Single track tunnel overall positioning equipment

A technology for positioning equipment and tunnels, used in overhead lines, power lines, transportation and packaging, etc., can solve problems such as traffic accidents, poor flow conditions, wear and tear of load-bearing cables, and achieve the effect of reducing pressure and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

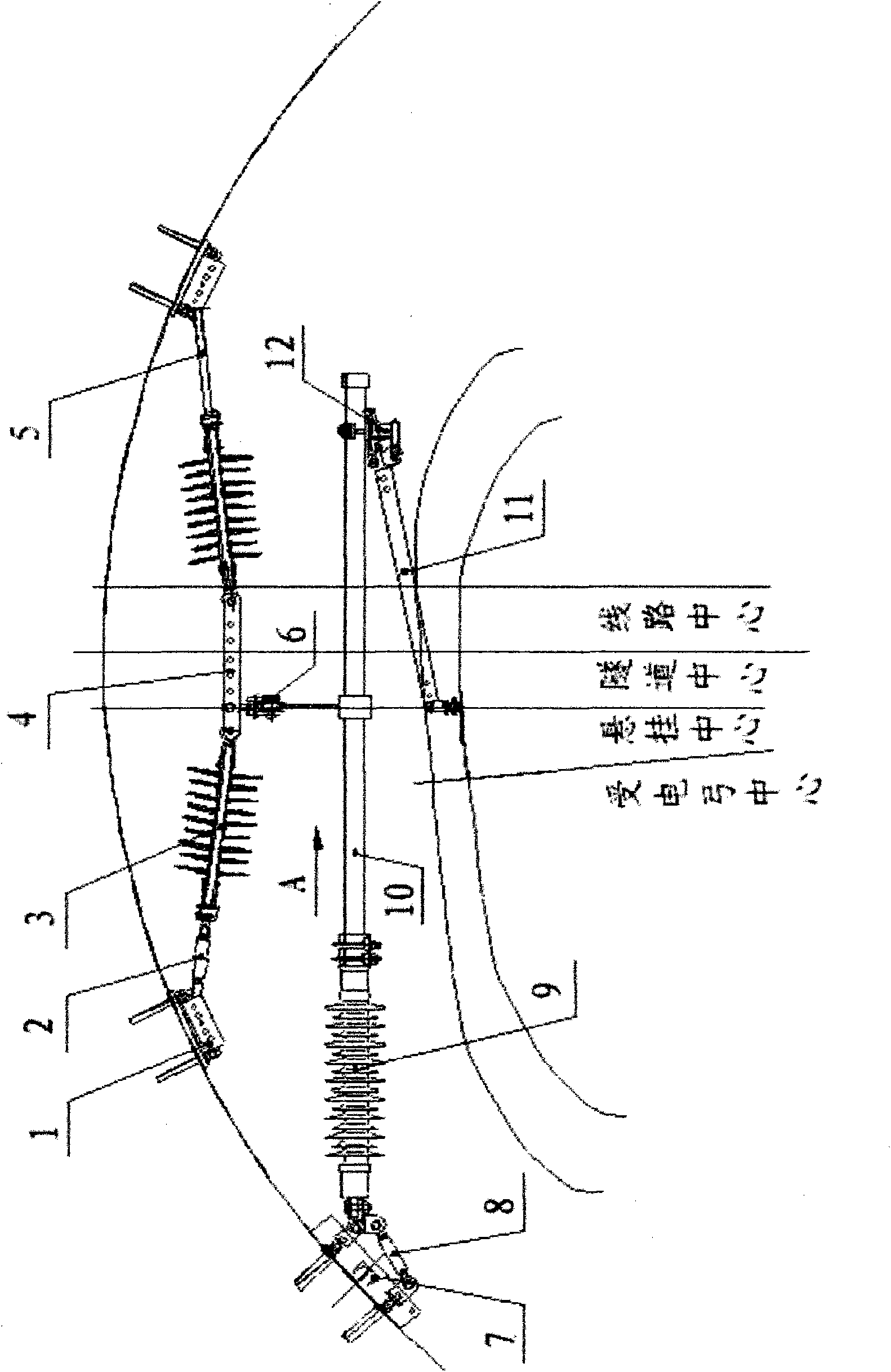

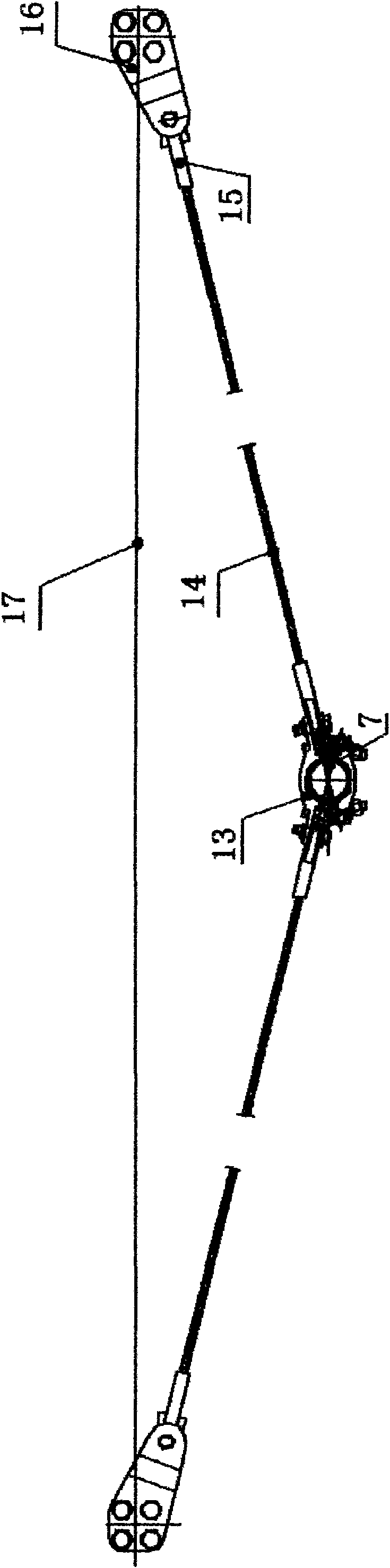

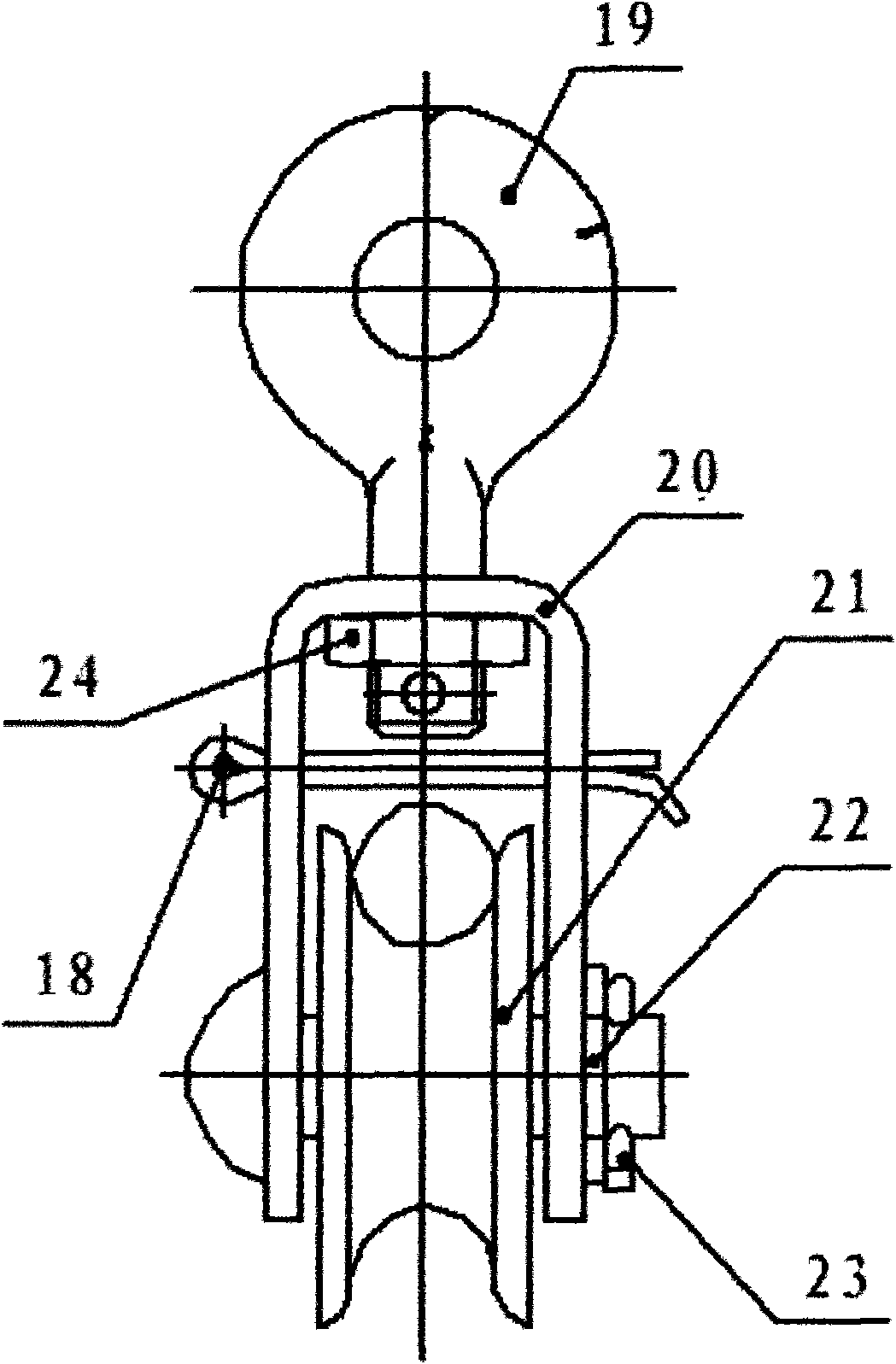

[0015] Such as figure 1 As shown, the catenary suspension device includes a catenary suspension base 1, an anti-corrosion adjustment bolt 2, a silicon rubber insulator 3, a pulley bracket 4, a pestle ring rod 5, and a tunnel pulley 6. The catenary cable suspension base 1 is a U-shaped structure, welded on the bottom plate, and fixed on the tunnel wall symmetrically along the top of the tunnel through chemical anchor bolts. One end of the ring rod 5 is connected with the round holes on the left and right catenary suspension bases 1 respectively, and the other end of the anti-corrosion adjustment bolt 2 and the pestle ring rod 5 are respectively connected with the pulley bracket 4 in the middle through the left and right silicon rubber insulators 3 . When the anti-corrosion adjustment bolt 2 is connected with the round hole of the catenary suspension base 1, the height of the catenary can be adjusted by selecting round holes of different heights; simultaneously tighten the silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com