Suspension insulator

A suspension insulator, insulator technology, applied in suspension/strain insulators and other directions, can solve problems such as high strength and rigidity requirements, local umbrella damage, product scrapping, etc. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

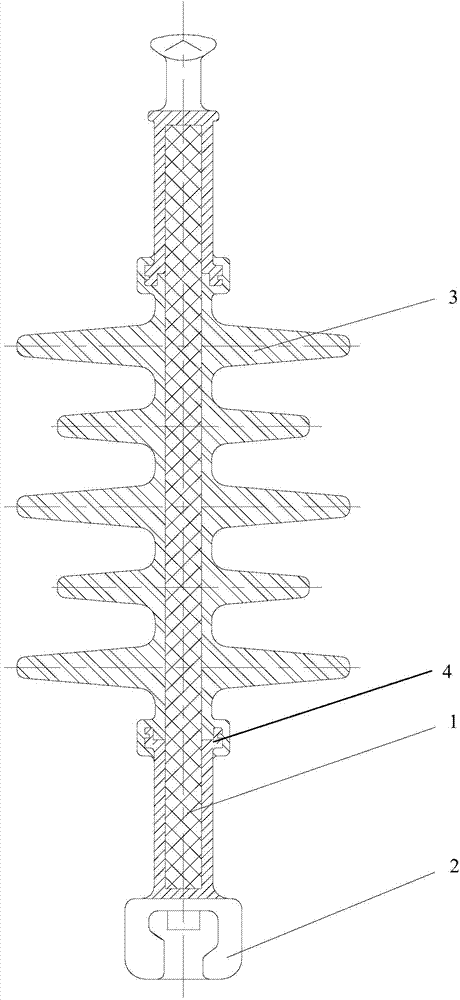

[0022] Such as figure 1 As shown, an epoxy insulator includes a pultruded mandrel 1, fittings 2 at both ends of the mandrel 1, and an epoxy resin umbrella skirt 3 on the outer surface. The fittings 2 are designed with reinforcing grooves 4; The device molds a flexible (20% elongation) epoxy onto mandrel 1.

[0023] In this embodiment, the fittings are designed with reinforced grooves, and the bottom of the reinforced grooves is designed in a circular arc shape. The reinforced grooves only strengthen the insulator, and the bottom of the reinforced grooves is circular-arc-shaped to increase the diversion effect.

[0024] In this embodiment, the arc-shaped design of the bottom of the fitting can effectively increase the filling of the epoxy glue in the reinforcement groove, so that the glue can fully fill all parts of the reinforcement groove.

[0025] In this embodiment, the mandrel 1 is epoxy resin and / or non-alkali glass fiber mandrel.

[0026] In this embodiment, the outer ...

Embodiment 2

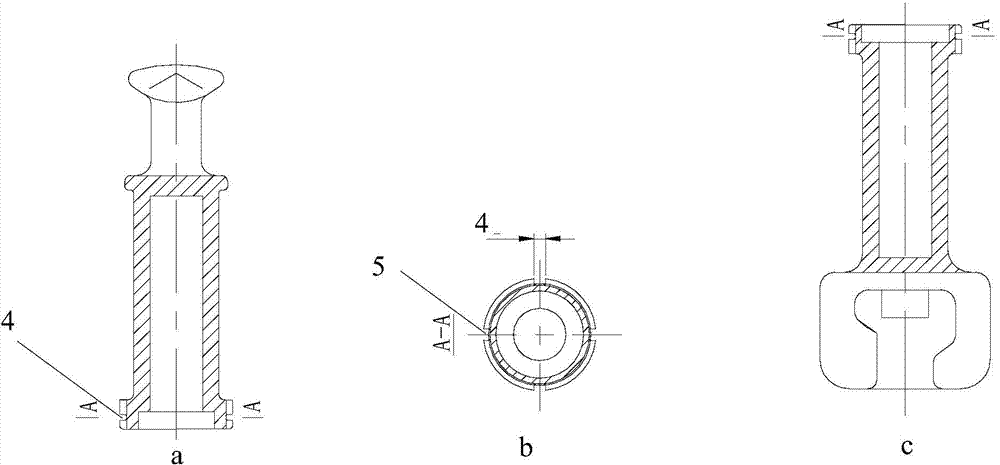

[0030] Such as figure 2 As shown, in this embodiment, the two ends of the mandrel 1 are crimped with the guide groove fittings 2, and then the epoxy resin with an elongation rate of about 20% is molded into an umbrella skirt on the surface of the mandrel 1 using APG equipment.

[0031] In actual production, the mandrel 1 is first extruded and formed, and then the fittings 2 are crimped at both ends of the mandrel 1 according to the actual situation. In the middle of the mandrel, use APG equipment to inject the epoxy resin umbrella skirt 3. The elongation rate of the epoxy resin used for injection molding is about 10-50%. The molding temperature is 150°C, and the molding time is 15 minutes. Post-treatment at 160°C for 2h. Epoxy resin needs to have specific performance requirements (mechanical performance, electrical performance, process performance) during molding, and vacuum degassing is required before injection. In this embodiment, the manufacturing process of the remaini...

Embodiment 3

[0033] Such as figure 1 As shown, in this embodiment, the two ends of the mandrel 1 are crimped with the guide groove fittings 2, and then the epoxy resin with an elongation rate of 50% is molded into an umbrella skirt on the surface of the mandrel 1 using APG equipment.

[0034] In actual production, the mandrel 1 is first extruded and formed, and then the fittings 2 are crimped at both ends of the mandrel 1 according to the actual situation. In the middle of the mandrel, use APG equipment to inject the epoxy resin umbrella skirt 3. The elongation rate of the epoxy resin used for injection molding is 50%, the molding temperature is 120°C, and the molding time is 20min. Processing 2h. Epoxy resin needs to have specific performance requirements (mechanical performance, electrical performance, process performance) during molding, and vacuum degassing is required before injection. In this embodiment, the manufacturing process of the remaining parts is the same as that of Embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com