Electrified changing device for silicone rubber insulator

A silicone rubber insulation, live replacement technology, applied in overhead lines/cable equipment and other directions, can solve problems such as hidden dangers that cannot be eliminated in time, long power outage maintenance cycle, complicated operating tools, etc., to improve safety and stability, save costs, and improve safety. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

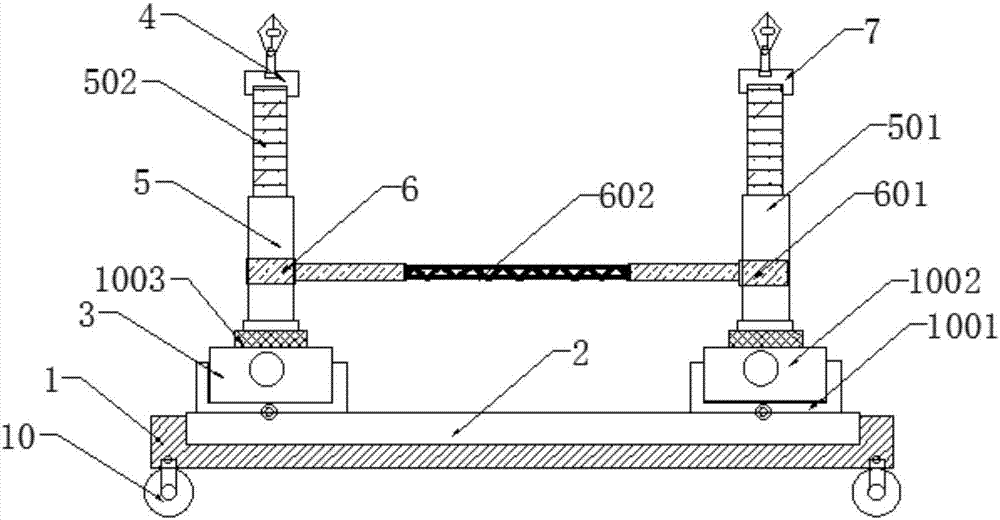

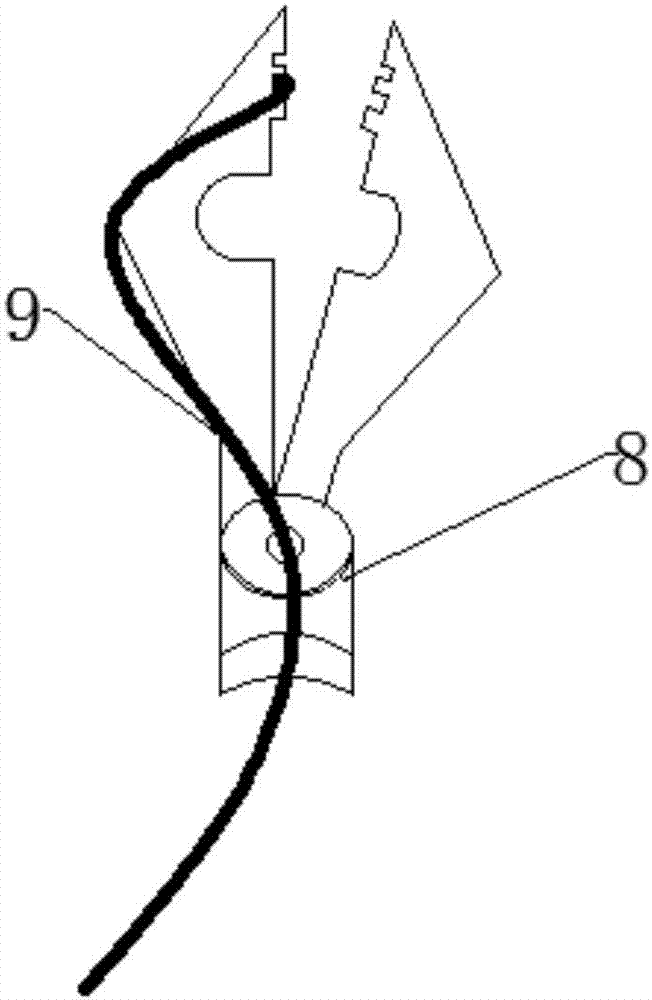

[0027] Such as figure 1 and 2 As shown, the present invention provides a live replacement device for silicone rubber insulators. There is an insulating lifting mechanism 3, and a shunt replacement device 4 is fixed on the top of the insulating lifting mechanism 3; the mobile base 1 is used to support and fix the entire device, and the insulating lifting mechanism 3 can move left and right in the sliding guide rail 2 to realize The adjustment of the relative distance between them, the shunt replacement device 4 is used to shunt the line and realize the replacement operation of the silicone rubber insulator;

[0028] The mobile base 1 is made of insulating rubber material wrapped on the outer surface of the stainless steel base, and the four corners of the mobile base 1 are connected with universal wheels 10 through rotating shafts, and the rotating shafts of the universal wheels 10 are welded There is a locking buckle, and the fixed end of the locking buckle is welded to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com