A UHV Composite Insulator with Uniform Electric Field Distribution

A technology for synthesizing insulators and electric field distribution, applied in insulators, circuits, electrical components, etc., can solve the problems of increasing the complexity and difficulty of equipment manufacturing, and the inability to achieve equalizing effects, improving safety, reliability and service life, reducing Small size, effect of improving unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

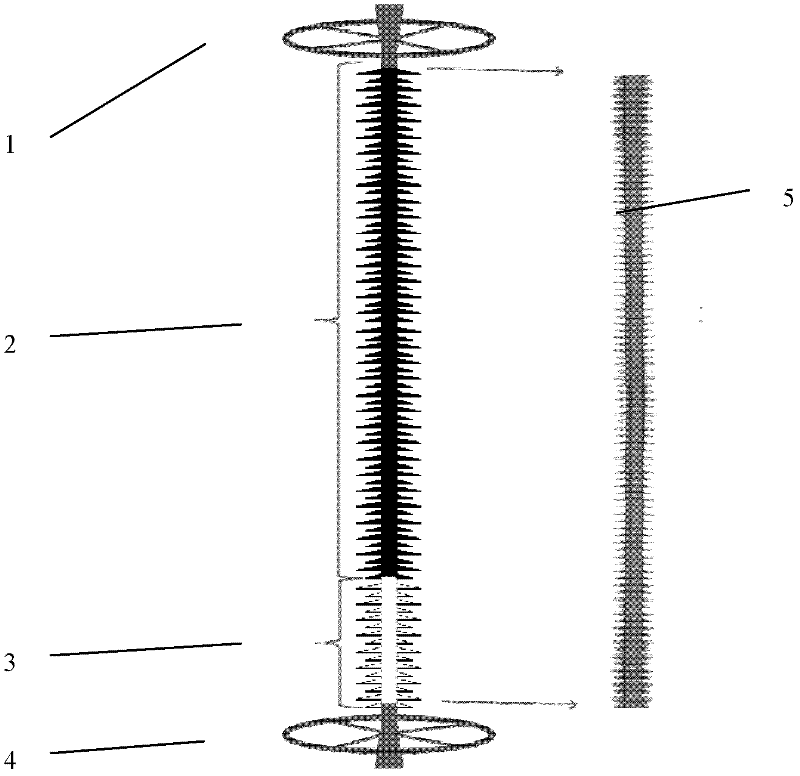

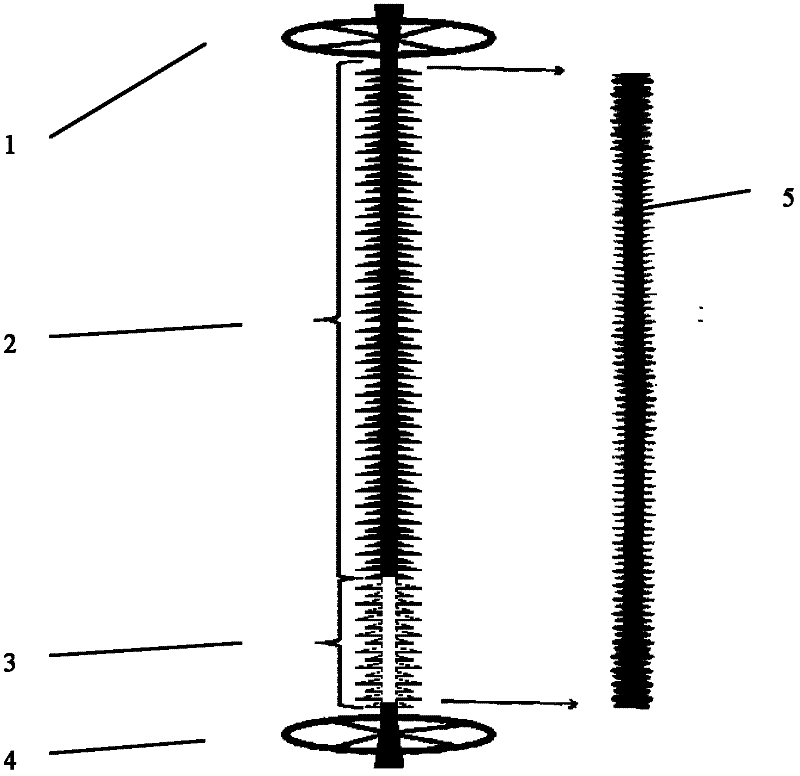

[0010] The UHV composite insulator with uniform electric field distribution proposed by the present invention has a structure such as figure 1 As shown, including the grounding electrode terminal and the voltage equalizing ring 1, the silicone rubber insulator 2, the nonlinear characteristic insulator 3 and the high voltage electrode terminal of the fixed wire and the voltage equalizing ring 5, the silicone rubber insulator 2 and the nonlinear characteristic insulator 3 are connected to each other. The ground electrode terminal and the equalizing ring 1 are placed at the end of the silicone rubber insulator 2 . The high-voltage electrode end of the fixed wire and the voltage equalizing ring 4 are placed at the end of the nonlinear characteristic insulator 3 . The silicone rubber insulator 2 accounts for 4 / 5 of the total length of the UHV composite insulator, and the non-linear characteristic insulator 3 occupies 1 / 5 of the total length of the UHV composite insulator.

[0011]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com