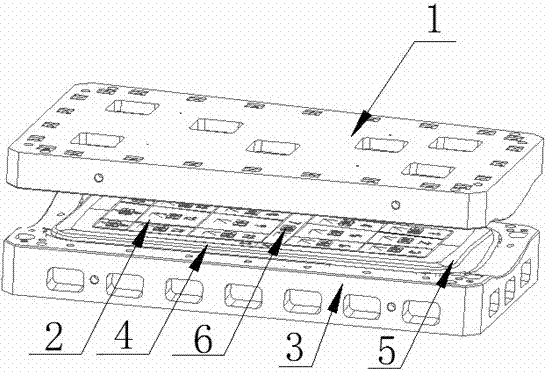

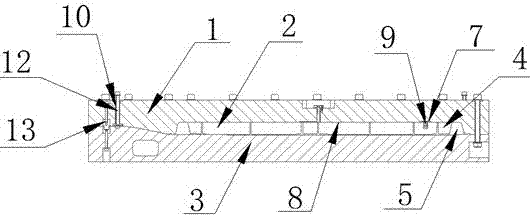

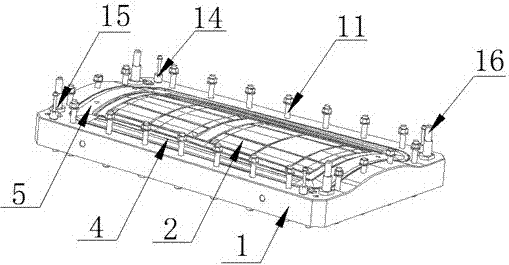

[0022] An RTM mold for composite parts with stiffeners, such as figure 1 and figure 2 , including upper mold 1, lower mold 3, several mandrels 2, edge strips 5 and bead 4, mandrel 2 is arranged between upper mold 1 and lower mold 3, upper mold 1 is provided with annular groove 8, side strips 5 and The bead 4 fits and is arranged in the annular groove 8 respectively, and the side bar 5 and the bead 4 are both arranged between the upper mold 1 and the lower mold 3, the core mold 2 is provided with a positioning boss 6, and the upper mold 1 is provided with a The rectangular groove 7 matched with the boss 6, the positioning boss 6 is provided with a first release bolt hole, the upper mold 1 and the lower mold 3 are respectively provided with a number of through holes, and the through holes are used to fix the upper mold 1 and the lower mold 3. The fastening bolts 11, the upper mold 1 and the lower mold 3 are respectively provided with a plurality of second demoulding bolts 12 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com