Stepless length regulating method in mounting course of viscous damping device

A viscous damper and installation process technology, which is applied in the field of bridge vibration reduction and anti-seismic, can solve problems such as inability to insert, adjustment cannot be performed, and cumbersome adjustment, etc., to achieve the effects of ensuring correct installation, improving installation efficiency, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

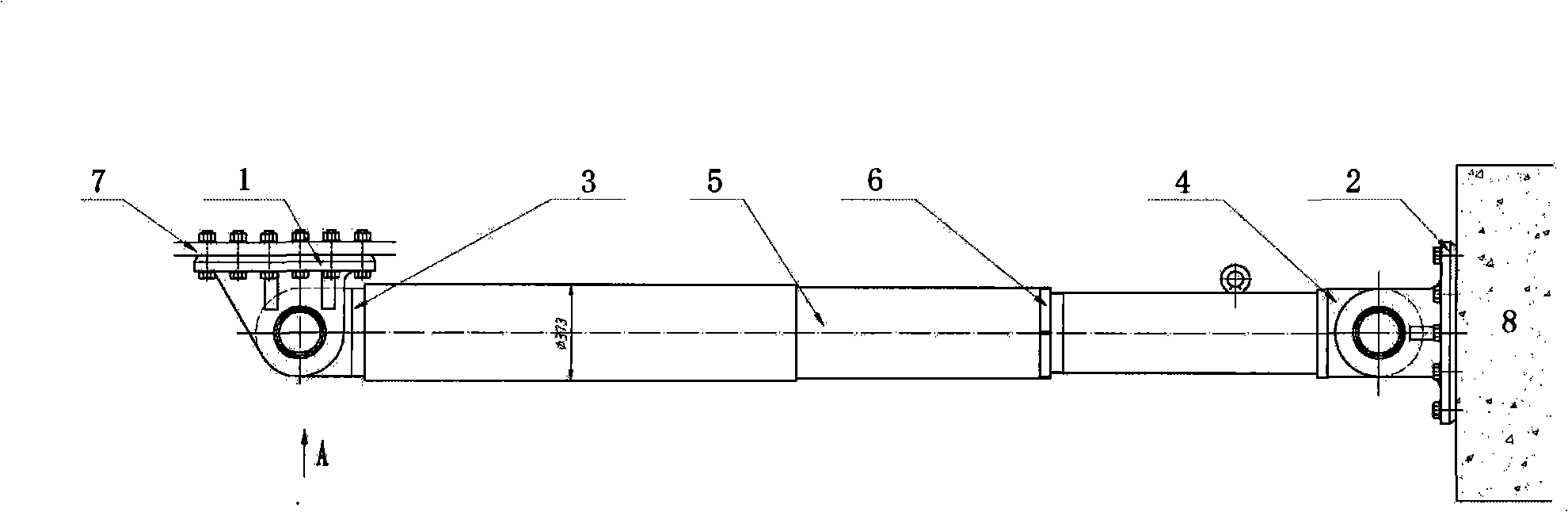

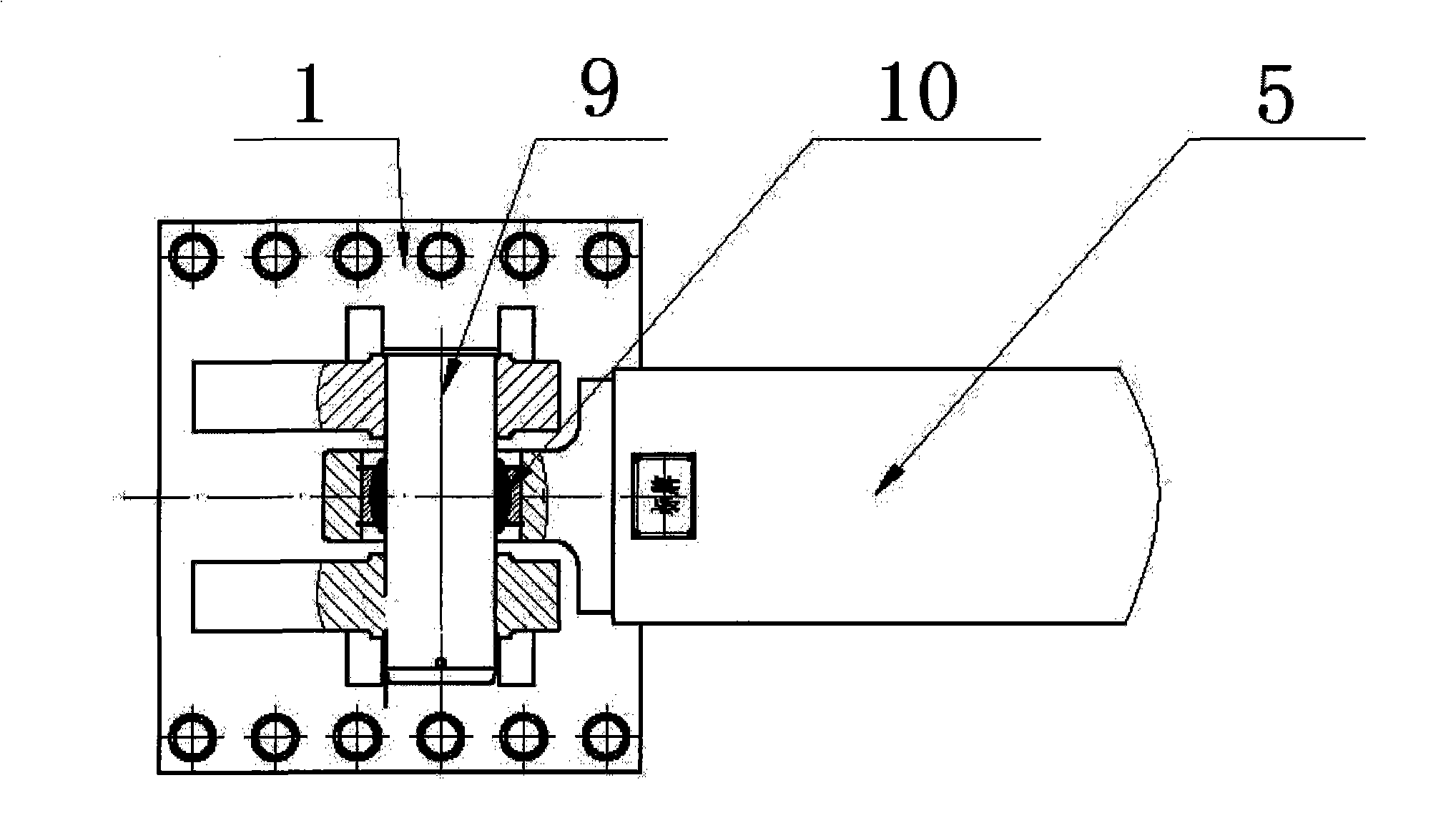

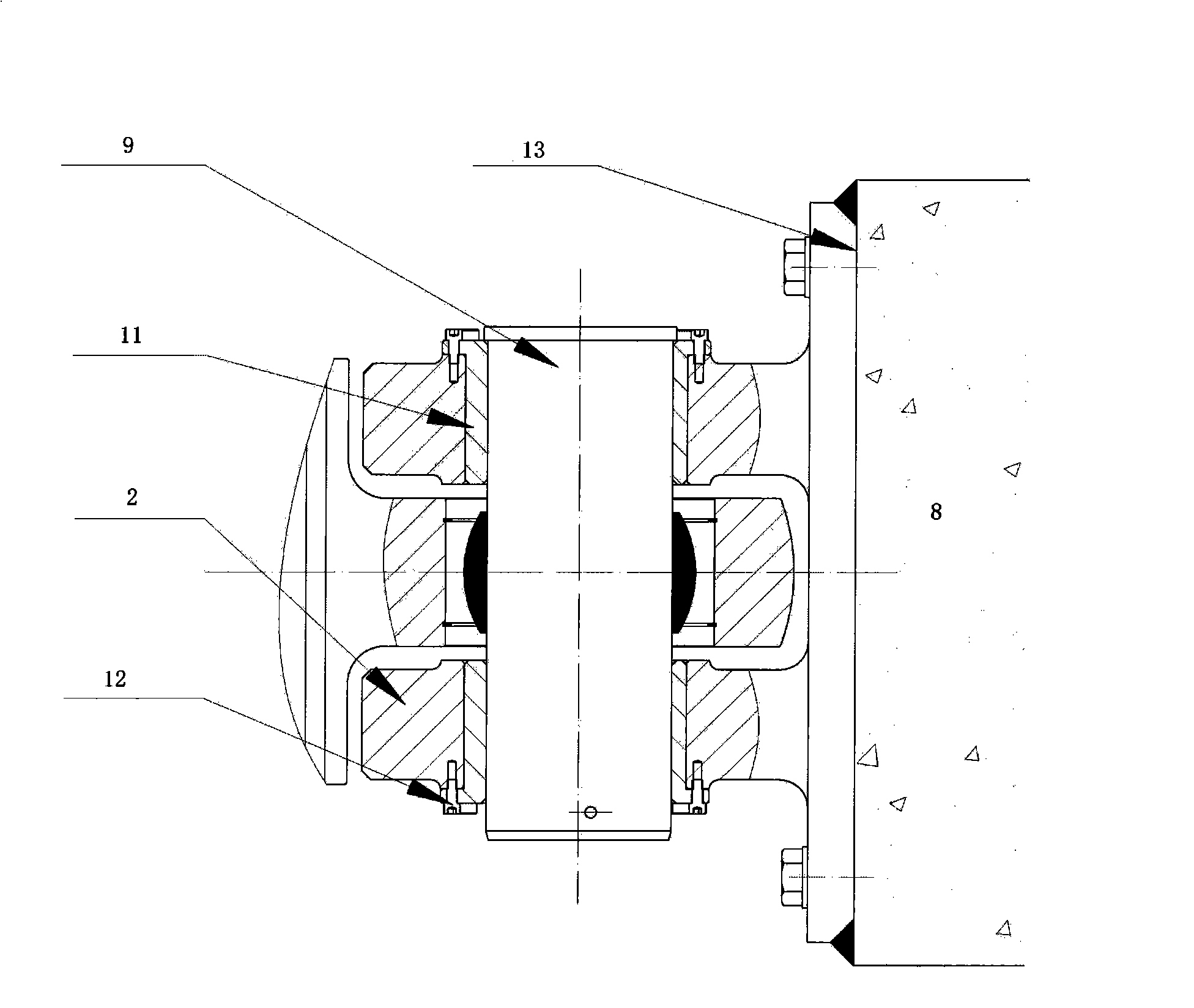

[0018] Such as Figure 3-5 As shown, a method for stepless adjustment of the length of the viscous damper during installation, the method is to add an eccentric sleeve 11 between the right double clevis seat 2 and the pin shaft 9, the outer diameter of the eccentric sleeve 11 is the same as that of the double clevis seat 2 The nominal diameter of the inner diameter of the hole is the same, and the fit tolerance is E8 / h8. The nominal size of the inner hole of the eccentric sleeve 11 is consistent with the outer diameter of the pin shaft 9, and the fit tolerance is F8 / h8, but the outer diameter and inner diameter of the eccentric sleeve 11 are not concentric circles. , the eccentric design of the eccentric sleeve is 15mm, then this fine-tuning device can adjust the distance of ±15mm, and an eccentric sleeve is also added between the left double clevis seat 1 and the pin shaft. When installing, first insert the damper ball hinge seat into the double clevis between the seats, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com