An extra-high voltage electric porcelain outer insulation outlet bushing

An outlet bushing and UHV technology, applied in the direction of insulators, insulators, lead-in/through-type insulators, etc., can solve the problems of easy occurrence of wet flashover and uneven distribution of external insulation voltage, and achieve improved wet flashover The effect of voltage and internal insulation electrical performance, production difficulty reduction, and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with examples. However, the invention is not limited to the examples given.

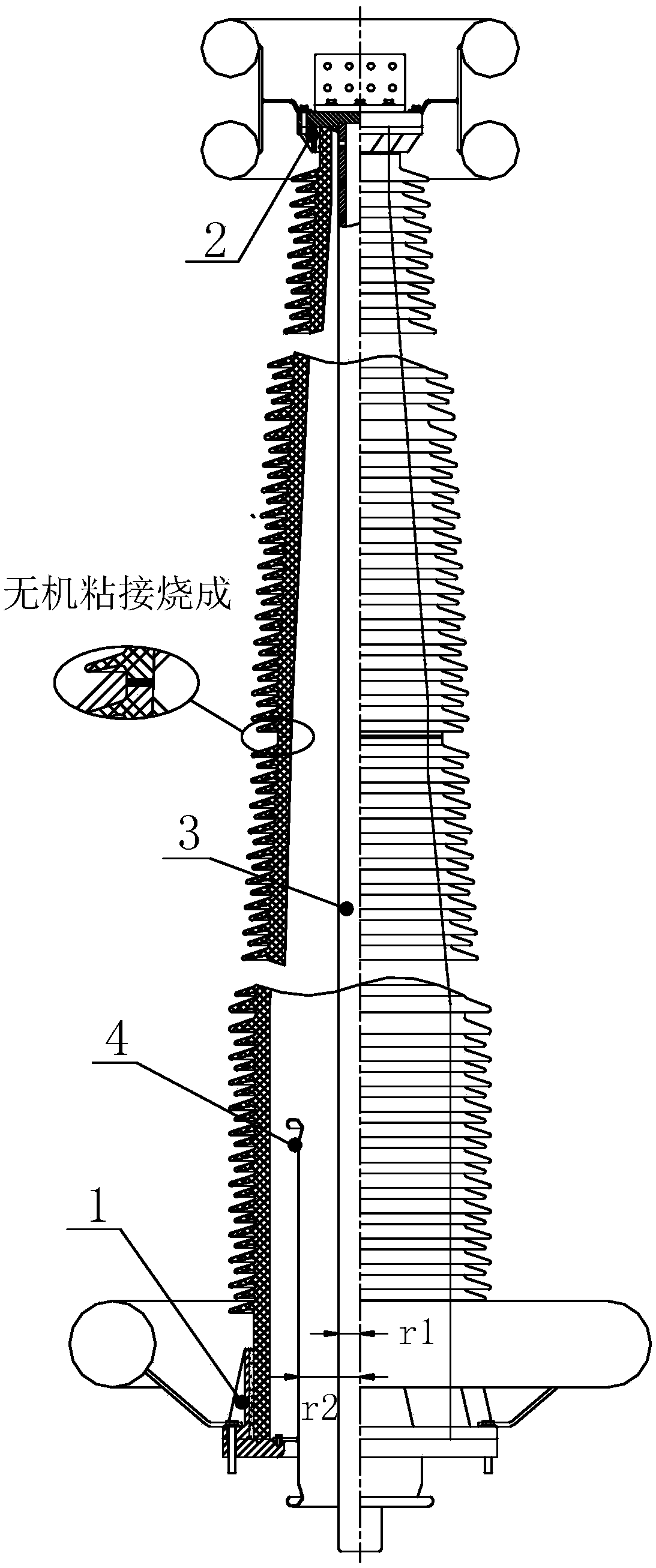

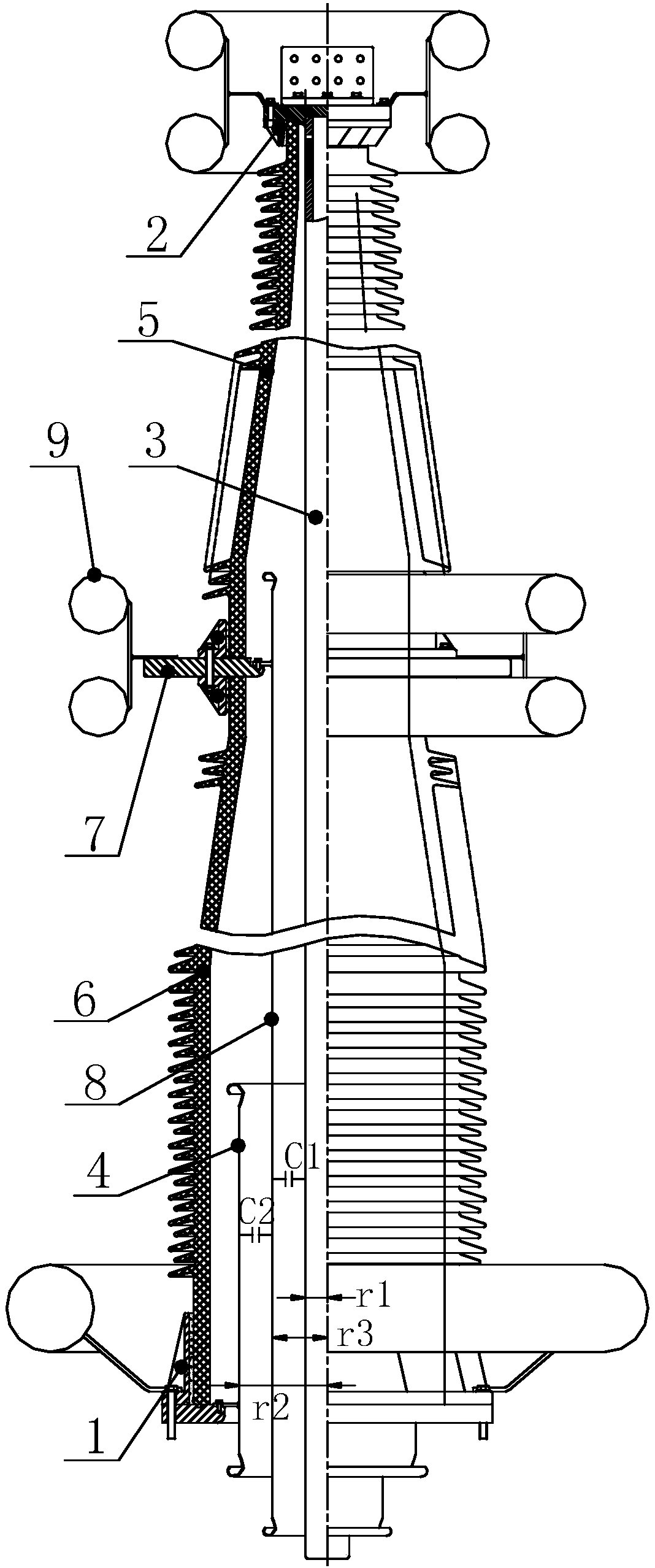

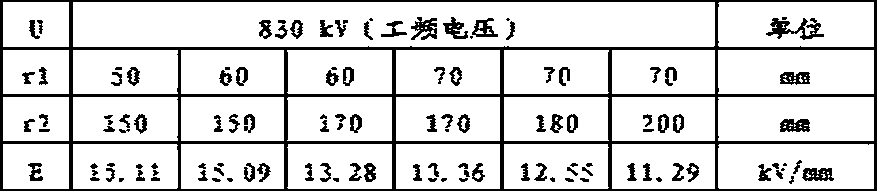

[0031] like figure 2 As shown, the UHV electric porcelain outer insulating outlet bushing of this embodiment has an upper porcelain sleeve 5 and a lower porcelain sleeve 6, and the upper and lower porcelain sleeves are fixed on the transition plate 7 through the intermediate flange, and the transition plate 7 is equipped with a pressure equalizing ring. The porcelain sleeve is filled with sulfur hexafluoride (insulating gas). The upper flange 2 is set on the top of the upper porcelain sleeve 5, the lower flange 1 is set on the bottom end of the lower porcelain sleeve 6 (the lower flange 1 is grounded, so the lower flange 1 is also called the grounding flange), and the grounding electrode 4 (can be Transition plate) is installed on the lower flange 1, and the ground electrode 4 is at the same potential as the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com