Layering and sectioning combined mining method for broken orebody interlayer

A segmented combination and mining method technology, applied in ground mining, mining equipment, earthwork drilling and mining, etc., can solve problems such as prone to caving and difficult excavation, and achieve strong adaptability, safe and efficient mining, and engineering layout flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

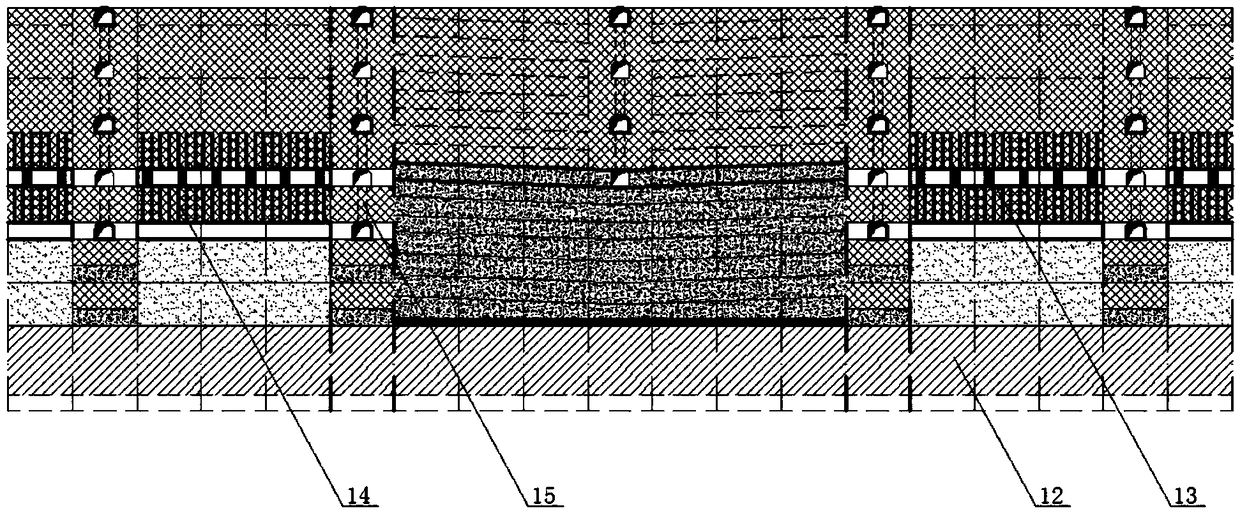

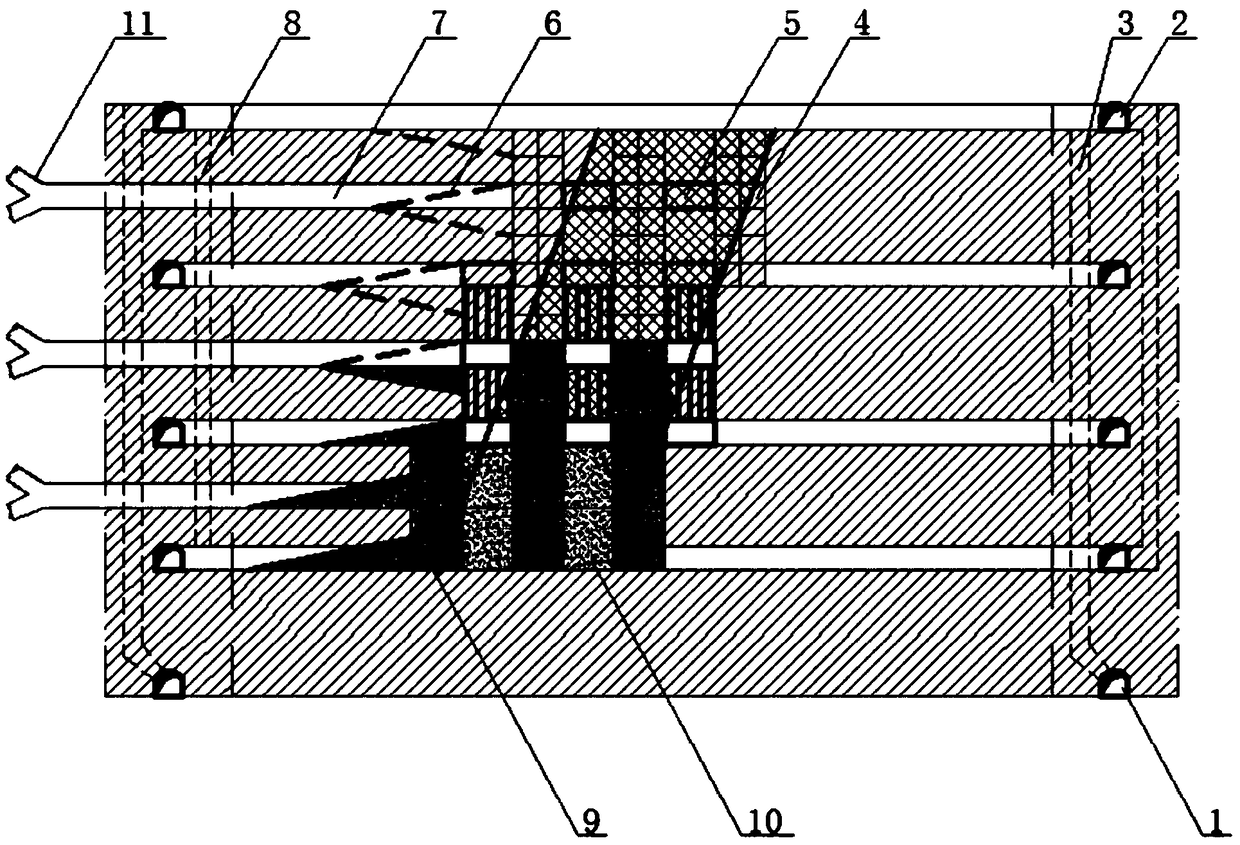

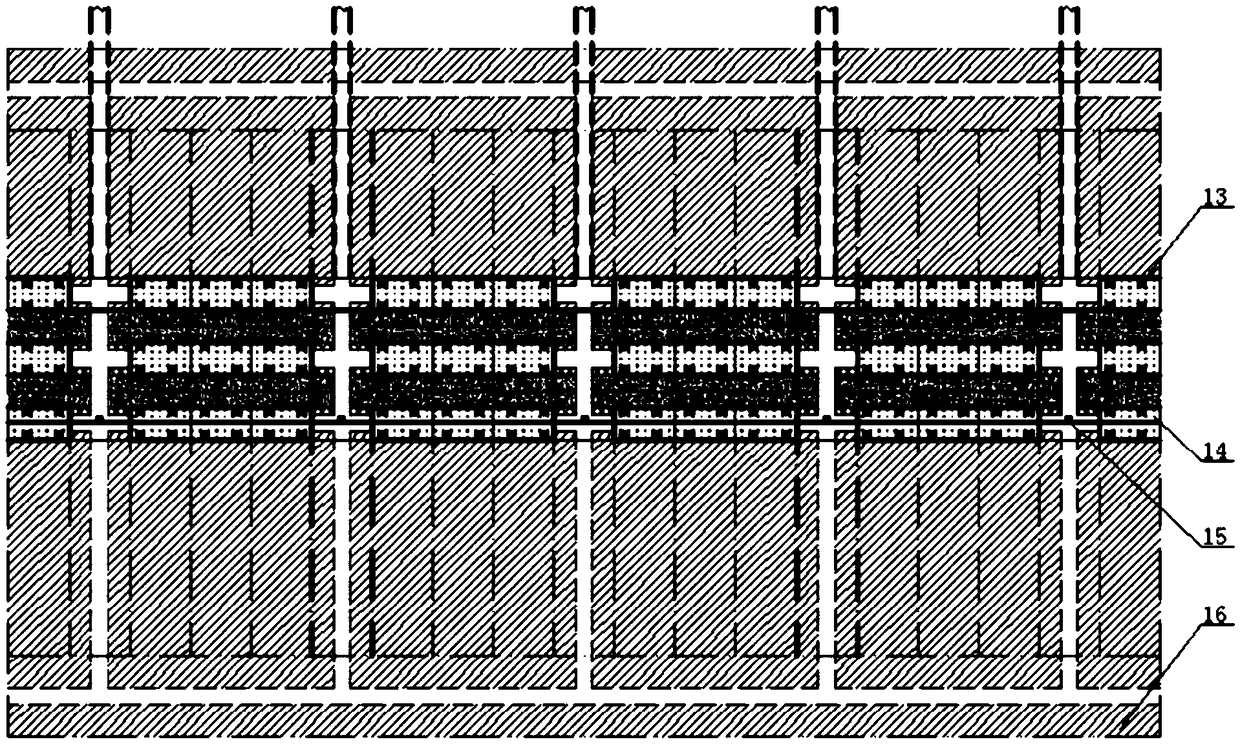

[0017] The layered and segmented combined mining method of the broken ore body interlayer of the present invention, its preferred embodiment is:

[0018] The layered and segmented combined mining method of the broken ore body interlayer comprises steps:

[0019] A. Along the trend of the broken ore body interlayer, the panel area and the inter-panel column are sequentially divided, and the vertical direction in each panel area is successively divided into a one-step mine stope and a two-step mine pillar stope. The one-step mine stope includes Broken ore body interlayer mining, the two-step ore pillar stope includes the stable ore body mining on both sides of the broken ore body interlayer;

[0020] B. The horizontal direction of the mine stope in the first step is composed of two parallel approaches, and the number of approaches in the vertical direction is determined by the height of the section, and it is filled immediately after mining to form a filling replacement column; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com