Tube rolling mill balanced device

A technology of balancing device and tube rolling mill, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of complicated equipment, and achieve the effect of convenient installation and increased degree of freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

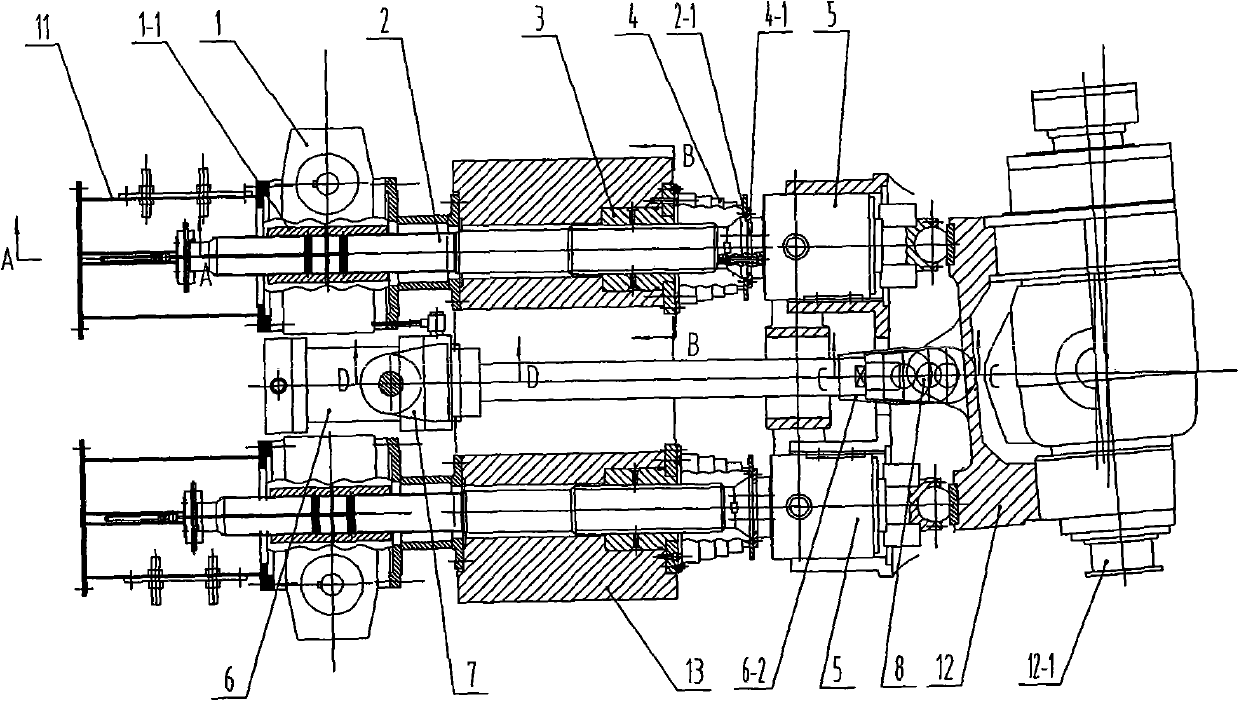

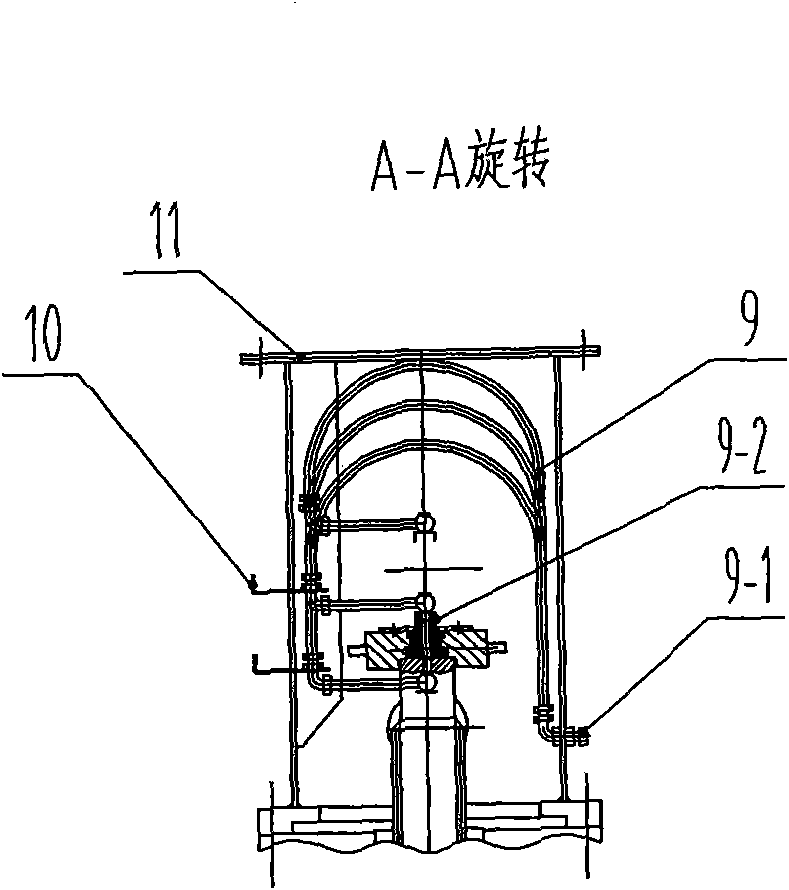

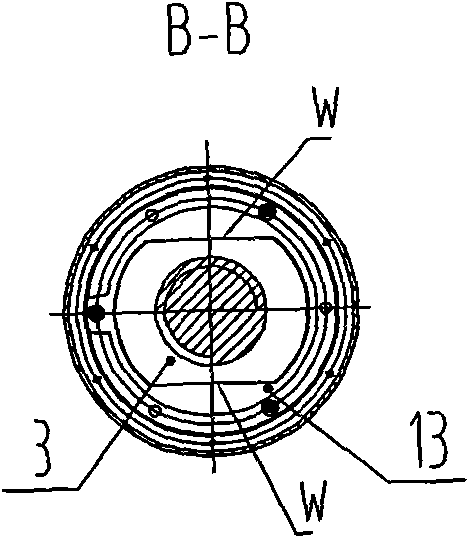

[0016] Such as figure 1 , 2 , 3, 4, and 5, a pipe mill balance device is composed of a pressing transmission device 1, a lead screw 2, a nut 3, a telescopic cover 4, a quick opening cylinder 5, a balance cylinder 6, a cylinder support 7, a pin Shaft 8, lubricating pipeline 9, electric control element 10, protective cover 11, roll box 12 and so on. The worm wheel 1-1 of the worm gear reducer is an internal spline, which cooperates with the spline body at one end of the lead screw 2. When the transmission device 1 is pressed down to rotate, due to the action of the spline, the lead screw 2 will rotate and allow Its axial linear movement; the other end of the screw 2 is a zigzag thread, which cooperates with the zigzag thread of the inner hole of the nut 3. When the screw 2 rotates, due to the effect of the screw thread, the screw 2 rotates while Axial linear movement; the balance oil cylinder 6 is installed in the middle of the two lead screws 2, and the cylinder body of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com