Preparation method of surface-flashover-resistant insulating material for high-temperature superconducting

A surface flashover and insulating material technology, applied in the field of preparation of new insulating materials, can solve problems restricting the development of superconducting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

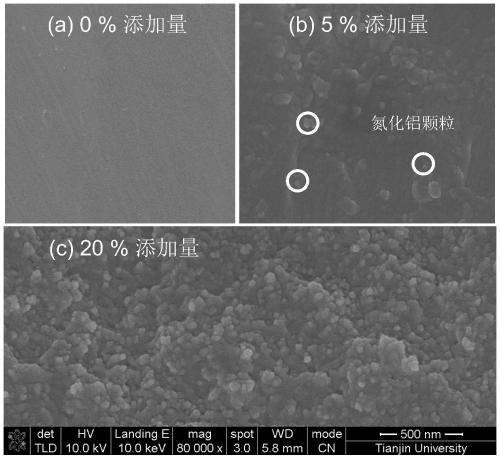

[0028] Embodiment 1: A kind of preparation method of surface flashover resistant insulating material for high temperature superconducting, comprises the following steps:

[0029] 1) Prepare polypropylene granules and weigh them;

[0030] 2) Prepare aluminum nitride particles and weigh them, the amount of aluminum nitride particles is 5% of the weight of polypropylene particles;

[0031] 3) Place the polypropylene granules on a two-roller machine and heat them;

[0032] 4) Add aluminum nitride particles after the polypropylene particles are melted, turn on the double-roller machine, set the speed at 50rmp and mix for 10 minutes to form a polypropylene / aluminum nitride composite material;

[0033] 5) After mixing evenly, the polypropylene / aluminum nitride composite material is taken out, and naturally cooled to room temperature for use;

[0034] 6) Preheat the stainless steel mold to 190°C, put it into the polypropylene / aluminum nitride composite material, pressurize at 15MPa ...

Embodiment 2

[0038] Embodiment 2: A kind of preparation method of surface flashover resistant insulating material for high temperature superconducting, comprises the following steps:

[0039] 1) Prepare polypropylene granules and weigh them;

[0040] 2) Prepare and weigh aluminum nitride particles, the amount of aluminum nitride particles is 20% of the weight of polypropylene particles;

[0041] 3) Place the polypropylene granules on a two-roller machine and heat them;

[0042] 4) Add aluminum nitride particles after the polypropylene particles are melted, turn on the double-roller machine, set the speed at 50rmp and mix for 10 minutes to form a polypropylene / aluminum nitride composite material;

[0043] 5) After mixing evenly, the polypropylene / aluminum nitride composite material is taken out, and naturally cooled to room temperature for use;

[0044] 6) Preheat the stainless steel mold to 190°C, put it into the polypropylene / aluminum nitride composite material, pressurize at 15MPa and ...

Embodiment 3

[0048] Embodiment 3: a kind of preparation method of surface flashover resistant insulation material for high temperature superconducting, comprises the following steps:

[0049] 1) Prepare polypropylene granules and weigh them;

[0050] 2) Prepare aluminum nitride particles and weigh them, the amount of aluminum nitride particles is 5% of the weight of polypropylene particles;

[0051] 3) Place the polypropylene granules on a double-roller and heat them;

[0052] 4) Add aluminum nitride particles after the polypropylene particles are melted, turn on the double-roller machine, set the speed at 50rmp and mix for 10 minutes to form a polypropylene / aluminum nitride composite material;

[0053] 5) After mixing evenly, the polypropylene / aluminum nitride composite material is taken out, and naturally cooled to room temperature for use;

[0054] 6) Preheat the stainless steel mold to 195°C, put it into the polypropylene / aluminum nitride composite material, pressurize at 17MPa and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com