180-degree steel plate turnover mechanism in hull planar section production line

A technology of planar segmentation and flipping mechanism, which is applied to auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unfavorable production safety, hidden safety hazards, low efficiency, etc., achieve simple structure and improve production efficiency , Reduce the effect of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings:

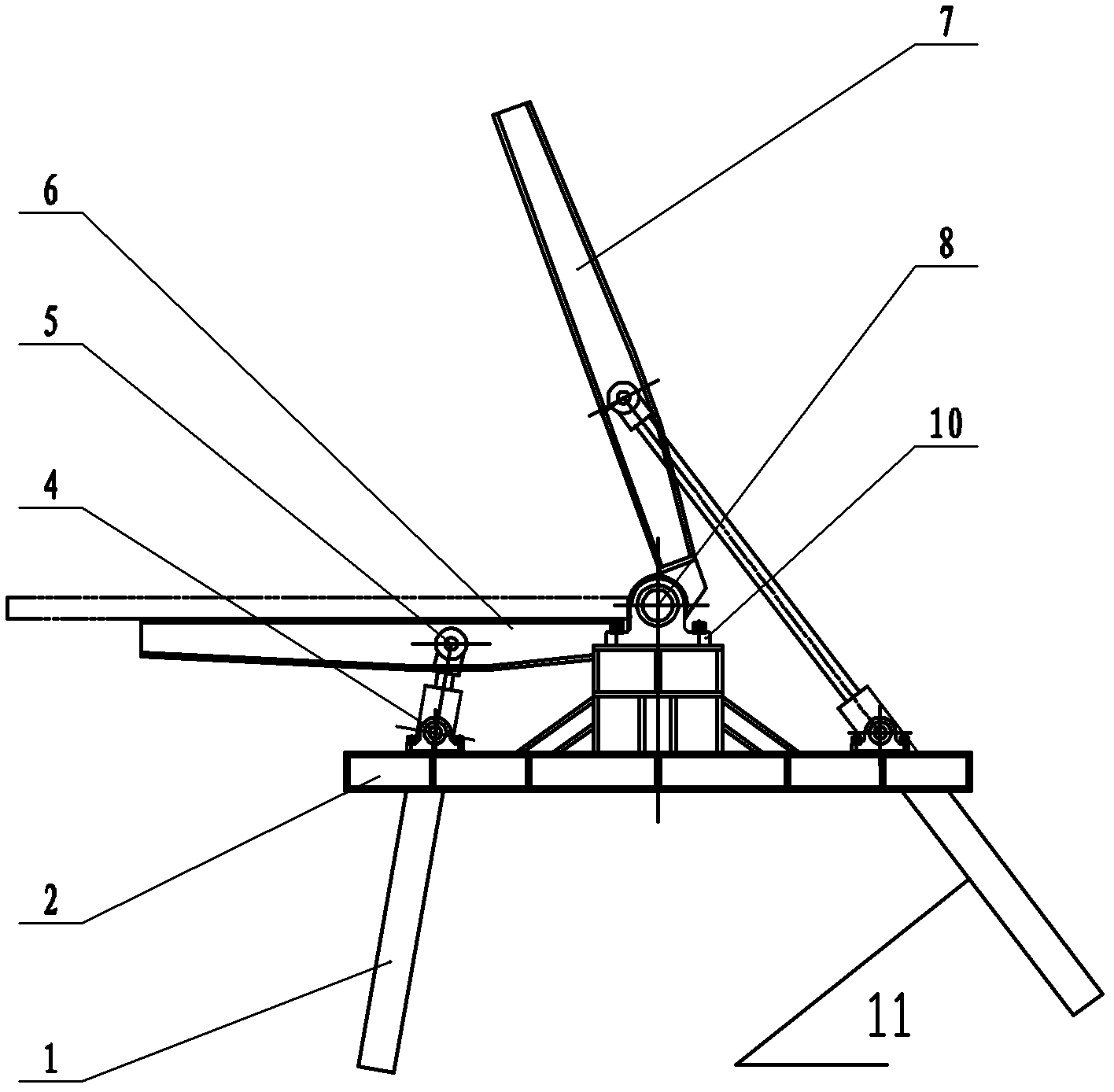

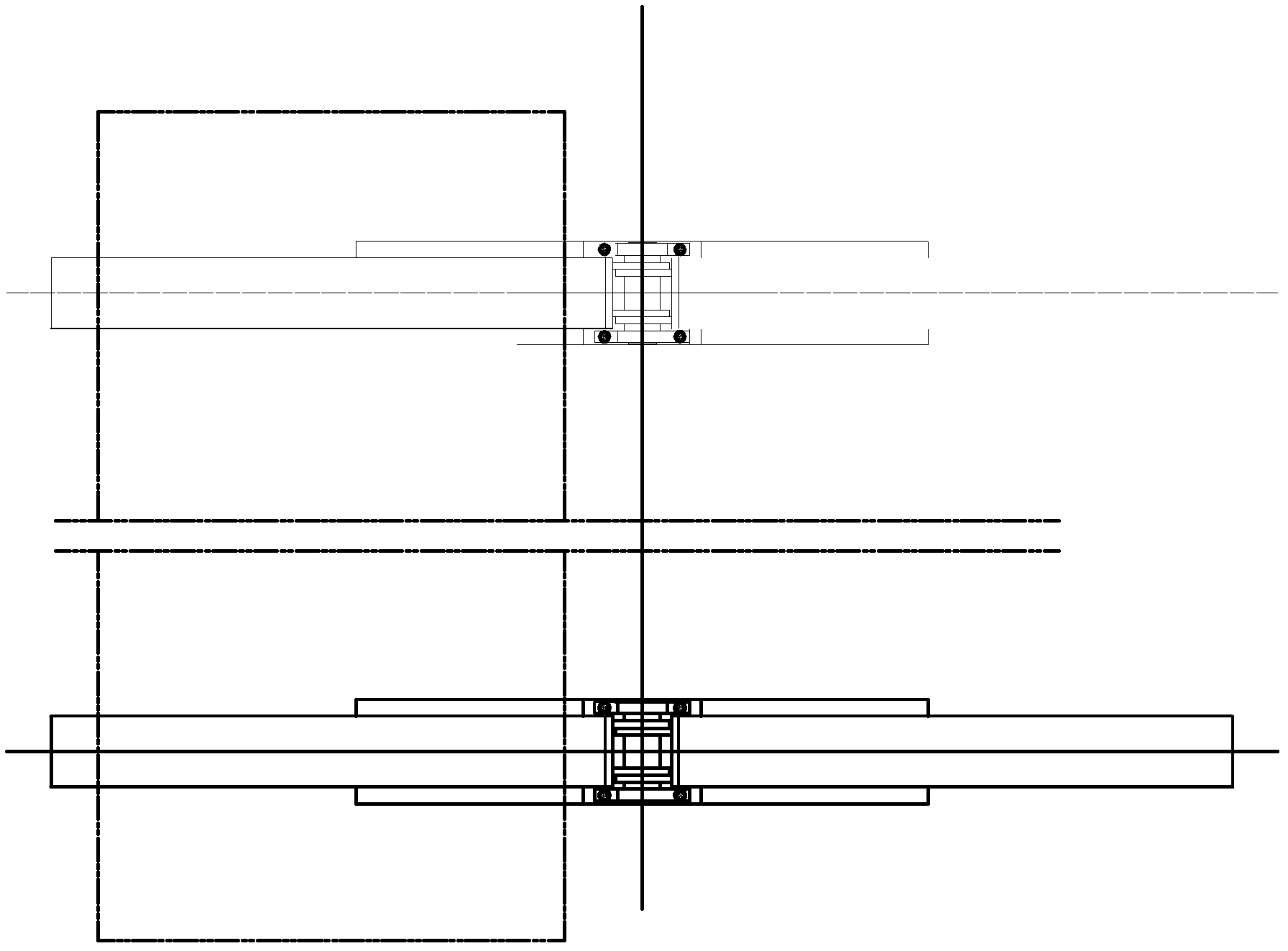

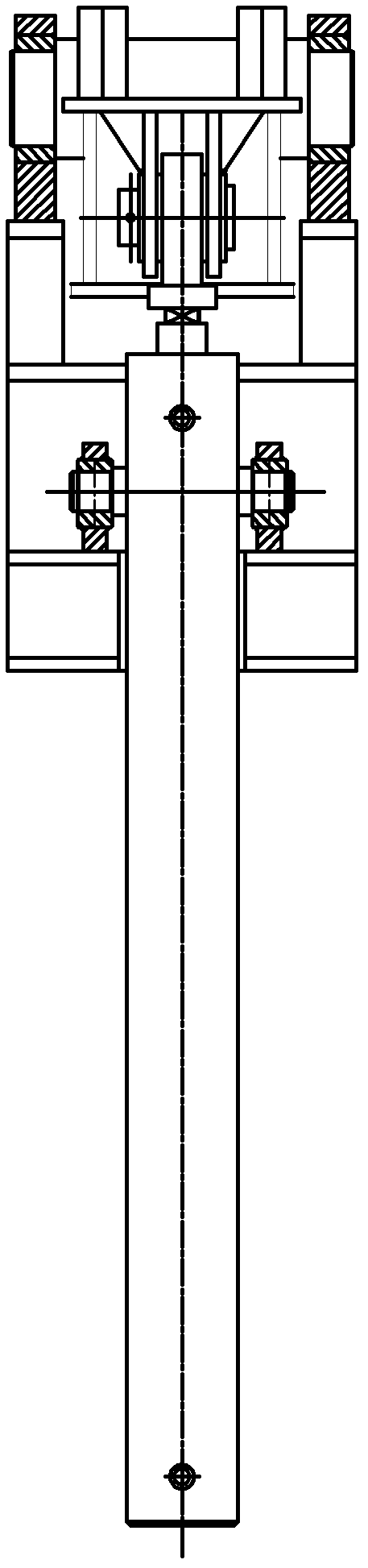

[0012] like Figure 1 ~ Figure 3 As shown, it includes a first hydraulic cylinder 1, a base 2, a first bolt 3, a first bearing seat 4, a first pin 5, a lift arm 6, a pull-down arm 7, a second pin 8, and a second bolt 9 , the second bearing seat 10 and the second hydraulic cylinder 11 and so on.

[0013] The hinge shaft of the first hydraulic cylinder 1 is connected with the first bearing seat 4 , the first bearing seat 4 and the base 2 are connected by the first bolt 3 , and the piston rod end earring of the hydraulic cylinder 1 is connected by the first pin shaft 5 Connected with the lift arm 6, the piston rod end earring of the second hydraulic cylinder 11 is connected with the pull-down arm 7 through the first pin 5, and the lift arm 6 and the pull-down arm 7 are connected to the second through the second pin 8 at the same time. The bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com