High-Voltage Flat Capacitor Based on Metal-Polymer Combined Electrode

A technology of plate capacitors and combined electrodes, which is applied in the directions of laminated capacitors, fixed capacitor electrodes, fixed capacitor shells/packages, etc., to achieve the effect of increasing the flashover voltage along the surface, extending the distance along the surface, and avoiding direct contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. The following embodiments are used to illustrate the present invention , but not to limit the scope of the present invention.

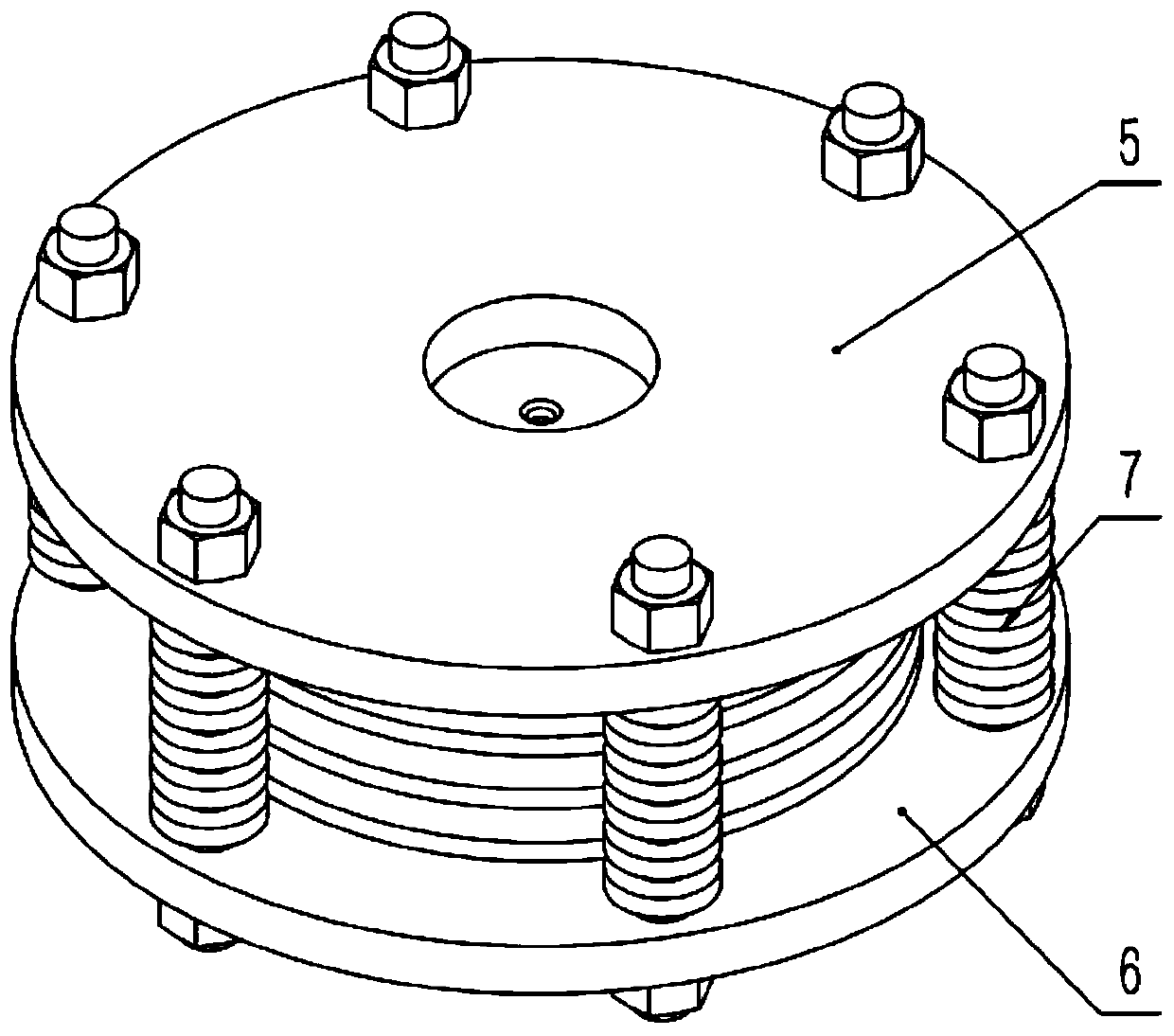

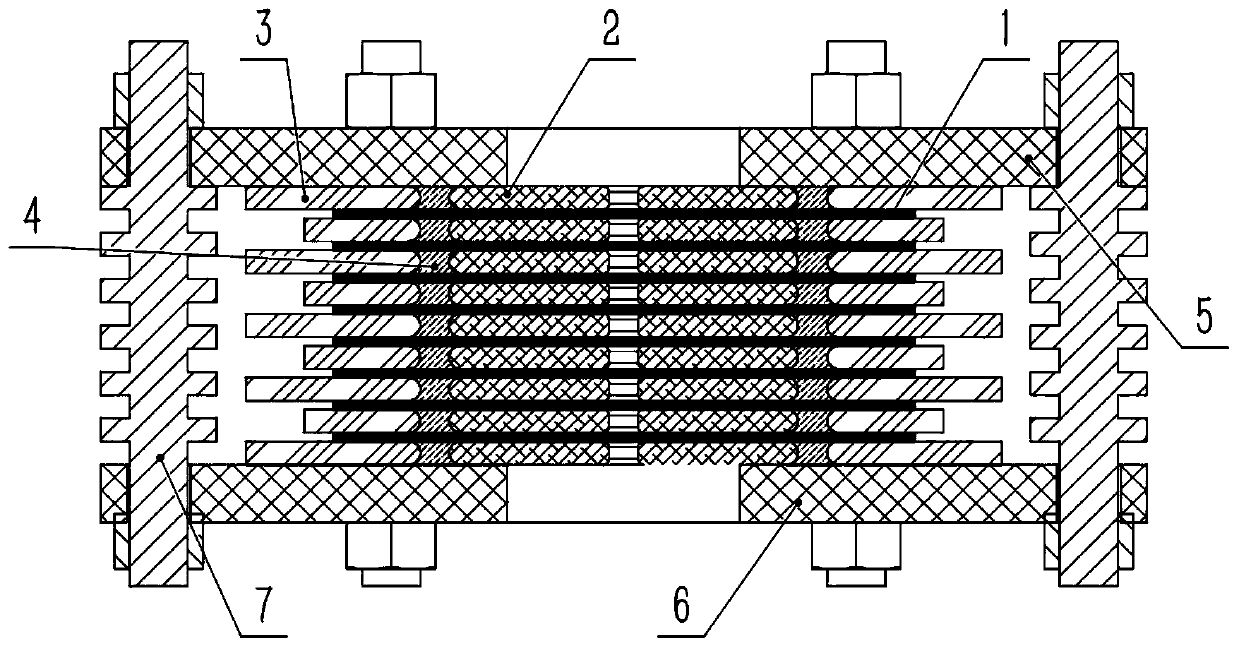

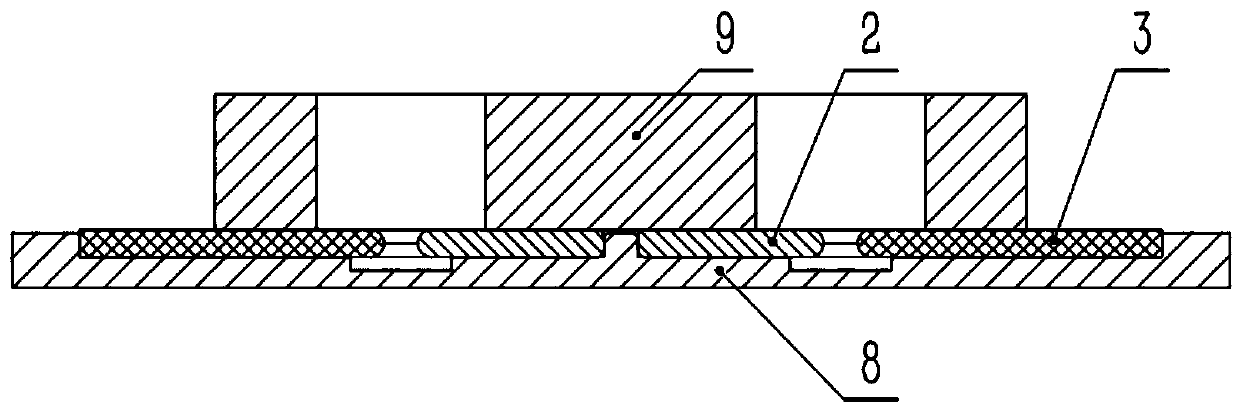

[0028] see figure 1 and figure 2 , a flat plate capacitor based on a metal-polymer composite electrode, the capacitor includes a metal-polymer composite electrode, a film dielectric 1, an upper pressing plate 5, a lower pressing plate 6 and a pull rod 7, the metal-polymer composite electrode and a thin film dielectric 1 The number is multiple, multiple metal-polymer composite electrodes are coaxially stacked together, and the film med...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com