Automatic ejecting device for silicon rubber insulator finished products

A silicone rubber insulation and automatic ejection technology is applied in the field of silicone rubber insulator production molding molds. The effect of high and high ejection stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

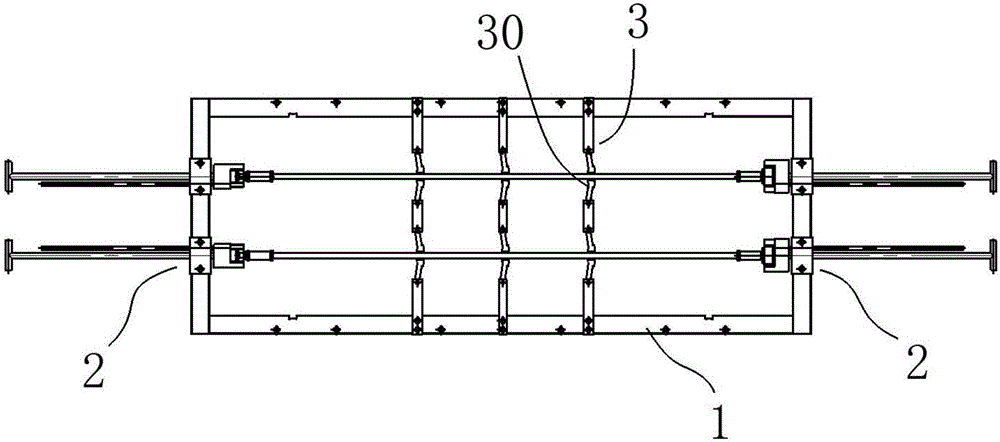

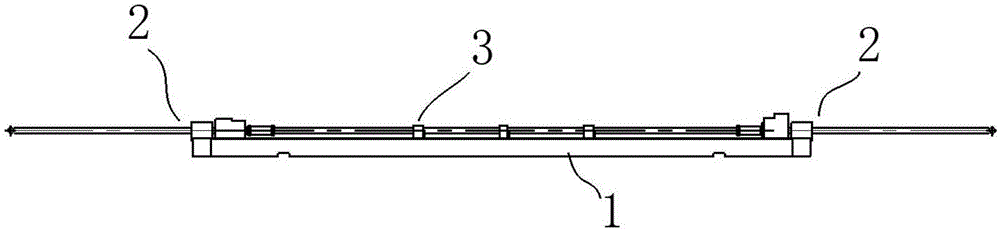

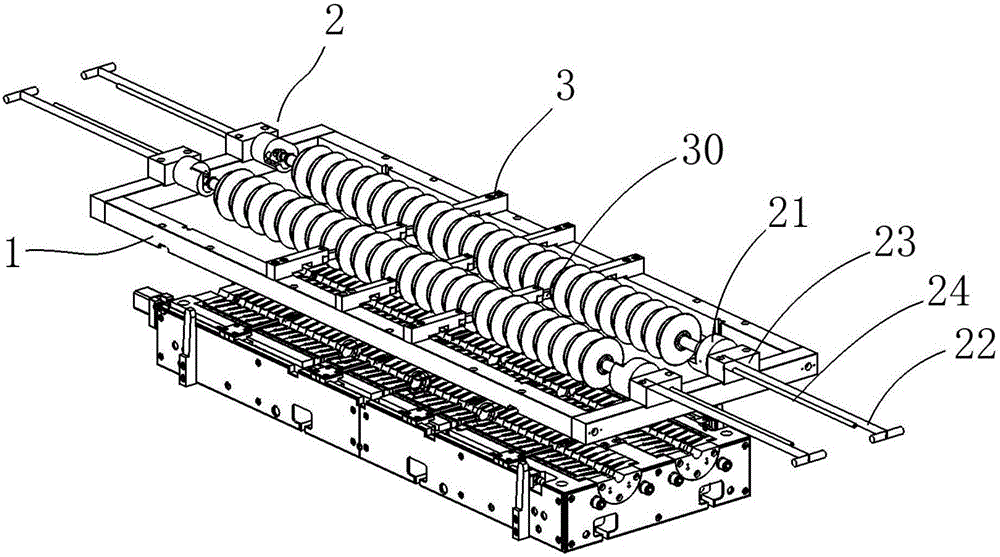

[0019] Such as Figure 1-3 Shown is an automatic ejector device for finished silicone rubber insulators of the present invention, including an ejector frame 1, an axial positioning device 2, and an ejector beam 3. The ejector frame 1 is set on the lower die of the silicone rubber insulator and can be vertically vertical The movable, axial positioning device 2 is installed on both ends of the ejector frame 1 for clamping and fixing the two ends of the finished silicon rubber insulator, and the ejector beam 3 is installed and fixed on the frame body of the ejector frame 1 and is located The parting surface of the rubber insulator forming mold is perpendicular to the central axis of the finished silicone rubber insulator.

[0020] Specifically, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com