Patents

Literature

93 results about "Ear ringing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

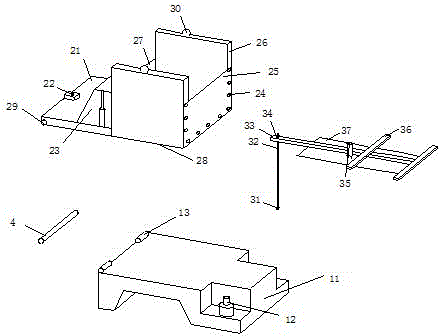

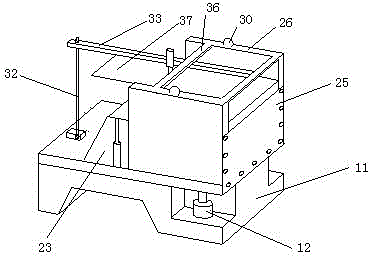

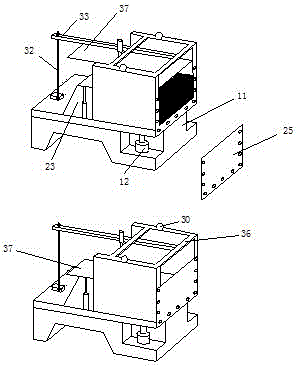

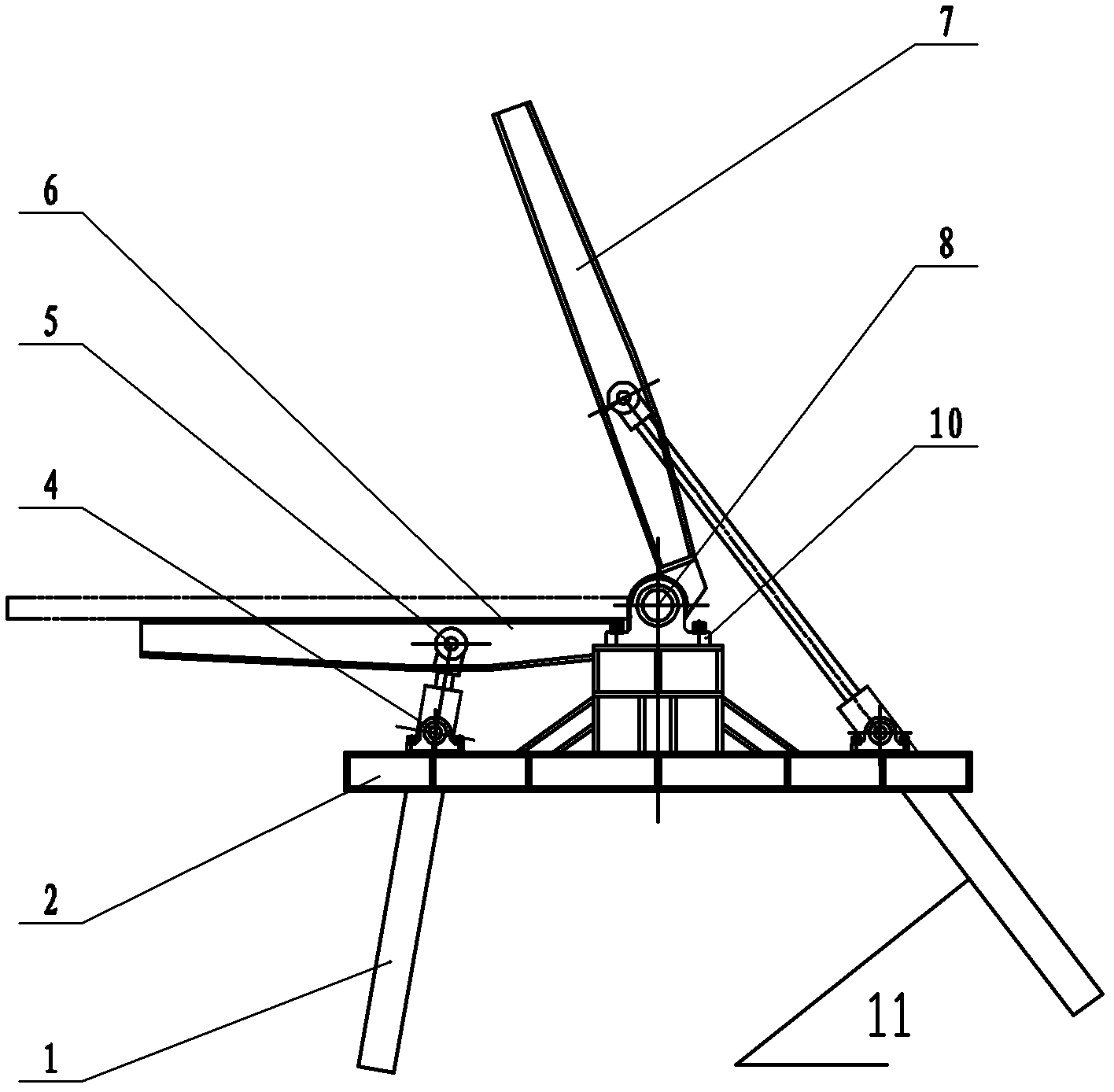

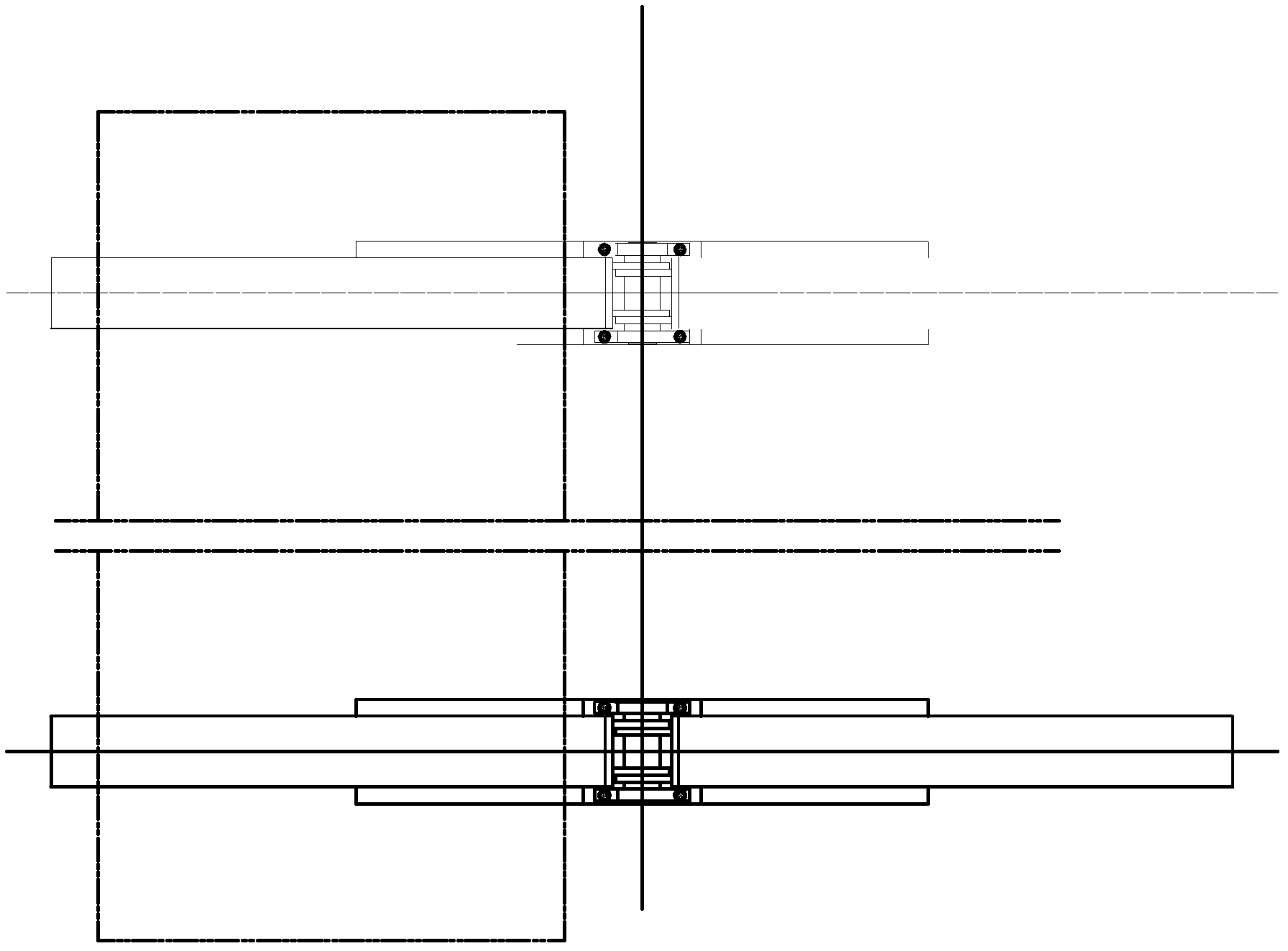

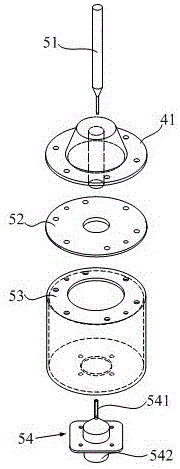

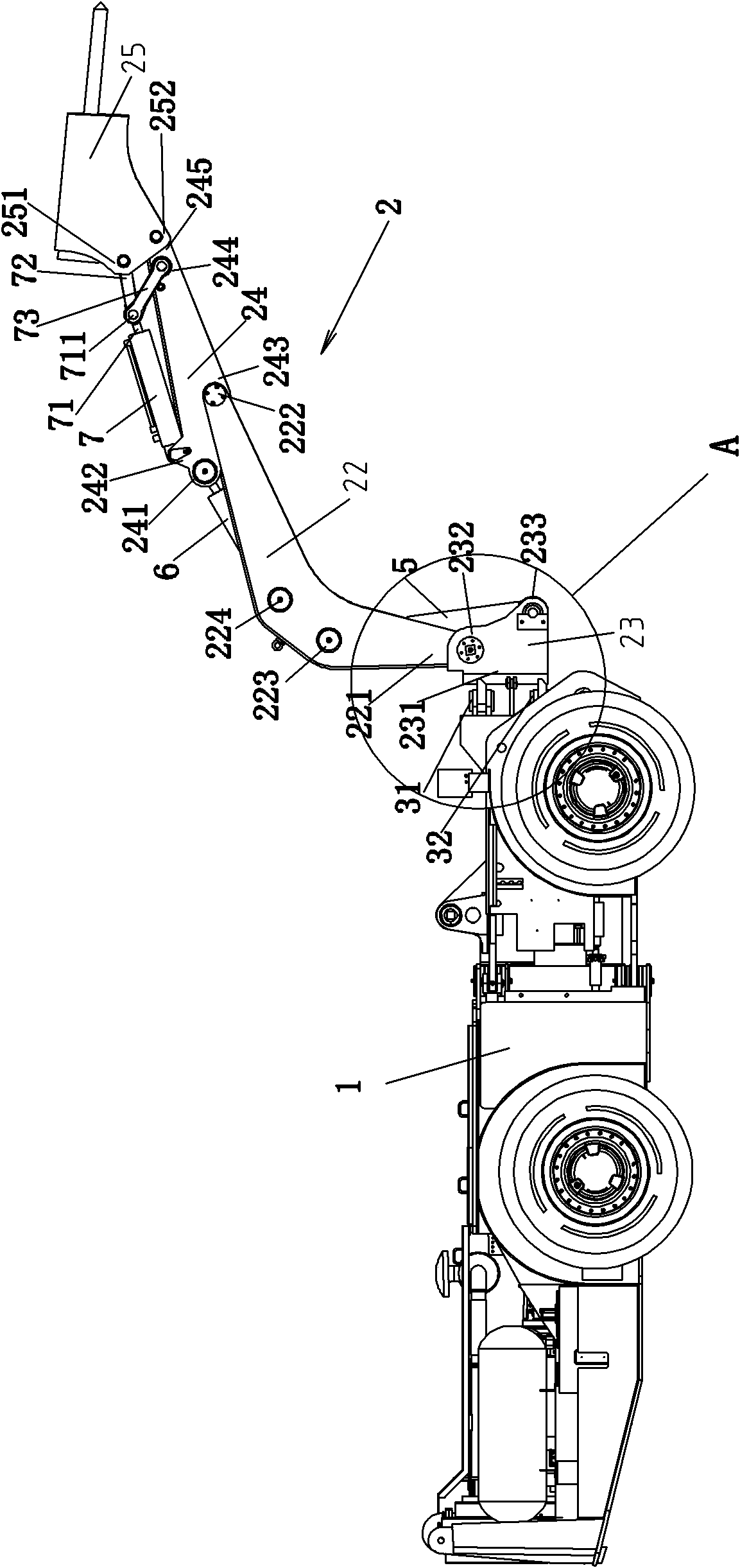

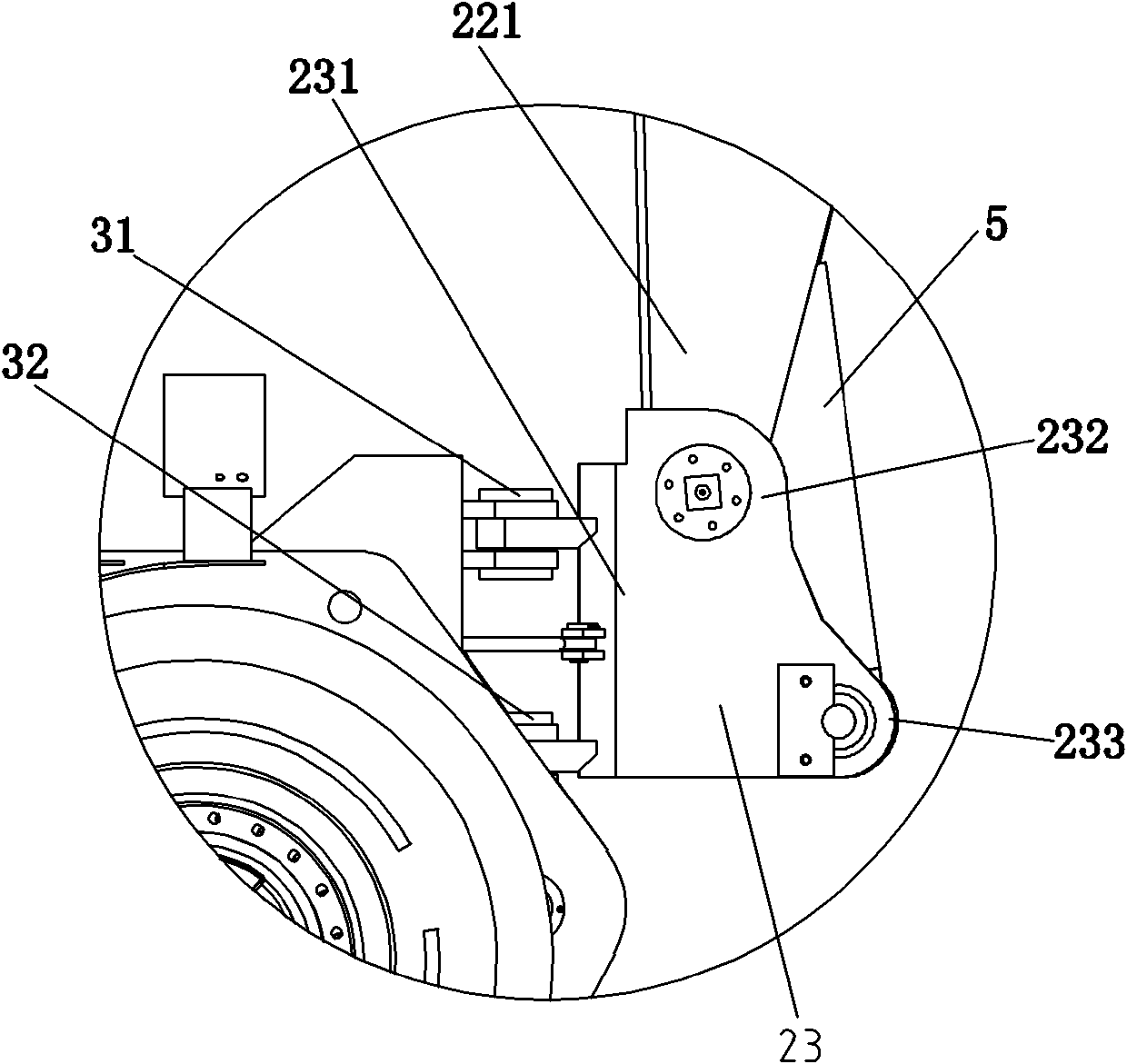

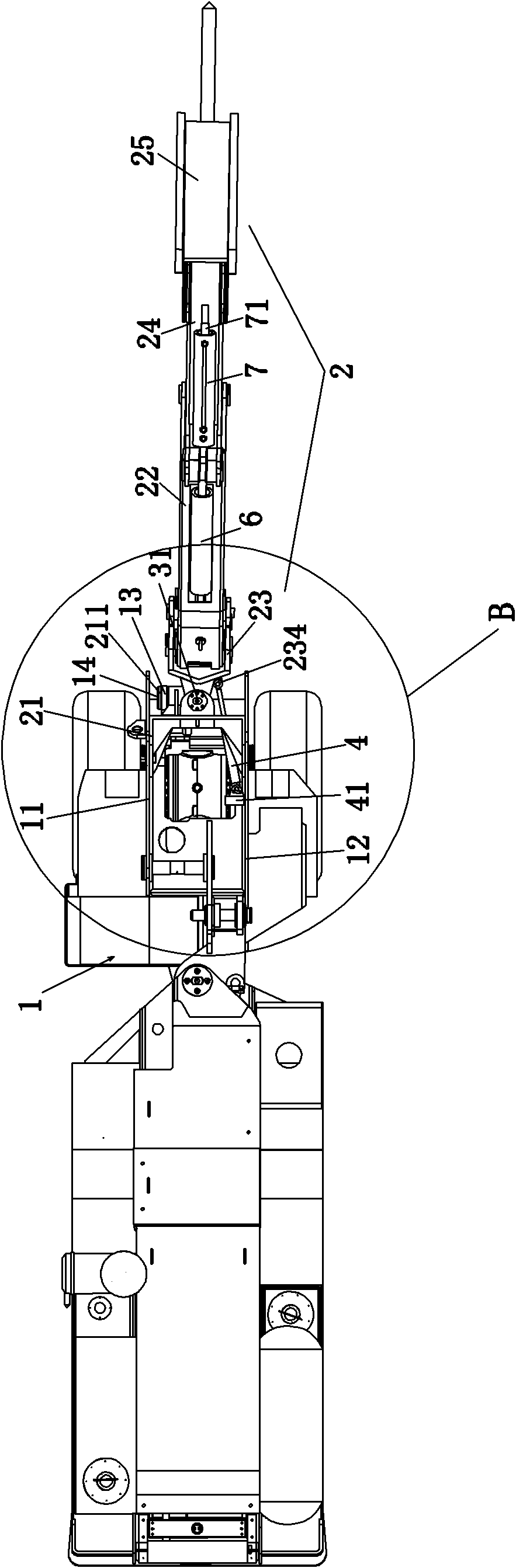

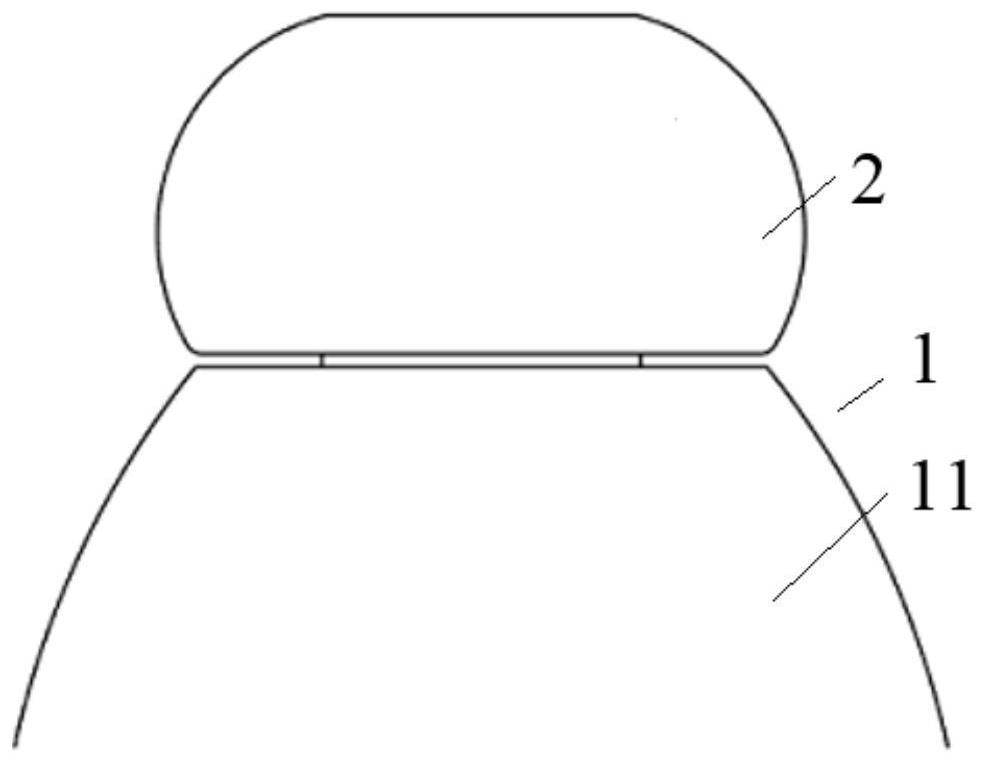

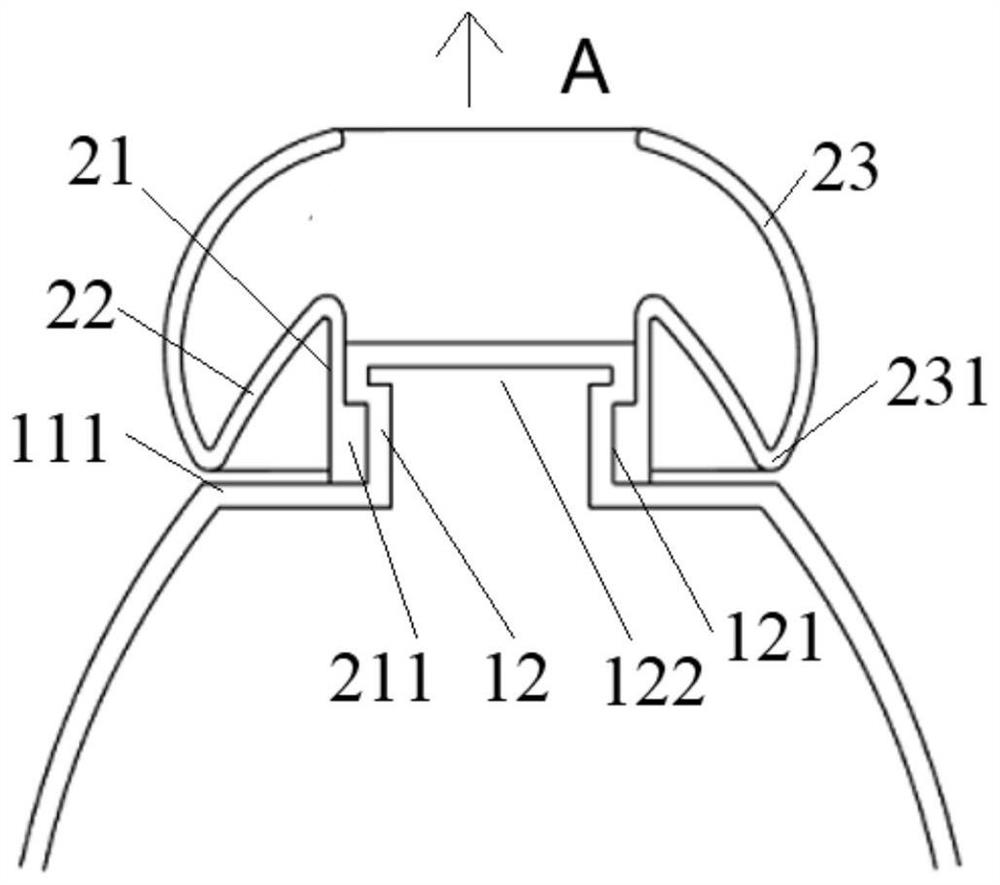

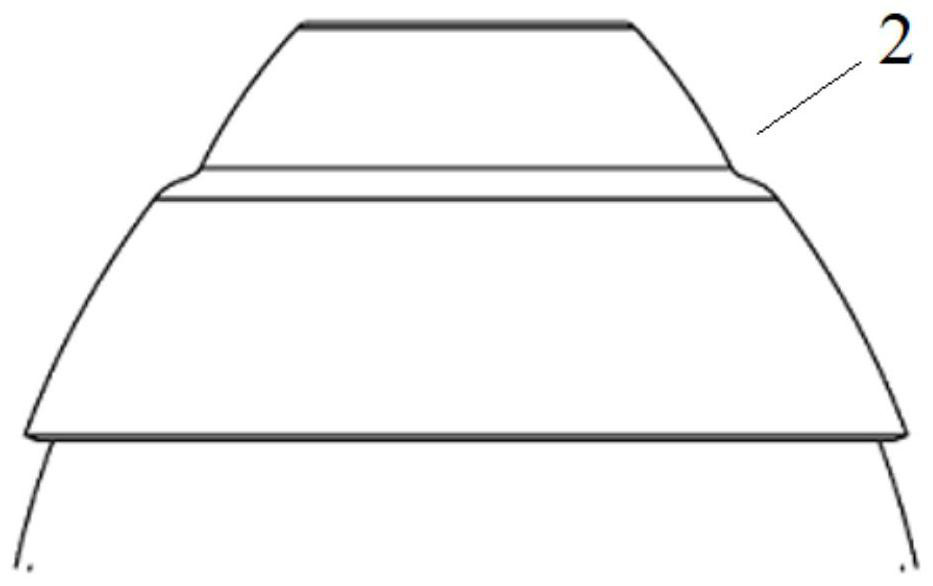

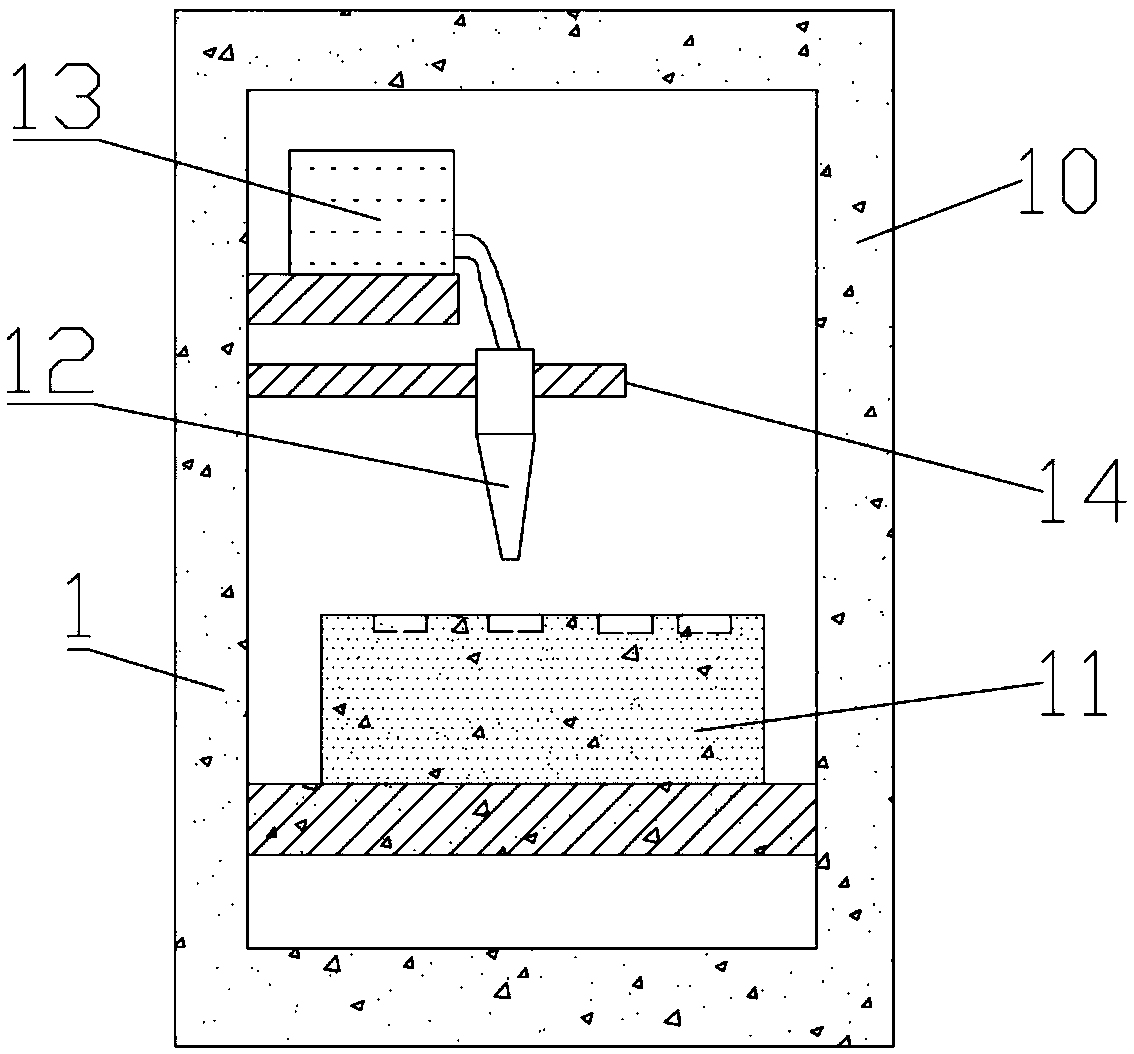

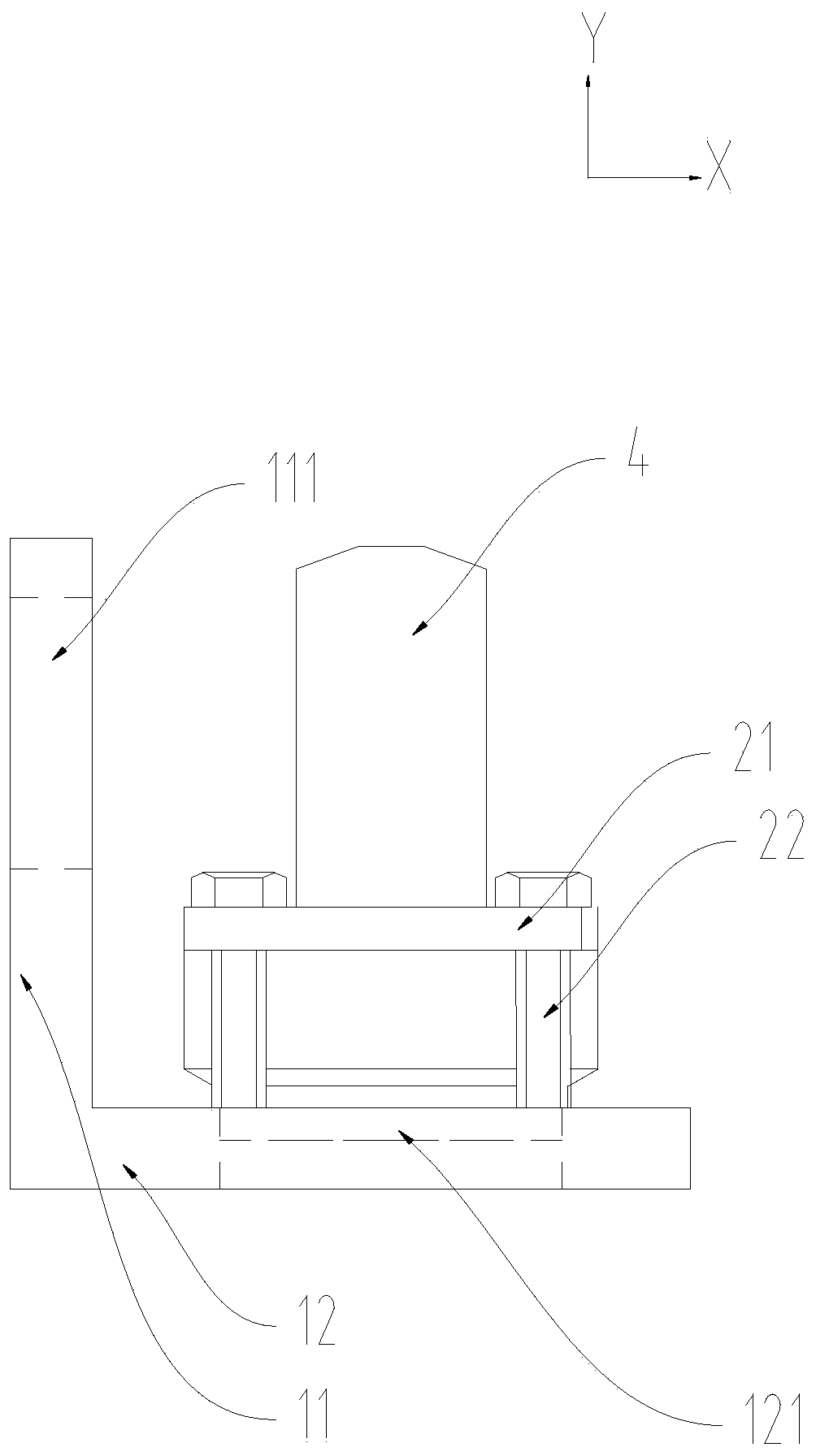

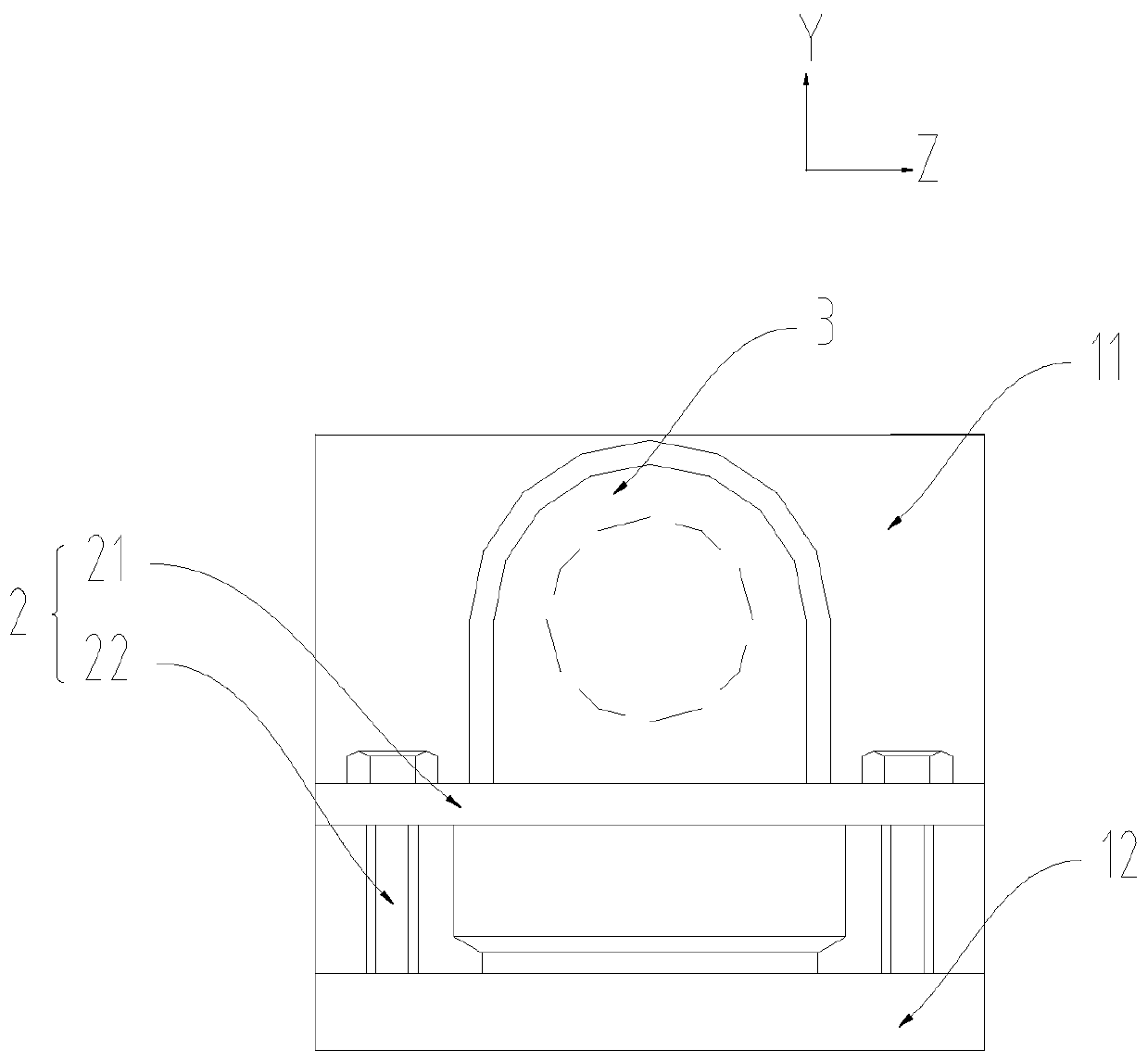

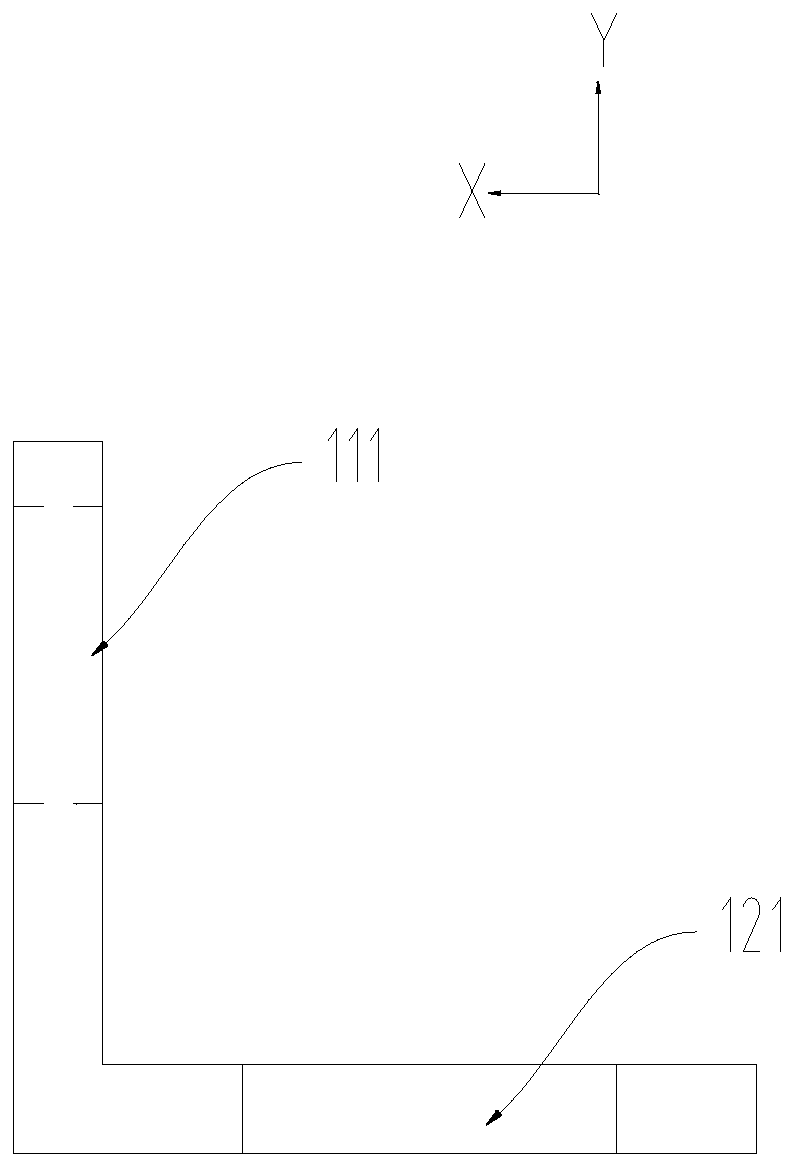

Working face coal wall stability control simulation experiment table and application method

ActiveCN104458418ASafe and Efficient MiningMaterial strength using tensile/compressive forcesModel selectionEngineering

The invention discloses a working face coal wall stability control simulation experiment table and an application method. The working face coal wall stability control simulation experiment table comprises a base mechanism, a bearing mechanism and a pressurizing mechanism, wherein the base mechanism is provided with a base, a slope adjustment jack, connecting groove holes and a connecting shaft; the bearing mechanism is provided with a bearing platform, a side protection plate, an ear ring, a rear cover, an organic glass baffle, a hydraulic support, reverse connecting groove holes, connecting holes, screw holes and screw rod angle steel; the pressurizing mechanism is provided with a cross beam, a longitudinal beam, a loading jack, a loading plate, a pull rod, pull rod connecting holes and a fastening nut. According to the invention, by the efficient matching of the base mechanism, the bearing mechanism and the pressurizing mechanism, coal wall deformation and damage characteristics with different mining height, different coal body intensity, different hydraulic support working resistance and different roof pressure can be obtained in an experiment, and the relationship of the accurate measurement of the coal wall stability with the mining height, the coal body intensity, the hydraulic support operation resistance and the roof pressure is achieved, the basis for the coal wall spalling prevention and control, stope roof load estimation, three-machine matched model selection and the like is provided, and the safe and efficient mining of a coal mining working face is realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

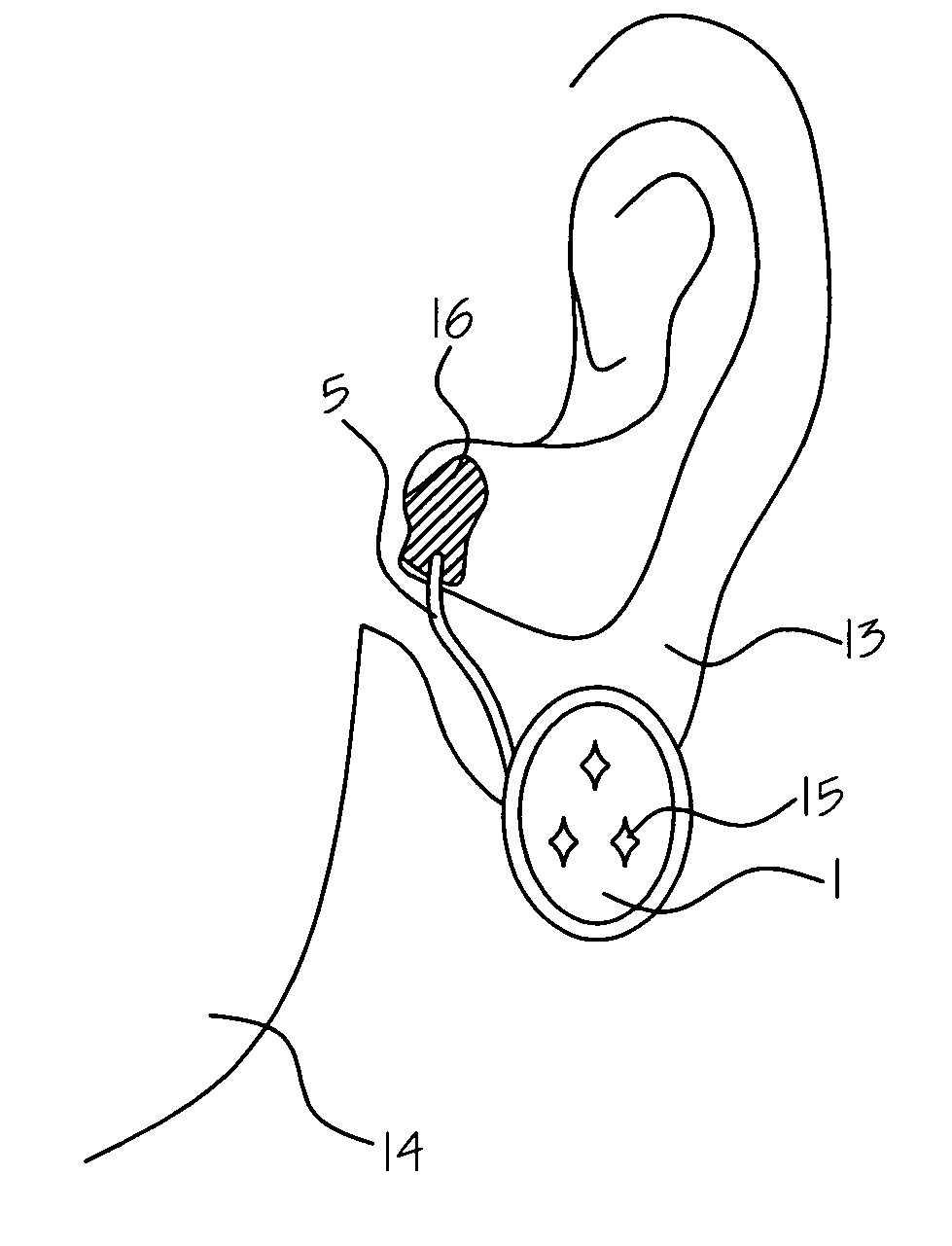

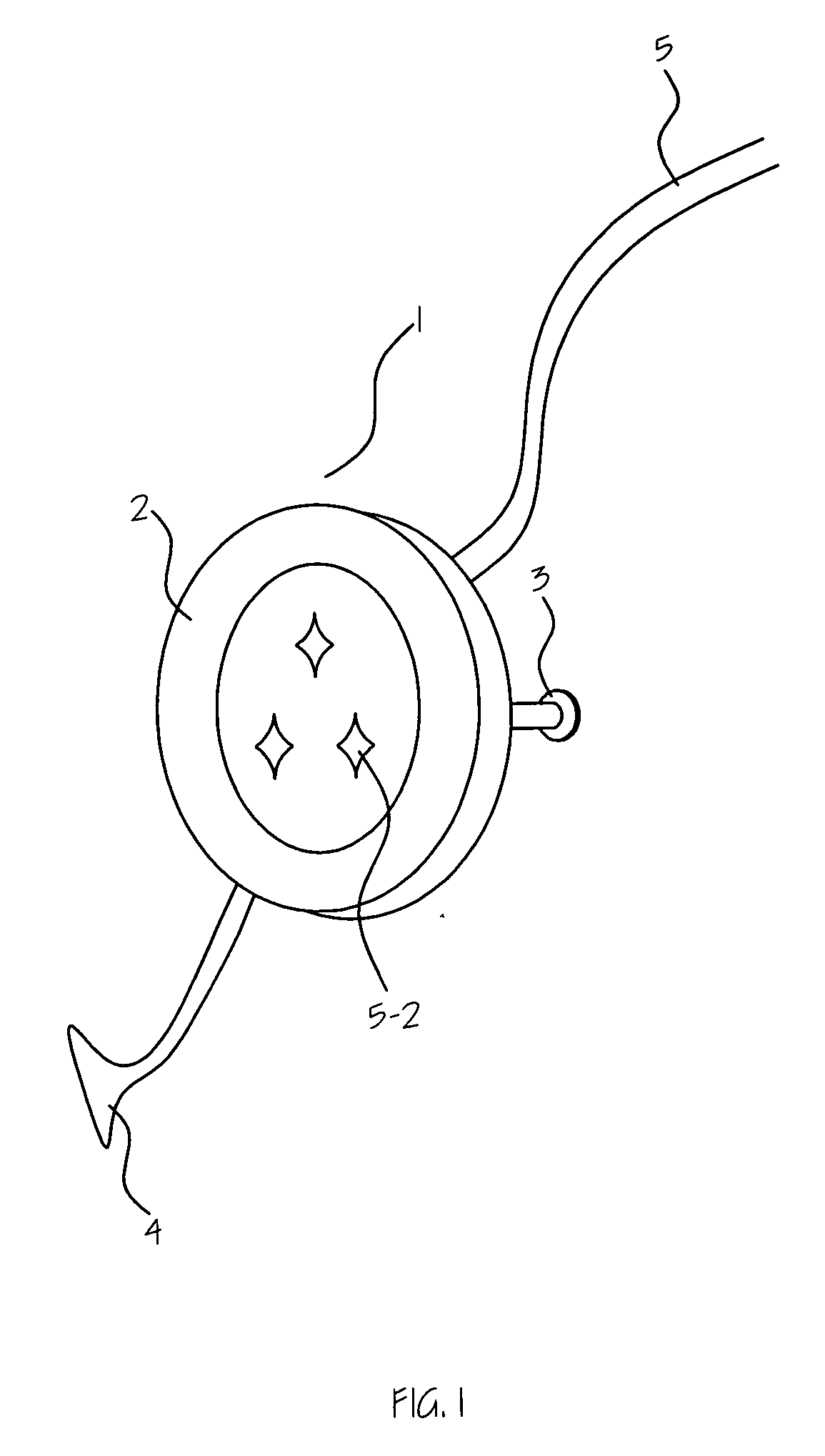

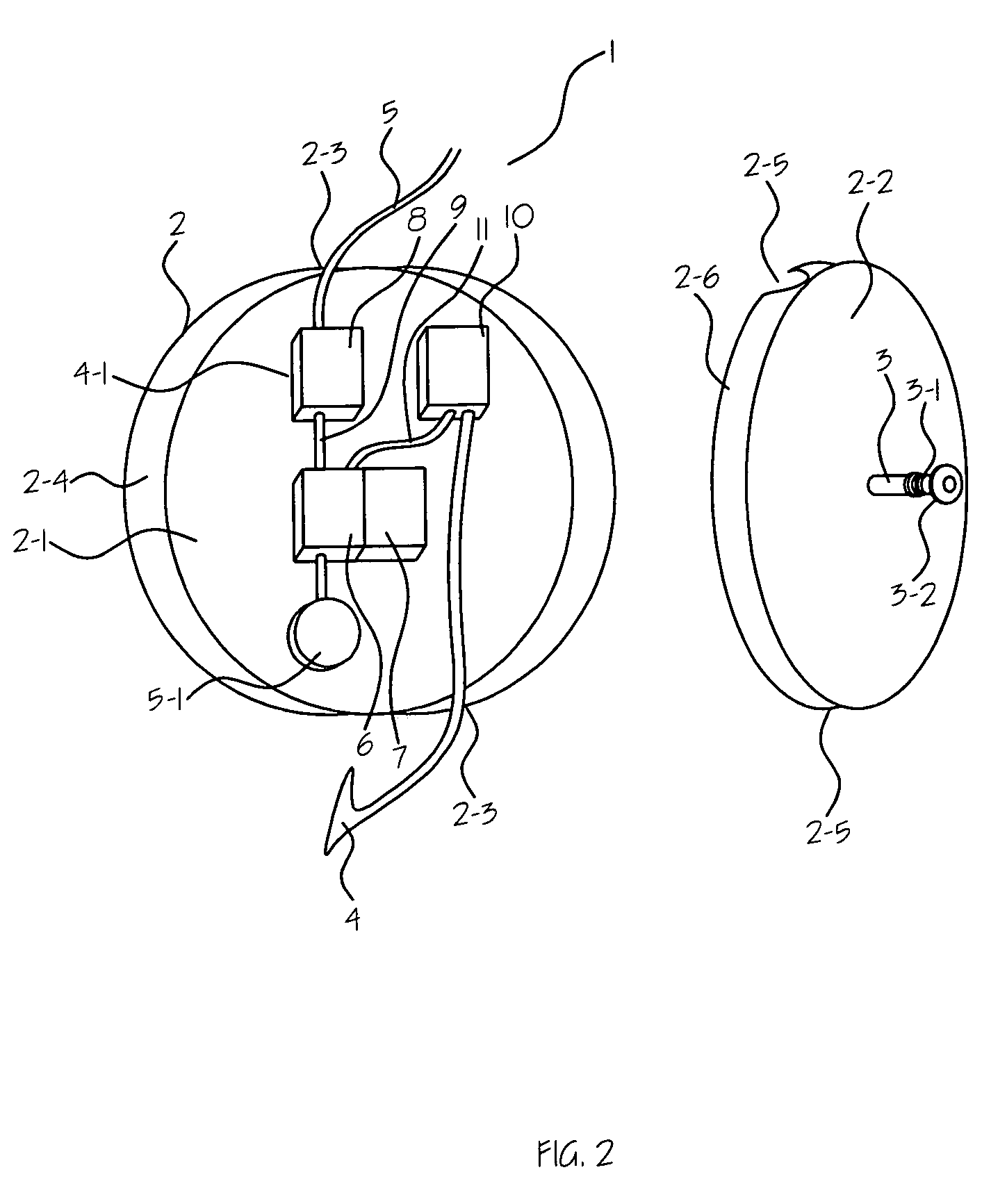

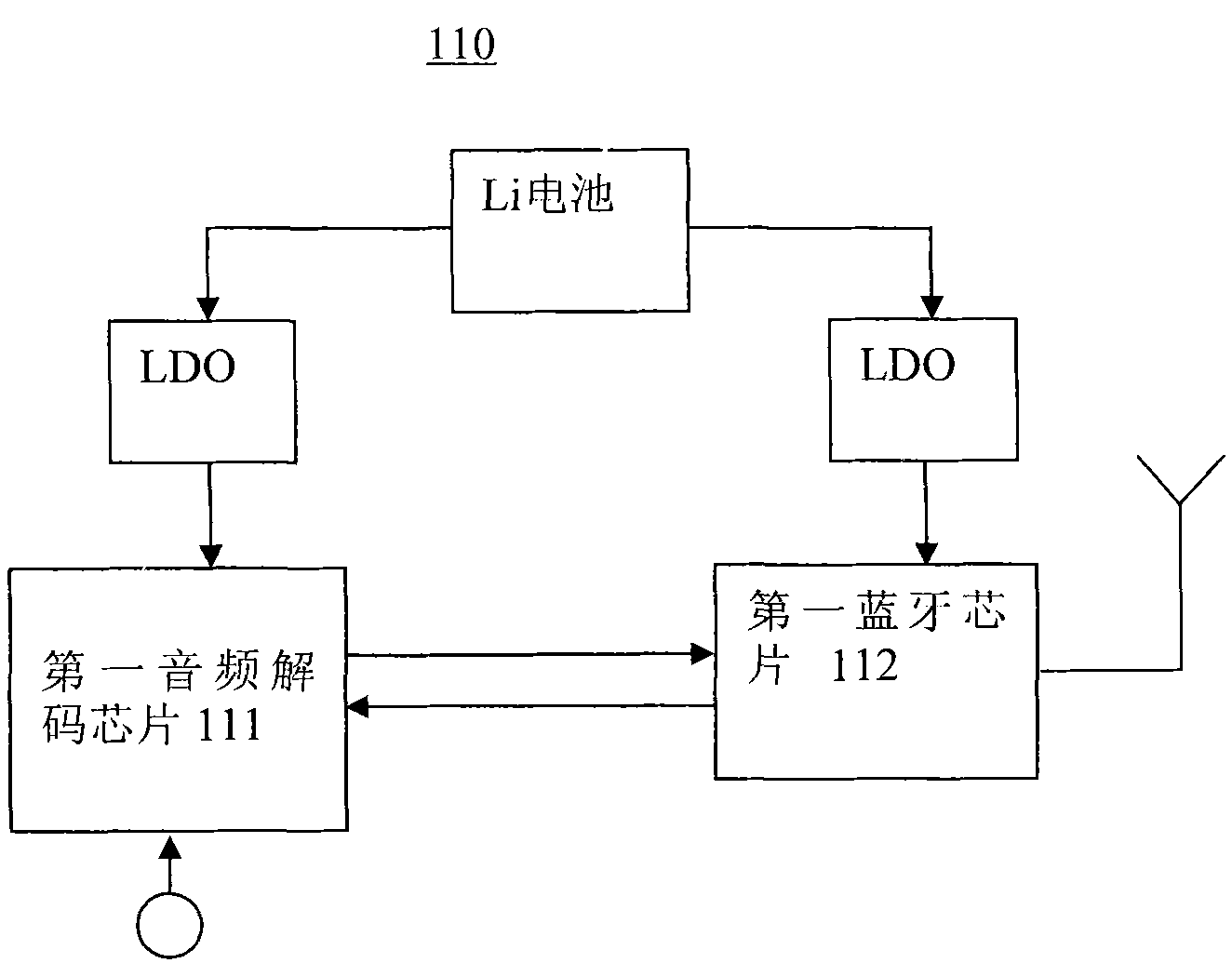

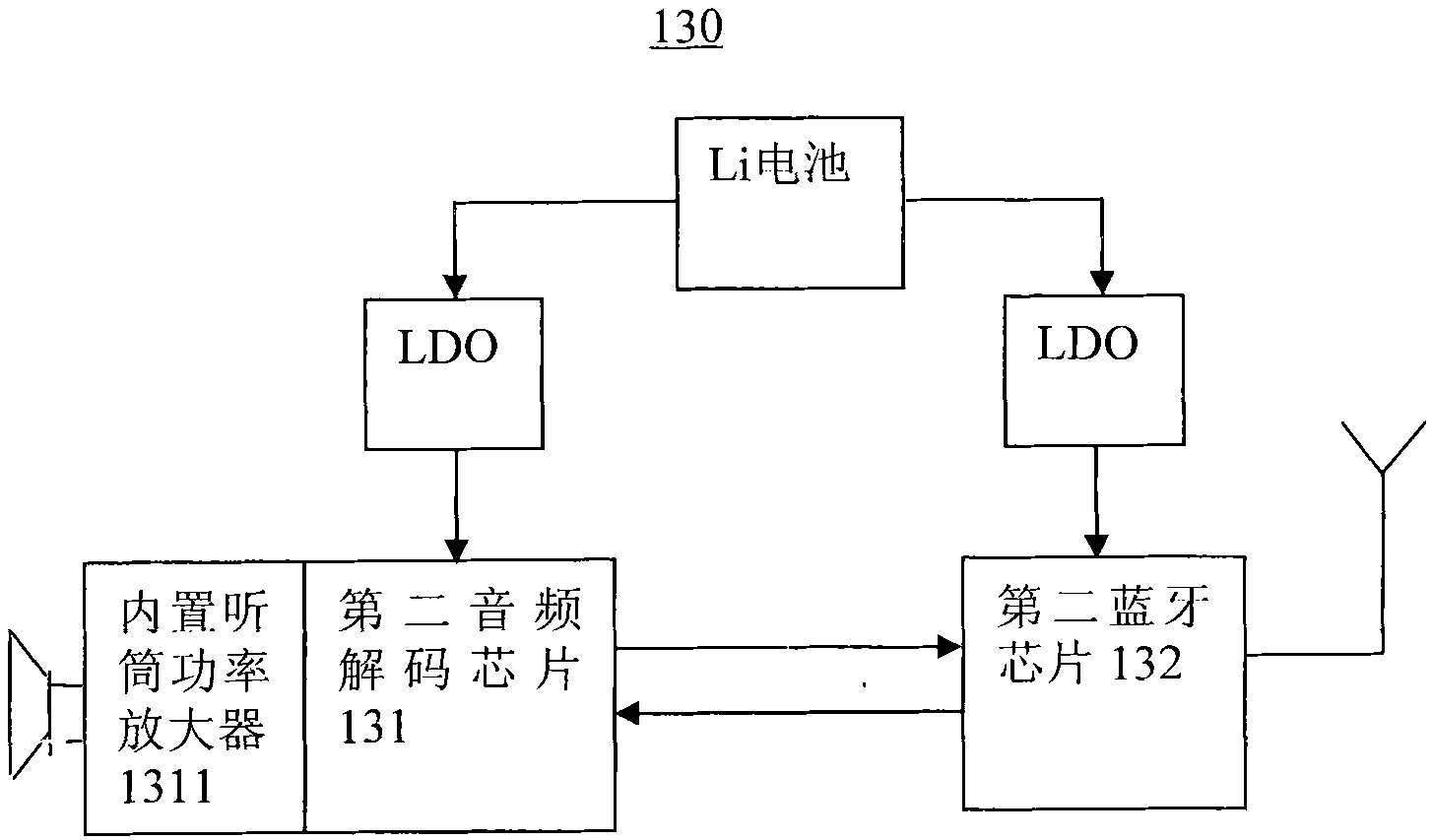

Ear ring type two way wireless mini-ear piece

A two-way communication earpiece, which is a small and comfortable. The ear-piece is comprised of a main body, a sound delivery probe, and a micro probe for sound pick up. The sound delivery probe, which is extended from main body, is configured to be inside of the external acoustic meatus of a user. The main body is attached to lobule of ear of the user like an ear ring. The sound delivery probe is coated with silicon for hygiene of the external acoustic meatus of the user. The micro probe for sound pick up is attached to a junction point of user's skin that locates behind the ear of the user, where rear surface of the antihelix, rear surface of the lobule, and neck skin of the user meets. At that point the microprobe picks up the voice of the user from the vibration of the skin.

Owner:RIE JIN

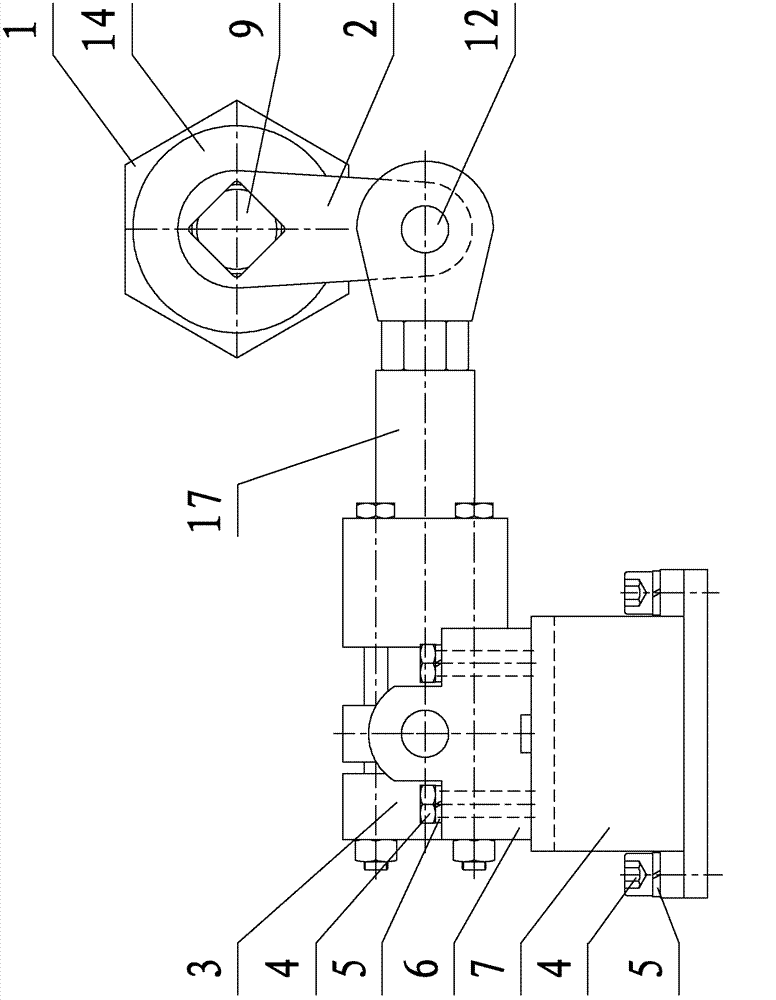

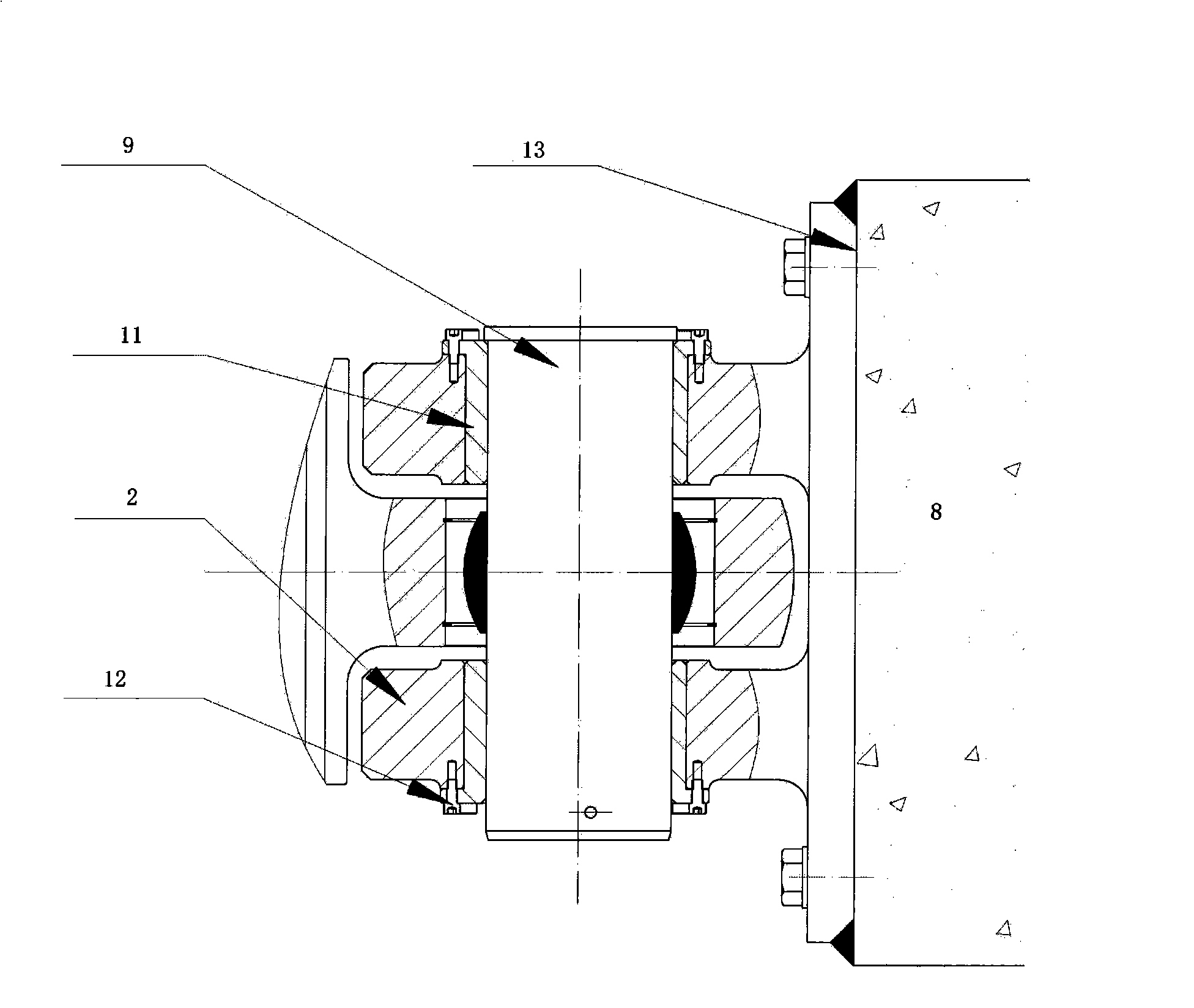

Viscous damping limiting method with limiting device and viscous damper

ActiveCN101942868AGood dynamic responseMeet the static limit requirementsShock proofingViscous dampingEngineering

The invention discloses a viscous damping limiting method with a limiting device; the limiting device is arranged between a left ear ring and a right ear ring at one side of a conventional viscous damper; the viscous damper is limited through the limiting device when the static load deformation thereof exceeds the design stroke; the limiting device is in an elastic rubber block structure; and the elastic rubber block structure is connected with a piston rod at one end of the viscous damper, and performs the limiting function through the compression of the elastic rubber block when the static load deformation of the viscous damper exceeds the design stroke. The invention has the effects of improving the dynamic response to the structure and generating the limit resistance to the excessive displacement of the structure. Compared with the prior art, the invention has simple structure, and saves cost and installation space.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

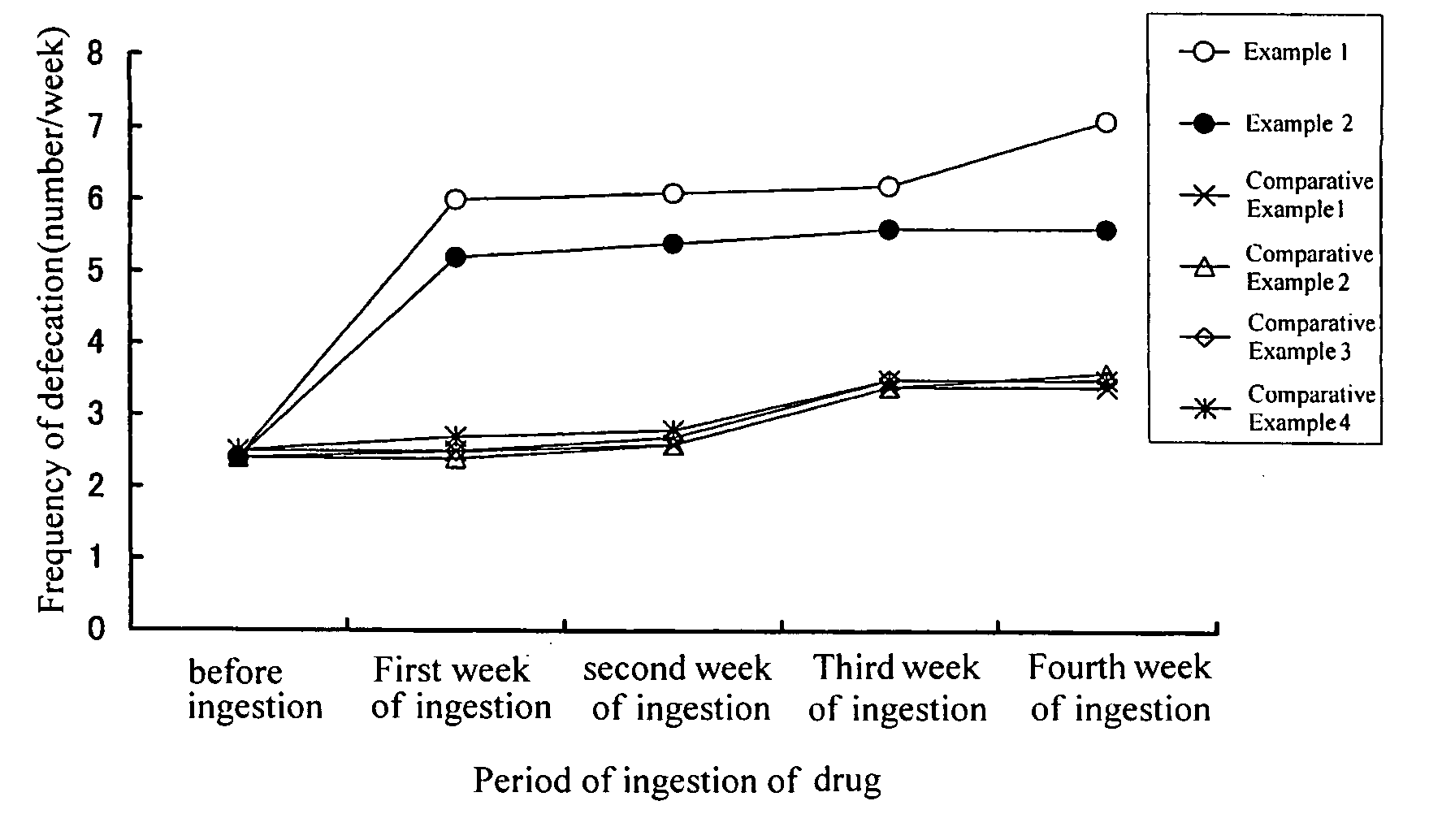

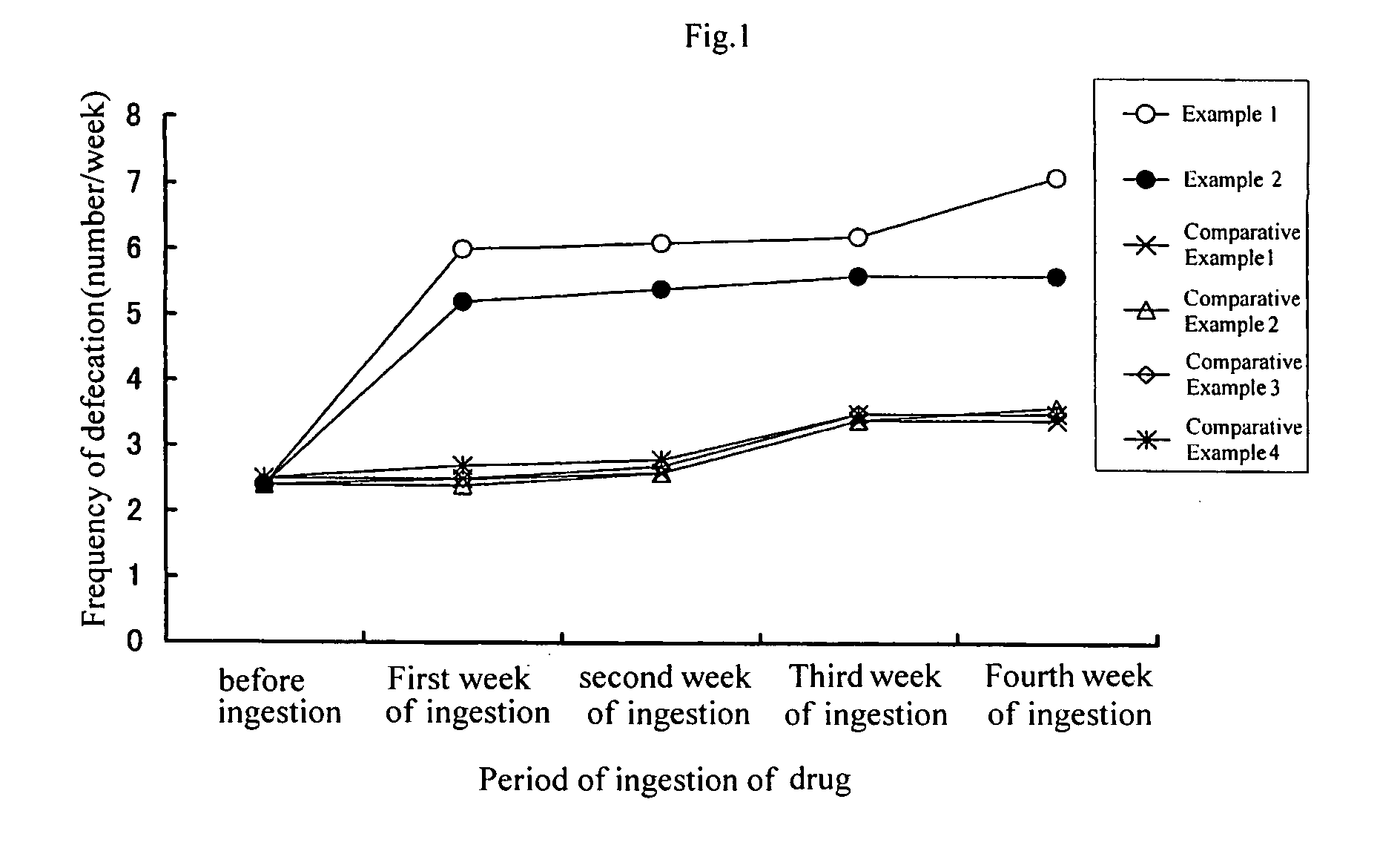

Composition containing ground lotus and/or lotus extract and lactic acid bacterium

InactiveUS20070059400A1Good synergyMore sensitivityBacteria material medical ingredientsTea extractionLactobacillusFood additive

The invention provides a composition, a drug, a food additive and a food, which comprises ground lotus and / or a lotus extract and a lactic acid bacterium. The composition, drug, food additive and food of the invention can be used to relieve and treat constipation, excessive sensitivity to cold, hemorrhoid, ear ringing, menopausal syndrome, hypertension and menstrual disorder.

Owner:TOYO R & D +1

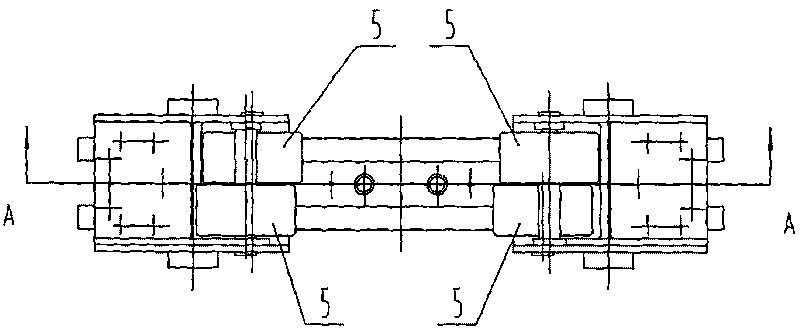

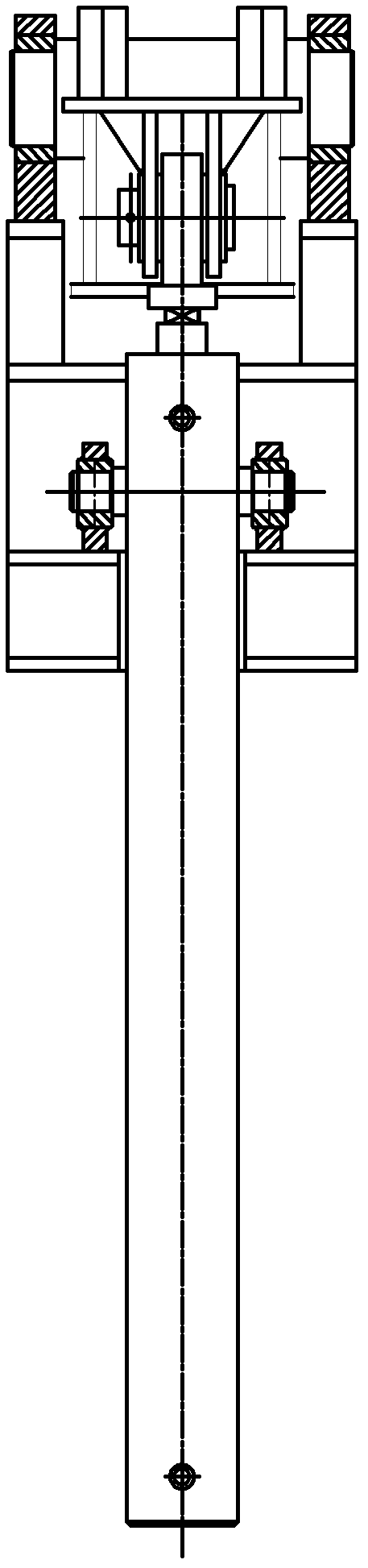

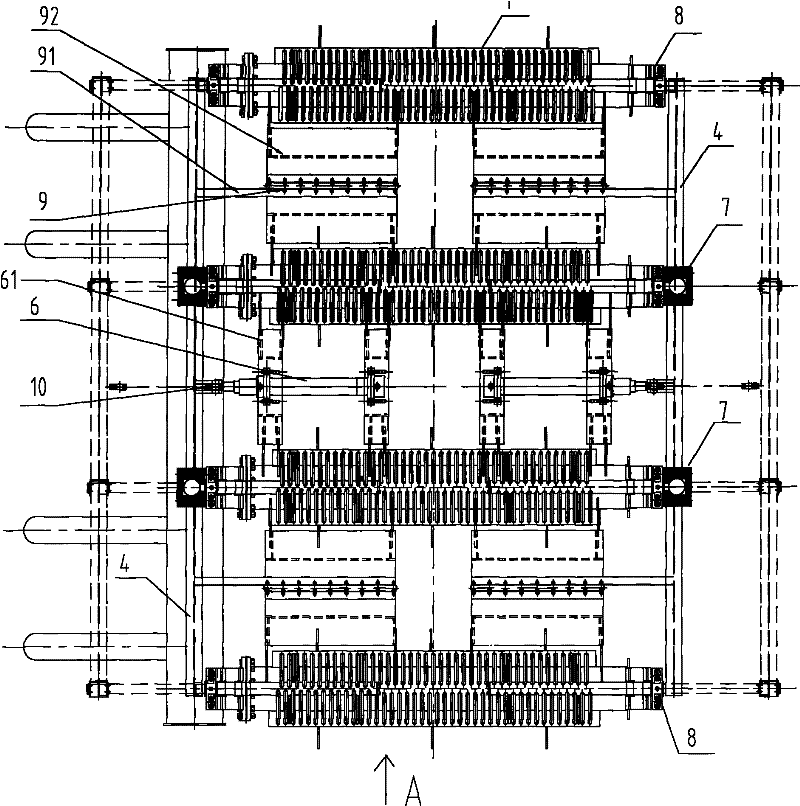

Mandrel-holding device for tube mills

InactiveCN101758074ALimit swingGuaranteed stabilityMandrelsMetal rolling arrangementsEngineeringScrew thread

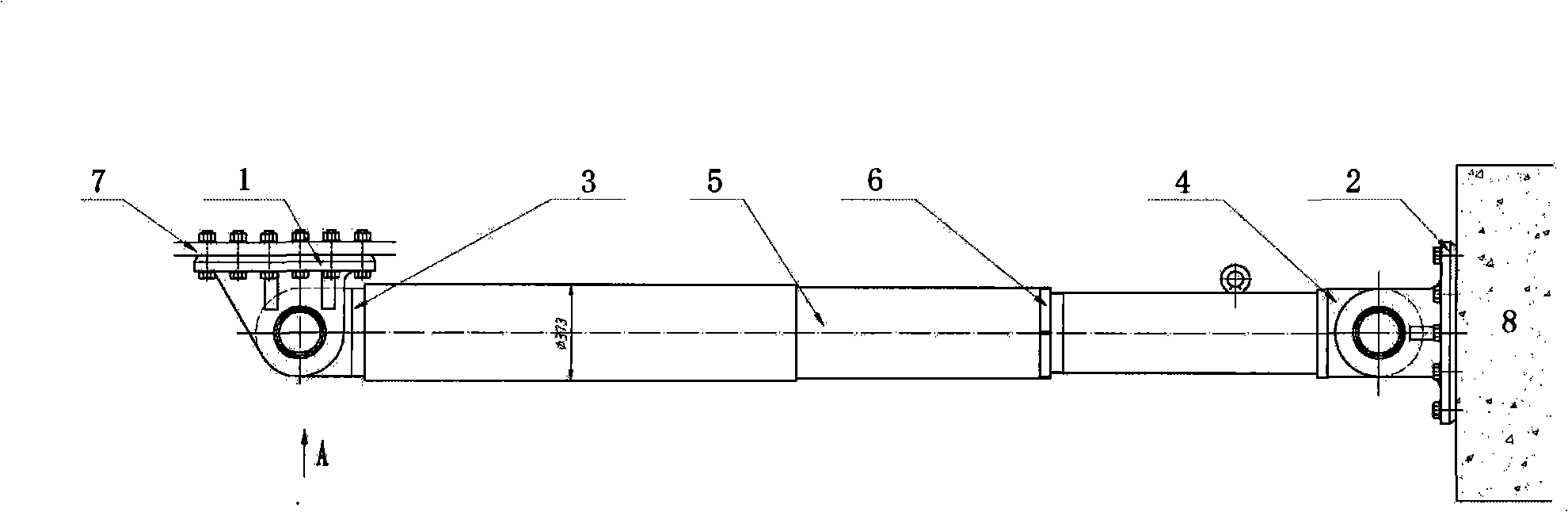

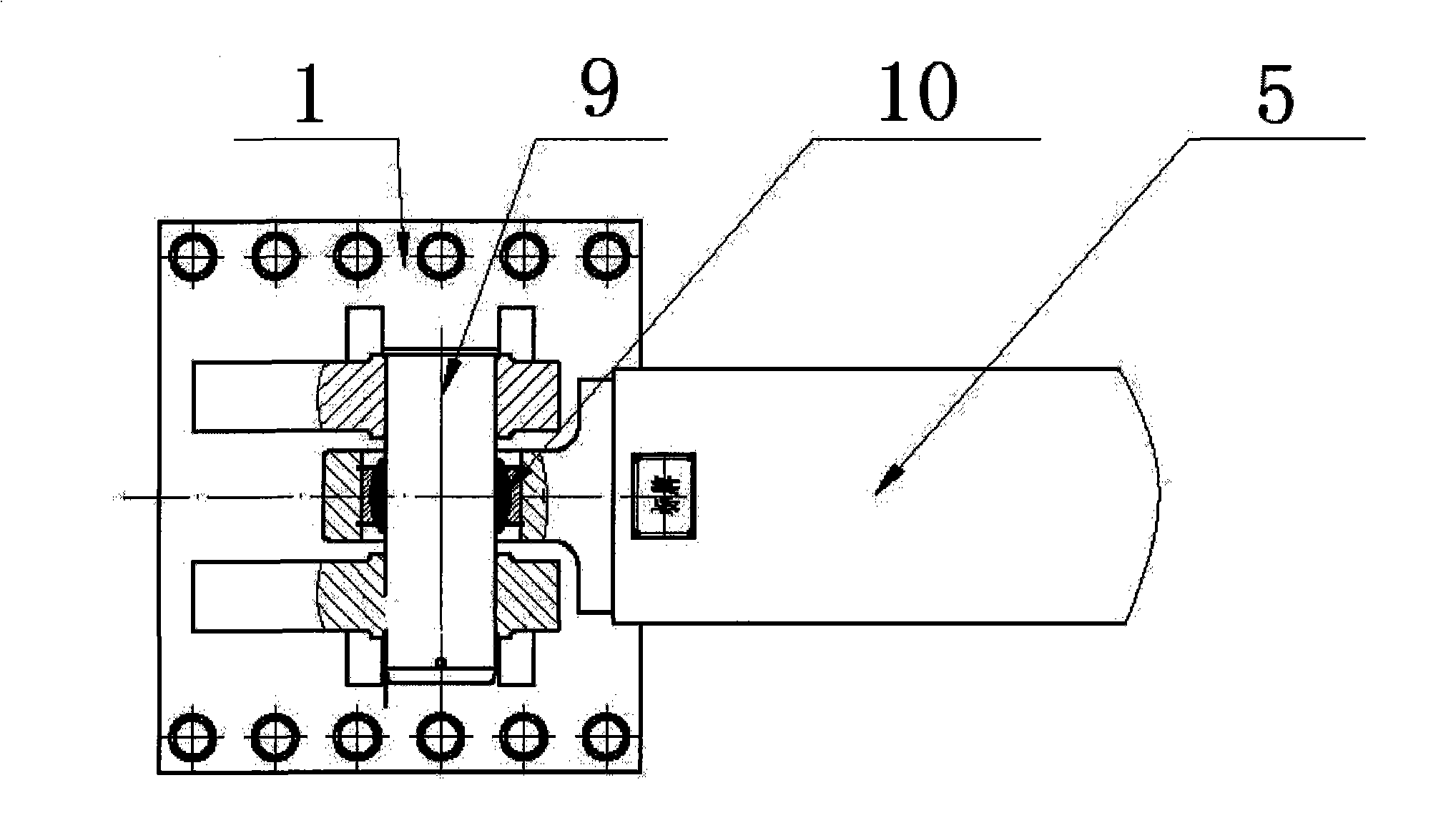

The invention discloses a mandrel-holding device for tube mills, which relates to a tube mill. The invention solves the problem that since the prior holding device cannot effectively limit the waggle of a mandrel, equipment can be damaged. A moving mechanism comprises a slide way, a left slide carriage and a right slide carriage, the slide way is mounted on a base, and is respectively connected with the bottom slide grooves of the left and the right slide carriages, the left slide carriage is connected with the bottom ear ring of a transversely arranged oil cylinder through a pin shaft, and the threaded piston rod of the oil cylinder is connected with the bottom of the right slide carriage through a nut; holding parts are four rollers, two of the holding parts are assembled on the left slide carriage, the other two holding parts are assembled on the right slide carriage, and the rollers are assembled on the carriage in a way that the rollers are transversely staggered from each other and that parts of the longitudinal excircles are superposed; a left rack is mounted on the left slide carriage, a right rack is mounted on the right slide carriage, and the left and the right racks are engaged with a gear fixed on the central line, so that a synchronous centering unit is formed.

Owner:TAIYUAN HEAVY IND

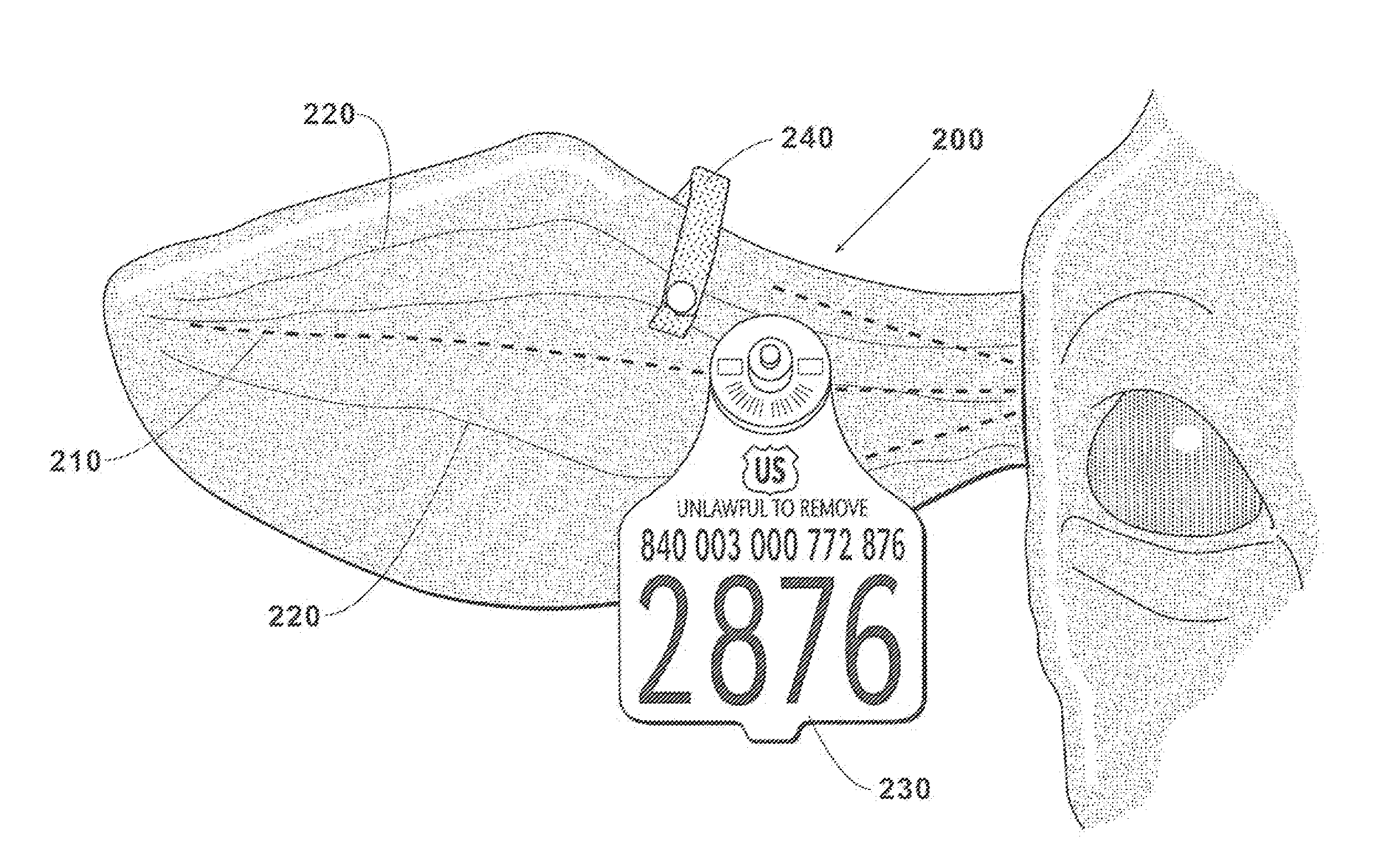

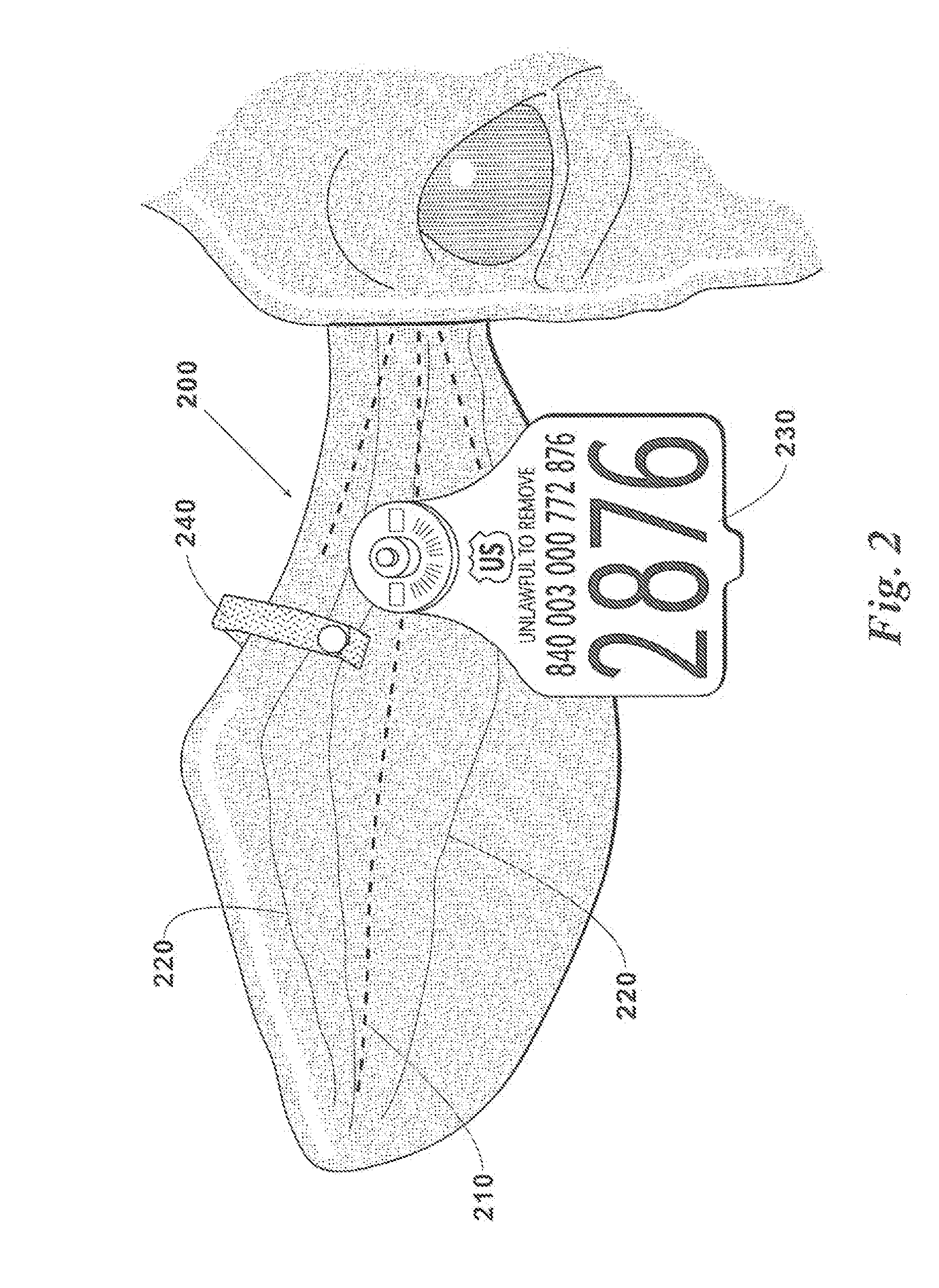

Fluttering ear tag for bovine vaccination

According to an aspect of the instant invention there is provided a method of medicating or vaccinating cattle via an ear tag, ear ring or other hardware affixed to or buried within the ear of the animal.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY

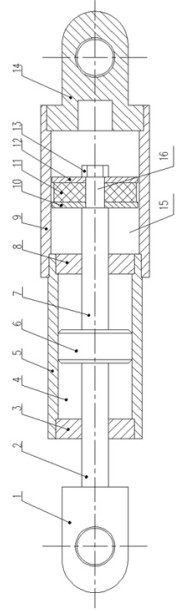

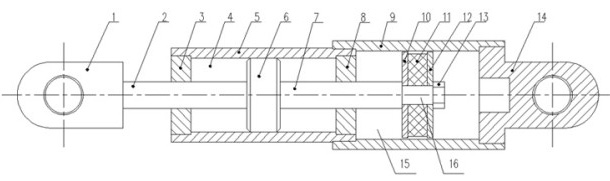

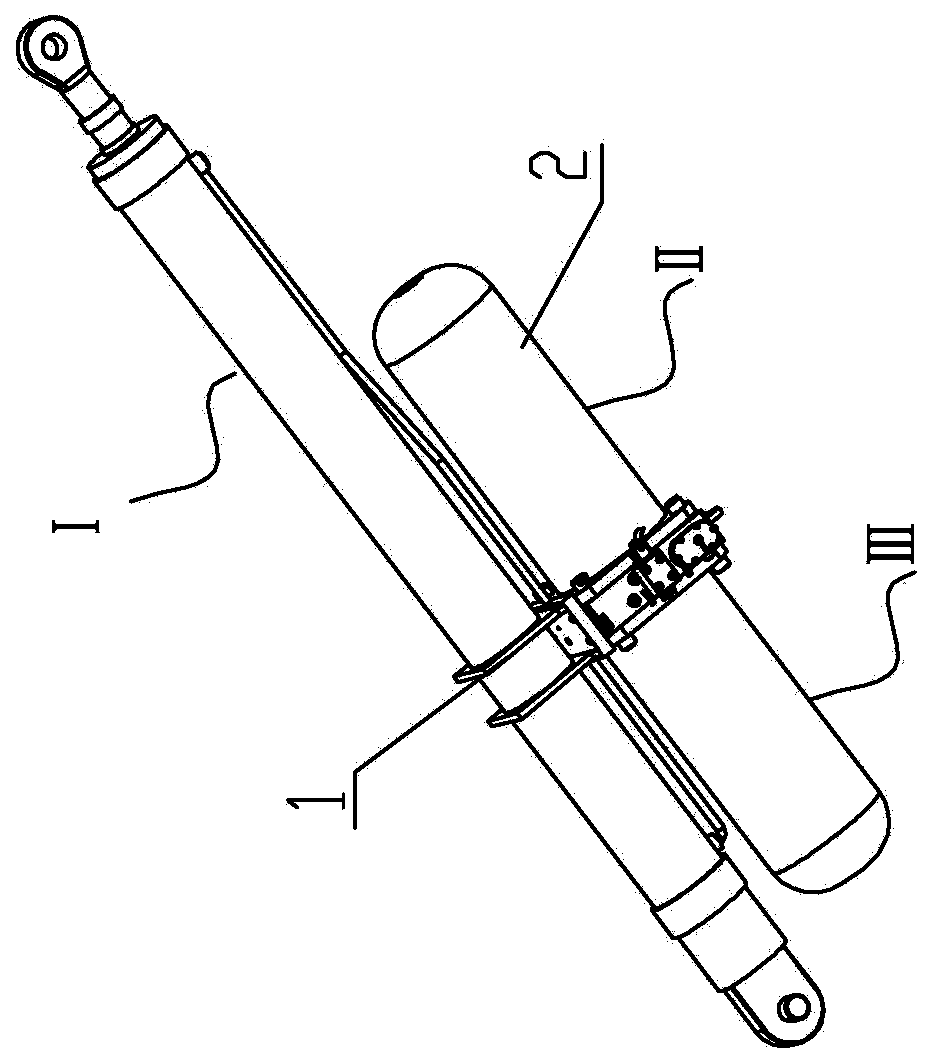

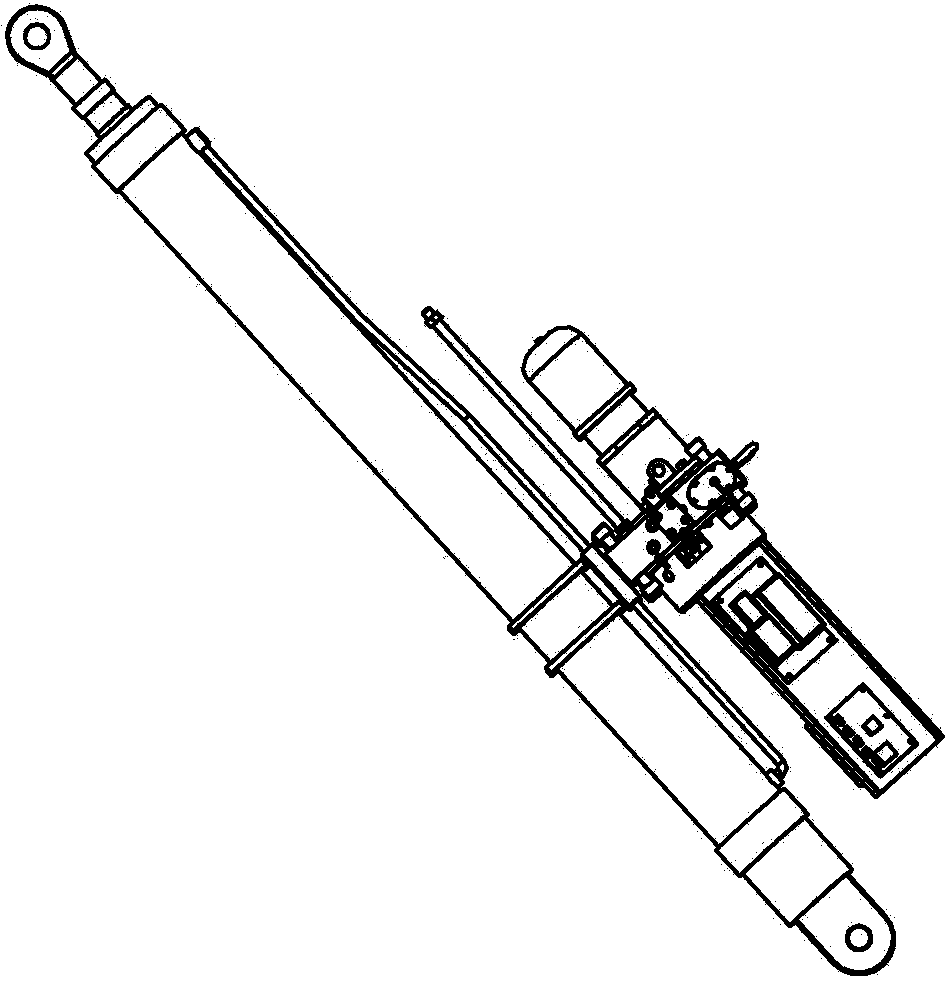

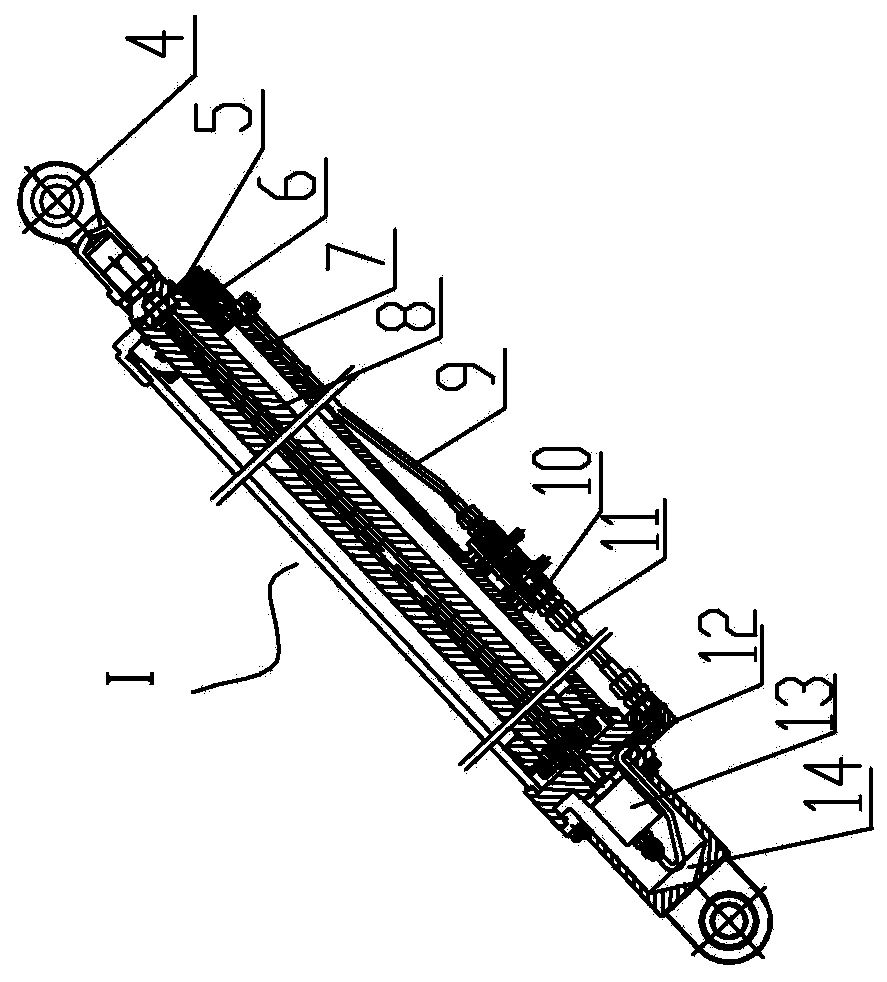

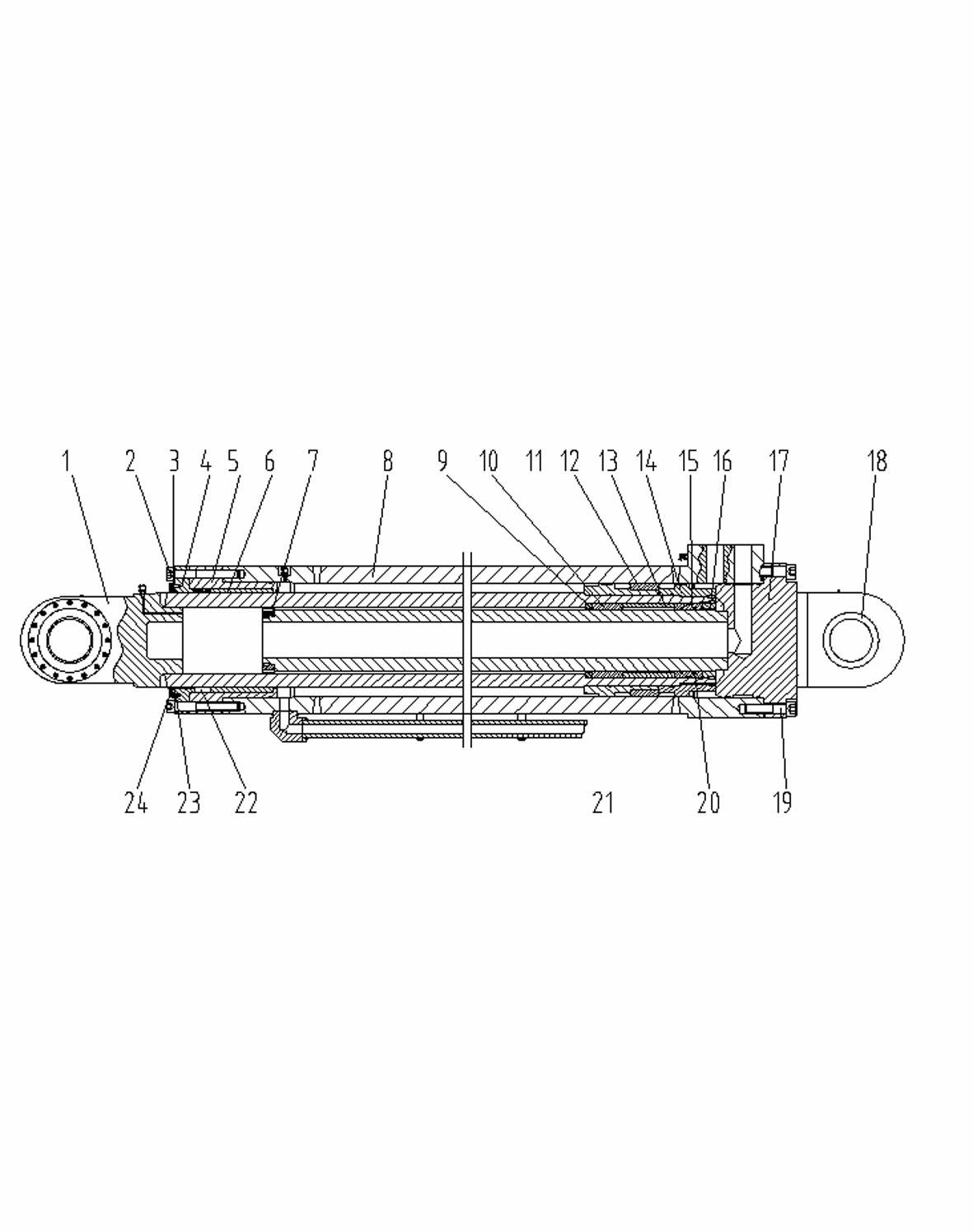

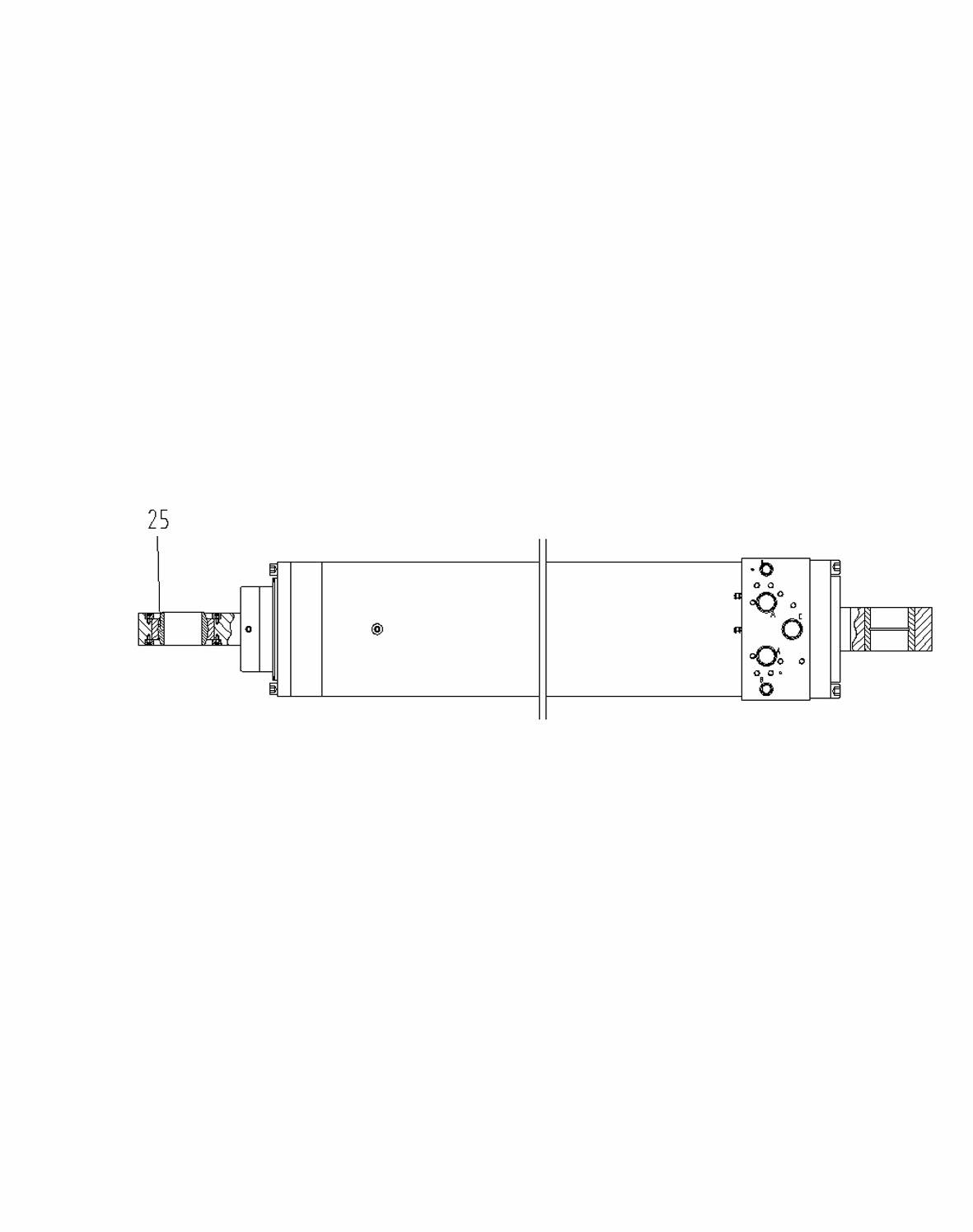

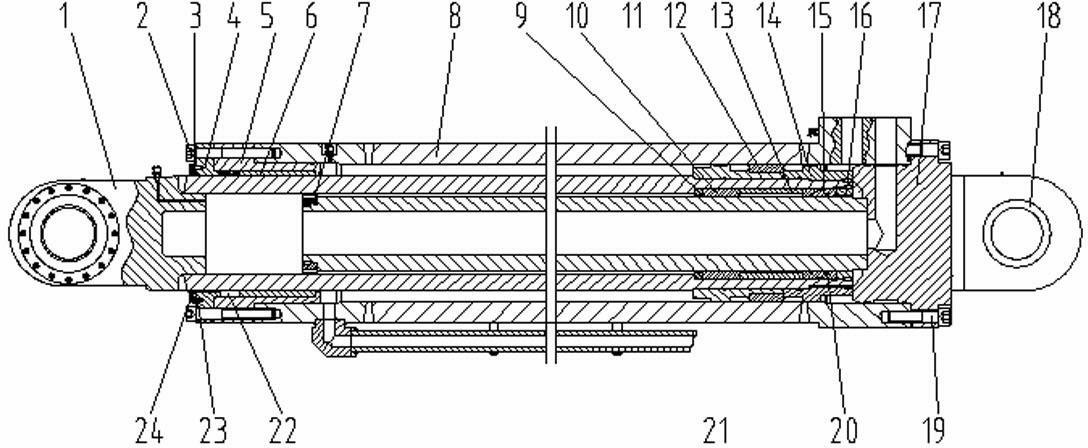

Hydraulic actuator and method for realizing positioning control and position feedback thereof

InactiveCN104235123ARealize scanningImplement trackingFluid-pressure actuator componentsLoop controlActuator

The invention discloses a hydraulic actuator. The hydraulic actuator comprises a hydraulic cylinder assembly, a hydraulic system and a local closed-loop control system, wherein the hydraulic cylinder assembly comprises a single-action oil cylinder, a displacement sensor, an upper ear ring and a lower ear ring; the upper ear ring is in threaded connection with a piston; the displacement sensor is arranged on a lower end cover; a measuring rod of the displacement sensor passes through the lower end cover, and extends into the piston; a magnetic ring of the displacement sensor is arranged on the end part of the piston; the piston drives the magnetic ring to move in a way of extending and retracting; the specific position of the magnetic ring is sensed through a waveguide tube in the measuring rod, so that the absolute position of the piston is detected; the hydraulic system comprises a motor, a pump, two leakage-free reversing valves and a pressure sensor, and is used for providing hydraulic power for a hydraulic cylinder and controlling the flow; the closed-loop control system comprises a main circuit module, a power supply module, a sensor module group and a microprocessor module. The hydraulic actuator has the advantages of high positioning accuracy and low cost, accurate source changing, scanning, tracking and position keeping of the oil cylinder can be realized, and continuous and stable control of the actuator during low-speed running can be ensured.

Owner:LIUZHOU OVM MASCH CO LTD

Differential-type plunger composite oil cylinder

InactiveCN102434530ACompact structureReduce processing difficultyFluid-pressure actuatorsCylinder headPiston Guide

The invention relates to a differential-type plunger composite oil cylinder, wherein an ear ring at the front end of a piston rod assembly is provided with a bearing, the rear end of the piston rod assembly is of a cylinder barrel structure which is integrally arranged in a cylinder body; the front end of the outer circle of the cylinder barrel is positioned by a rod guide sleeve arranged in a cylinder head; the front end and the rear end of a piston are arranged on the outer circle of the rear end of the piston rod assembly; the middle of the piston is provided with a piston guide sleeve and a rod seal; the rear end of the piston is fixed with the piston rod assembly through threads; a locking sleeve is fixed with the piston rod assembly through threads; a cylinder bottom assembly is fixed on the front end of the cylinder body through an internal hexagon screw; an ear ring at the rear end of the piston bottom assembly is provided with a bushing; the front end of the small cylinder outer circle at the front end is provided with a guiding ring; a gland and a cylinder head are fixed on the rear end of the cylinder body through internal hexagon screws; and the a gland of a dustproof ring is fixed on the gland through an internal hexagon screws, and a dustproof ring is arranged in an inner hole. Through simple structure improvement, multiple working conditions can be realized; and the differential-type plunger composite oil cylinder has the advantages of compact structure, low machining difficulty, convenience for installation and using reliability.

Owner:韶关液压件厂有限公司

180-degree steel plate turnover mechanism in hull planar section production line

InactiveCN102357764AReduce incidenceSimple structureWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderSheet steel

The invention relates to a 180-degree steel plate turnover mechanism in a hull planar section production line. The 180-degree steel plate turnover mechanism comprises a first hydraulic cylinder, a base, a first bolt, a first bearing block, a first pin shaft, a lifting arm, a pull-down arm, a second pin shaft, a second bolt, a second bearing block and a second hydraulic cylinder, wherein the hinged shaft of the first hydraulic cylinder is connected with the first bearing block, the first bearing block and the base are connected through the first bolt, an ear ring at a tip of the piston rod of the first hydraulic cylinder is connected with the lifting arm through the first pin shaft, an ear ring at a tip of the piston rod of the second hydraulic cylinder is connected with the pull-down arm through the first pin shaft, the lifting arm and the pull-down arm are simultaneously connected with the second bearing block through the second pin shaft, and the second bearing block is connected with the base through the second bolt. The 180-degree steel plate turnover mechanism in the invention has a simple, compact and reasonable structure, can turn over steel plates 180 degrees, and can improve the production efficiency and lower the occurring rate of safe accidents.

Owner:WUXI HUALIAN SCI & TECH GROUP

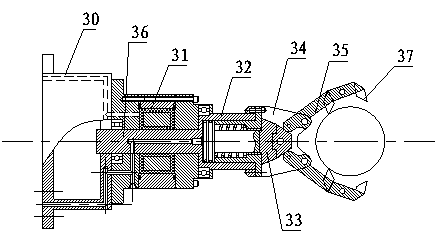

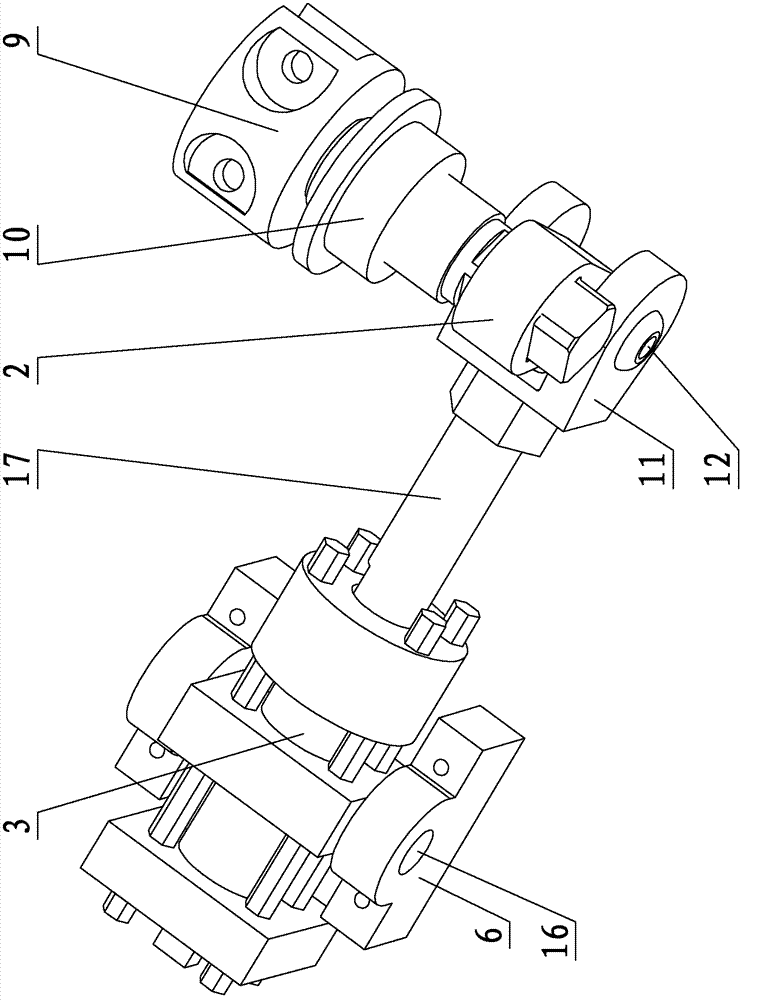

Rotary hydraulic mechanical hand body of hydraulic large-sized mechanical hand

InactiveCN103640017AMoment of activity is largeLow protection level requirementsProgramme-controlled manipulatorElectricityEar ringing

The invention discloses a rotary hydraulic mechanical hand body of a hydraulic large-sized mechanical hand. The rotary hydraulic mechanical hand body of the hydraulic large-sized mechanical hand comprises a connecting base, a rotary oil cylinder, a mechanical hand oil cylinder outer cavity, an ear-ring type mechanical hand oil cylinder piston rod, a mechanical finger base and mechanical fingers, the connecting base is fixed to the left end of a shell of the rotary oil cylinder through screws, a rotary shaft of the rotary oil cylinder and the mechanical hand oil cylinder outer cavity are integrated, the mechanical finger base is fixed to the right end of the mechanical hand oil cylinder outer cavity, the mechanical finger base is movably connected with the middle of the mechanical fingers, the left ends of the mechanical fingers are connected with the ear-ring type mechanical hand oil cylinder piston rod, and a plurality of skid-resistant burrs are arranged on the mechanical fingers. By means of the mode, the rotary hydraulic mechanical hand body of the hydraulic large-sized mechanical hand is under pure hydraulic drive, each movable joint is large in movable torque, the rotary hydraulic mechanical hand body can be used in severe industrial environment, the requirements for protecting levels are low, the working force of the rotary hydraulic mechanical hand body is much higher than that of electrically-driven mechanical hands of the same level, and the cost of the rotary hydraulic mechanical hand body is much lower than that of the electrically-driven mechanical hands of the same level.

Owner:WUZHONG DISTRICT MUDU KUAIBIN MOLD PROCESSING FACTORY

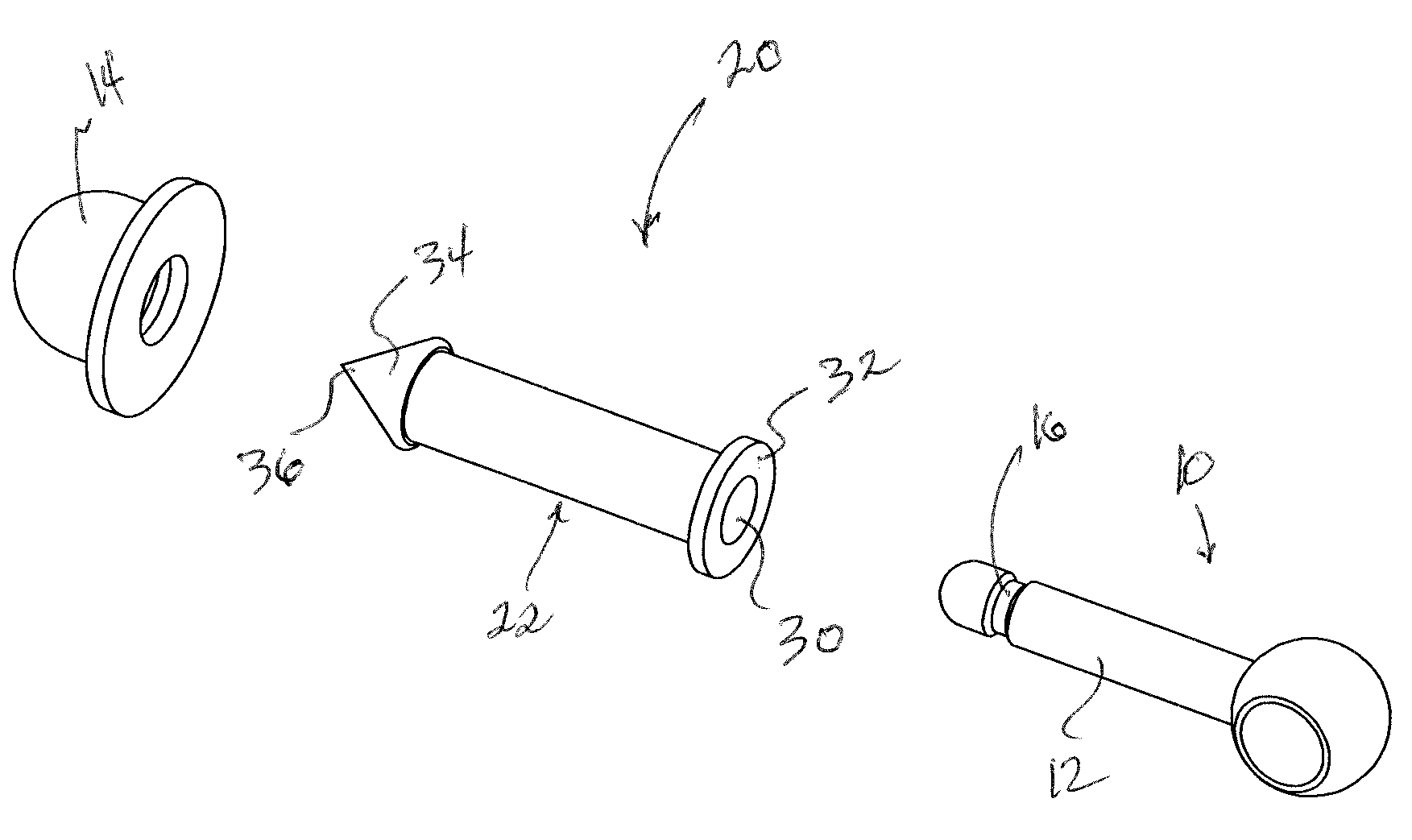

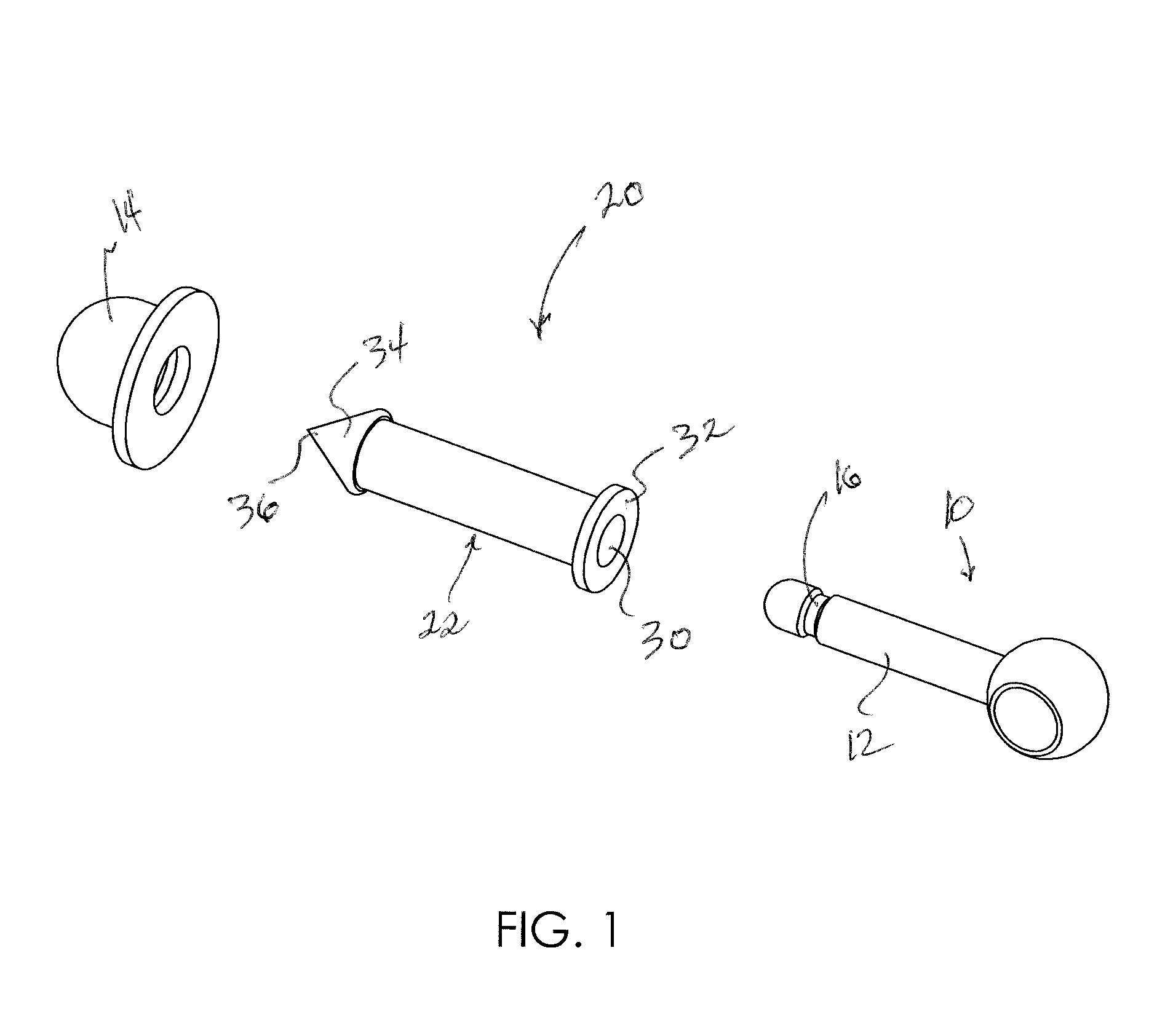

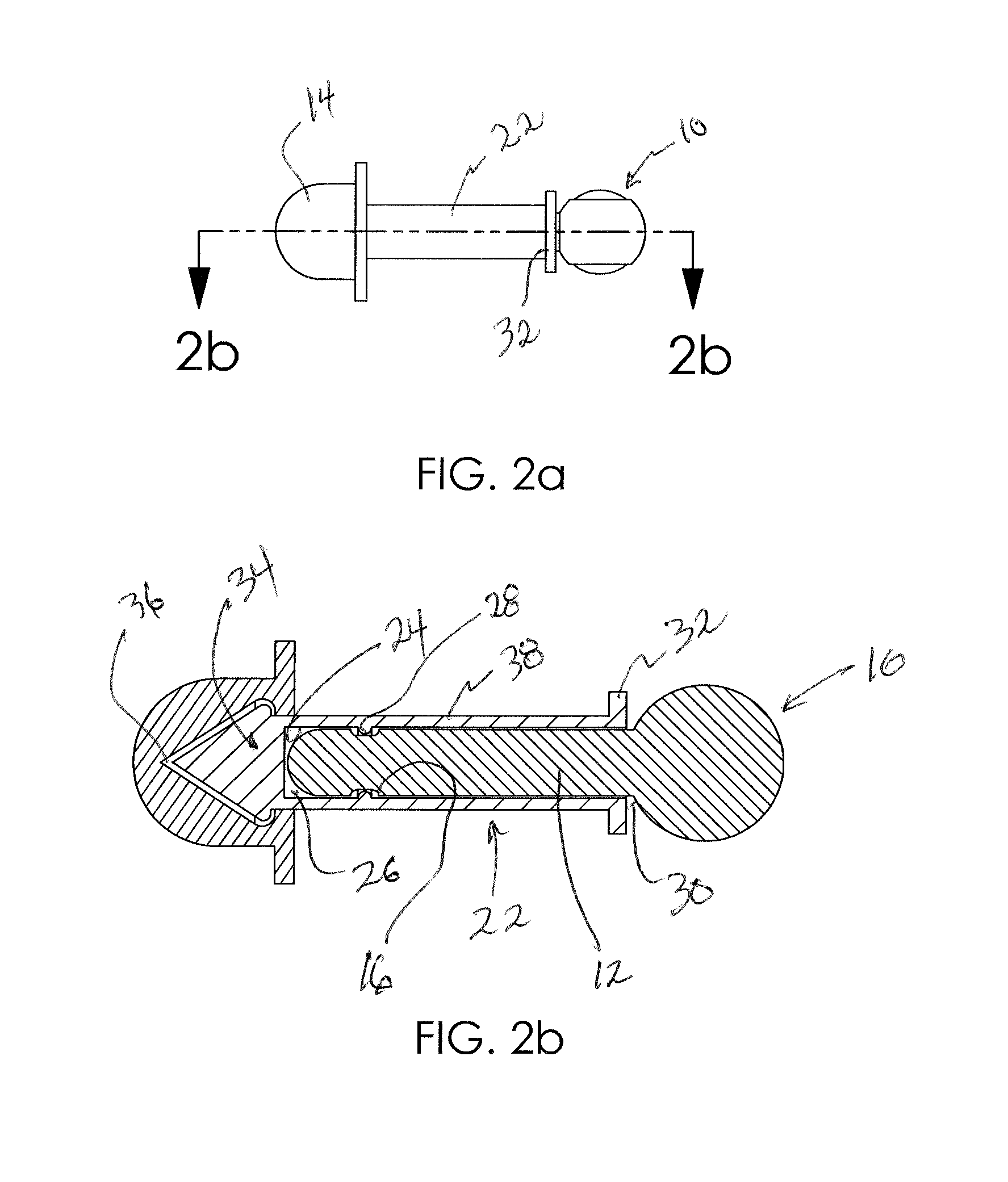

Ear Piercing Socket for Removable Starter Ear Rings

InactiveUS20130006289A1Easy to useReduce manufacturing costSurgical needlesEar-ringsEngineeringEar ringing

An ear piercing socket for use in piercing an ear includes a socket body having a generally tubular configuration sandwiched between an open body bottom and a closed body top. The socket body includes an interior surface defining an interior area, the open body bottom being in communication with said open body bottom. The interior area includes a configuration complementary to a configuration of an ear ring shaft so as to selectively and removably receive an ear ring shaft therein. The socket body top includes a pointed end extending away from the socket body, the socket body top being configured to puncture through a person's ear. The socket body top also includes a configuration to nest in the open end of an ear ring back. In some embodiments, the socket body may include an exterior surface having structures for releasing a medicament onto a person's ear.

Owner:HARPER SONYA

Mandrel-holding device for tube mills

InactiveCN101758074BLimit swingGuaranteed stabilityMandrelsMetal rolling arrangementsEngineeringMechanical engineering

The invention discloses a mandrel-holding device for tube mills, which relates to a tube mill. The invention solves the problem that since the prior holding device cannot effectively limit the waggle of a mandrel, equipment can be damaged. A moving mechanism comprises a slide way, a left slide carriage and a right slide carriage, the slide way is mounted on a base, and is respectively connected with the bottom slide grooves of the left and the right slide carriages, the left slide carriage is connected with the bottom ear ring of a transversely arranged oil cylinder through a pin shaft, and the threaded piston rod of the oil cylinder is connected with the bottom of the right slide carriage through a nut; holding parts are four rollers, two of the holding parts are assembled on the left slide carriage, the other two holding parts are assembled on the right slide carriage, and the rollers are assembled on the carriage in a way that the rollers are transversely staggered from each other and that parts of the longitudinal excircles are superposed; a left rack is mounted on the left slide carriage, a right rack is mounted on the right slide carriage, and the left and the right racks are engaged with a gear fixed on the central line, so that a synchronous centering unit is formed.

Owner:TAIYUAN HEAVY IND

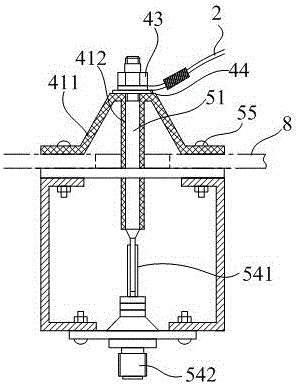

Feeder insulator and on-plane short-wave radio station wire antenna using same

ActiveCN106532225ACompact structureGood electromagnetic shieldingAntenna supports/mountingsAntenna adaptation in movable bodiesElectromagnetic interferenceElectromagnetic radiation

The invention provides a feeder insulator and an on-plane short-wave radio station wire antenna using same. The wire antenna comprises a first steel wire and a second steel wire. The top ends of the two steel wires are connected through screwing, and furthermore the two steel wires are mounted on a vertical tail of a plane through a connector. The connector comprises an insulator, a vibration damper and an ear ring. The lower end of the first steel wire is fixed on a skin at the front end of the plane through a through insulator. Furthermore the lower end of the second steel wire is connected with a short-wave radio station antenna RF feeder wire at the back end of the plane through the feeder insulator. The feeder insulator comprises a metal column core, an insulating cover, an insulating pad and a shielding housing. The feeder insulator provided by the invention can prevent electromagnetic radiation of a short-wave radio-station antenna signal in the plane body and prevents electromagnetic interference to operation of other electronic equipment in the plane. The double-steel-wire structure of the on-plane short-wave radio station wire antenna has advantages of sufficiently utilizing a limited short-wave antenna mounting space at top of the plane body, simplifying shape structure of the wire antenna, reducing number of outer projections of the antenna, and reducing aerodynamic resistance of the antenna in flight process of the plane.

Owner:中国人民解放军海军航空大学青岛校区

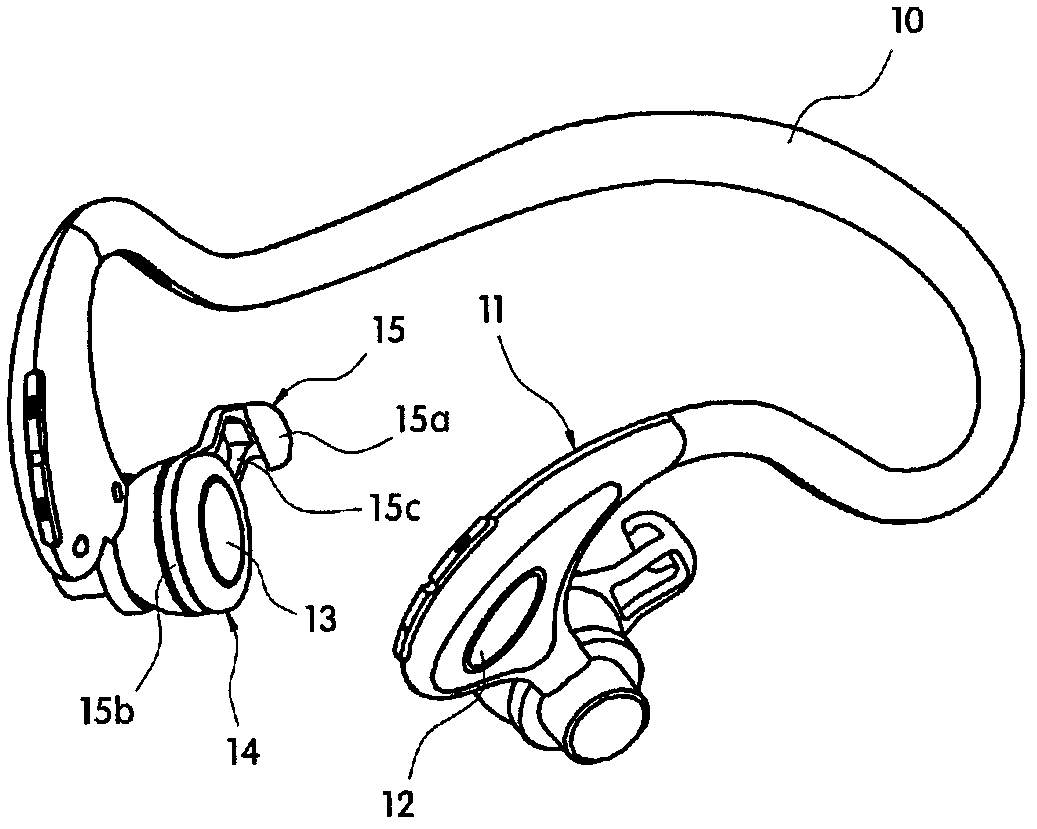

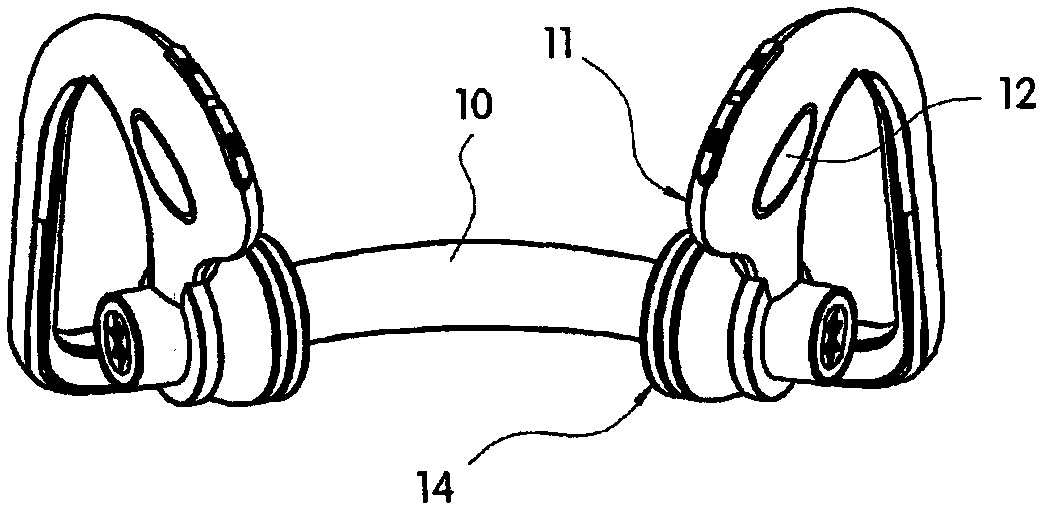

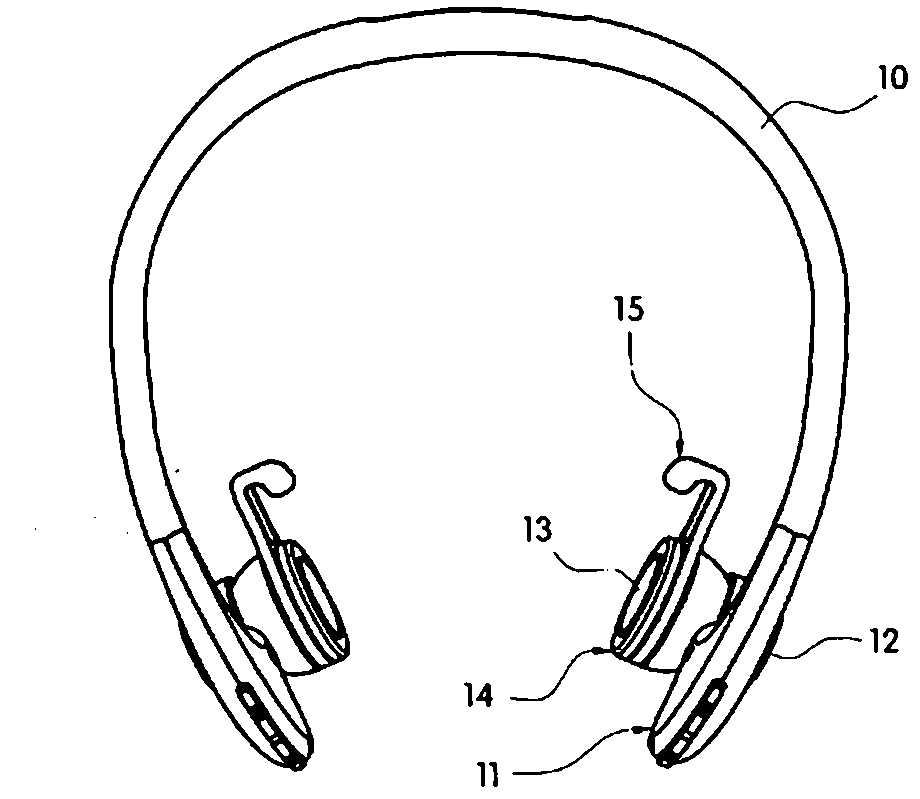

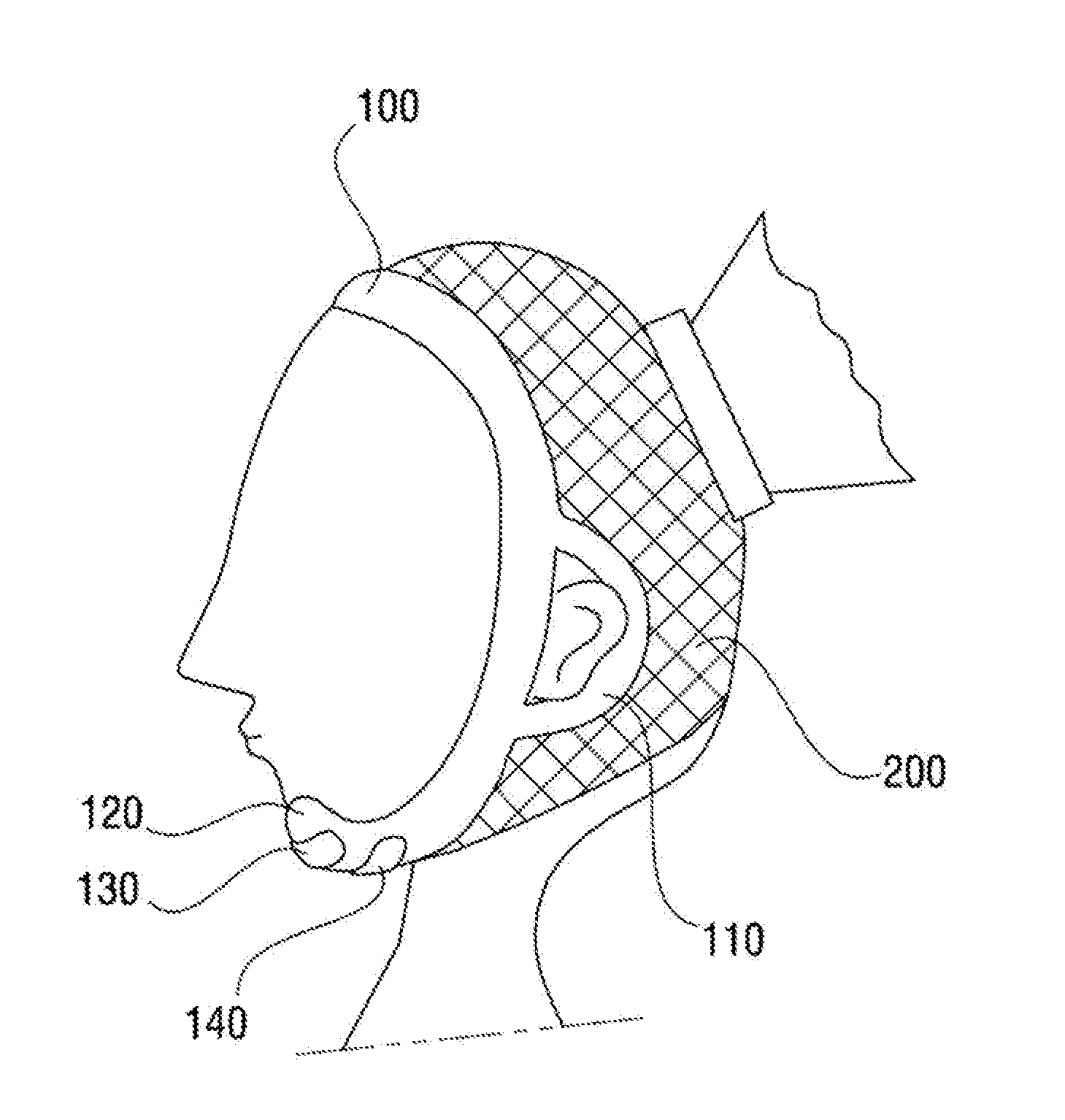

Bone conduction headphones

InactiveCN102428712AImprove hearingReduce inconvenienceMicrophonesHeadphones for stereophonic communicationMedicineWireless data

The present invention relates to Bluetooth bone conduction headphones capable of performing wireless data communication and having auxiliary vibration ear rings for reducing the loss of vibrations transmitted to the human skull as well as for reducing noise from an external source. The bone conduction headphones of the present invention consist of a novel type of headphones comprising main vibration housings which are brought into contact with the temples of a user, and auxiliary vibration ear rings directly inserted into the ears of the user, thereby inducing lost vibrations from the main vibration housings into the ears, and thus fully transmitting sound through bone conduction to improve the listening ability of the user.; The bone conduction headphones of the present invention closes the earholes by means of the auxiliary vibration ear rings connected to the main vibration housings, thereby effectively reducing noise from an external source, and thus further improving the listening ability of the user.

Owner:朴义峰

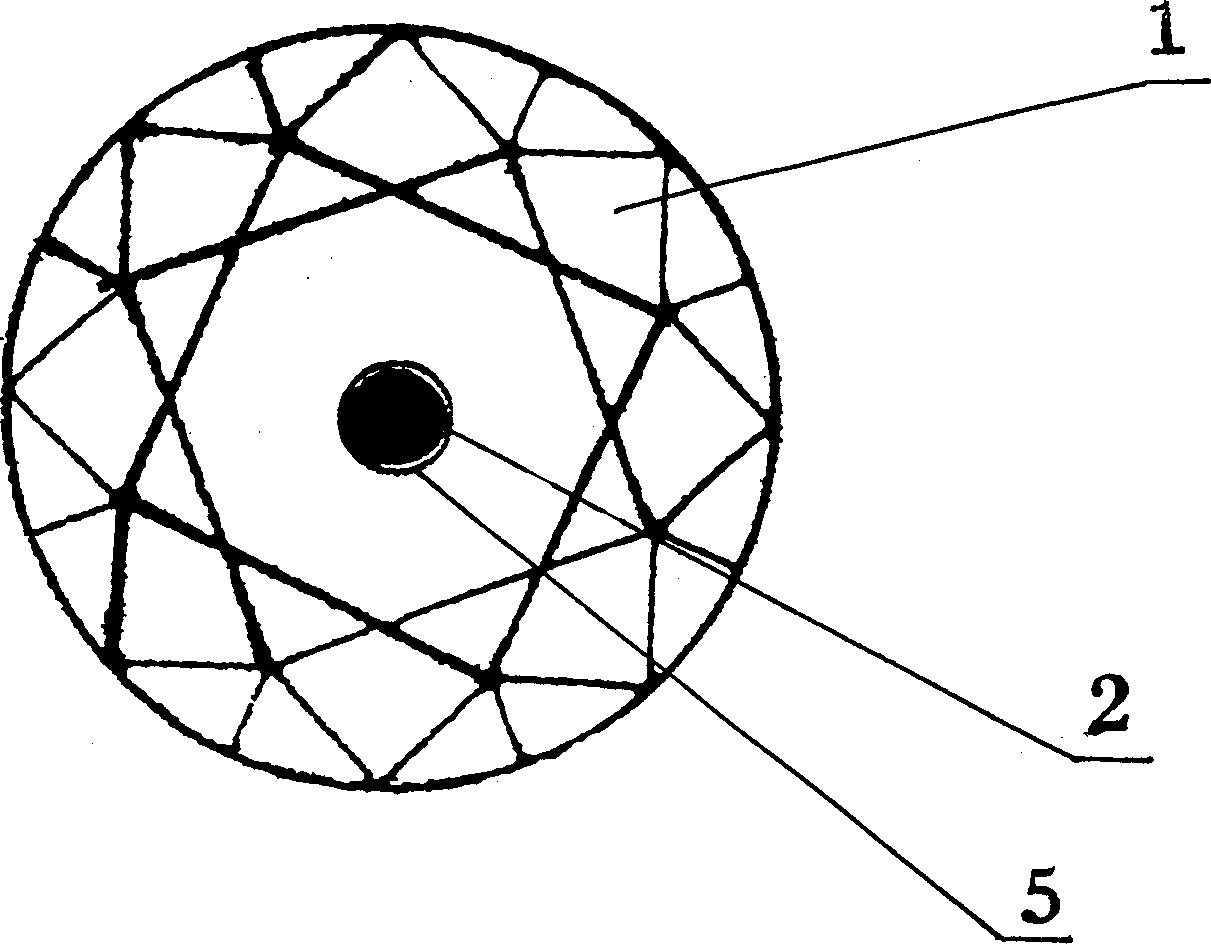

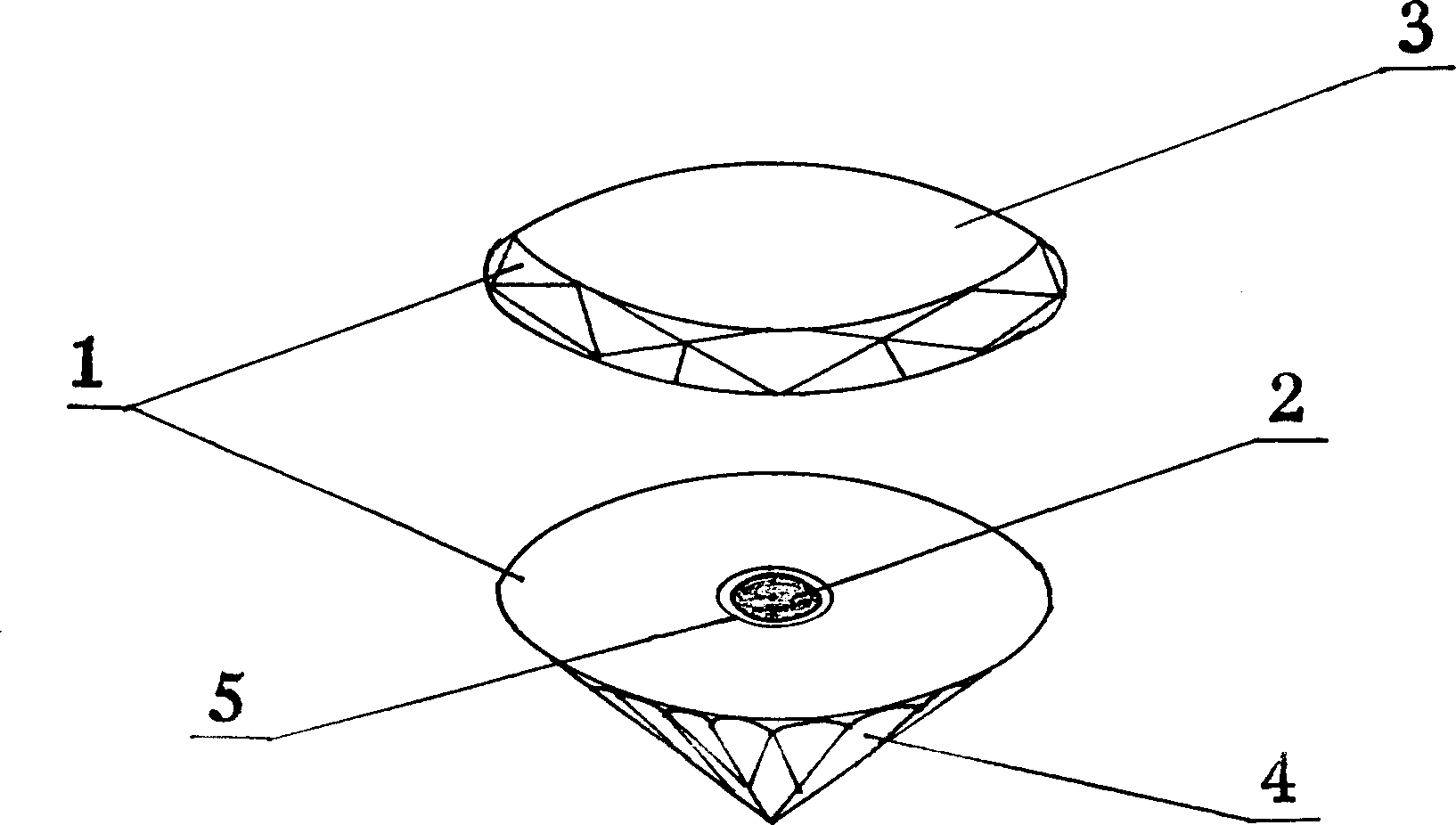

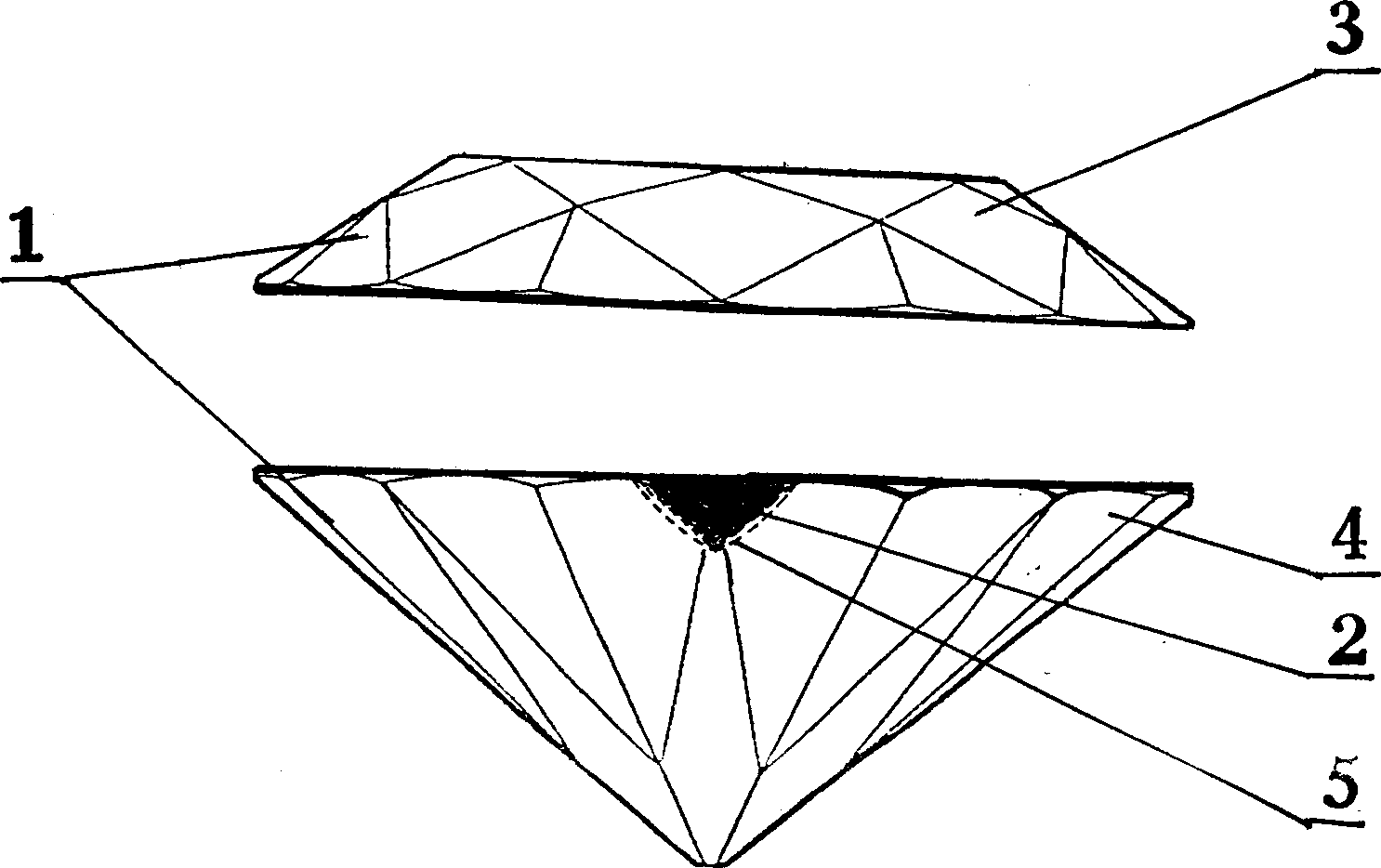

Gemstone and its processing process

The present invention provides a kind of gemstone with a small gemstone embedded inside a large one. During the processing, the large gemstone is cut by the waist into two, one upper and one lower, parts; one notch is dug for the small gemstone to be set; and the upper and the lower parts are then adhered together. The small gemstone rotates by vibration to refract color light and the great colordifference between the large gemstone and the small gemstone to make the combined gemstone bright, colorful, beantiful and royal. The gemstone may be produced into pendant, ear ring, chain, etc.

Owner:WU ZHOU CUISHI GEM & JEWELRY MFR

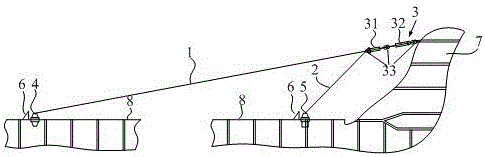

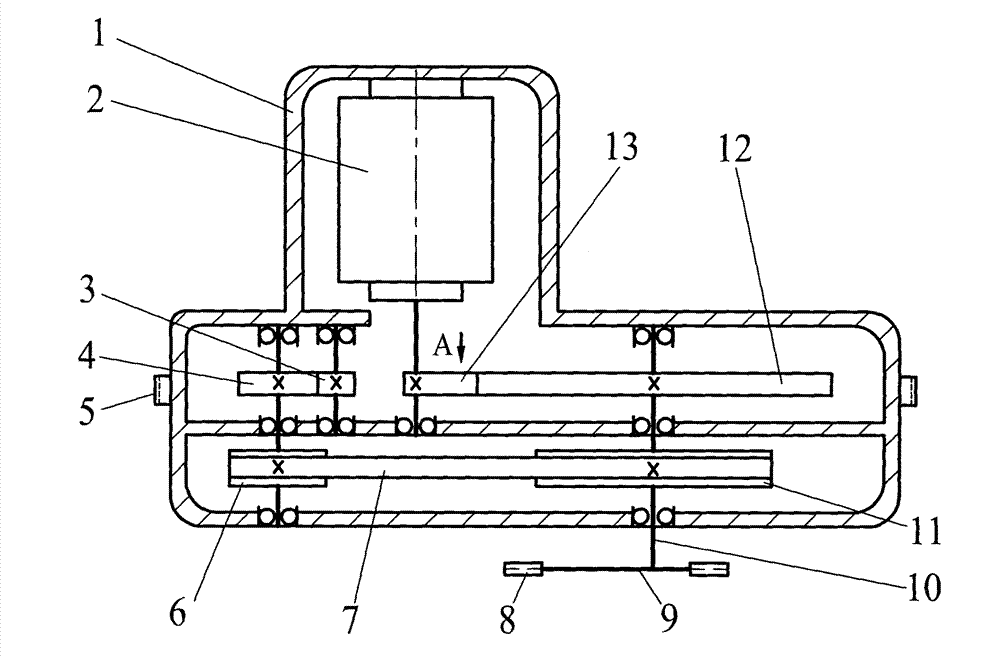

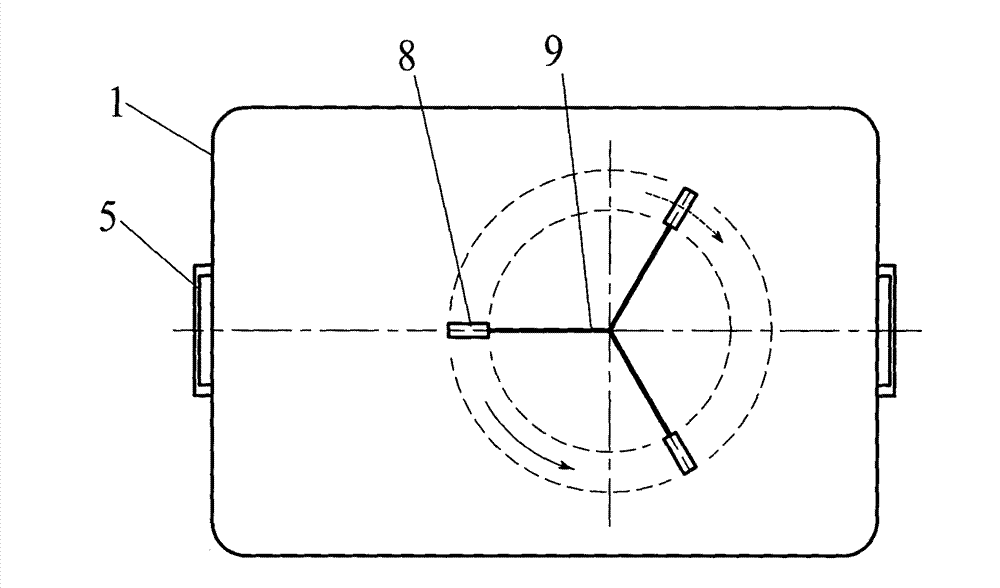

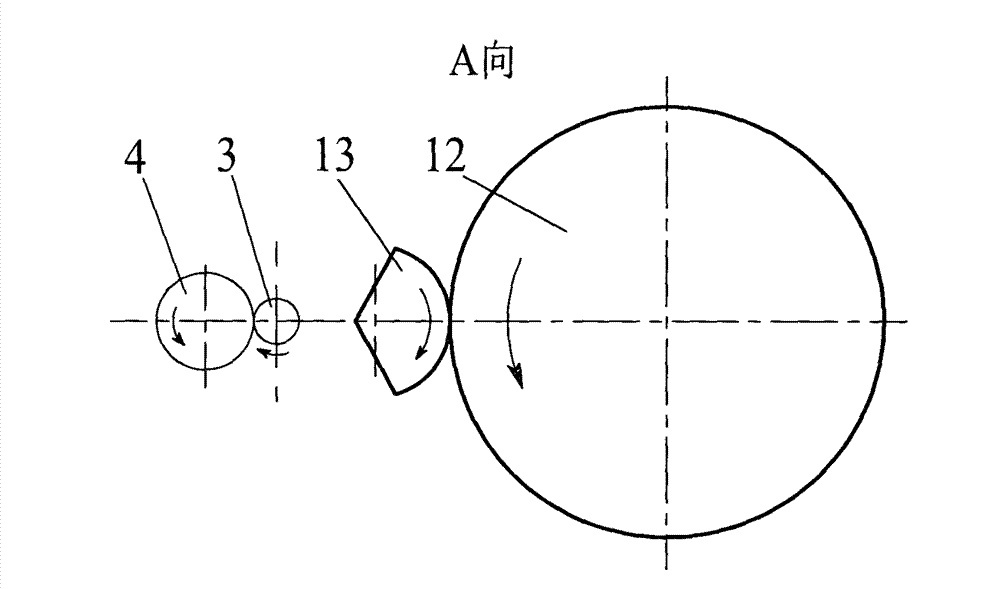

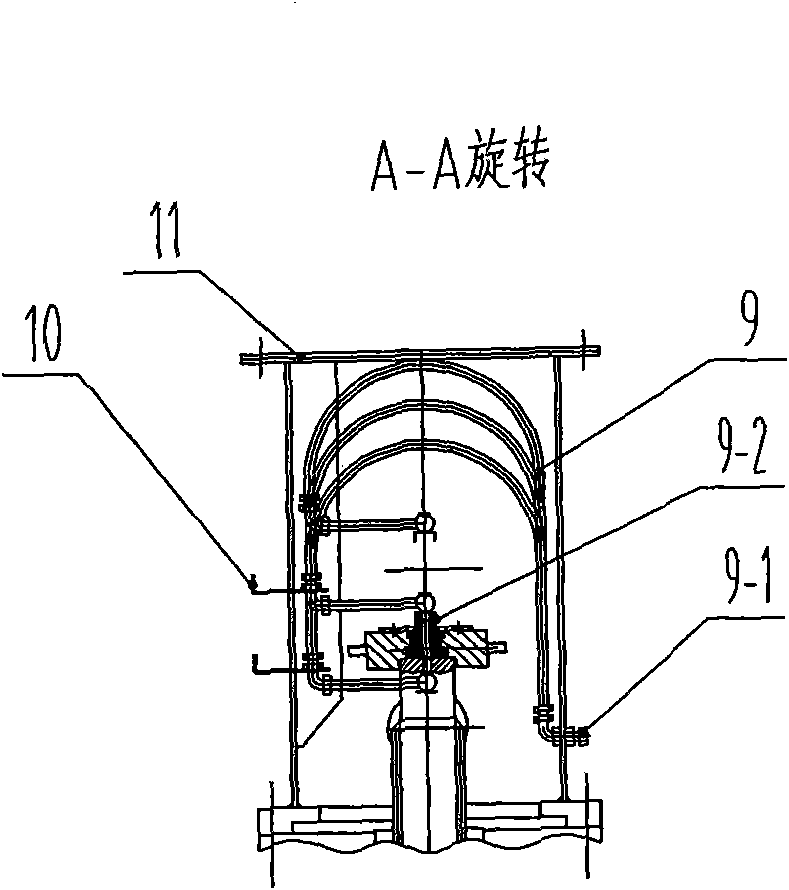

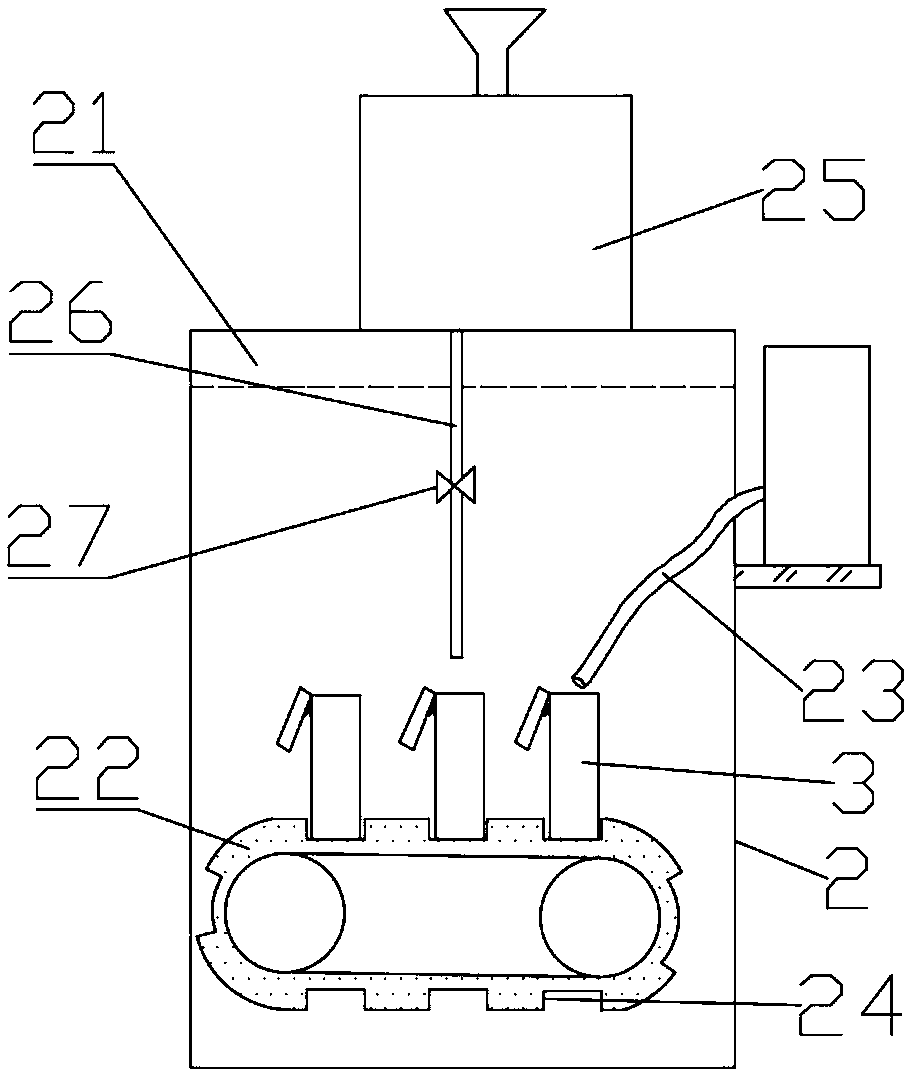

Belly massager capable of bidirectionally rotating

The invention relates to a belly massager capable of bidirectionally rotating, comprising a motor (2), a sector gear (13), a reversing gear (3), a transmission gear (4), ear rings (5), a large and a small belt wheels (6 and 11), a belt (7), a massaging roller (8), a supporting frame (9), a transmission shaft (10) and a main gear (12), wherein the sector gear (13) is fixed on an output shaft of the motor (2); the large belt wheel (11), the main gear (12) and the supporting frame (9) are mounted on the transmission shaft (10); the massaging roller (8) is sleeved at the end of the supporting frame (8) to rotate freely; and the motion range is corresponding to the human body belly area. By utilizing the massaging roller (8) to bidirectionally rotate on the human belly to simulate massage by the human hand clockwise and anticlockwise, the massager can strengthen belly muscle, promote gastrointestinal motility, help digestive absorption and reduce fat and lose weight; a user can use the massager when sitting or lying down, and can massage while having a rest; and the healthy persons and the patients with gastrointestinal diseases can both use the massager.

Owner:陈国全

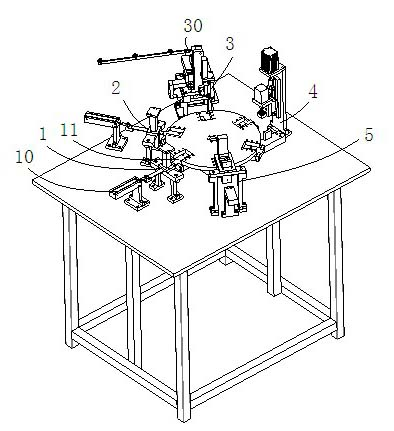

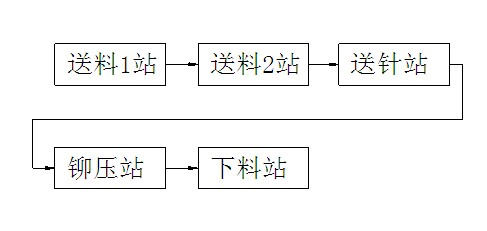

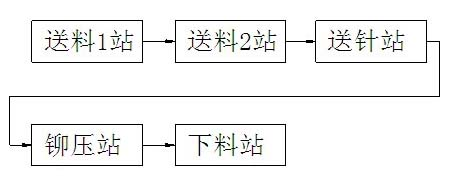

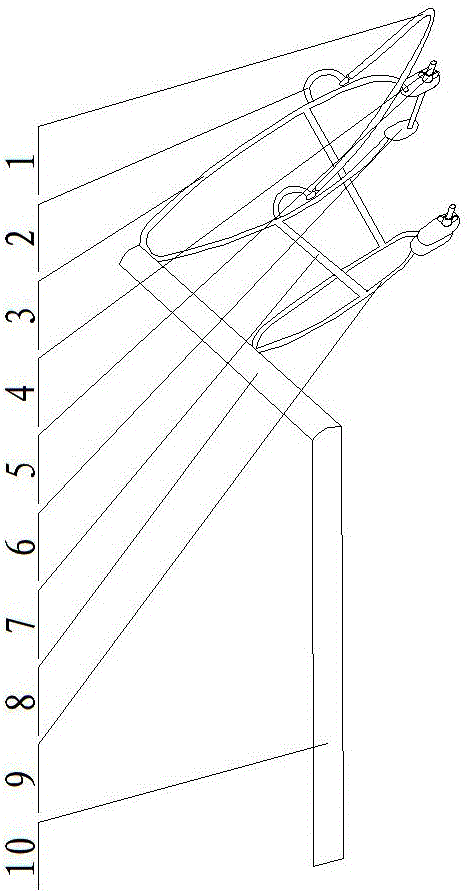

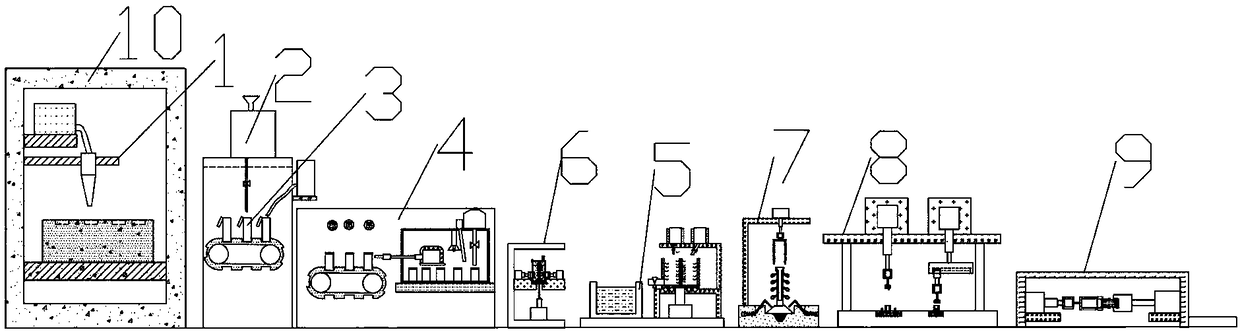

Production process for ear ring machine

The invention relates to a production process for an ear ring machine, which comprises the following steps: placing a fixed seat and a movable seat into a first vibration plate and a second vibration plate respectively to allow the fixed seat and the movable seat to enter a feeding tank under direct vibration, feeding into a fixture, passing a copper wire through a regulating wheel tensioning mechanism, passing the copper wire through a guide hole, cutting the copper wire off with a spring cutter, allowing the copper wire to enter a needle shift position under dead weight, delivering the copper wire to the position of a pressure needle, pressing the pressure needle into the joining hole of the fixed seat and the movable seat, rotating a rotating disc to a next procedure, tightly pressing the needle by upper and lower cylinders with the drive of the upper and lower cylinders, allowing the upper and lower cylinders to push a motor and a riveting and pressing head to rotate forward and backward to rivet and press the copper to prevent the fixed seat and the movable seat from separating, and thus, realizing a moving function; allowing a rotating disc to enter a feeding station, and ejecting a finished product by an ejecting head into the feeding tank to complete feeding. As mechanical operation is used in place of manual operation, the assembly speed is high, the production efficiency is high and the yield of finished products is improved relatively. The production process can realize industrial production and automatic production.

Owner:金湖县综合检验检测中心

Ox-head fixator and use method thereof

InactiveCN106175970AEasy to administerConvenient gastric lavageAnimal fetteringSplit ringCanine tooth

The invention provides an ox-head fixator and a use method of the ox-head fixator. In the prior art, when oral examination or drenching operation is carried out on domestic animals, especially, the animals including sheep, dogs and oxen or the animals with developed canine teeth, the animals have great strength, and thus the oral cavities of the animals can not be manually opened. The ox-head fixator comprises a short handle, a head ring and a mouth ring, wherein the head ring (3) is an oval split ring, adjustment sheets (6) are respectively welded to two sides of the opening part, holes for an adjusting bolt (4) to pass through are formed in the adjustment sheets, the adjusting bolt is fastened by adopting an adjusting nut (5), the opposite side of the opening part is welded to the head part of the short handle (8), ear rings (2) are respectively welded to the middle parts of the two sides of the opening part and the welded part, reinforcing beams (7) are respectively welded to the opposite sides of the ear rings, and the reinforcing beams are respectively connected to the mouth ring (9) having the shape being consistent with that of the head ring but having the smaller size. The invention relates to the field of livestock medical treatment, and in particular relates to the ox-head fixator and the use method of the ox-head fixator.

Owner:HEILONGJIANG PROVINCE ECONOMIC MANAGEMENT CADRE COLLEGE

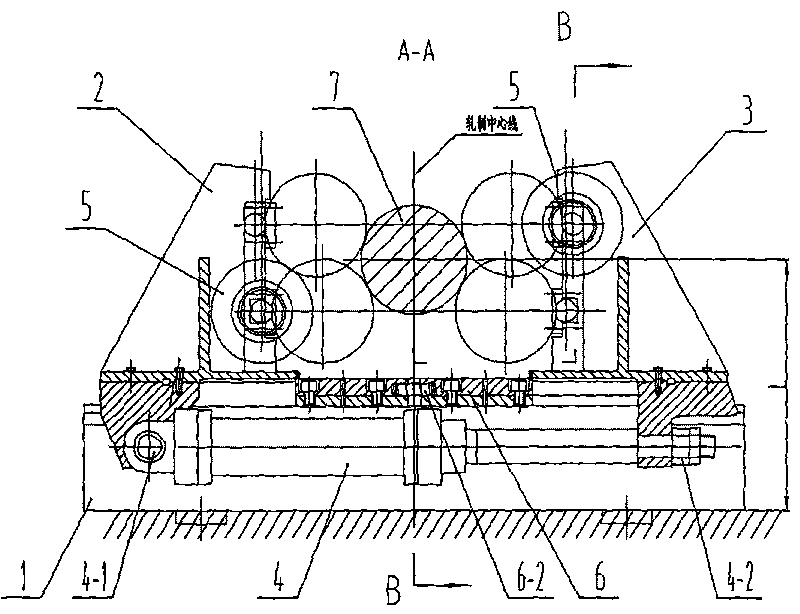

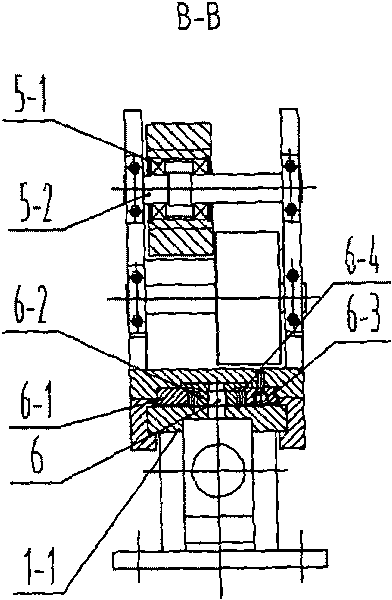

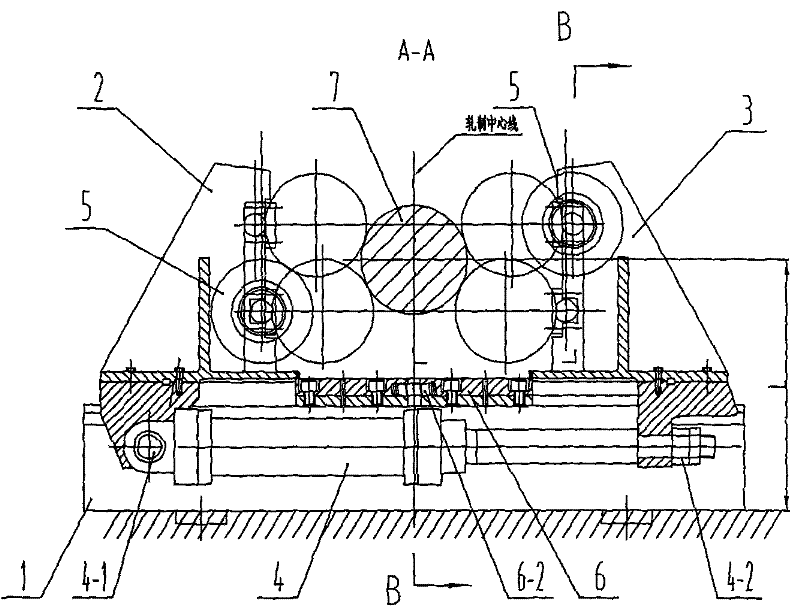

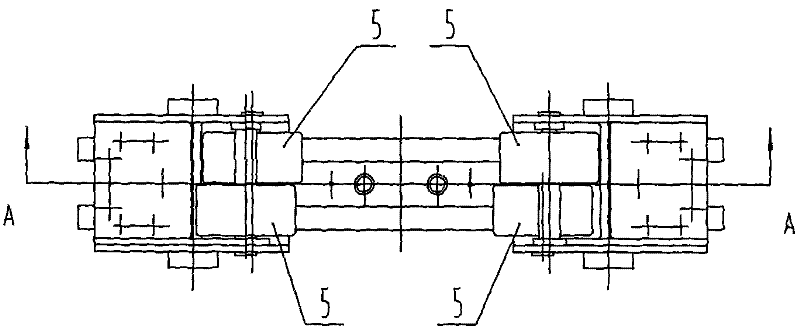

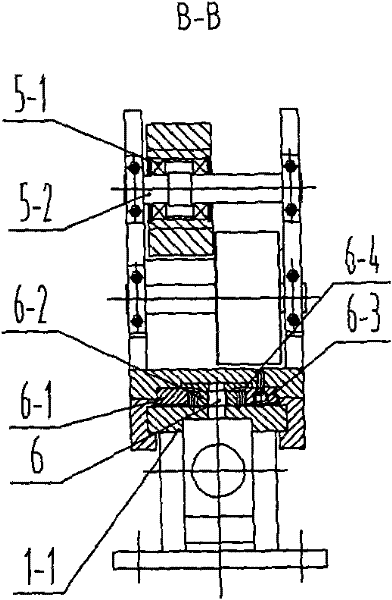

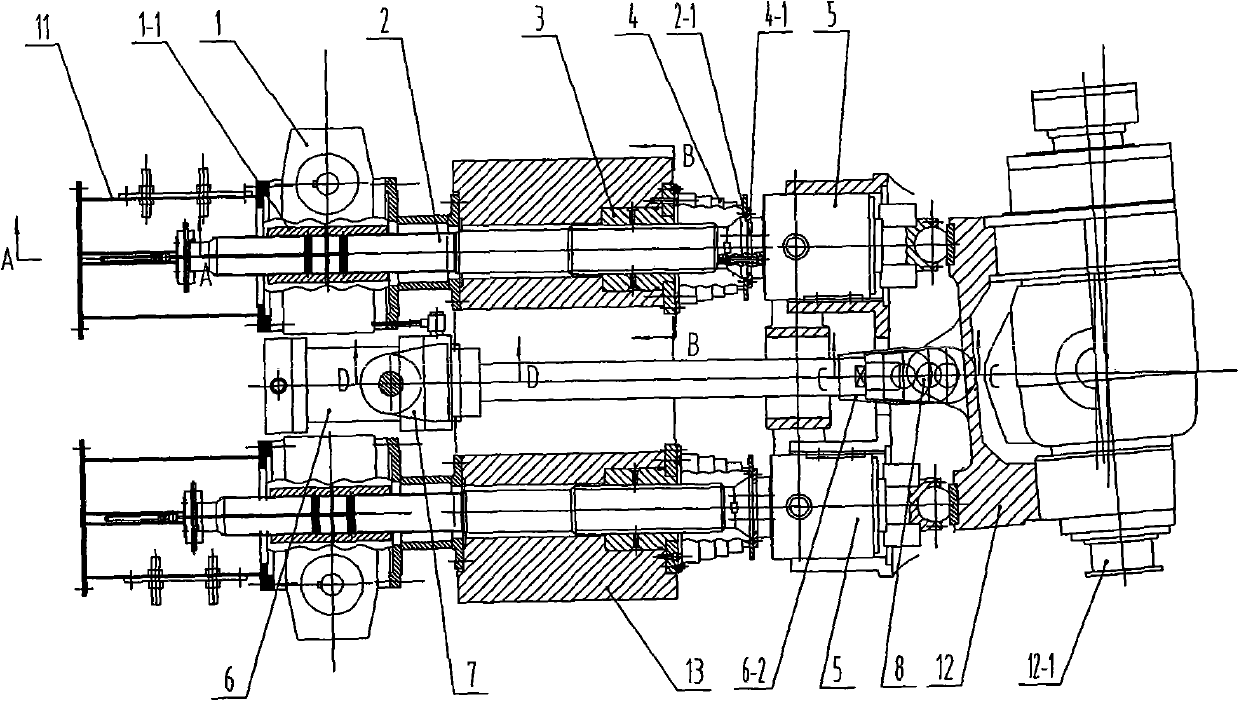

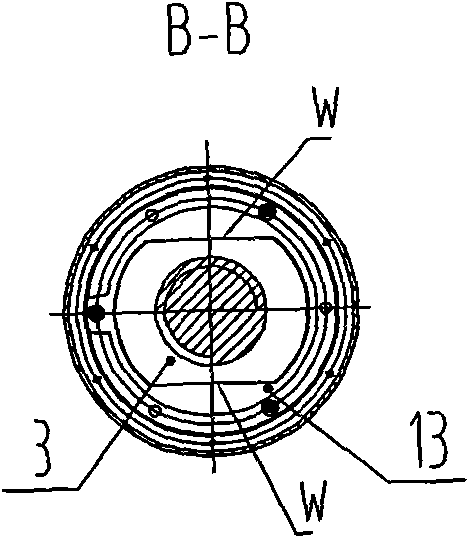

Tube rolling mill balanced device

InactiveCN101767109AQuick liftEliminate gapsMetal rolling stand detailsRolling equipment maintainencePulp and paper industryEar ringing

The present invention discloses a tube rolling mill balanced device, which relates to a steal rolling machine. The present invention solves the problem that the existing tube rolling mill balanced device only can get rid of gaps of guide screws, and can not enable rollers to rapidly lift up. The present invention is characterized in that a balanced oil cylinder 6 is arranged at the middle of two guide screws 2; a cylinder body of the balanced oil cylinder 6 is beyond the outer part of a machine frame 13; a cylinder body ear shaft 6-1 of the balanced oil cylinder 6 is hinged with an oil cylinder support 7 fixed on the machine frame 13; a piston ear ring 6-2 of the balanced oil cylinder 6 is hinged with the middle of a roller box 12; a roller 12-1 is arranged in the roller box 12; and the two guide screws 2 are respectively linked with both ends of the roller box 12 through two quick-opening cylinders 5.

Owner:TAIYUAN HEAVY IND

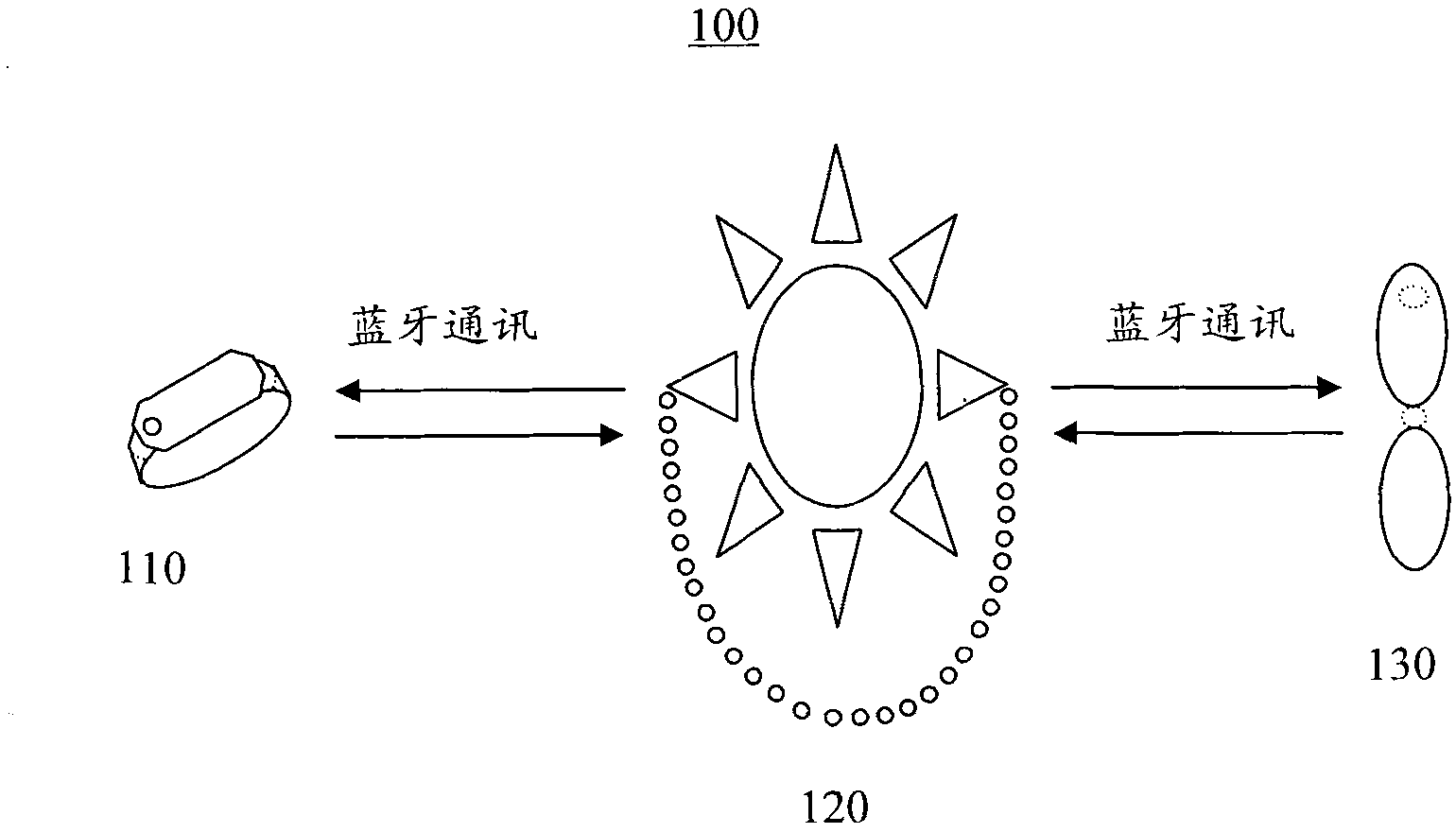

Discrete mobile phone

InactiveCN102014179AFashionable and convenient experienceTelephone set constructionsEar ringingWireless connectivity

The invention discloses a discrete mobile phone which has a plurality of physically isolated functional modules. The functional modules are in wireless connection and used for realizing the data input and output of the mobile phone. The plurality of functional modules can be shaped into finger rings, ear rings, brooches, and the like, then worn on the clothes like jewelry and used for dialing or answering a call when the mobile phone is in use. The invention can bring fashion and convenient experience for users.

Owner:SHANGHAI WINGTECH ELECTRONICS TECH

Breaking hammer for wheel type loader

InactiveCN102383451AMeet the needs of all-round steeringSoil-shifting machines/dredgersEngineeringMechanical engineering

The invention discloses a breaking hammer for a wheel type loader and belongs to the technical field of breaking devices. The breaking hammer comprises a wheel type loader body and a breaking hammer, wherein the breaking hammer comprises a mounting bracket and a movable arm connecting frame; the movable arm connecting frame is provided with a first connecting end; the mounting bracket is hinged with the first connecting end of the movable arm connecting frame through an upper vertical pin roll and a lower vertical pin roll; a left frame and a right frame of the mounting bracket are fixedly connected with a left side plate and a right side plate of a front vehicle body of the wheel type loader body; a return oil cylinder is arranged between the movable arm connecting frame and the right side plate of the front vehicle body; one end of the return oil cylinder is hinged with an oil cylinder connecting block; the other end of the return oil cylinder is hinged with an ear ring on the movable arm connecting frame; and the oil cylinder connecting block is fixedly arranged on the right side plate of the front vehicle body. The breaking hammer of the wheel type loader which is disclosed by the invention can laterally move relative to the loader body and is suitable for operating in a narrow space.

Owner:LAIZHOU YATONG HEAVY EQUIP

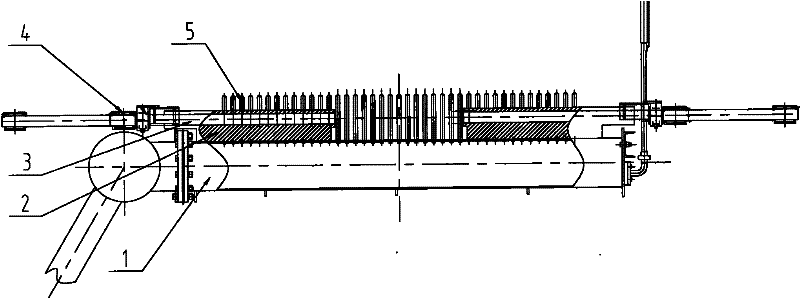

Connecting rod type hydraulic steering engine

The invention relates to a steering gear, and particularly relates to a connecting rod type hydraulic steering engine. The connecting rod type hydraulic steering engine is suitable for underwater robots and other narrow-space marine vehicles requiring large torque. The connecting rod type hydraulic steering engine comprises a servo oil cylinder, an ear ring, a rudder tiller, a rubber rob, a copper bush and a rudder blade, wherein the servo oil cylinder is positioned in a marine robot carrier, an output end of a telescopic piston rod in the servo oil cylinder is provided with the ear ring, the copper bush is arranged on the marine robot carrier, the rudder rod penetrates through the copper bush, one end of the rudder rob is positioned in the marine robot carrier, and is connected with one end of the rudder tiller, the other end of the rudder tiller is hinged with the ear ring, the other end of the rudder rod is positioned on the outer part of the marine robot carrier, and is provided with the rudder blade, the rudder rod is rotated relative to the copper bush through the extension and the contraction of the piston rod, and the rudder blade is linked with the rudder rod. The connecting rod type hydraulic steering engine adopts the servo oil cylinder as the power source of the steering engine, and can provide the large torque output required by the steering of large and middle marine robots.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Earphone

ActiveCN112272345AReduce in quantityEasy to switchEarpiece/earphone attachmentsHeadphonesEar ringing

The invention discloses an earphone which comprises an earplug and an annular earplug sleeve, one end of the earplug sleeve is in butt joint with a sound outlet hole of the earplug, the other end of the earplug sleeve is a deformable in-ear ring, the in-ear ring can be turned over towards the sound outlet direction of the sound outlet hole to form an in-ear earphone, and the in-ear ring can be turned over reversely and arranged on the outer side of the earplug in a sleeving mode to form a half-in-ear earphone. Through the deformable arrangement of the earplug sleeve, the earphone can switch the use modes by adjusting the direction of the in-ear ring, the switching operation is convenient, the earphone can be used as an in-ear earphone and can also be used as a half in-ear earphone, and thenumber of earphones purchased by a user can be reduced.

Owner:GEER TECH CO LTD

Finished product processing equipment for jewelry production streamline

InactiveCN108515169AThe processing flow is orderlyStep by stepCasting plantsFoundry mouldsCircular discPulp and paper industry

The invention discloses finished product processing equipment for a jewelry production streamline. The equipment comprises a polishing and grinding device which comprises a grinding table and an ejecting plate, wherein a plurality of T-shaped sliding chutes are formed in the grinding table; an iron slide block and an electromagnet located at one end of the slide block are inserted into each T-shaped sliding chute, and a first grinding seat and a second grinding seat are mounted at the top end of the ejecting plate; a fourth oil cylinder and a fifth oil cylinder are mounted in the first and second grinding seats, the bottom ends of the fourth oil cylinder and the fifth oil cylinder are separately connected to a first polishing motor and a round disc separately through piston rods, and the bottom end of the first polishing motor is connected to a polishing disc; the equipment also comprises a walking trolley, and the bottom end of the walking trolley is connected to a second polishing motor through a suspension rod; the equipment is suitable for grinding annular jewelry, for example, rings, bracelets and ear rings; if non-annular jewelry needs to be ground, for example, spherical eardrops, necklace parts, the grinding discs at the bottom of the first and second polishing motors are replaced, so that the applicability of the polishing device is improved.

Owner:北京乾淳知识产权运营有限公司

Up-spray laminar flow cooling device

ActiveCN102189128AGuaranteed uptimeReduce configuration costsWork treatment devicesMetal rolling arrangementsHydraulic cylinderEar ringing

The invention discloses an up-spray laminar flow cooling device which comprises multiple up-spray device groups. Each up-spray device group comprises 4-6 up-spray devices; each up-spray device comprises a header and two plungers, wherein multiple spray pipes are uniformly distributed on the header; two plunger holes are arranged above the two ends of the header; and the two plungers are arranged in the plunger holes respectively. Each up-spray device group also comprises two shoulder pole beams, two hydraulic cylinders and multiple pairs of plunger connection mechanisms, wherein the two shoulder pole beams are vertically arranged at the two sides of the header respectively; the two hydraulic cylinders are arranged between adjacent two headers in the middle; the hydraulic rods of the hydraulic cylinders are arranged in parallel with the headers; ear rings of the two hydraulic cylinders are fixedly connected with the two shoulder pole beams respectively through the two hydraulic cylinder connection mechanisms; and the multiple pairs of plunger connection mechanisms are used for connecting the plungers and the shoulder pole beams, and comprise multiple pairs of free connection mechanisms.

Owner:BAOSHAN IRON & STEEL CO LTD +1

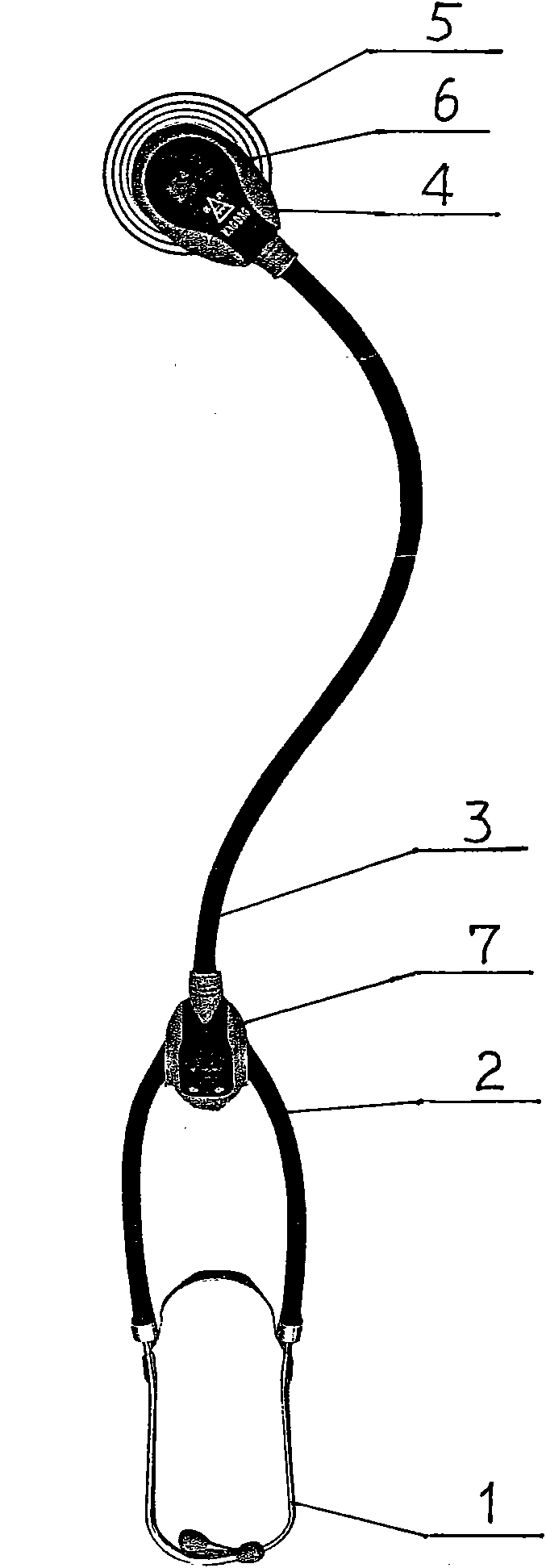

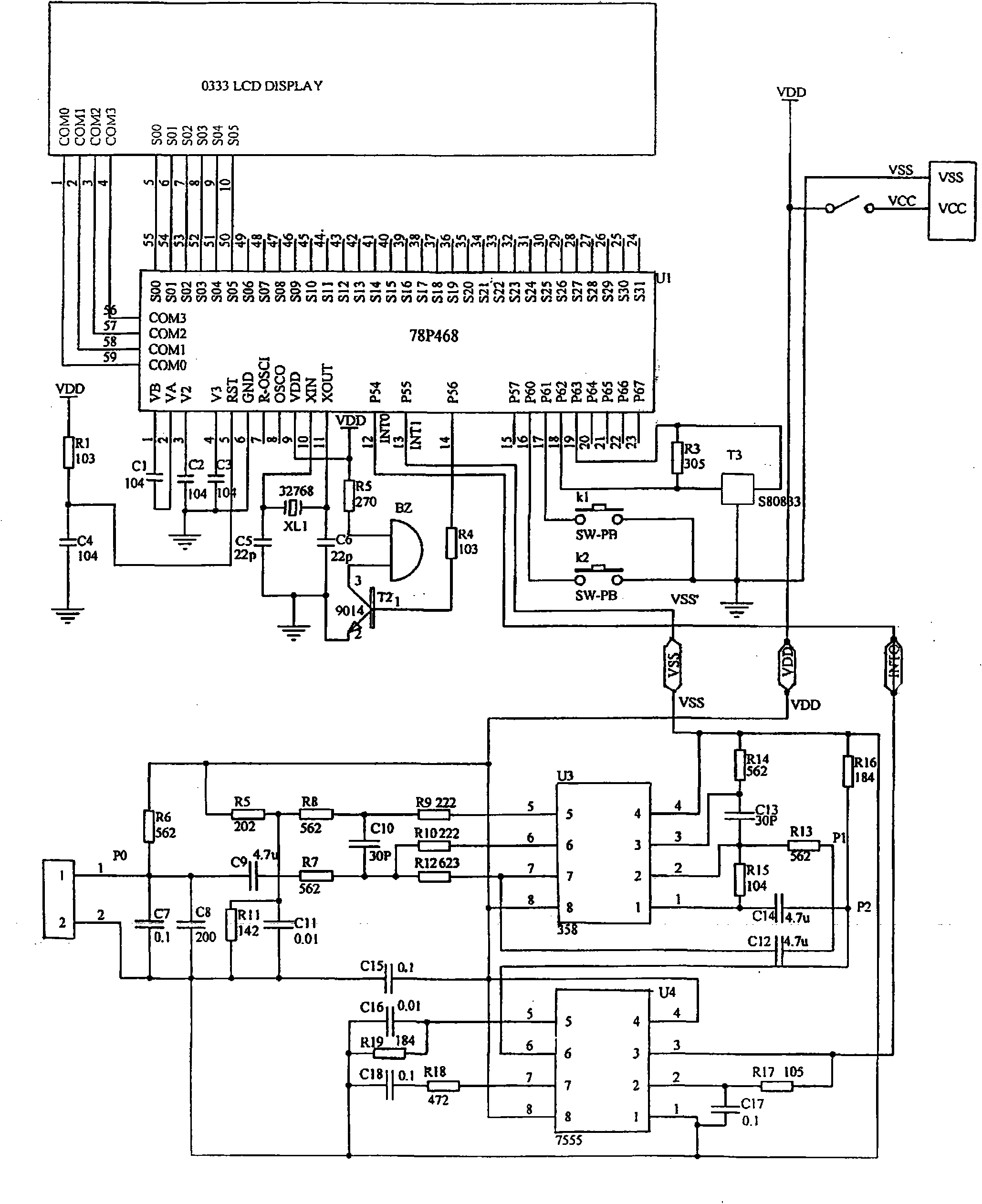

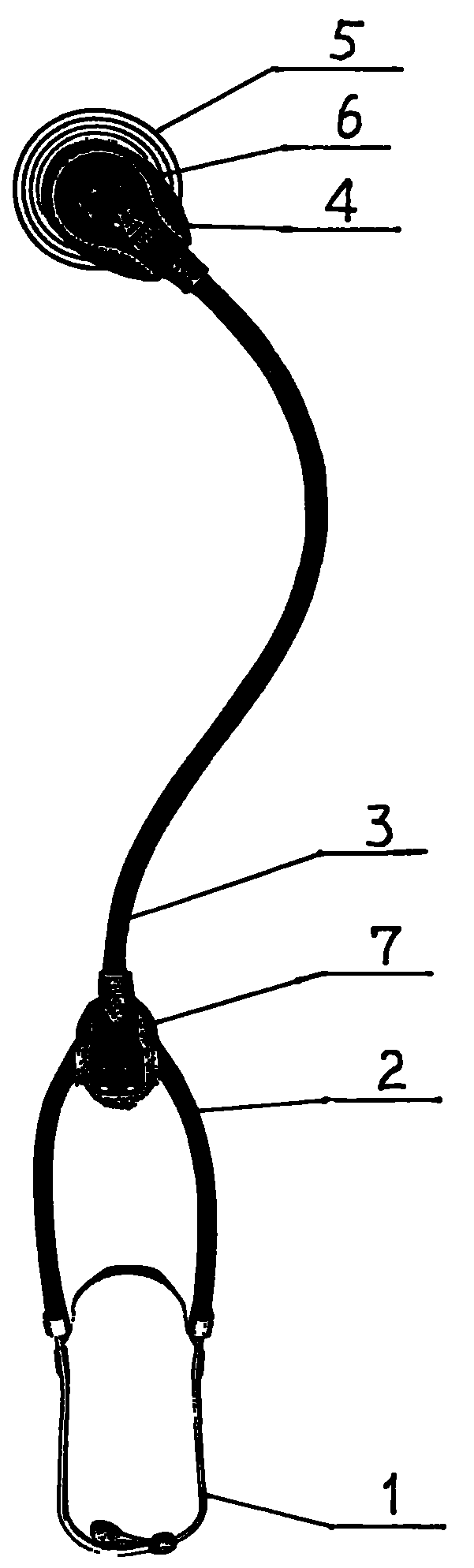

Electronic timing and counting stethoscope

InactiveCN102113894AAvoid drudgeryConvenient diagnosis and treatment workStethoscopeMicrocontrollerSTETHOSCOPE HEAD

The invention discloses an electronic timing and counting stethoscope. The stethoscope comprises an ear ring, a bushing, a rubber-plastic pipe and a master control box which are connected with one other and are tightly sleeved in turn, wherein the master control box comprises a stethoscope head and a master control box body; the master control box body is provided with a switch, a key and a liquid crystal display screen; a double-layer sealed passage is adopted by the stethoscope head, the master control box, the rubber-plastic pipe, the bushing and the ear ring; a signal acquisition circuit of a master control box circuit consists of a capacitive electret microphone, an operational amplifier and a time-base circuit which are connected with one another in turn; an output pulse signal of the time-base circuit is connected to a singlechip; the singlechip performs signal identification and operation; an output is connected to a liquid crystal display; and an electronic watch box can also be sleeved on the bushing. In the stethoscope, a vibration principle is used for signal acquisition; and the stethoscope is directly used for auscultation without distortion, is convenient to operate and use, is humanized, has a naturally increased hearing effect and intuitive and accurate electronic display, contributes to clinic diagnosis and is low in price.

Owner:HUNAN MINGDING MEDICAL EQUIP

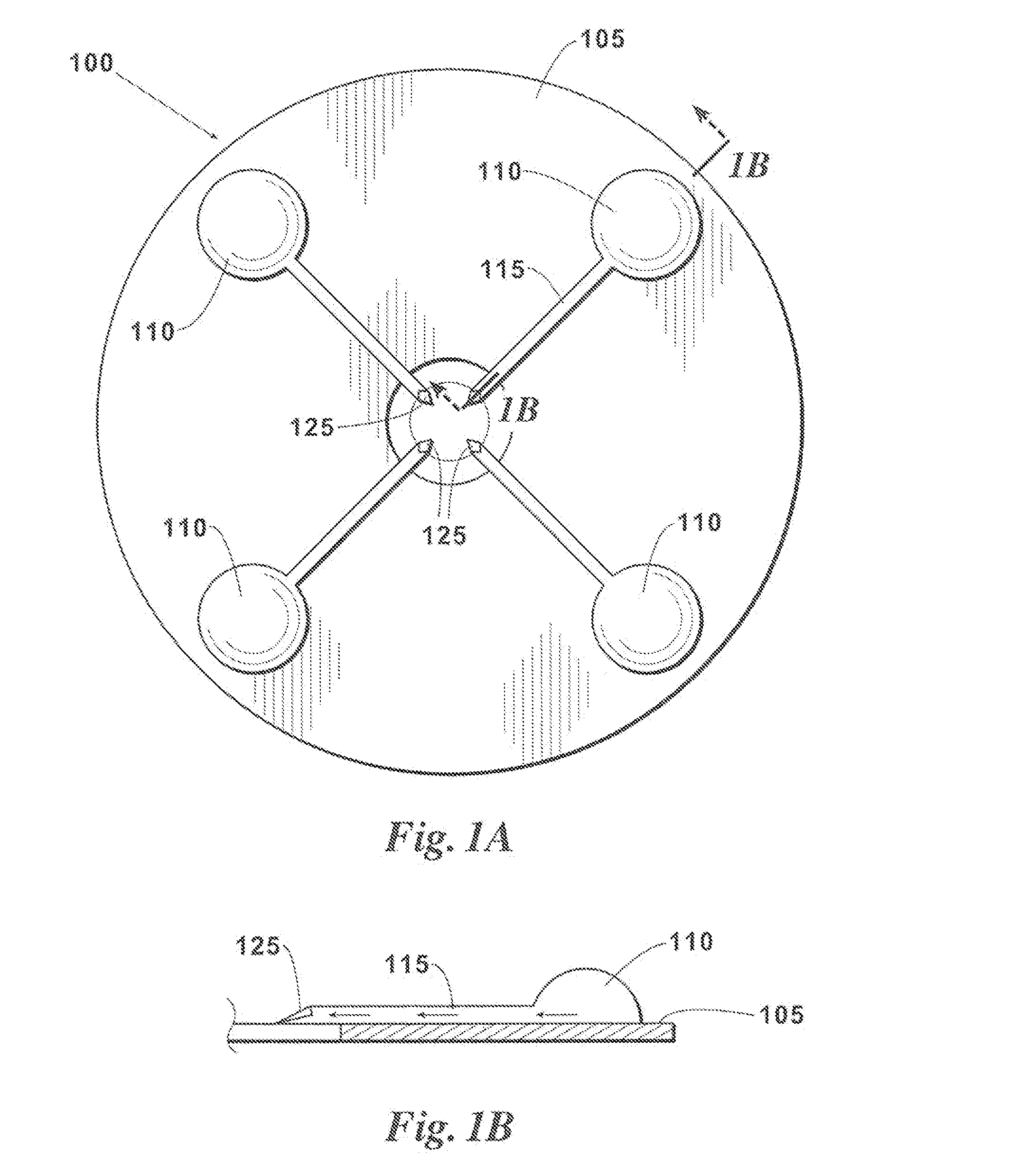

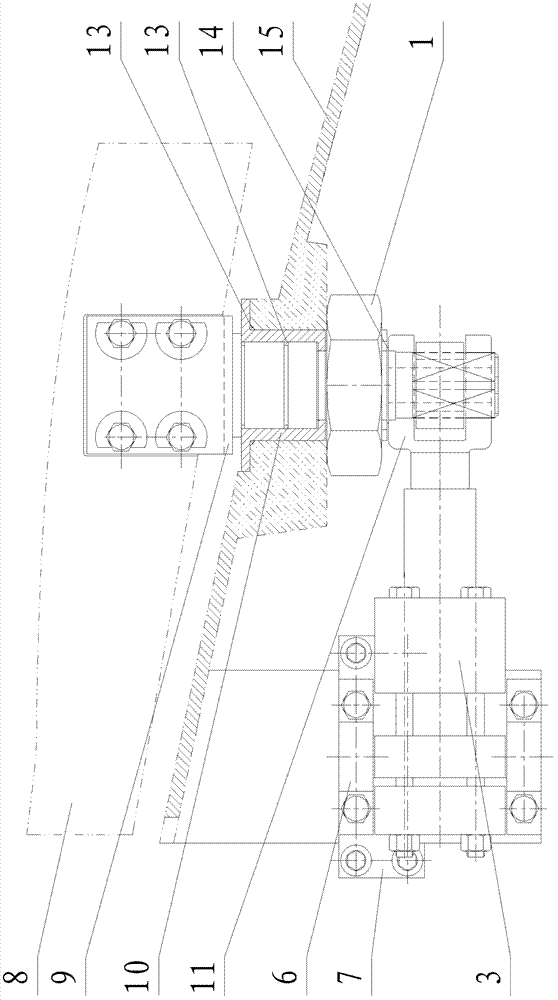

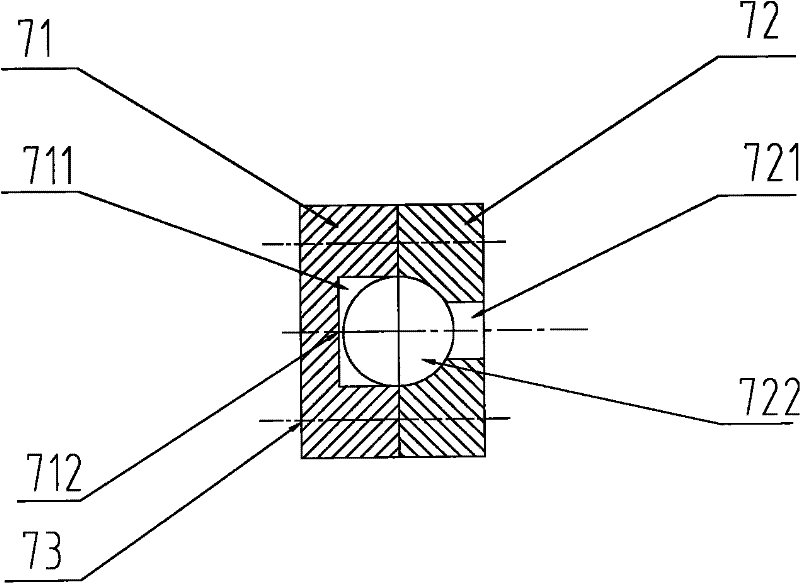

Oil cylinder rear ear ring inner pin hole machining tool and machining method

InactiveCN111113079ASimple structureShort processing timePositioning apparatusMetal-working holdersMachining timeMachine tool

The invention provides an oil cylinder rear ear ring inner pin hole machining tool and machining method, and belongs to the technical field of oil cylinder machining. The oil cylinder rear ear ring inner pin hole machining tool comprises a limiting structure used for being connected with a machine tool chuck and a positioning structure used for fixing a rear ear ring and the limiting structure, wherein the limiting structure comprises a first limiting part and a second limiting part, the first limiting part is connected with the machine tool chuck, the second limiting part is connected with the rear ear ring, the positioning structure comprises a positioning part and a connecting part, the positioning part is connected with the rear ear ring, and the connecting part is used for connectingthe positioning part and the second limiting part. Compared with the prior art, according to the oil cylinder rear ear ring inner pin hole machining tool and machining method, when inner pin holes ofear rings are machined in batches, the limiting structure does not need to be separated from the machine tool chuck, the positioning structure can be directly disassembled for machining on the rear ear rings, the structure is simple, the machining time is short, and the machining efficiency is improved.

Owner:哈尔滨通用液压机械制造有限公司

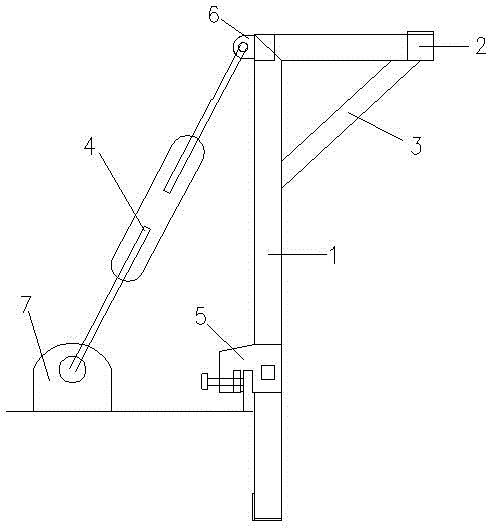

Nacelle suspension bracket for ship

InactiveCN105730613ADoes not take up spaceDoes not affect other operationsVessel partsLifting devicesNacelleMarine engineering

The invention relates to a suspension frame of a hanging basket for a ship. The clamping plate is welded to the lower part of the column; the column is clamped on the deck of the ship through the clamping plate welded to the lower part, and the upper part of the column is fixedly connected to the rear of the flat suspension; one end of the diagonal brace is welded to the flat suspension The other end is welded on the vertical bracket; one end of the stay cable is connected to the earring at the rear of the suspension, and the other end is fixedly connected to the ground lug welded on the deck of the ship. The structure of the invention is ingenious and reasonable, and the main body of the suspension can be directly fixed on the deck plane of the ship, without parapet support or counterweight. Only the stay cables of the suspension mechanism extend into the deck, and the structural main body and other components of the hanging basket suspension are all near the side of the ship. The suspension mechanism does not take up space and does not affect other operations on the deck. The main body of the suspension can cooperate with the slide rail, which is easy to move and flexible.

Owner:WUXI COSMO SUSPENDED PLATFORM

Stepless length regulating method in mounting course of viscous damping device

InactiveCN101319487AStable deliveryEasy to installBridge structural detailsViscous dampingControl theory

The invention relates to a method for stepless control of length of a viscous damper when the damper is mounted. In the method, eccentric sleeves are arranged between a double ear ring base of the damper and a pin shaft of the damper, and fixed on the double ear ring base by a positioning bolt; when the damper is mounted, firstly a spherical hinge base of the damper is inserted in the double ear ring base, one eccentric sleeve is sleeved in a hole on one side of the double ear ring base; the pin shaft is inserted in the damper from the side on which the eccentric sleeve is sleeved; the other eccentric sleeve is sleeved on the other side of the double ear ring base; the eccentric sleeves are turned, so that the eccentric sleeves are sleeved between the double ear ring base and the pin shaft, and the double ear ring base closely contacts the mounting surface; the eccentric sleeves are tightly locked by positioning bolts; and finally the double ear ring base is fixed, the whole process of mounting the damper is completed. Compared with the prior art, the method of the invention has the advantages of low cost, simple and convenient operation, high precision and great improvement of the mounting efficiency.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

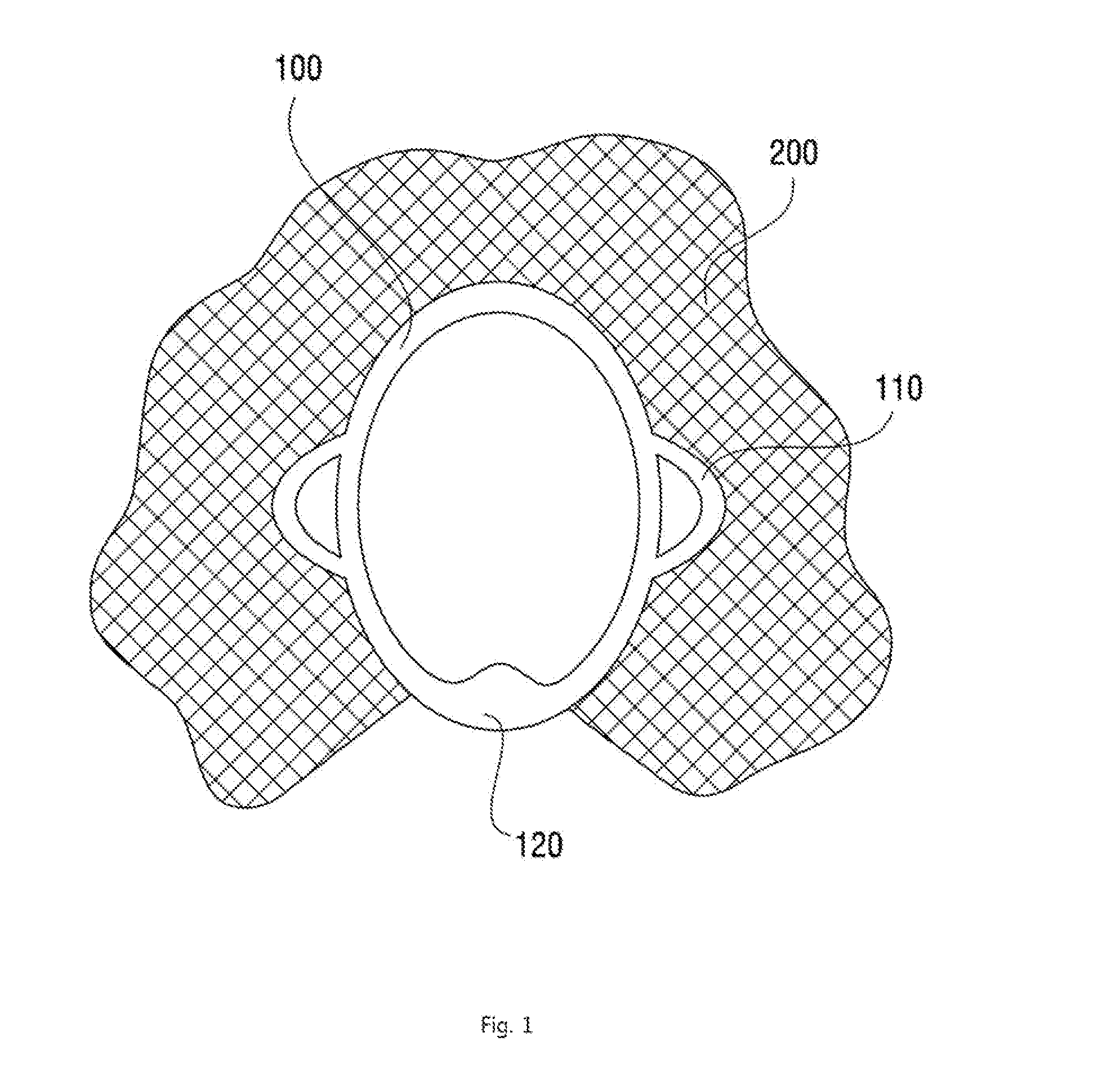

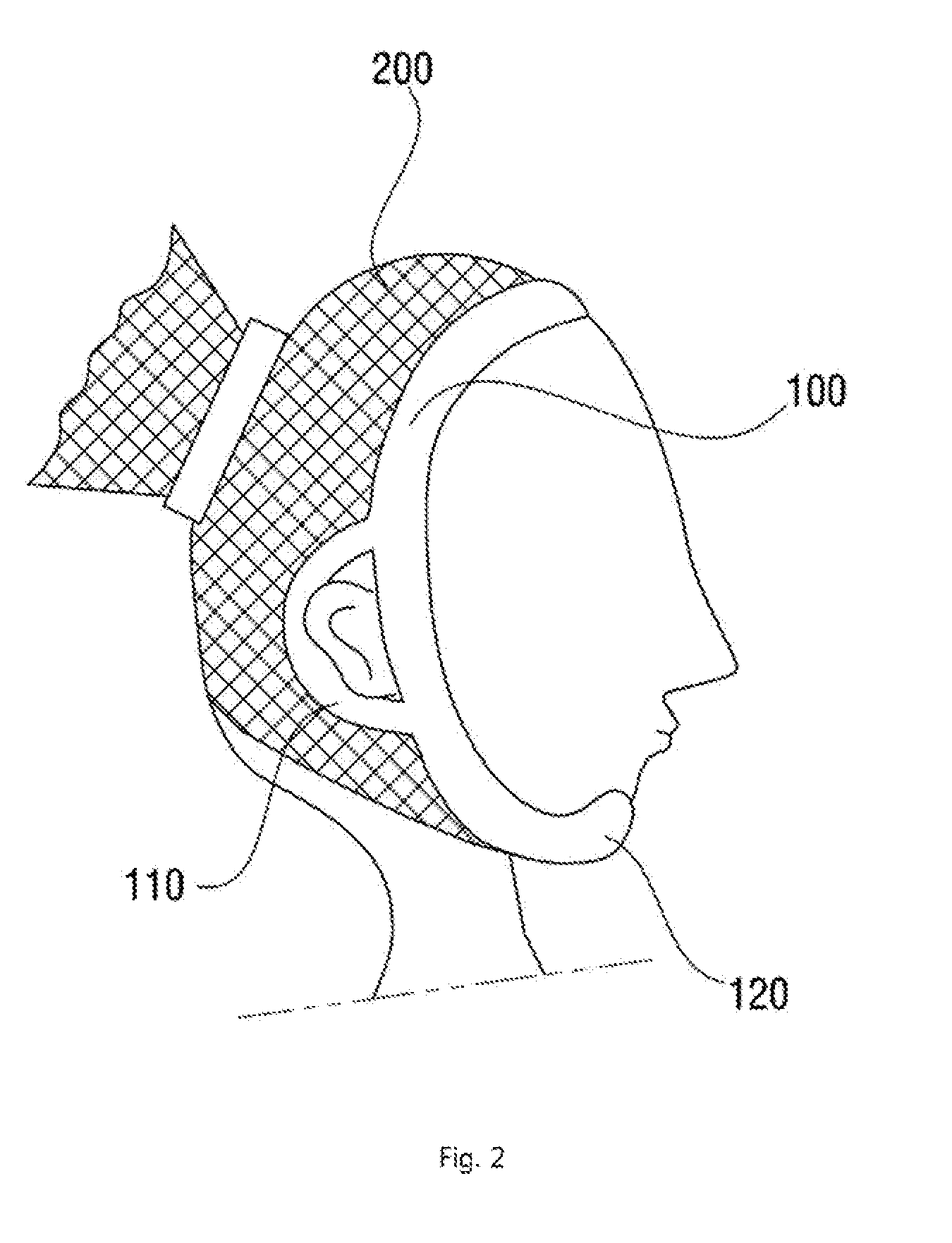

Face lifter

InactiveUS20160331056A1Reduce thicknessIncrease elasticityPackaging toiletriesPackaging cosmeticsChinEngineering

A face lifter comprises an elastic band surrounding a user's face along an edge of the user's face from the chin of the user to the forehead and including ear rings respectively formed at two opposite sides of the elastic band and a hair net provided backward the elastic band and holding a back of the user's head, wherein the elastic band is shaped as an elliptical ring, wherein a chin rest protrudes in a width direction thereof from a lower portion of the elastic band to surround a front and lower portion of the user's chin, and wherein the elastic band has a decreasing thickness and an increasing elastic force to the user's chin.

Owner:SON SU JEONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com