Differential-type plunger composite oil cylinder

A composite oil cylinder and differential technology, applied in the field of hydraulic cylinders, can solve the problems of complex working conditions, high working requirements and long working strokes of full hydraulic oil drilling rigs, and achieve the effects of compact structure, low processing difficulty and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings and embodiments:

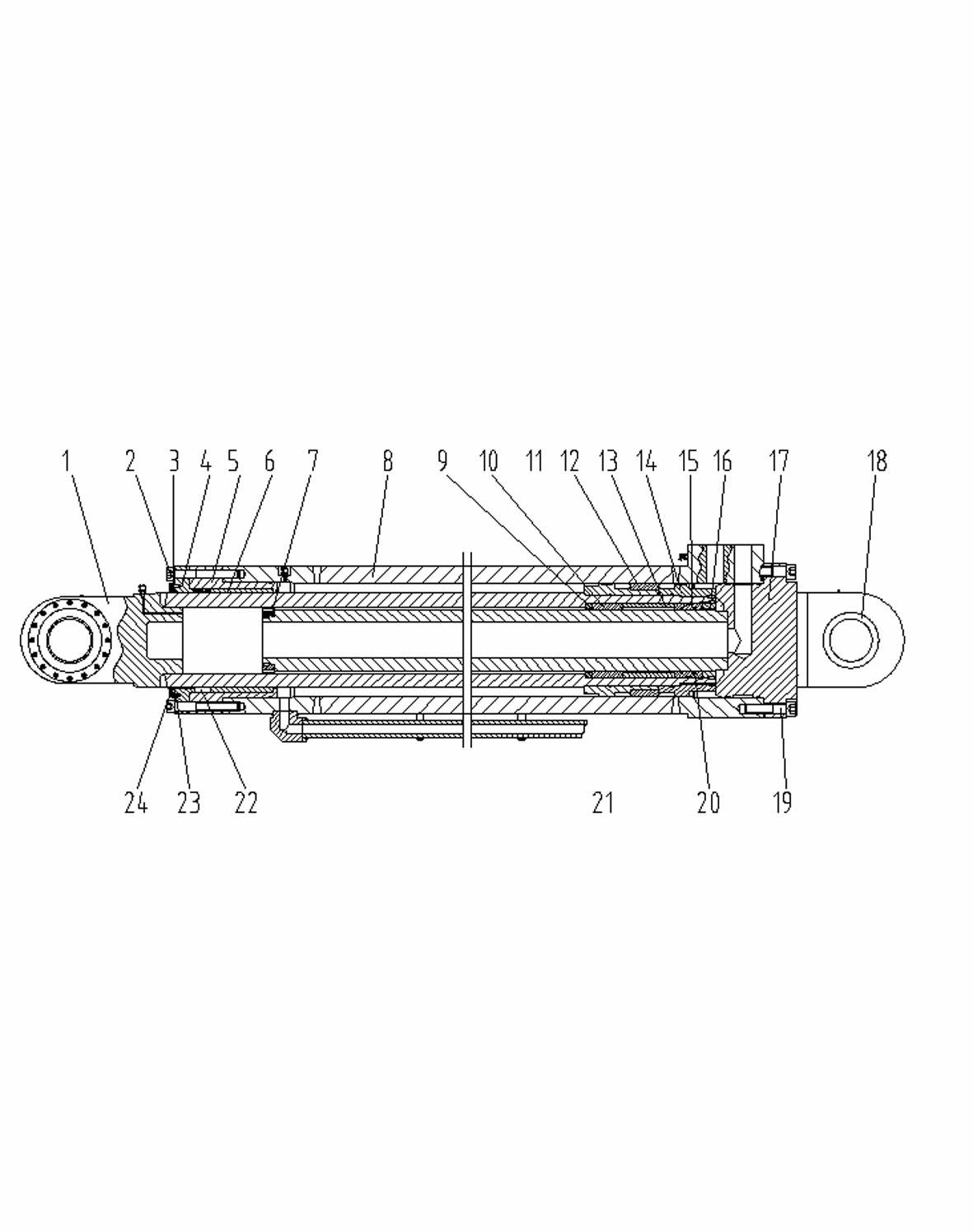

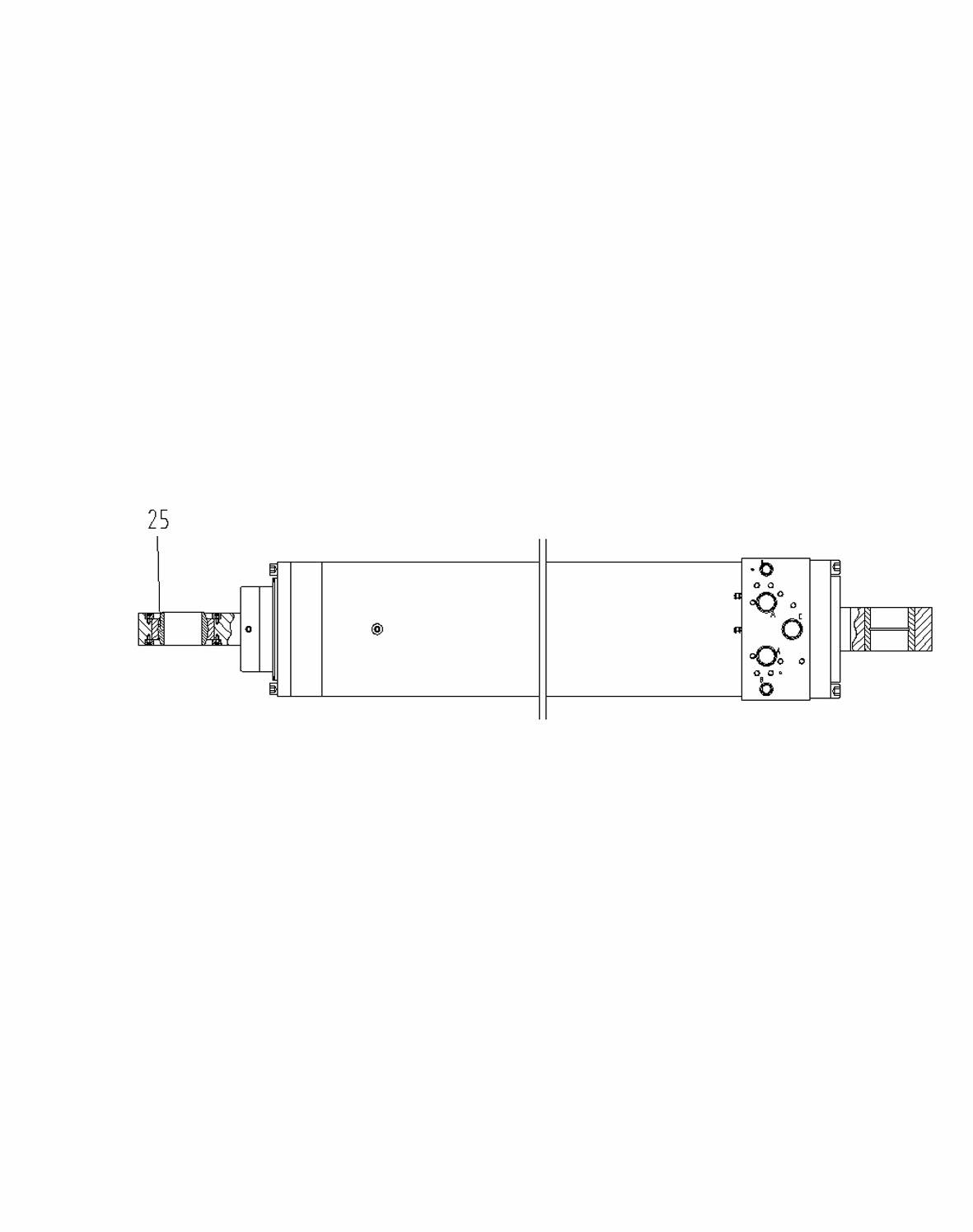

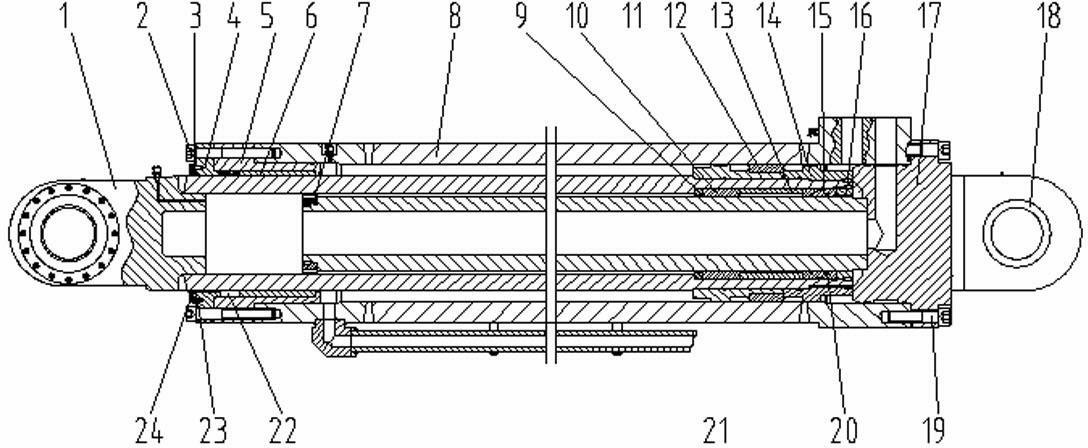

[0014] See figure 1 with figure 2 , A differential plunger composite hydraulic cylinder, including: piston rod assembly 1, hexagon socket screw I2, dust ring gland 3, gland 4, cylinder head 5, rod guide sleeve 6, guide ring 7, cylinder block 8. Positioning ring 9, front support sleeve 10, piston front end 11, piston guide sleeve 12, spacer sleeve 13, piston rear end 14, rear support sleeve 15, locking sleeve 16, cylinder bottom assembly 17, bushing 18, inner Hexagon screw Ⅱ19, rod seal Ⅰ20, piston seal 21, rod seal Ⅱ22, hexagon socket screw Ⅲ23, dust ring 24, bearing 25, etc.

[0015] The front end of the piston rod assembly 1 is equipped with a bearing 25. The rear end of the piston rod assembly 1 is a cylinder structure and is integrally installed in the cylinder block 8. The front end of the cylinder is positioned by a rod guide sleeve 6 installed in the cylinder he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com