Electrified sintering die

A mold, energization technology, applied in the direction of molds, manufacturing tools, ceramic forming cores, etc., can solve the problems of cold welding, inconsistent temperature distribution sintering, sample crushing, etc., to achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following embodiments are only for illustrating the present invention, rather than limiting the present invention.

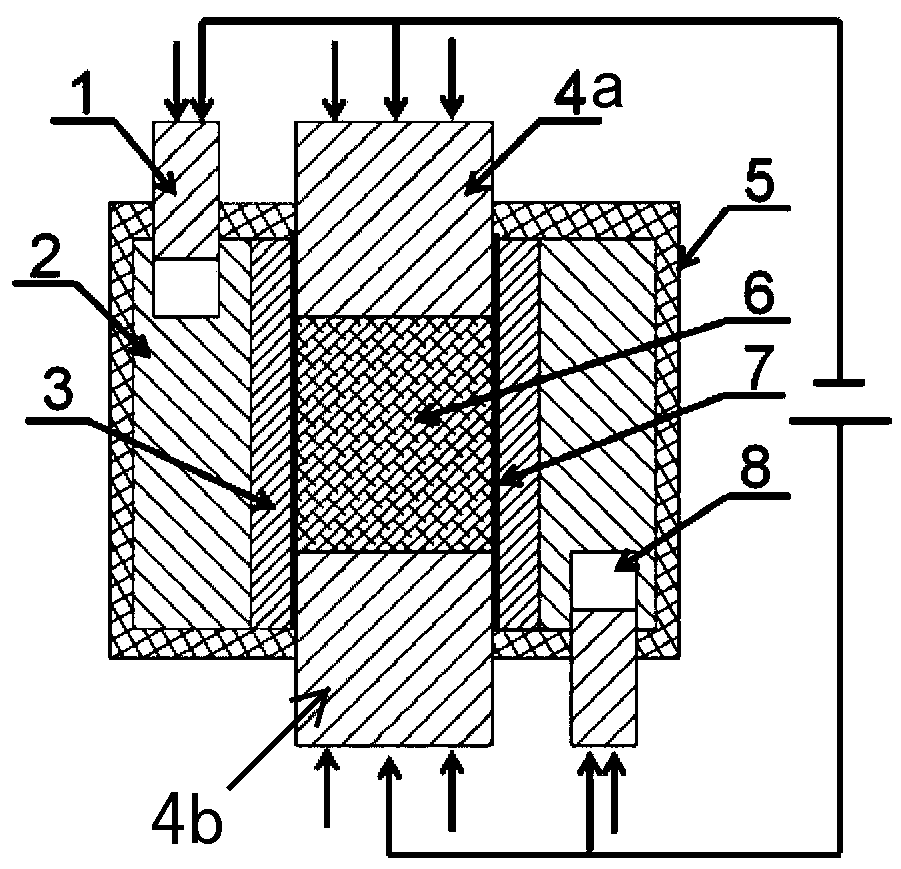

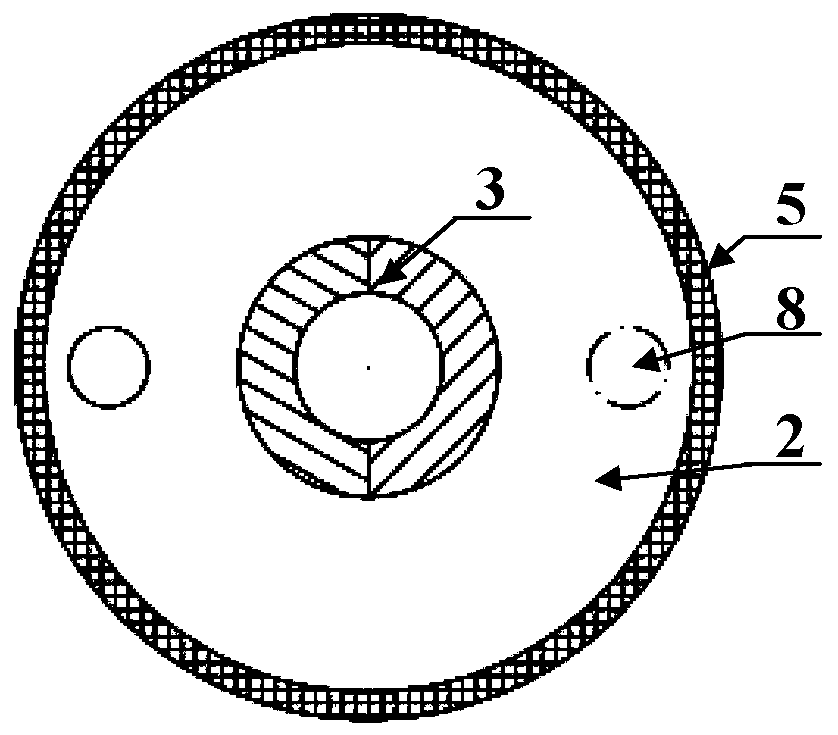

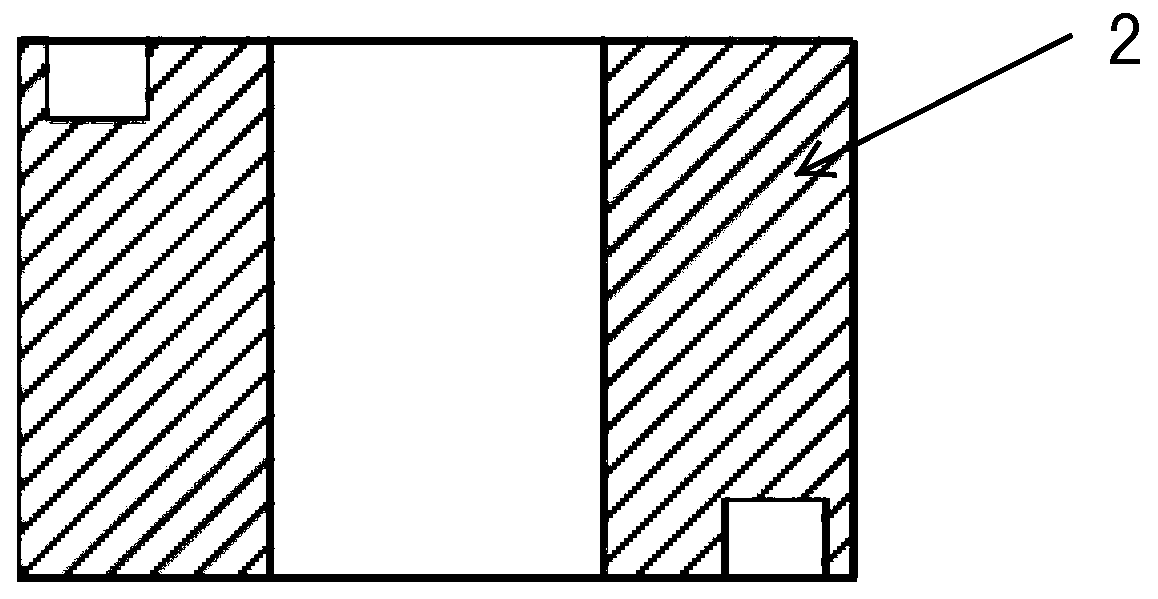

[0039] Aiming at the problems of uneven temperature distribution of the energized sintering mold and easy damage of the mold and samples in the prior art, the present invention provides an energized sintering mold capable of improving the uniformity of the sintering temperature field and thereby improving the sintering uniformity of the sample. The mold includes: an inner loose block forming die and an outer mold cover arranged from the inside to the outside; and an upper pressure head and a lower pressure head arranged in the inner loose block forming die; a counterbore is provided on the outer mold cover ; There is a shunt guide body in the counterbore; a mold release agent is coated on the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com