Thermal analysis method for measuring contents of polydimethylsiloxane (PDMS), SiO2 and aluminum hydroxide (ATH) in silicone rubber composite insulator

A composite insulator and silicone rubber insulation technology, which is applied in the thermal development of materials, instruments, calculations, etc., can solve the problem of the lack of systematic and effective components of silicone rubber insulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1 A silicone rubber insulator with a certain component (PDMS is 120 parts, ATH is 80 parts, and white carbon black is 25 parts), the calculation method of its component content comprises the following steps:

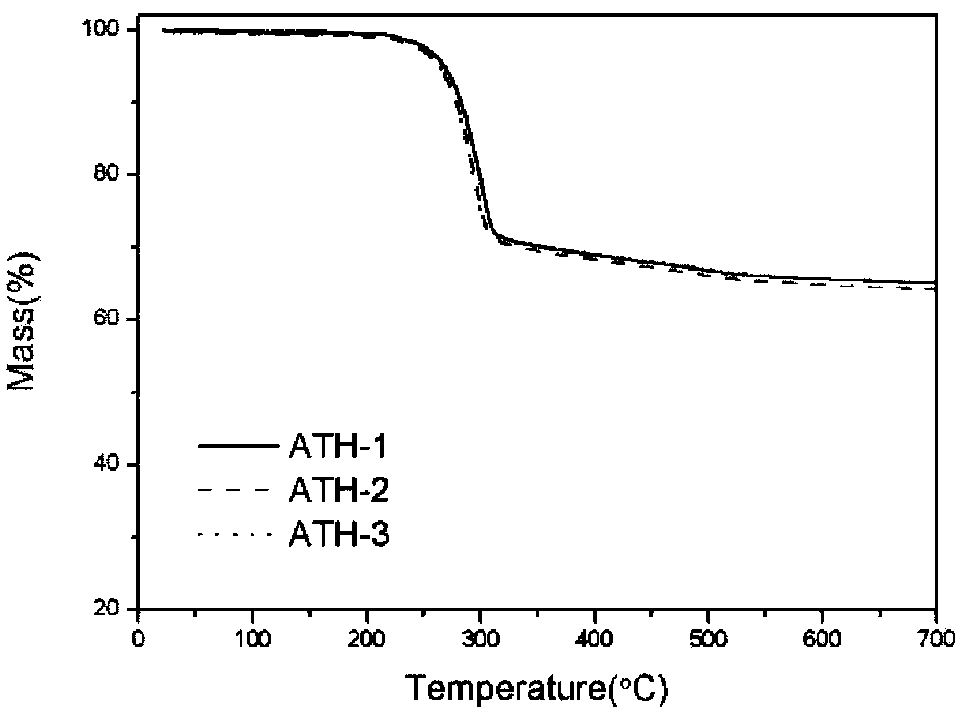

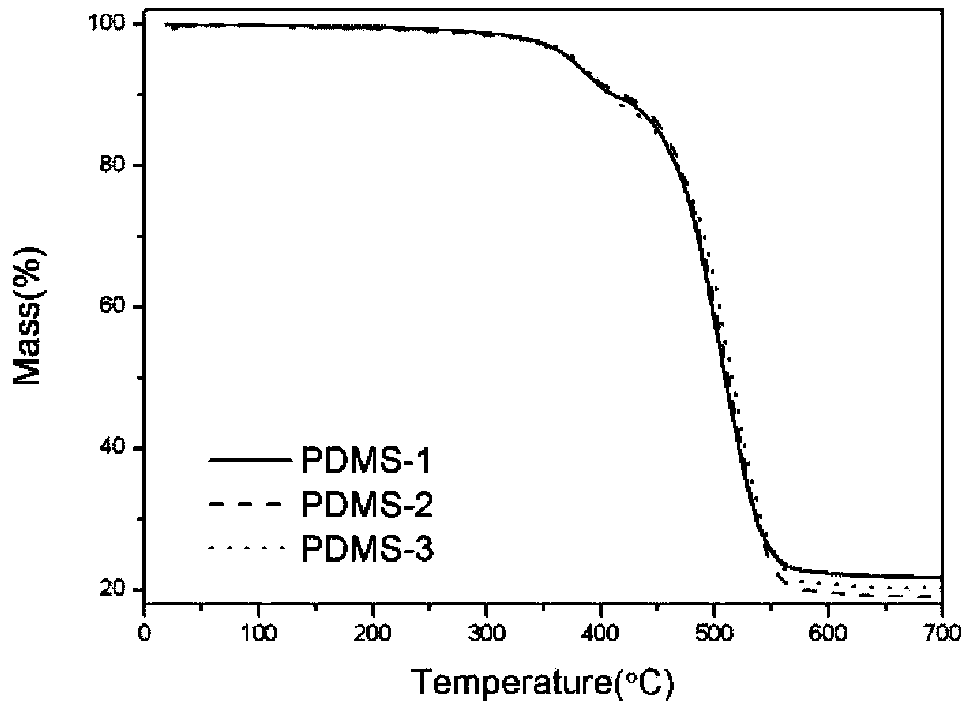

[0055] (1) The thermal weight loss rate of silicone rubber at 20-360° C. is 12.63%, and the thermal weight loss rate of silicone rubber at 360-700° C. is 43.65% as measured by analysis software.

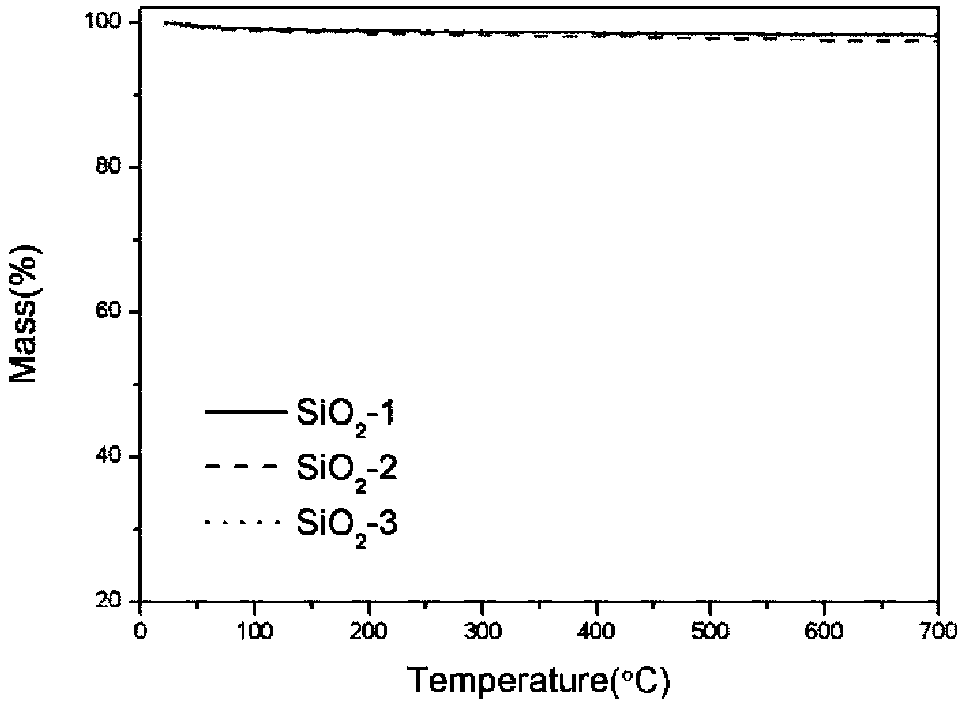

[0056] (2) Using analysis software to measure PDMS, ATH, SiO at 20-360°C 2 The thermal weight loss rates are 2.85%, 30.49%, and 1.81%, respectively, and the equation ① can be obtained: 12.63%=(m ATH ×30.49%+100×2.85%+m SiO2 ×1.81%) / (m ATH +100+m SiO2 ).

[0057] (3) Use analysis software to measure PDMS, ATH, SiO at 360-700°C 2 The thermal weight loss rates are 77.22%, 5.17%, and 0.67%, respectively, and the equation ② can be obtained: 43.65%=(m ATH ×5.17%+100×77.22%+m SiO2 ×0.67%) / (m ATH +100+m SiO2 ).

[0058] (4), solve equations ①② to get: m ATH...

Embodiment 2

[0062] Embodiment 2 A silicone rubber insulator with a certain component (PDMS is 120 parts, ATH is 110 parts, and white carbon black is 25 parts), the calculation method of its component content comprises the following steps:

[0063] (1) The thermal weight loss rate of silicone rubber is 15% at 20-360°C and 38.68% at 360-700°C by analysis software.

[0064] (2) Using analysis software to measure PDMS, ATH, SiO at 20-360°C 2 The thermal weight loss rates are 2.85%, 30.49%, and 1.81%, respectively, and the equation ① can be obtained: 12.63%=(m ATH ×30.49%+100×2.85%+m SiO2 ×1.81%) / (m ATH +100+m SiO2 ).

[0065] (3) Use analysis software to measure PDMS, ATH, SiO at 360-700°C 2 The thermal weight loss rates are 77.22%, 5.17%, and 0.67%, respectively, and the equation ② can be obtained: 43.65%=(m ATH ×5.17%+100×77.22%+m SiO2 ×0.67%) / (m ATH +100+m SiO2 ).

[0066] (4), solve equations ①② to get: m ATH =94.11,m SiO2 =18.43.

[0067] (5), calculate the mass fraction of ...

Embodiment 3

[0069] Embodiment 3 A certain component (120 parts of PDMS, 160 parts of ATH, and 25 parts of white carbon black) of a silicone rubber insulator, the calculation method of its composition comprises the following steps:

[0070] (1) The thermal weight loss rate of silicone rubber is 17.35% at 20-360°C and 32.81% at 360-700°C by analysis software.

[0071] (2) Using analysis software to measure PDMS, ATH, SiO at 20-360°C 2 The thermal weight loss rates are 2.85%, 30.49%, and 1.81%, respectively, and the equation ① can be obtained: 17.35%=(m ATH ×30.49%+100×2.85%+m SiO2 ×1.81%) / (m ATH +100+m SiO2 ).

[0072] (3) Use analysis software to measure PDMS, ATH, SiO at 360-700°C 2 The thermal weight loss rates are 77.22%, 5.17%, and 0.67%, respectively, and the equation ② can be obtained: 32.81%=(m ATH ×5.17%+100×77.22%+m SiO2 ×0.67%) / (m ATH +100+m SiO2 ).

[0073] (4), solve equations ①② to get: m ATH =135.71,m SiO2 =21.47.

[0074] (5), calculate the mass fraction of each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com