Food processor with tools combined to a tool unit

A technology of food processor and tool unit, which is applied in home appliances, kitchen appliances, applications, etc. It can solve the problems of large storage space, difficulty in use, and complexity, and achieve good protection and prevent accidental disappearance or loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

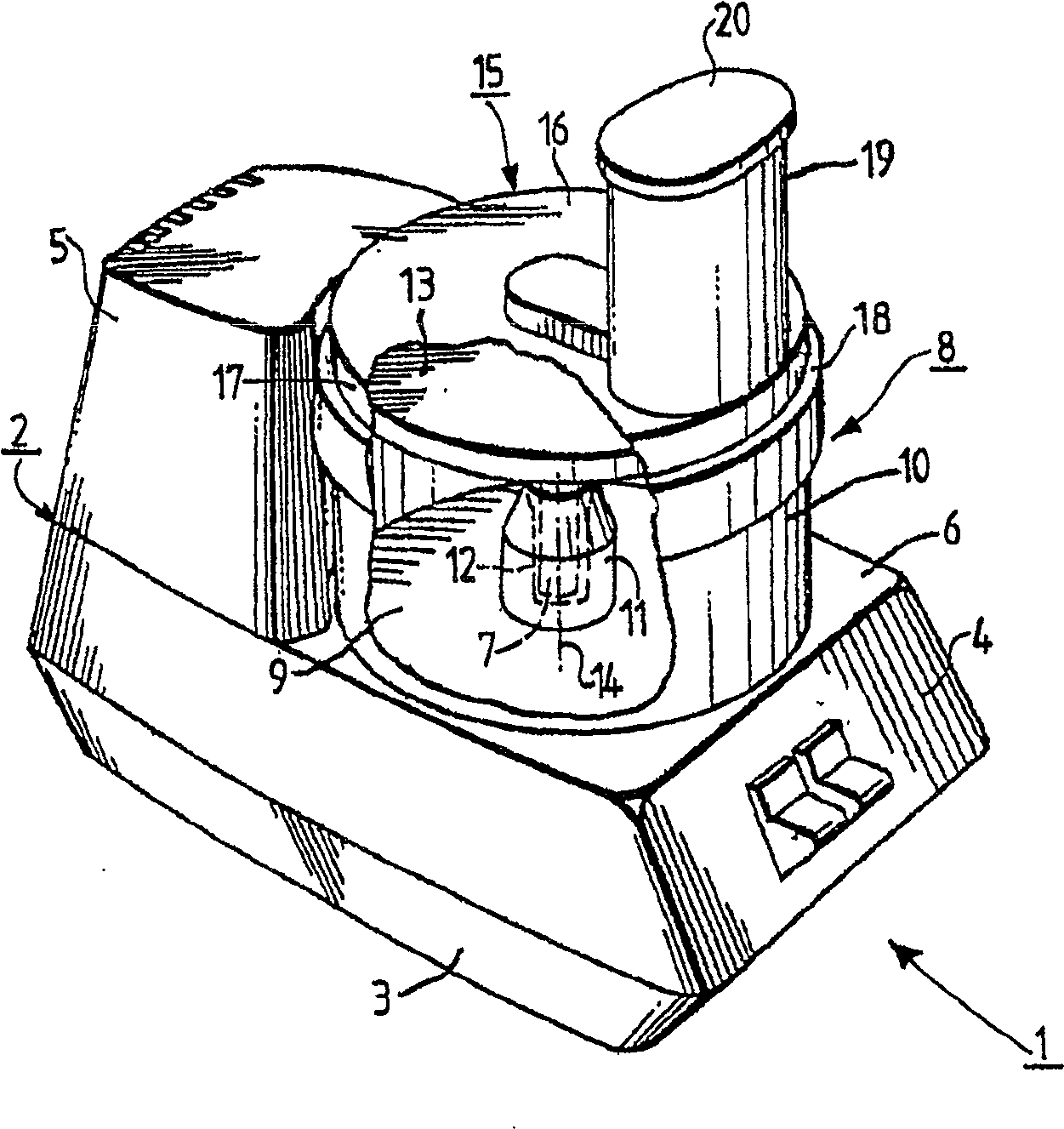

[0022] figure 1 A food processor 1 is shown. This food processor 1 is designed for processing food. For example, this food processor can be used to chop vegetables into thick or thin strips, or they can be grated through the grate into small pieces. Also, vegetables can be sliced thinly.

[0023] The food processor 1 is equipped with a housing 2 comprising a trough-shaped bottom 3 and an inverted trough-shaped top 4 from which tower-shaped sides 5 protrude. The drives for the tools for operating the food processor and the power circuits for the drives are housed in the housing area comprising the bottom 3 and the top 4 . The drive unit is equipped with an electric motor and a transmission that can be driven by the motor, however they are figure 1 is not shown in . The reason is that the specific design of the drive is not important in this case. The drive shaft 7 passing from the drive through the cover wall 6 of the top 4 is in the figure 1 visible in .

[0024] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com