Surface drilling pre-splitting blasting shallow burying method for room type goaf roof

A technology for pre-split blasting and goaf, which is applied in the field of roof disaster prevention and control in short-distance coal seam long-wall mining under shallow-buried house goaf, can solve problems such as damage, support column shrinkage, support crushing, etc., and can reach a wide range of Practicality, simple implementation process, safe and efficient mining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

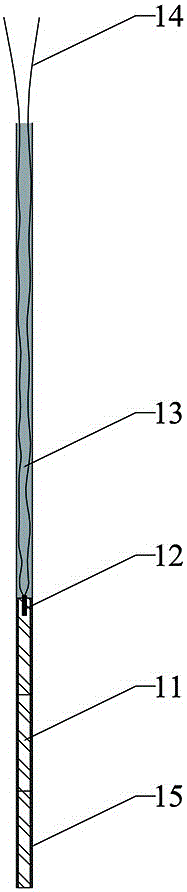

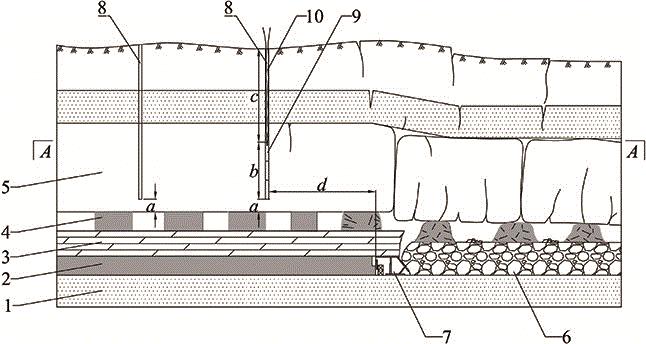

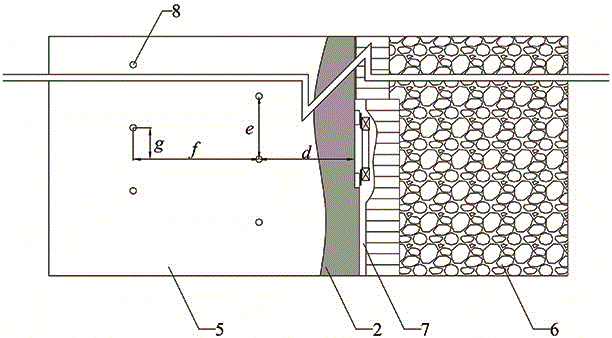

[0024] exist figure 1 , figure 2 Among them, the coal seam floor (1) can also be called the immediate bottom; the mined coal seam (2) is mined by comprehensive mechanized coal mining; the immediate roof (3) is between the mined coal seam (2) and the upper goaf; The room-type coal pillar (4) is the leftover coal pillar of the room-type goaf formed after the upper coal seam is mined by the room-type coal mining method; the basic roof (5) is the old roof; the goaf (6) is the fully mechanized mining face The area formed by the roof caving directly behind the coal; the working face (7) has various mechanical equipment and equipment required for comprehensive mechanized coal mining. The ground drilling pre-splitting blasting method for the roof of the shallow-buried house type goaf of the present invention, the specific steps are as follows:

[0025] a. Arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com