Silicon rubber insulator injection mold demolding device

A silicone rubber insulation and injection mold technology, applied in the field of silicone rubber injection molds, can solve problems such as product scratches and fractures, and achieve the effect of high production efficiency and less damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

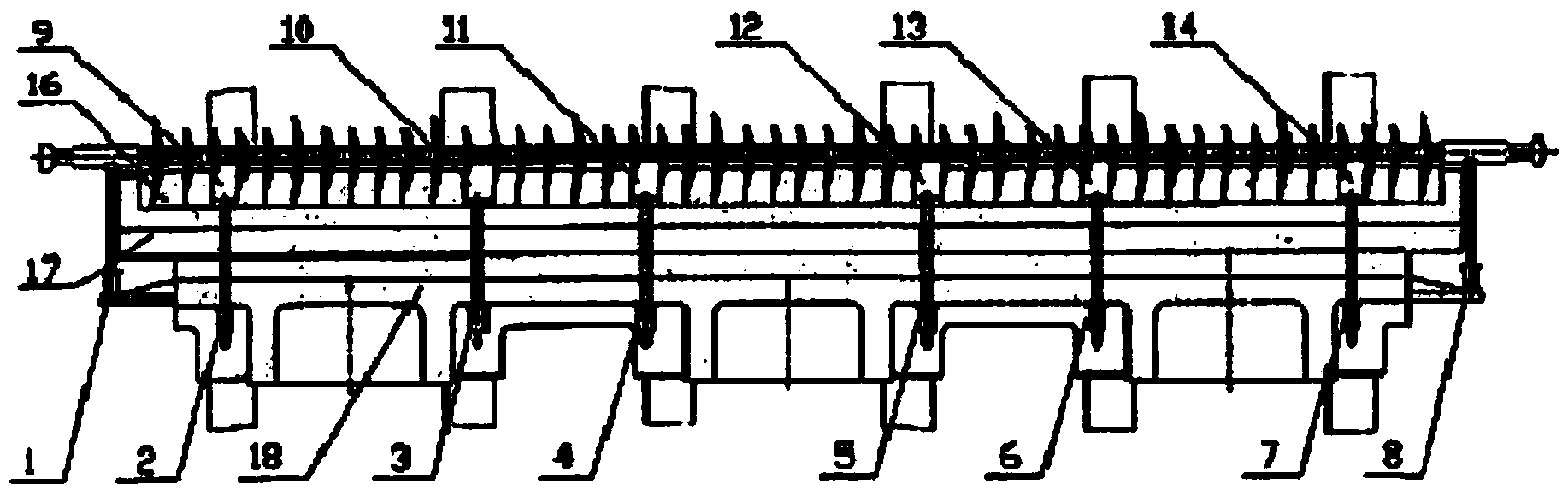

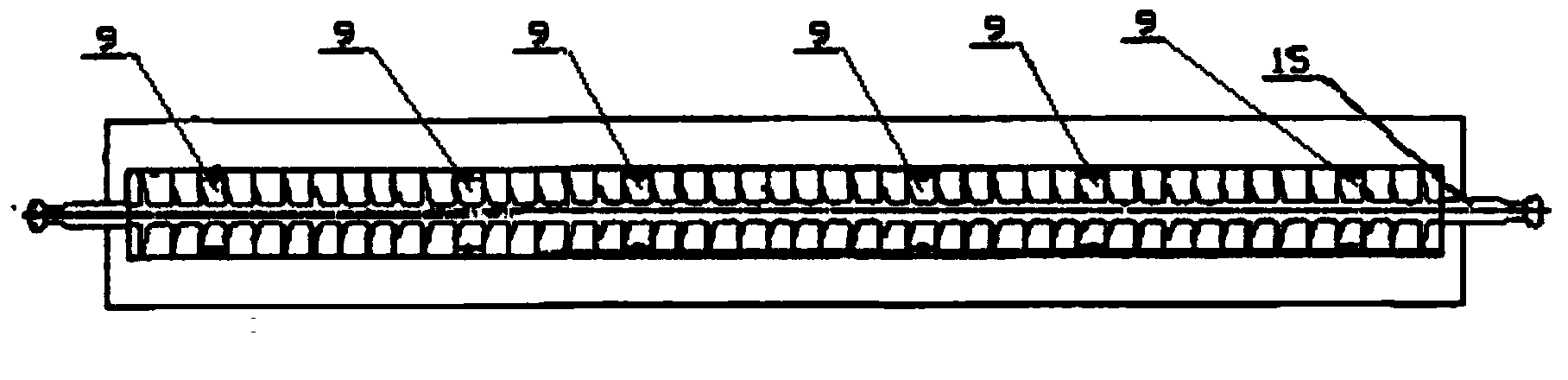

[0025] Such as figure 1 with figure 2 As shown, a silicone rubber insulator injection mold demoulding device is composed of a lower template 16, a lower hot plate 17, a movable template 18, a mandrel 15, a demoulding cylinder 1-8 and a movable insert 9-14, wherein the lower The template 16 is fixed on the upper end of the movable template 18, and a lower hot plate 17 is arranged between the two, and the mandrel 15 is correspondingly placed in the cavity of the lower template 16, and the movable inserts 9-14 can slide up and down from left to Right is arranged at the lower end of the mold cavity of lower template 16, and movable insert 9-14 is symmetrically distributed on the left and right sides of lower template, and the upper end of movable insert 9-14 can protrude from the mold cavity of lower template 16, and its upper end The shape corresponds to the shape of the cavity surface of the lower formwork 16. Before the movable inserts 9-14 are jacked up, the upper end thereo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com