Production process for ear ring machine

A production process, earring machine technology, applied in clothing, application, jewelry and other directions, can solve the problems of low productivity, slow assembly speed, cumbersome process, etc., to achieve industrialized production and automated production, improve the good rate of finished products, and assemble fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

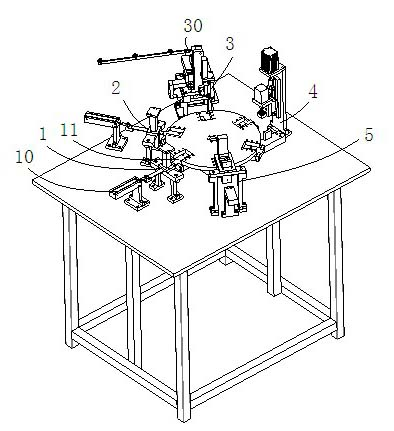

[0024] see figure 1 with figure 2 As shown, the production process of the earring machine of the present invention, the earrings include a fixed seat, and a movable seat movably connected with the fixed seat, and a rotating pin is arranged between the fixed seat and the movable seat.

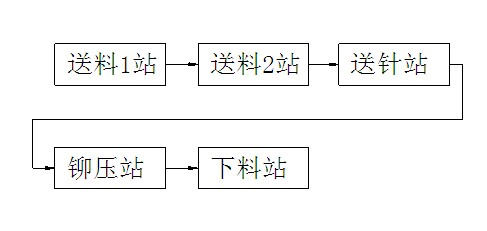

[0025] The earring machine includes a feeding station 1, a feeding station 2, a needle feeding station 3, a riveting station 4, a blanking station 5 and a turntable 6. The turntable 6 is provided with a clamp 11, the feeding 1 station 1 and the feeding 2 station 2 are provided with a feeding cylinder 10, and the needle feeding station 3 includes an adjusting wheel tensioning mechanism 30, a guide hole, a cylinder, a moving Needle positions, pressing needles and spring cutters, the riveting station 4 includes upper and lower cylinders, and the unloading station 5 includes a plug and an unloading chute.

[0026] The production technology of described earring machine comprises the following step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com