Mining method for inclined medium-thick bedded or thick-bedded orebody continuous stoping

A mining method and thick ore body technology, applied in surface mining, underground mining, special mining, etc., can solve the problems of increased physical labor, large loss of poverty, high mining costs, etc., to achieve improved labor productivity, good economic benefits, eliminate The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

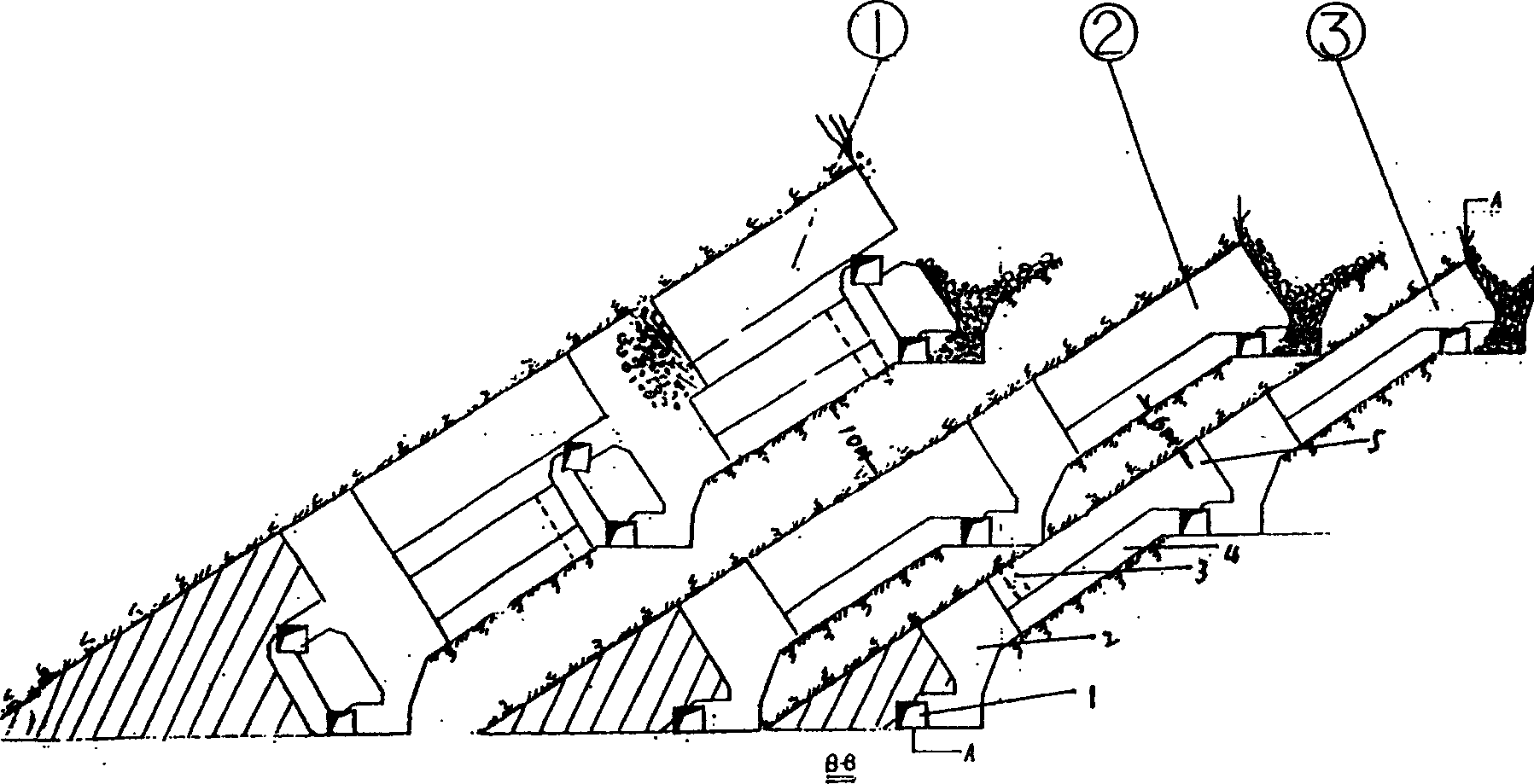

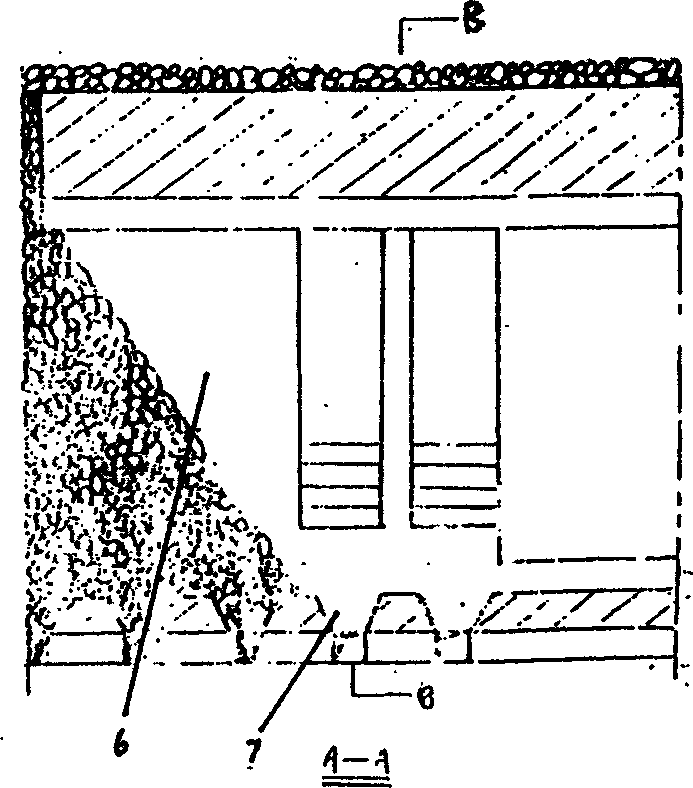

[0024] figure 1 and figure 2 It is a successful example of mining three layers of overlapping ore bodies. The specific conditions are: ① The thickness of the ore body is 20m, the thickness of the ② layer is 10m, and the thickness of ③ is 6.5m. The thickness of the stone layer is 10m, and the thickness of the interlayer stone layer between the ② mine layer and the ③ mine layer is 6m; the implementation steps:

[0025] ①Excavate the transport roadway 1 along the ore body floor line in the footwall of the ore body, excavate the ore loading horizontal roadway and rock drilling uphill 4 in the direction of the ore body footwall every 8m in the roadway 1, and penetrate the upper horizontal transport roadway 1;

[0026] ② Excavate the cutting lane along the direction at the cutting level, and enlarge it to form the cutting groove 2;

[0027] ③ In the rock drilling uphill 4, the recovery blast hole 3 is drilled in the direction vertical to the roof of the ore body;

[0028] ④Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com