Method for improving flashover voltage of silicon rubber

A technology of flashover voltage and silicone rubber is applied in the field of high-voltage power transmission and distribution engineering to achieve the effect of improving flashover voltage, wide application range and low economic cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

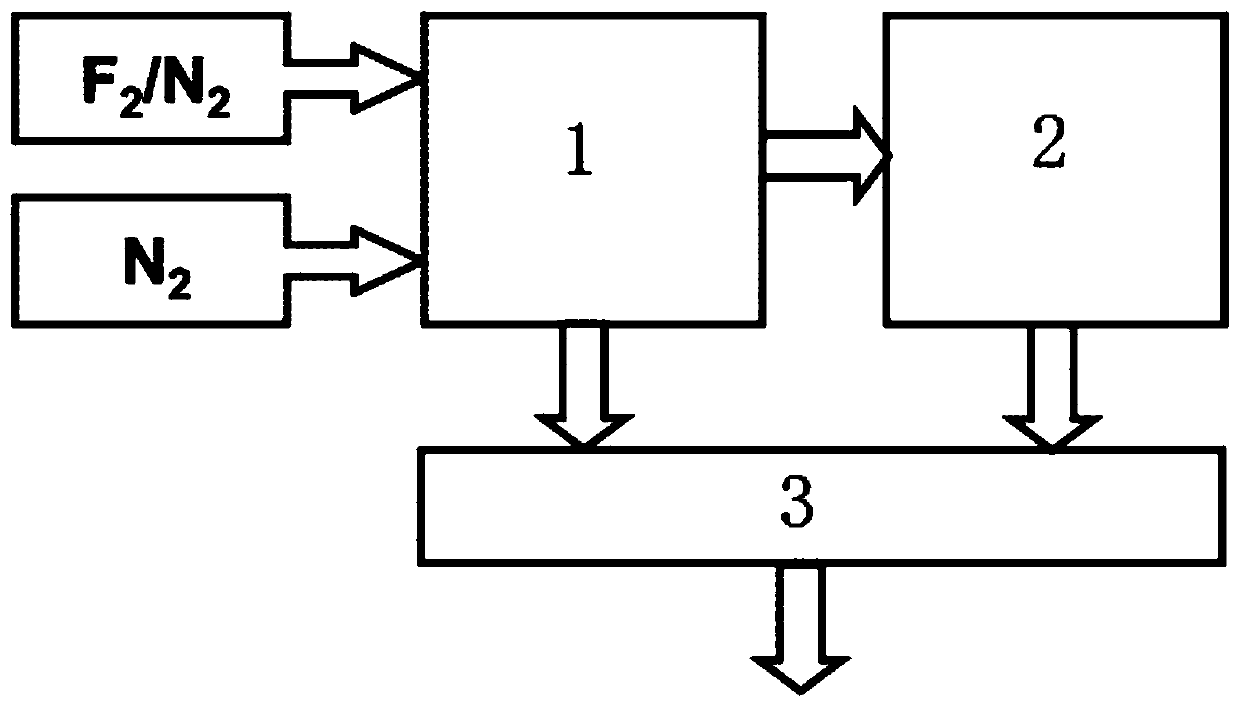

Method used

Image

Examples

Embodiment 1

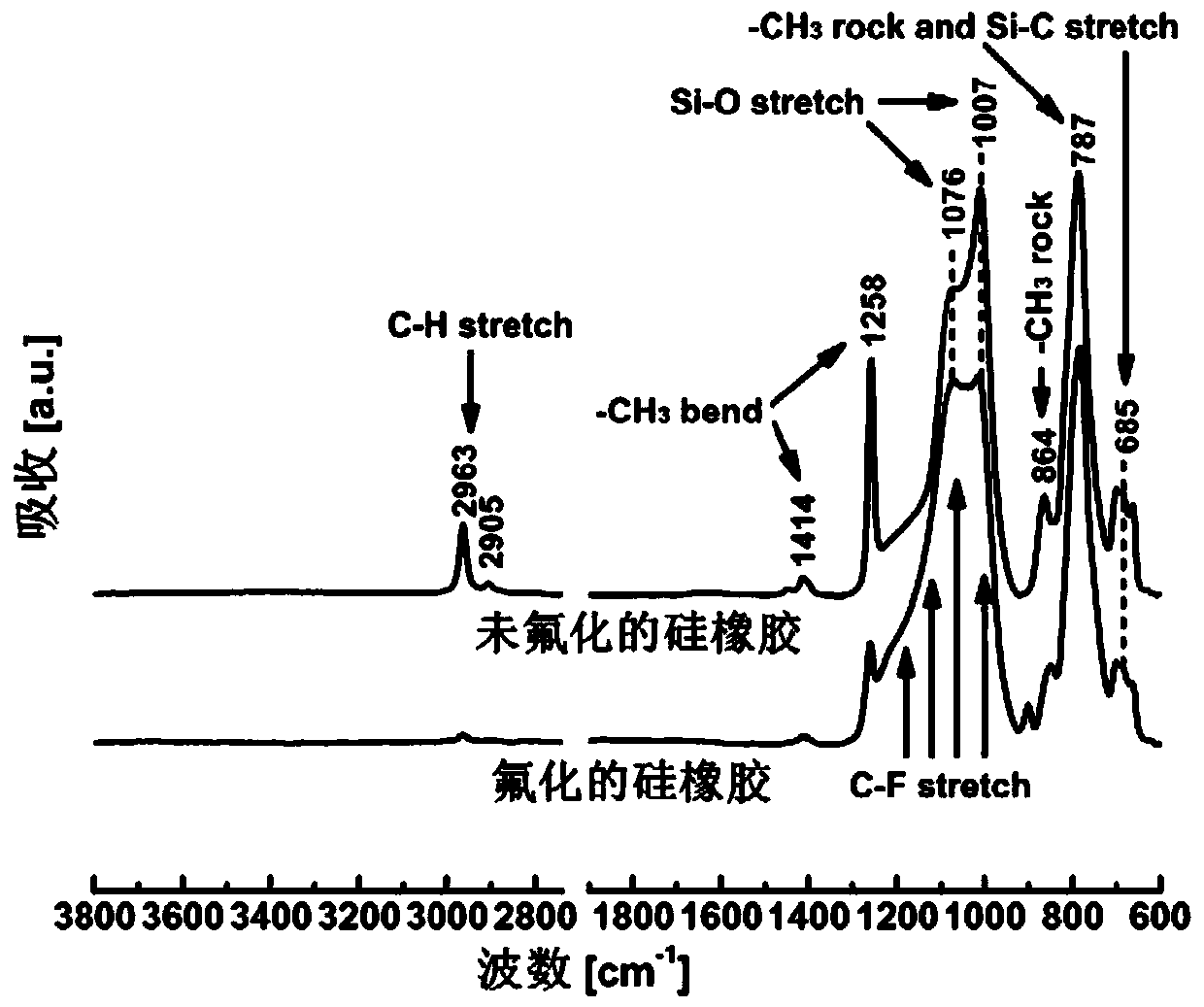

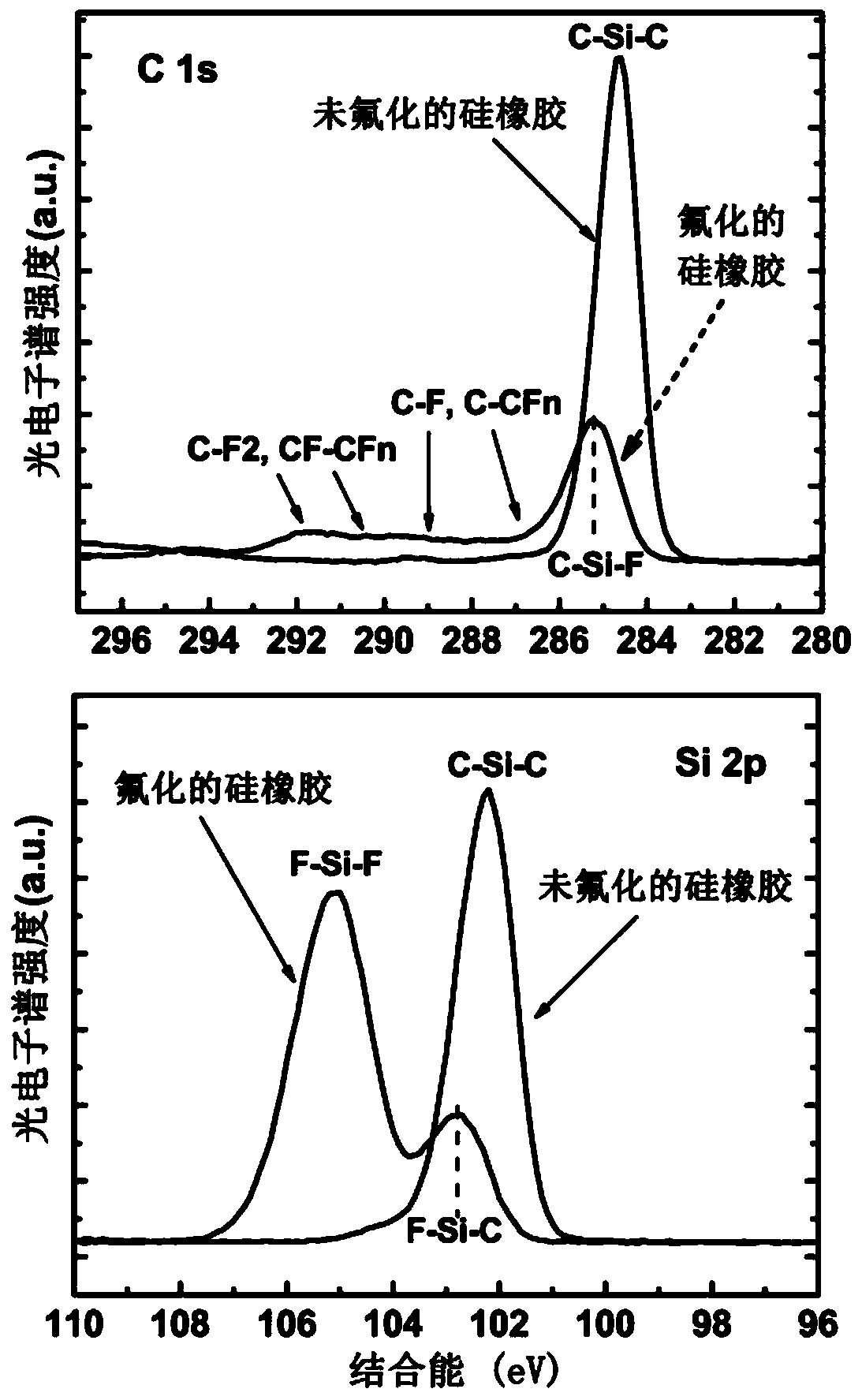

[0040] The fluorination treatment conditions of the silicone rubber sample: the temperature of the closed reaction chamber is 55°C, the pressure is 1 bar, the fluorine gas accounts for 12% by volume of the reactive mixed gas, and the fluorination treatment time is 60.

[0041] The results are shown in Table 1. After the surface layer of the silicone rubber sample was fluorinated and modified, a fluorinated layer with a thickness of 0.80 μm was formed, and the DC flashover voltage increased by 50.3% compared with that before fluorinated.

Embodiment 2

[0043] The fluorination treatment conditions of the silicone rubber sample: the temperature of the closed reaction chamber is 65°C, the pressure is 0.8 bar, the fluorine gas accounts for 12% by volume of the reactive mixed gas, and the fluorination treatment time is 30 minutes.

[0044]The results are shown in Table 1. After the surface layer of the silicone rubber sample was fluorinated and modified, a fluorinated layer with a thickness of 0.72 μm was formed, and the DC flashover voltage increased by 51.9% compared with that before fluorinated.

Embodiment 3

[0046] The fluorination treatment conditions of the silicone rubber sample: the temperature of the closed reaction chamber is 85°C, the pressure is 1 bar, the fluorine gas accounts for 12% by volume of the reactive mixed gas, and the fluorination treatment time is 2h.

[0047] The results are shown in Table 1. After the surface layer of the silicone rubber sample was fluorinated and modified, a fluorinated layer with a thickness of 1.14 μm was formed, and the DC flashover voltage increased by 35.8% compared with that before fluorinated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com