Working face coal wall stability control simulation experiment table and application method

A technology of stability control and simulation experiment, applied in the direction of applying stable tension/pressure to test the strength of materials, which can solve problems such as systematic research and little coal wall stability, and achieve the effect of ensuring safe and efficient mining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

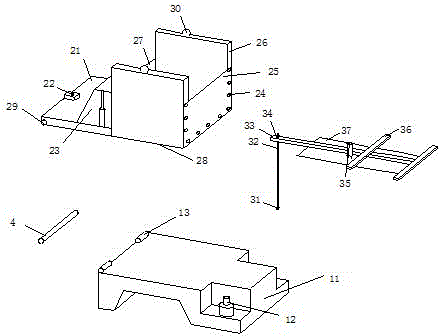

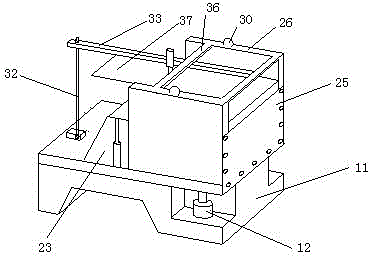

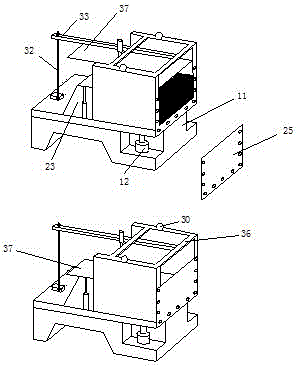

[0026] combine figure 1 , figure 2 As shown, a coal wall stability control simulation test bench for working face includes a base mechanism, a bearing mechanism, a pressurizing mechanism, and a data acquisition and analysis mechanism. Strength, working resistance of different hydraulic supports, deformation and failure characteristics of coal wall under different roof pressures.

[0027] In the base mechanism, the lower part of the tilting jack 12 is connected to both sides of the rear part of the base 11, and the upper part is connected to the bearing platform 21. The base 11 uses the connecting slot 13 and the reverse connecting slot 29 through the connecting shaft 4 and the The hinge knot at the front end of the carrying platform 21;

[0028] In the carrying mechanism, the side guard plate 26 is welded to the bearing platform 21 through the angle steel 28, the earring 30 is welded to the upper end of the side guard plate 26, and the rear cover 25 is connected to the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com