Method for increasing surface flashover voltage of epoxy resin insulating material

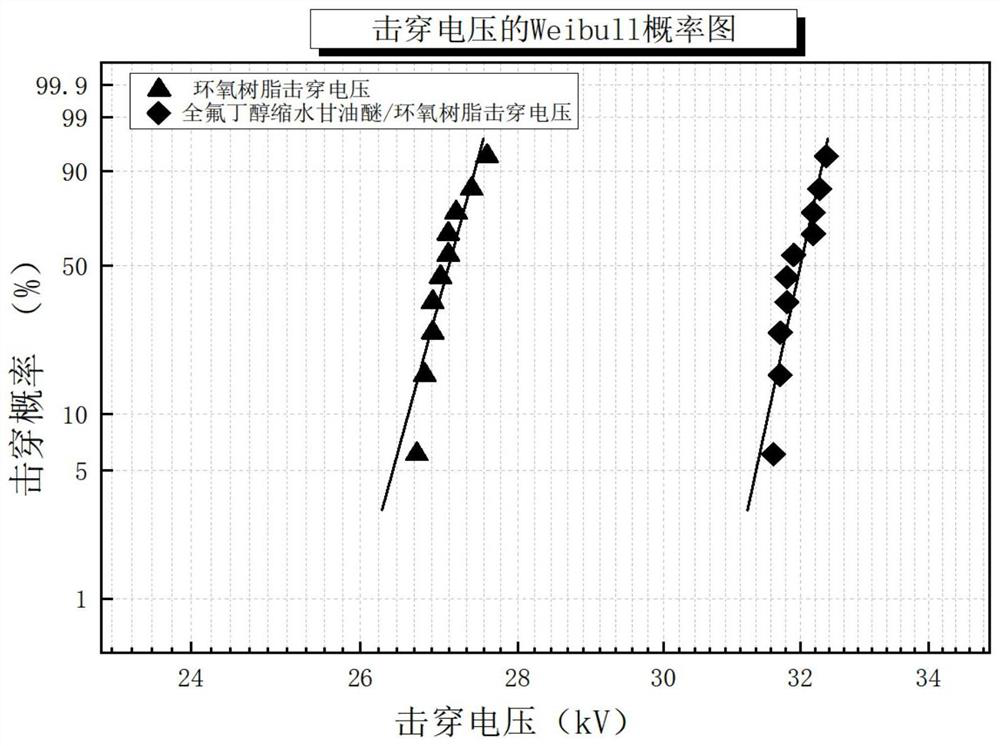

An epoxy resin and surface flashover technology, which is applied in the field of modified resins, can solve the problems of large space charge distortion, inability to better improve the surface flashover voltage of epoxy polymer matrix, and slow charge transfer rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The method for increasing the flashover voltage along the surface of the epoxy resin insulating material in this embodiment specifically includes the following steps: S1 Preparation of fluorine-containing molecular fragments:

[0037] S1-1: Heat perfluorobutanol in an oil bath, then stir, and purify the fraction to obtain moisture-free perfluorobutanol, which is sealed and stored for later use;

[0038] S1-2: Add boron trifluoride ether to the moisture-free perfluorobutanol obtained in the step S1-1, add sodium hydroxide several times to react, control the temperature of the system to remain unchanged, and add epichlorohydrin dropwise , carry out etherification reaction;

[0039] S1-3: After the reaction in step S1-2, add the solvent benzene for extraction, remove the lower water layer, and repeat washing with deionized water until the pH is detected as 7;

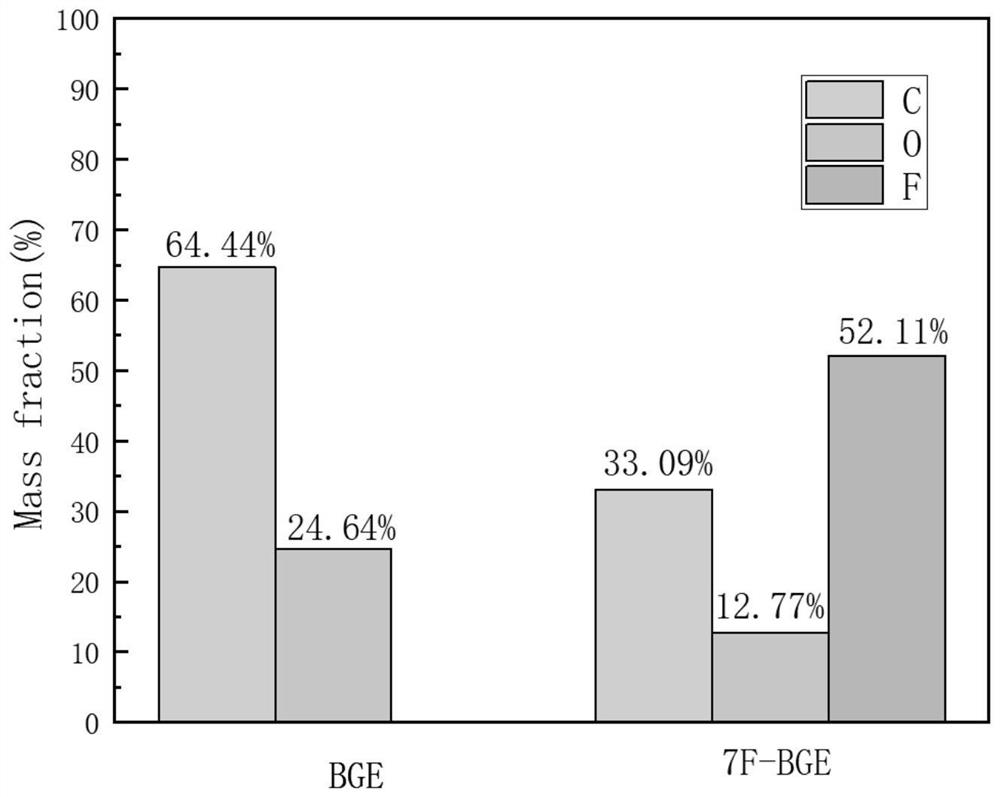

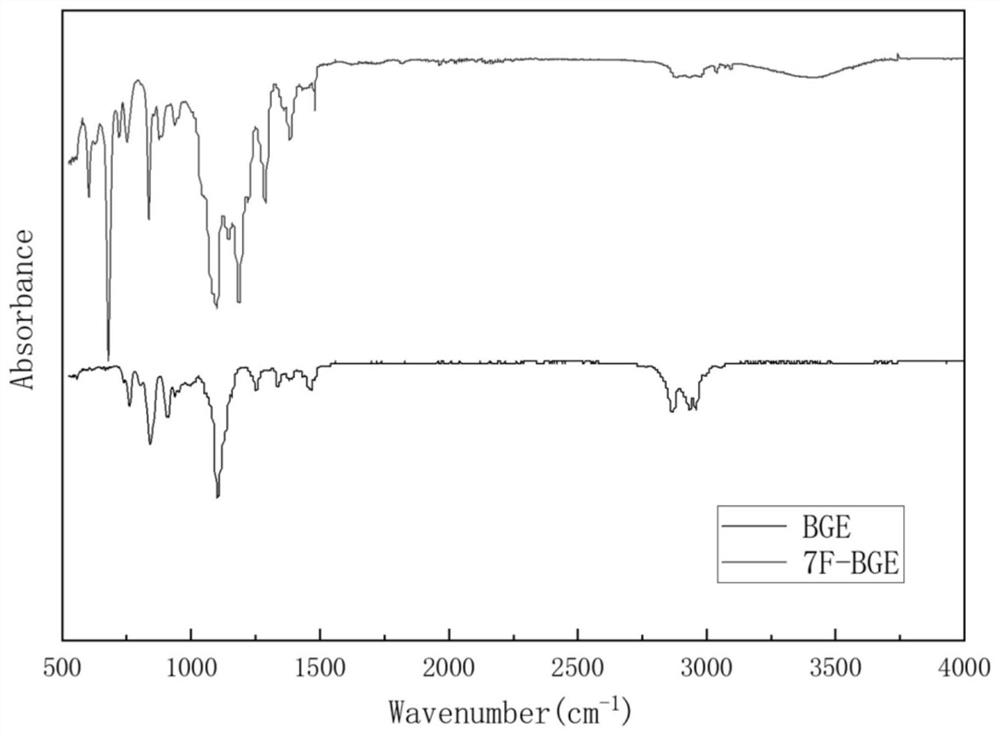

[0040] S1-4: heating and distilling the filtered liquid obtained in the step S1-3 to obtain perfluorobutanol gly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com